Transformer substation robot intelligent inspection system and method based on active cooperation of intelligent sensor

A technology of intelligent sensors and robot intelligence, applied in the direction of information technology support systems, electrical components, circuit devices, etc., can solve the problems of sensor data not forming interconnection and comprehensive analysis and utilization, single inspection strategy and method, and single application scenarios. Achieve the effect of improving environmental response learning ability, avoiding personnel safety risks, and reducing manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

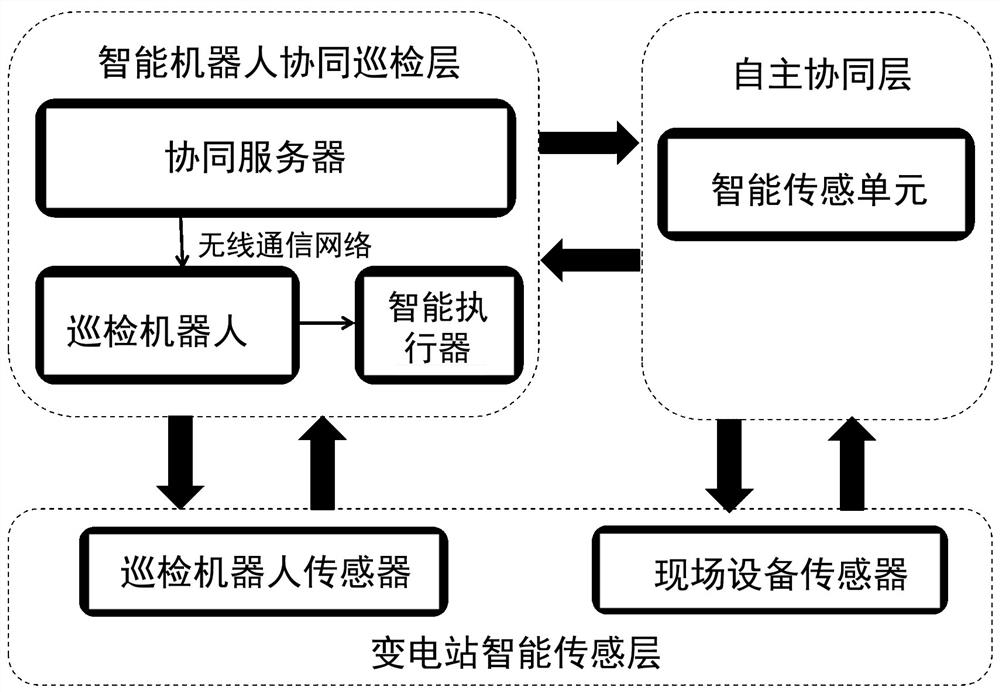

[0116] The present invention provides an embodiment, which is a substation robot intelligent inspection system actively coordinated by intelligent sensors, including a collaborative server, a wireless communication network, an inspection robot, an intelligent sensing unit, an intelligent actuator, and a detected device. like figure 1 as shown, figure 1 It is the organization chart of the present invention.

[0117] The inspection system of the present invention includes: an intelligent robot cooperative inspection layer, an autonomous coordination layer and a substation intelligent sensing layer to form a three-layer intelligent inspection architecture. Among them, the intelligent robot collaborative inspection layer and the autonomous collaboration layer realize two-way communication connection. The intelligent robot collaborative inspection layer also realizes two-way communication connection with the substation intelligent sensing layer. The autonomous coordination layer...

Embodiment 2

[0126] The present invention provides another embodiment, which is an intelligent inspection method for a substation robot with active cooperation of intelligent sensors, including the following steps:

[0127] Step 1. Firstly, a three-layer intelligent inspection architecture is formed by the intelligent robot collaborative inspection layer, the autonomous collaborative layer and the substation intelligent sensing layer;

[0128] The intelligent robot collaborative inspection layer includes: a collaborative server, an inspection robot, and an intelligent actuator;

[0129] The autonomous coordination layer includes: smart sensors;

[0130] The substation intelligent sensing layer includes: the detected equipment forms a three-layer intelligent inspection architecture.

[0131] Step 2. The inspection robot performs autonomous path planning to complete image data collection;

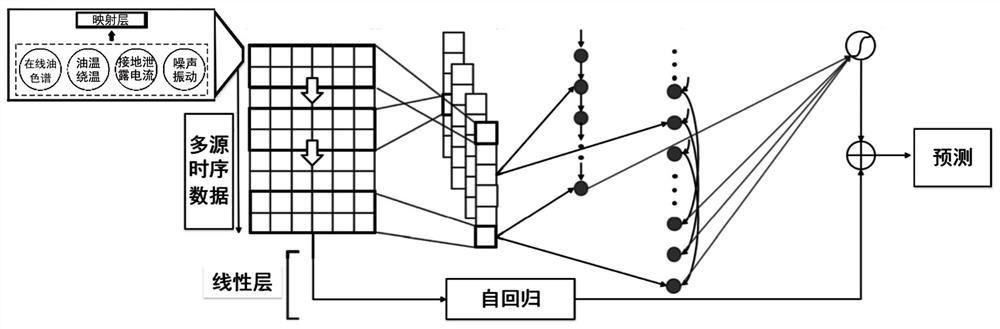

[0132] Step 3. The intelligent sensing unit perceives the state of the detected device and performs ...

Embodiment 3

[0224] Based on the same inventive concept, an embodiment of the present invention also provides a computer storage medium, on which a computer program is stored. The steps of the collaborative substation robot intelligent inspection method.

[0225] Those skilled in the art should understand that the embodiments of the present application may be provided as methods, systems, or computer program products. Accordingly, the present application may take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present application may take the form of a computer program product embodied on one or more computer-usable storage media (including but not limited to disk storage, CD-ROM, optical storage, etc.) having computer-usable program code embodied therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com