Testing method for cigarette packing sealing intensity

A testing method and technology of airtightness, which is applied in the field of tobacco industry, can solve the problems that the airtightness of packaging cannot be improved, the specific parts that affect the airtightness of packaging cannot be obtained, and it is not suitable for testing the airtightness of cigarette hard box packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

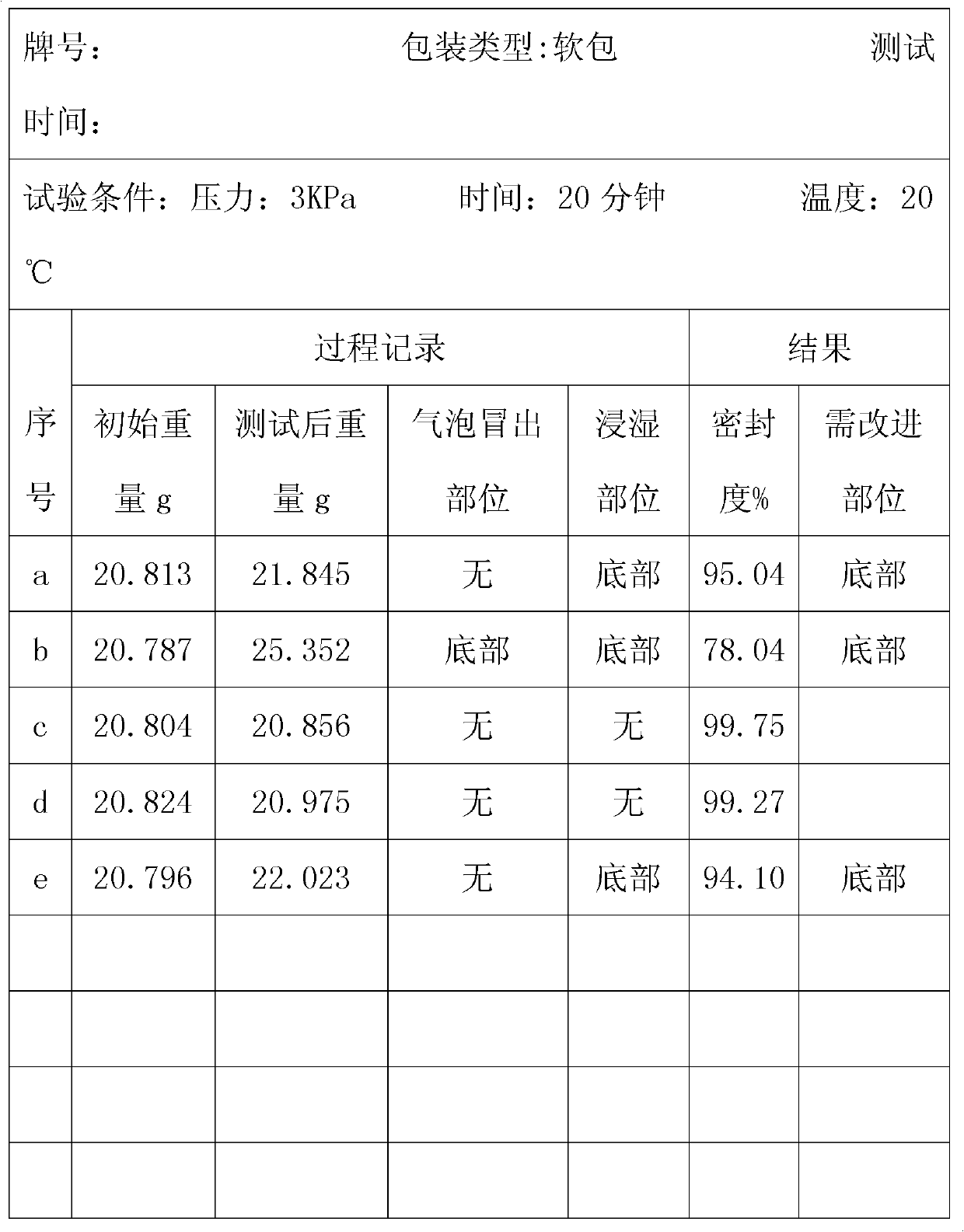

[0016] For the test method for the sealing degree of the soft pack of cigarettes of the same specification, (1) Take five packs of soft pack cigarettes (marked as a, b, c, d, e) and wipe them clean.

[0017] (2) Weigh with an electronic balance and record the data. The results are shown in Table 1.

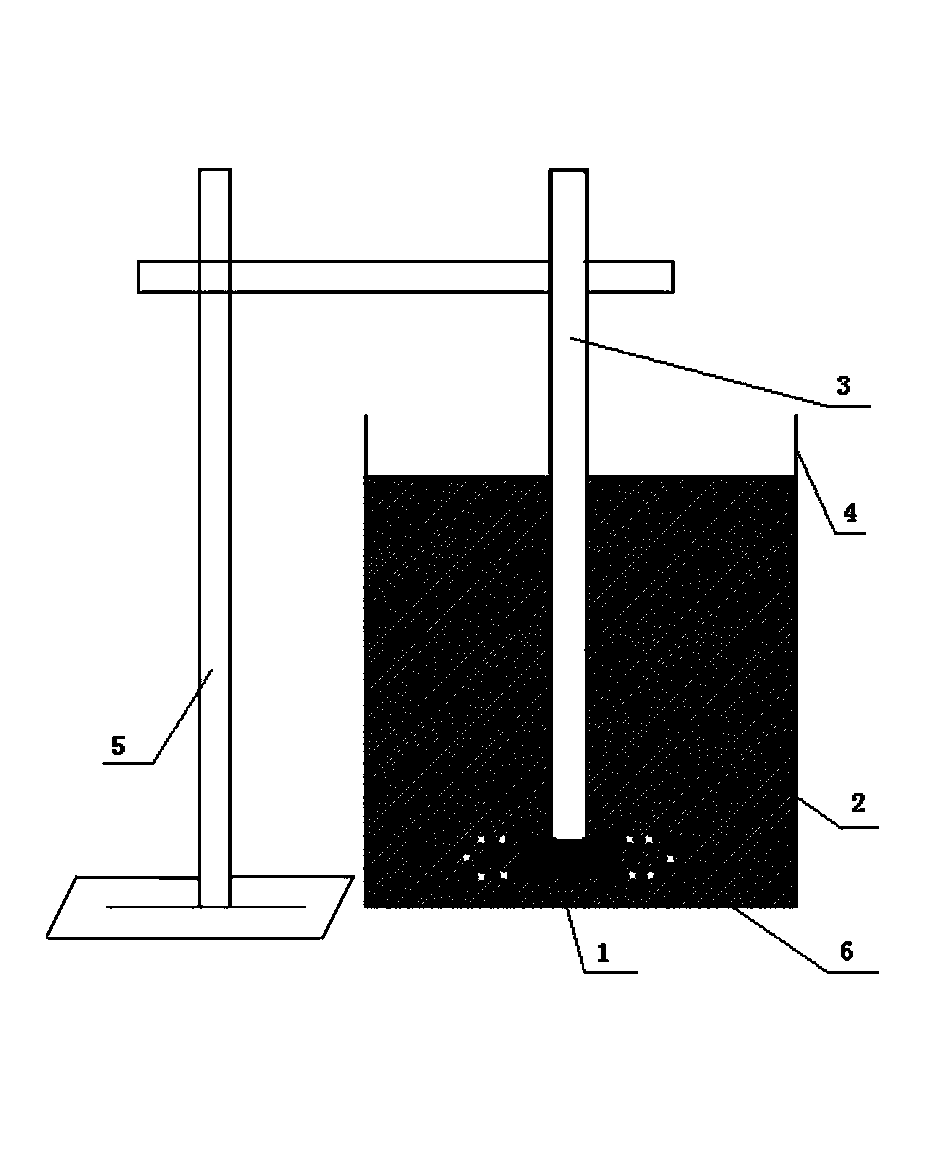

[0018] (3) such as figure 1 As shown, the tested cigarette 1 is put into the cigarette fixing frame 6, and the cigarette is immersed into the liquid 2 in the container 4 through the telescopic rod 3. The pressure of the liquid 2 on the tested cigarette 1 is 3KPa, the immersion time is 20 minutes, and the liquid temperature 20°C.

[0019] (4) At the initial stage of immersion of the tested cigarette 1, observe whether there are bubbles on the surface of the package. If there are bubbles, record the parts of the cigarette. The results are shown in Table 1.

[0020] (5) After the immersion is completed, the cigarette fixing frame 6 is separated from the liquid by the telescopic rod 3, the c...

Embodiment 2

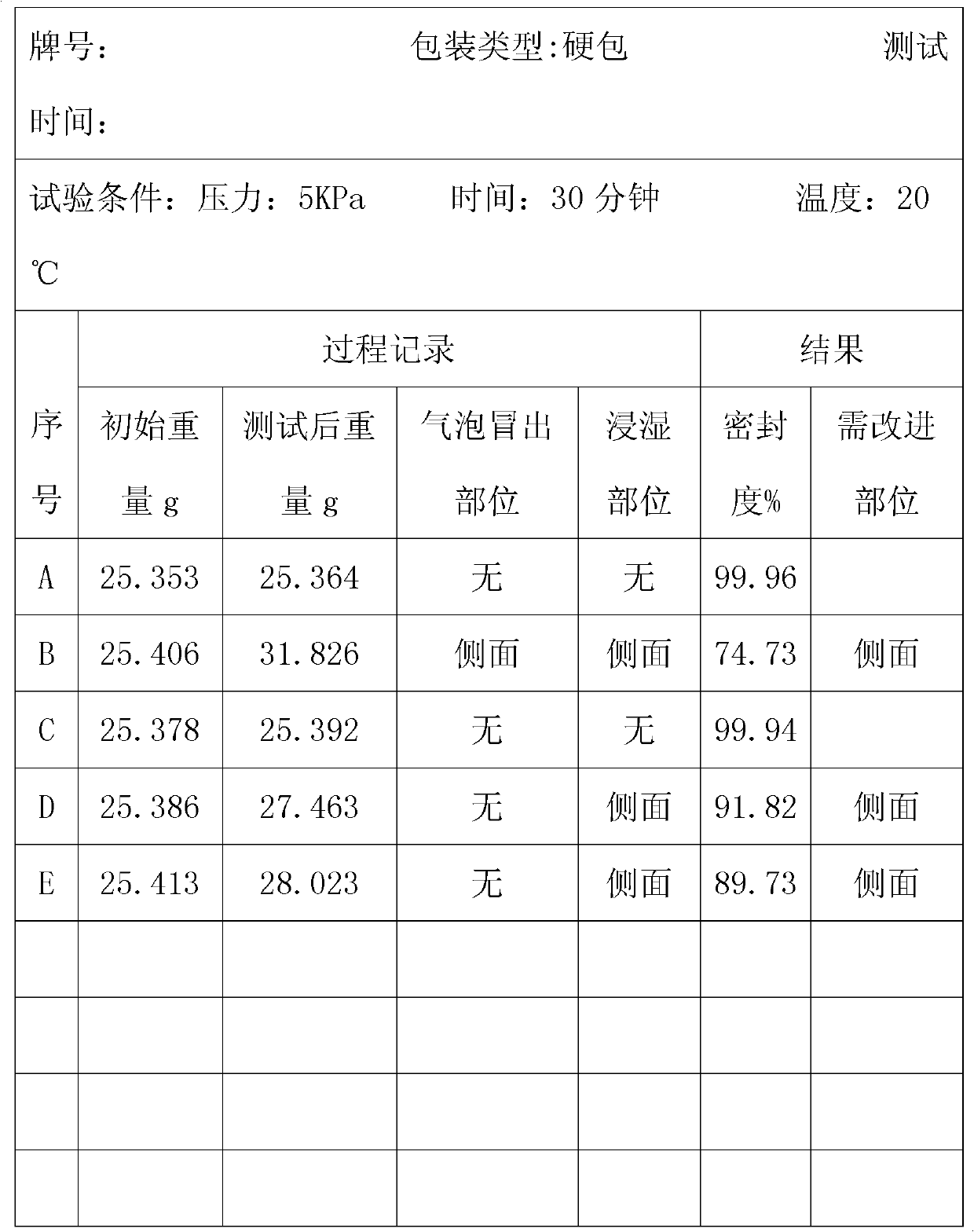

[0026] For the test method for the tightness of hard packs of cigarettes of the same specification, (1) Take five boxes of hard pack cigarettes (marked as A, B, C, D, E) and wipe them clean.

[0027] (2) Weigh with an electronic balance and record the data. The results are shown in Table 2.

[0028] (3) such as figure 1 As shown, the tested cigarette 1 is put into the cigarette fixed frame 6, and the cigarette is immersed into the liquid 2 in the container 4 through the telescopic rod 3. The pressure of the liquid 2 on the tested cigarette 1 is 5KPa, the immersion time is 30 minutes, and the liquid temperature 20°C.

[0029] (4) At the initial stage of immersion of the tested cigarette 1, observe whether there are bubbles on the surface of the package. If there are bubbles, record the locations of the bubbles. The results are shown in Table 2.

[0030] (5) After the immersion is completed, the fixed frame 6 of the tested cigarette 1 is separated from the liquid by the telescopic rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com