Artificial knee joint bone fusion prosthesis

An artificial knee joint and bone fusion technology, applied in the direction of knee joints, prostheses, elbow joints, etc., can solve the problems of loose prosthesis, high elastic modulus, and mechanical properties of bone tissue that cannot match each other, and achieve the induction of bone cell growth , the effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

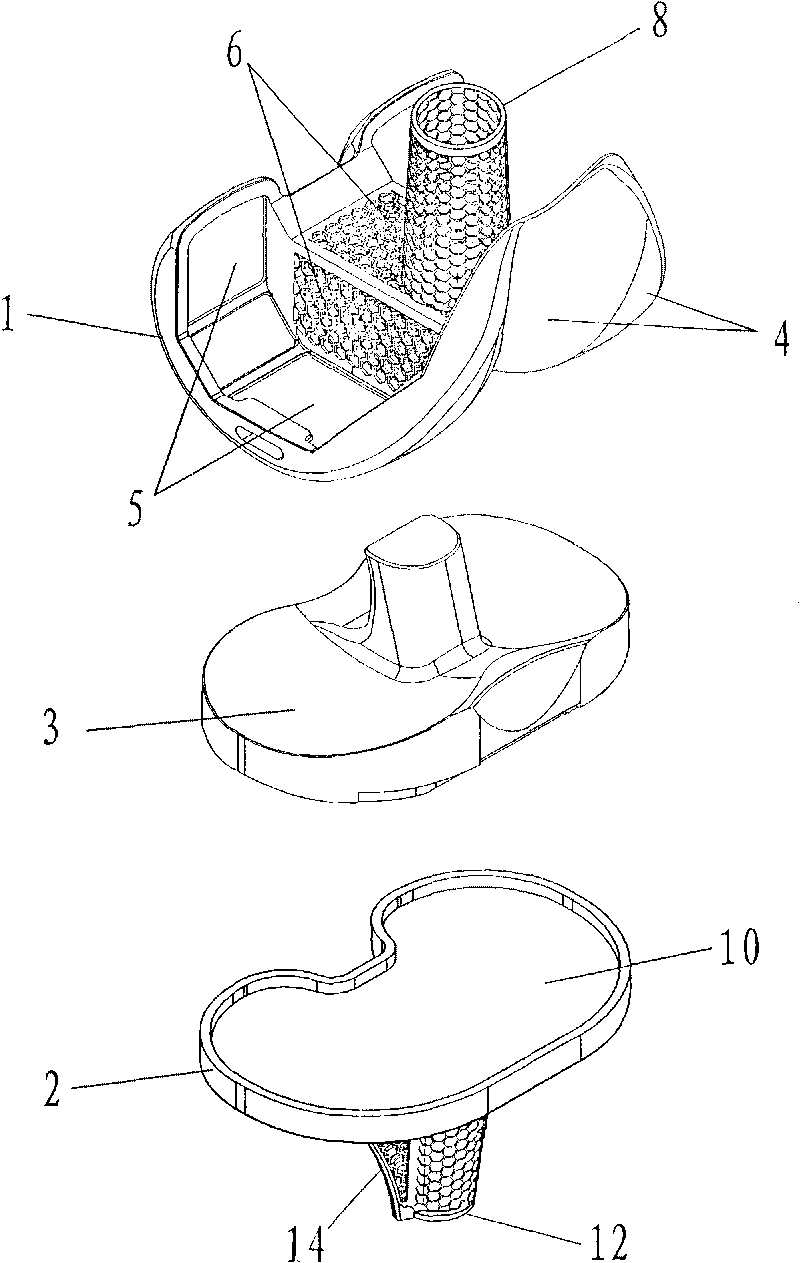

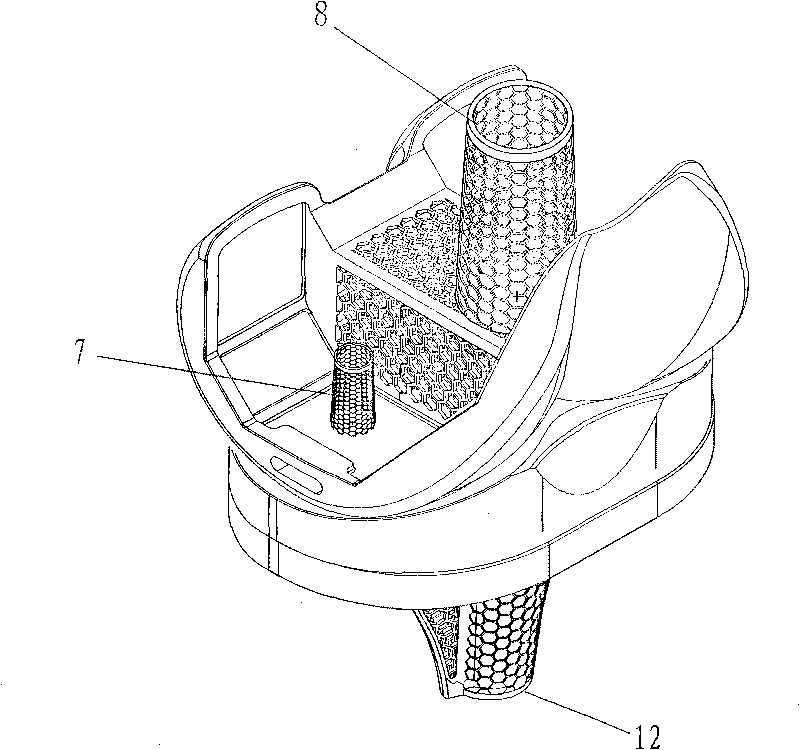

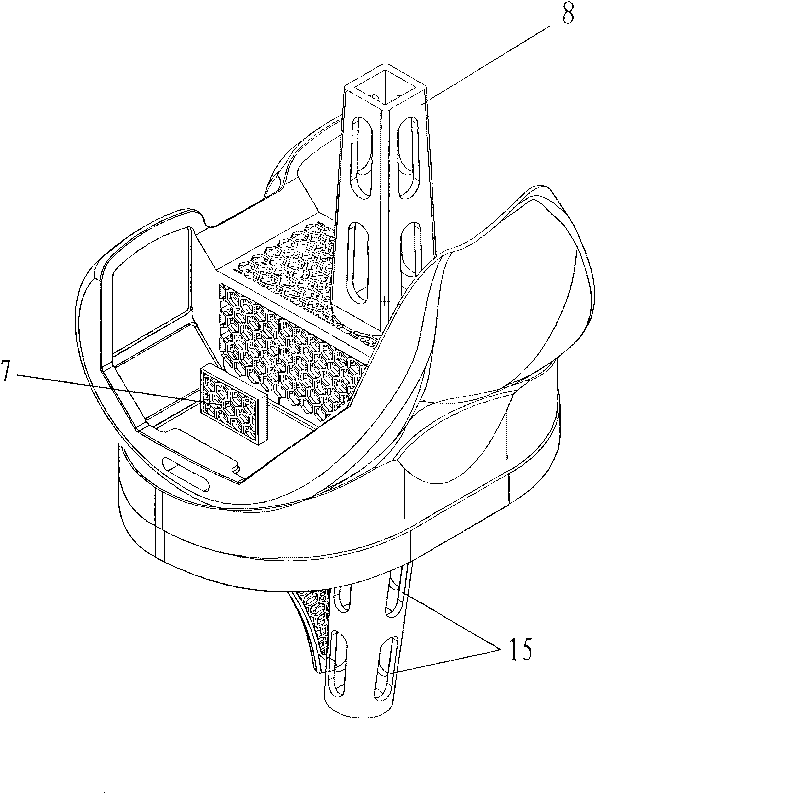

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 Shown, a kind of artificial knee joint bone fusion prosthesis of the present invention, it comprises: femoral condyle prosthesis 1, tibial plateau prosthesis 2 and joint liner 3, it is characterized in that, femoral condyle prosthesis 1 has articular surface 4, condyle Joint surface 5, intercondylar joint surface 6, positioning body 7, femoral intramedullary stem 8 and femoral intramedullary extension stem 9; tibial plateau prosthesis 2 has platform body 10, tibial joint surface 11, tibial intramedullary stem 12, tibial marrow Inner extension handle 13, wing plate 14 or positioning body 7; femoral intramedullary stem 8, femoral intramedullary extension handle 9, tibial intramedullary stem 12, and tibial intramedullary extension handle 13 have a hollow structure inside, and the outer wall has a plurality of holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com