Permanent bridge plug available for unsetting

A bridge plug and permanent technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of high risk of milling, difficult recovery, difficult unblocking, etc., to meet the needs of isolation, Ease of unpacking, no need for milling and recycling tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

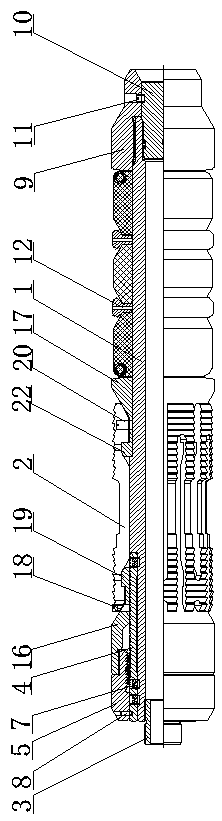

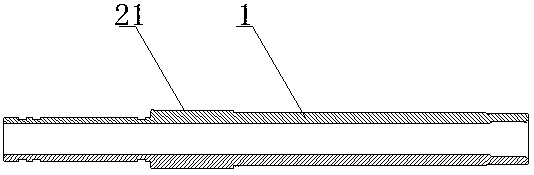

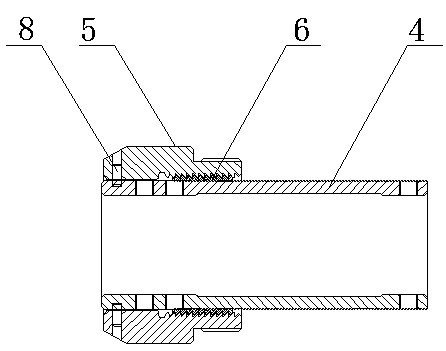

[0027] The unsealable permanent bridge plug is composed of a central tube 1, a pressurizing piece, a slip 2 and a rubber cartridge assembly. One end port of the central tube 1 is threaded with a release ring 3, which is used to connect the setting joint Package 23, the release ring 3 is provided with a pre-break ring groove, so that after the setting is completed, it will break to complete the setting. The inner side of the release ring 3 is equipped with a pressure piece on the circumference of the central tube 1, and the pressure piece is composed of the lock ring seat 4, The lock ring sleeve 5 and the lock ring 6 are composed, the lock ring seat 4 is connected and fixed with the central tube 1 through the unsealing shear pin 7, and the unsealing shear pin 7 is used to limit the lock ring seat 4 before setting, and lock The ring seat 4 is equipped with a lock ring sleeve 5 through the lock ring 6, and the lock ring sleeve 5 is connected with the lock ring seat 4 through the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com