Shoe full set packaging seamless technology

A seamless, complete set of technology, applied in applications, footwear, clothing, etc., can solve the problems of installing the main heel and inner toe cap, and achieve the effects of reducing weight, saving processes, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

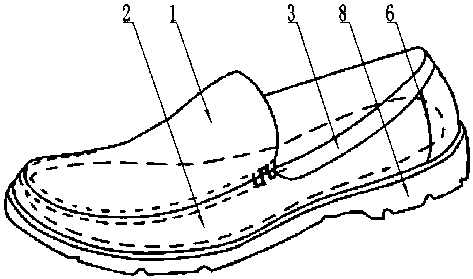

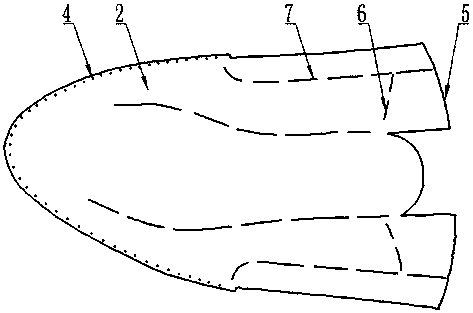

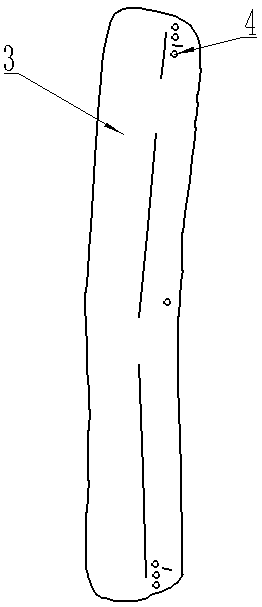

[0030] Such as Figure 1-4 Shown, a kind of shoe is used for a full set of bag seamless technology, comprises the following steps:

[0031] Step 1: Lining the back of the shoe cover 1, glue the side of the shoe cover 1 and the unlined side of the shoe cover 1, and sew the tongue and the shoe cover 1, and remove the stubble on the edge of the shoe tongue after sewing Trim clean;

[0032] Step 2: Punch holes 4 on the shoe cover 1 and the upper circumference 2 respectively. The punching holes 4 on the shoe cover 1 are set on the inside circle of the toe arc of the shoe cover 1. The punching holes 4 on the upper circumference 2 are set on the shoe The inner circle of the toe arc of cover 1;

[0033] Step 3: Sew the back seams 5 on both sides of the heel of the upper circumference 2 on the front of the upper circumference 2;

[0034] Step 4: Sew the back heel and the heel of the upper circumference 2 through two stitches;

[0035] Step 5: 3-pass the catchy strip;

[0036] Step...

Embodiment 2

[0043] Such as Figure 1-3 As shown, on the basis of Example 1, the distance between the edge of the lining in step 1 and the edge in the shoe cover is 12-13 mm, and the distance between the tongue and the shoe cover 1 suture line and the side of the shoe cover 1 is 1.5-1.5 mm. 2.0mm.

[0044] In the step 3, the suture line of the back seam 5 on both sides of the heel of the shoe upper circumference 2 is 51.5-2.0 mm away from the back seam.

[0045] In step 4, the distance between the back heel and the upper circumference 2 of the two sutures is 61.5-2.0mm from the first suture to the back heel marking line, and the second suture is 61.5-2.0 mm from the back heel marking line Print 63.0 ~ 3.5mm.

[0046] In the step 5, the thickness of the through sheet is 1.0mm or 1.1mm.

[0047] In the step 6, one side of the top strip 3 is stitched with the shoe upper circumference 2, and the suture line is located on the side away from the top strip line print 7 away from the shoe upper...

Embodiment 3

[0050] Based on Example 1, both the shoe cover 1 and the shoe upper circumference 2 are made of genuine leather.

[0051] Both the shoe cover 1 and the shoe upper circumference 2 are made of genuine leather, which can increase the air permeability of the sole, greatly improve the comfort of the sole, and make the inner cavity of the shoe dry and transparent. At the same time, the comfort of wearing is improved, and it is suitable for casual and formal occasions and people who have high requirements for shoes, and it relieves the trouble of uncomfortable feet in the shoe cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com