Soluble bridge plug

A bridge plug and mandrel technology, applied in the field of soluble bridge plugs, can solve the problems of high risk of encountering obstacles and single direction of the bridge plug slip teeth, and achieve the effects of reducing potential safety hazards, reducing area and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

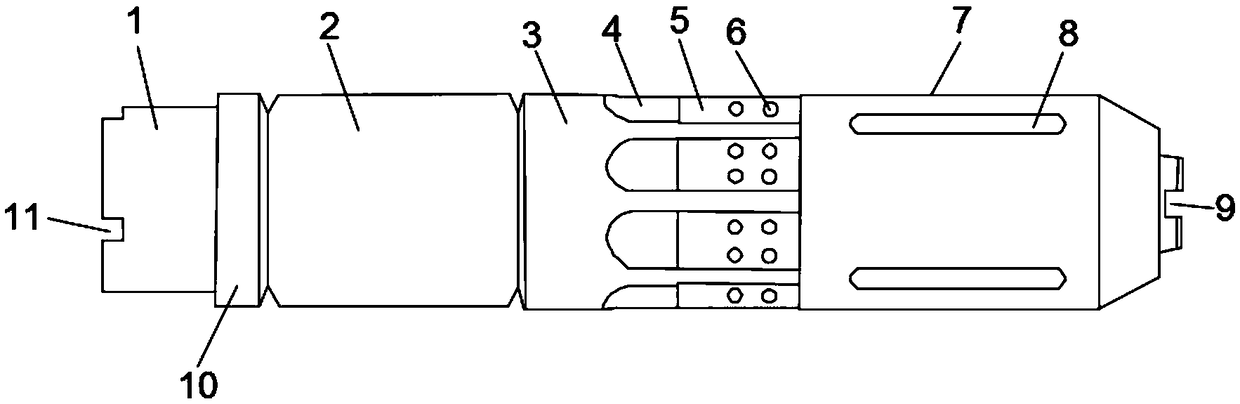

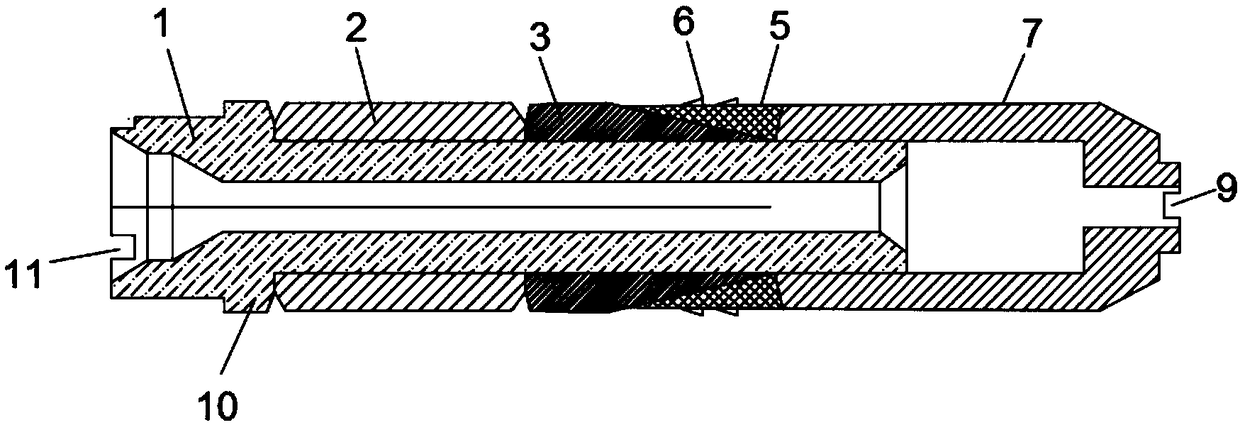

[0028] Such as Figures 1 to 2 As shown, this embodiment provides a dissolvable bridge plug, including a mandrel 1, a rubber sleeve 2, a cone sleeve 3, slips 5 and a lower joint pup 7; the mandrel 1 is a hollow structure, and the The mandrel 1 is provided with a limiting boss 10, and the rubber sleeve 2 and the cone sleeve 3 are sequentially sleeved on the outer surface of the mandrel 1 on one side of the limiting boss 10; The boss 10 is in contact with each other, and the other end of the rubber sleeve 2 is in contact with the end away from the tapered surface of the cone sleeve 3; there are multiple slips 5, and the cone sleeve 3 is provided with the number of slips 5 Corresponding to the guide groove 4, the plurality of slips 5 are located on the tapered surface of the cone sleeve 3 through the radial limit structure; one end of the lower joint nipple 7 is slidably sleeved on the other end of the mandrel 1 And abut against the slips 5, the other end of the lower joint nipp...

Embodiment 2

[0030] Such as Figures 1 to 2 As shown, this embodiment has been further improved on the basis of embodiment 1. Specifically, the rubber cylinder 2 is a single rubber, and the existing rubber cylinder adopts double rubber. If there is no pumping in place, the upper and lower rubber of the double rubber is easy to crack Opening causes the setting seal to not be in place, and the present invention avoids the above-mentioned risks by adopting a single rubber.

[0031] The mandrel 1, the rubber tube 2, the cone sleeve 3, the slips 5 and the lower joint sub-joint 7 are all made of soluble materials.

Embodiment 3

[0033] Such as Figures 1 to 2 As shown, this embodiment is further improved on the basis of embodiment 2. Specifically, the end of the mandrel 1 away from the lower sub-section 7 is provided with a plurality of grooves-11, which can reduce the dissolution time of the bridge plug. A plurality of grooves 2 8 are arranged on the lower joint sub-section 7 to reduce the dissolving time of the bridge plug to meet the working time requirement. The second groove 8 is a strip groove. The depth of the second groove 8 is 3-6mm.

[0034] When the temperature is 90°C, the pressure is 70MPa, and the chloride ion concentration is 10000mg / L, the dissolution time of Example 2 of the present invention is 240h, and the dissolution time of Example 3 of the present invention is 180h, indicating that the mandrel 1 is far away from the lower joint. One end of section 7 is provided with a plurality of grooves 11 and a plurality of grooves 2 8 are arranged on the lower joint sub-section 7, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com