Multi-channel welded pipe high-speed packing and discharging system

A discharging system and multi-channel technology, applied in the field of high-speed packaging and discharging systems for multi-channel welded pipes, can solve problems such as restricting production efficiency and increasing labor costs, achieving great use value and economic benefits, reducing labor intensity, and ensuring connection. Effects of sex and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

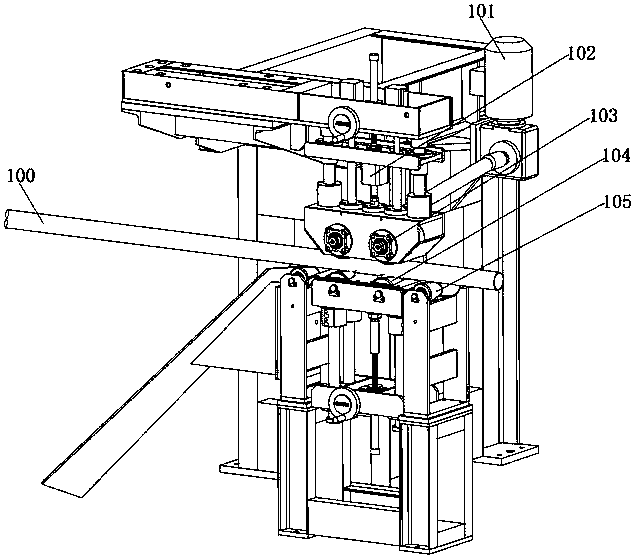

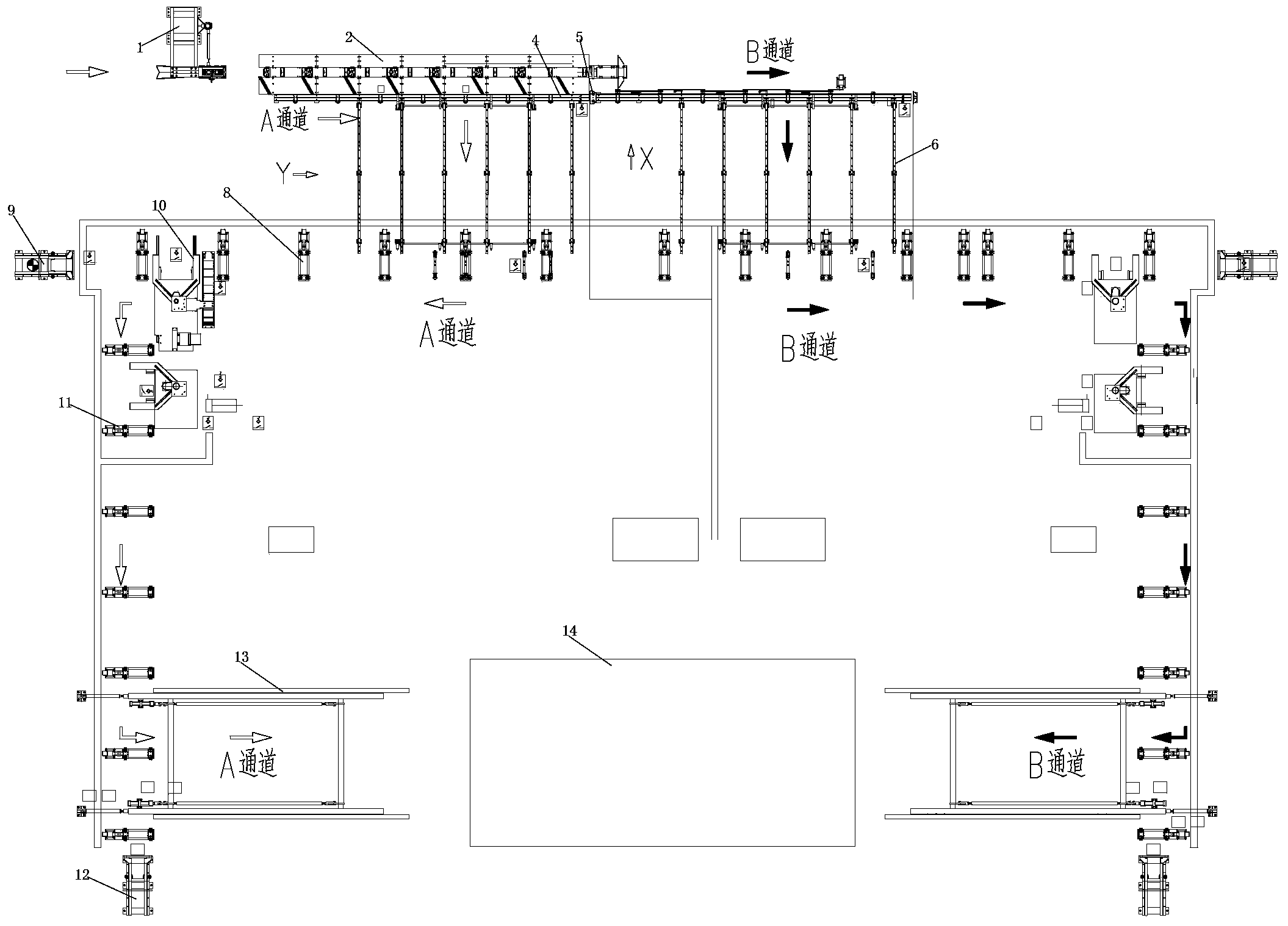

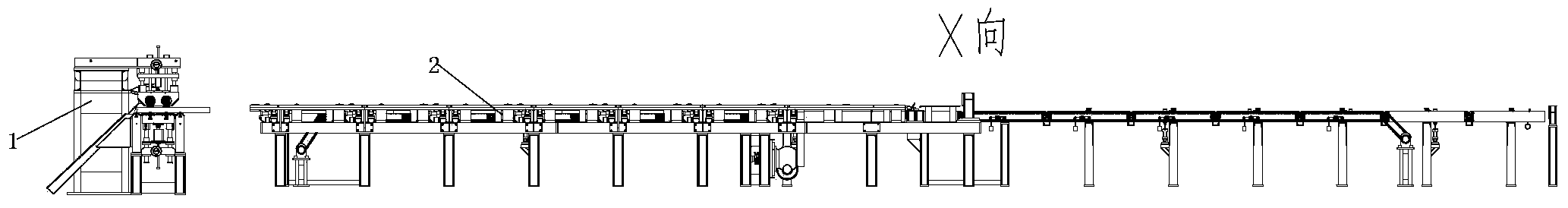

[0038] Example: such as Figure 1-15 As shown, the present invention provides a specific embodiment of a multi-channel welded pipe high-speed packaging and discharging system, which includes: receiving the welded pipe 100 produced by the pipe making system and accelerating the output of the material output pinch unit 1, for The output acceleration pinch unit 1 accelerates the output of the welded pipe to identify and distinguish the turning roller table 2, which is located on the side of the turning roller table 2 and is used to collect defective products. The waste collection unit 3 is located on the other side of the turning roller table 2 and selects The transfer roller table 4 for transferring good products from different channels, the switching unit 5 arranged in the transfer roller table 4 and used to switch between different channels, and the temporary storage unit for correspondingly storing welded pipes 100 through different storage subunits according to different chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com