Sealing structure for asbestos packing of water pump bearing

A technology of asbestos packing and sealing structure, used in pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of low manufacturing cost, high wear and friction power consumption, short service life, etc., and achieve convenient installation and save processing. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

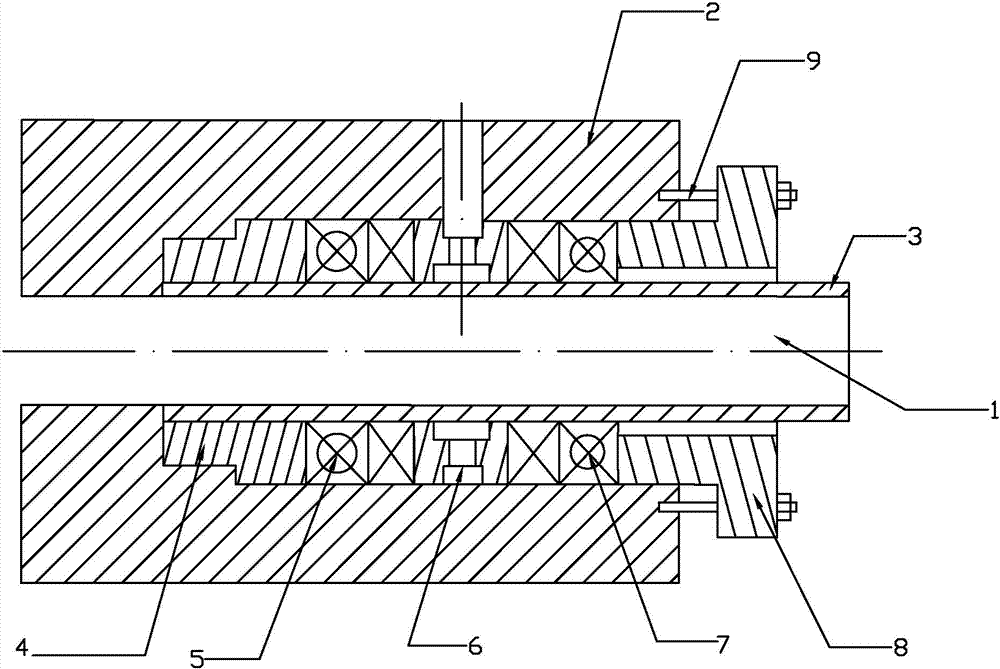

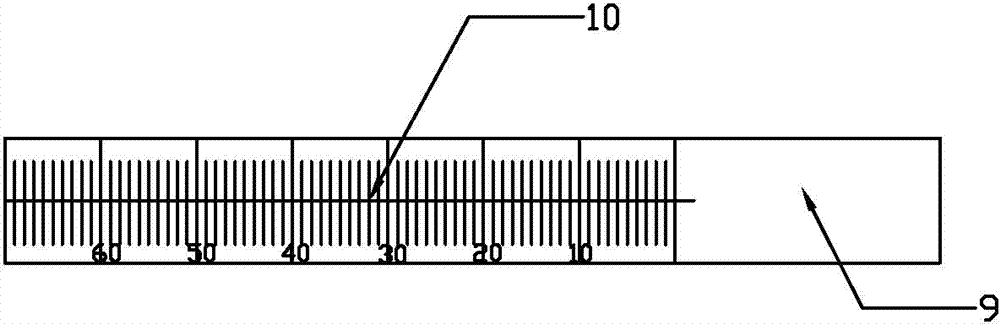

[0014] Such as figure 1 , figure 2 As shown, the water pump bearing asbestos packing sealing structure of the present invention includes a main shaft 1 and a stuffing box case 2. There is a shaft sleeve 3 on the main shaft, and a stuffing box case 2 is wrapped around the shaft sleeve 3. The stuffing box case 2 Between the shaft sleeve 3 and the inner bushing 4, asbestos filler 5, water seal ring 6, asbestos filler 5, and packing gland 8 are provided in turn from left to right, and the water seal ring 6 and the asbestos filler 5 are also provided with There is a graphite sealing ring 7, and the packing gland 8 is fixed on the stuffing box case 2 through the cooperation of the nut and the screw rod 9 on the fixed stuffing box case 2, and the said screw rod 9 has a scale 10.

[0015] In order to achieve the sealing effect, the bottom surface of the packing gland 8 is a striped rough surface, which can increase the fastening degree between the packing gland 8 and the shaft slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com