Packaging device capable of setting packing weight

A technology of weight and packing box, applied in the field of packing device that can set the filling weight, can solve the problems of low work efficiency, inability to actually adjust the weight of the packing bag, time-consuming and laborious, etc., so as to improve the production efficiency, and be suitable for popularization and operation. Simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

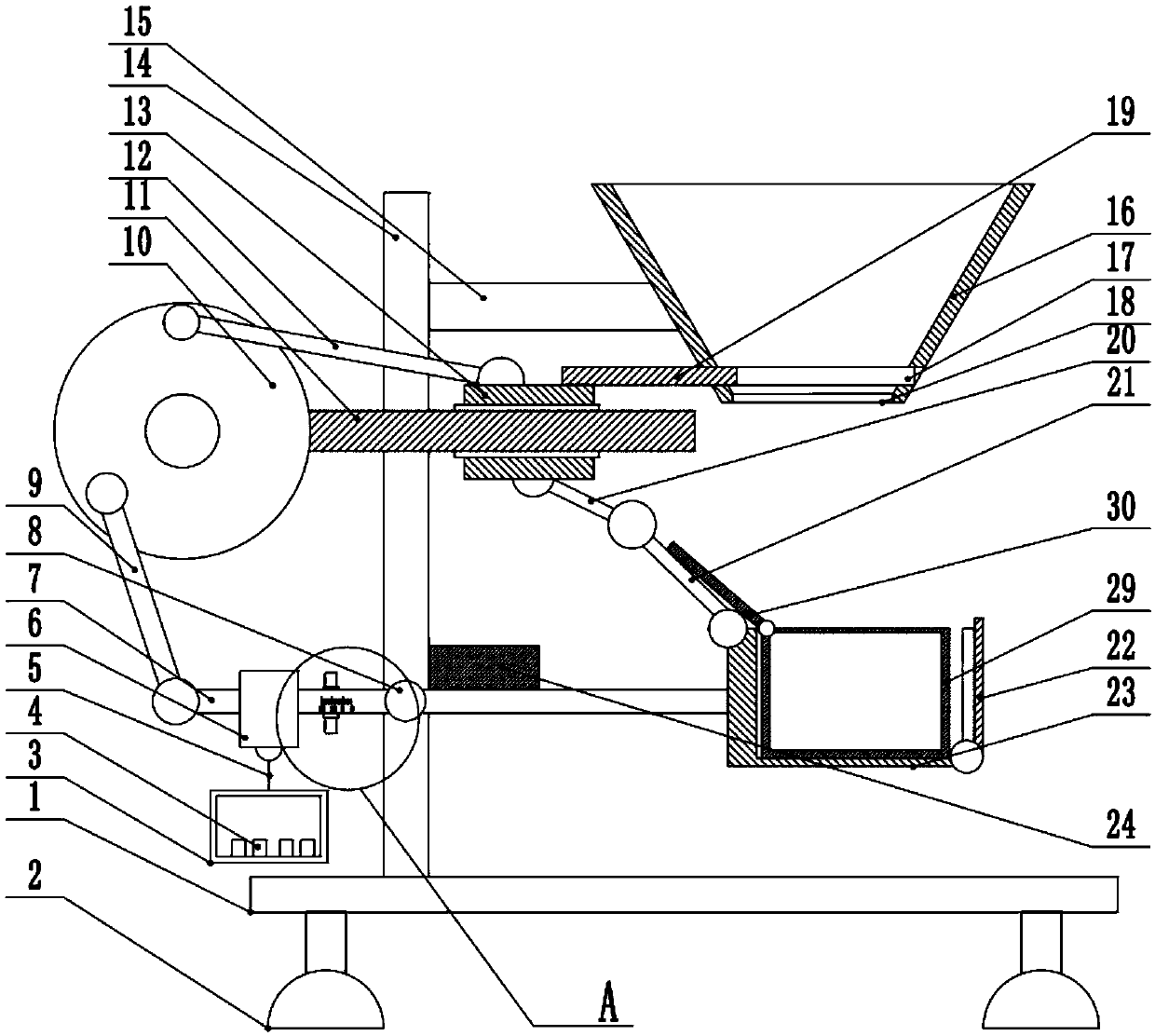

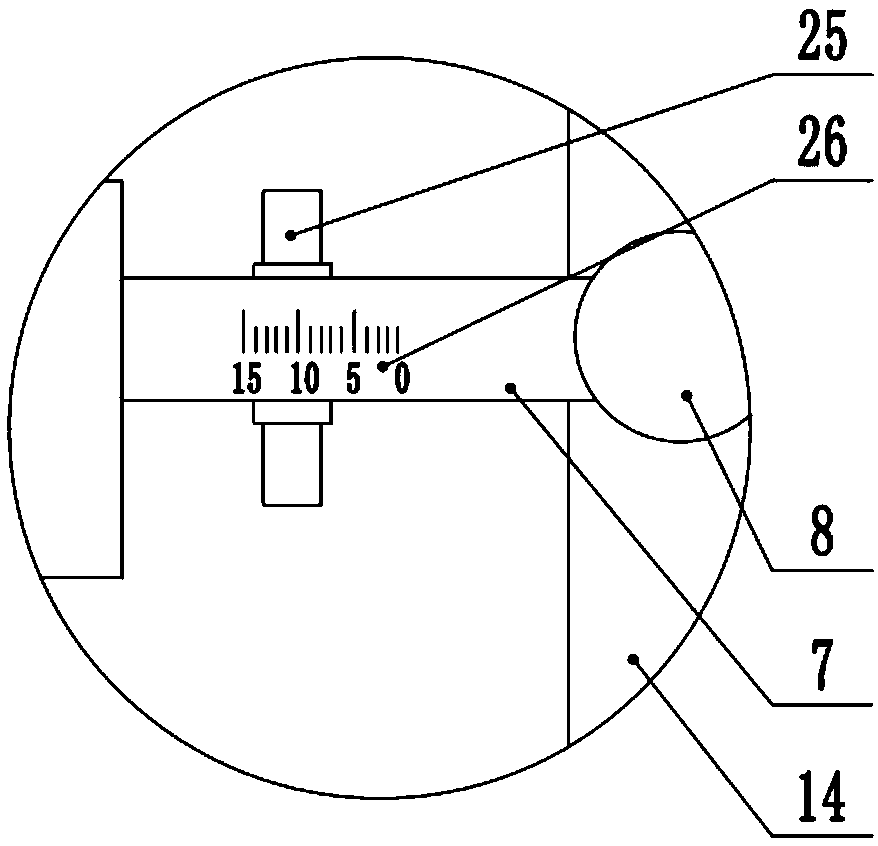

[0025] see figure 1 with 2 , a packaging device that can set the filling weight, including a base 1, the base 1 is fixedly connected to the feet 2, and the level of the entire device can be adjusted by adjusting the feet 2, so that the device can be stable during operation. Rocking occurs; the left side of the base 1 is fixedly connected to the column 14, the top of the column 14 is fixedly connected to the fixed rod 15, the fixed rod 15 is fixedly connected to the material storage box 16, the bottom of the column 14 is connected to the rotating shaft 8 by rotation, and the rotating shaft 8 is fixedly connected to rotate Rod 7, the right side of rotating rod 7 is fixedly connected to packaging box 23, and packaging box 23 is provided with packaging box 29, and described rotating rod 7 is fixedly connected to fixed block 6, and the bottom of fixed block 6 is connected to counterweight frame 3 through steel wire rope 5, counterweight The inside of the frame 3 is provided with a...

Embodiment 2

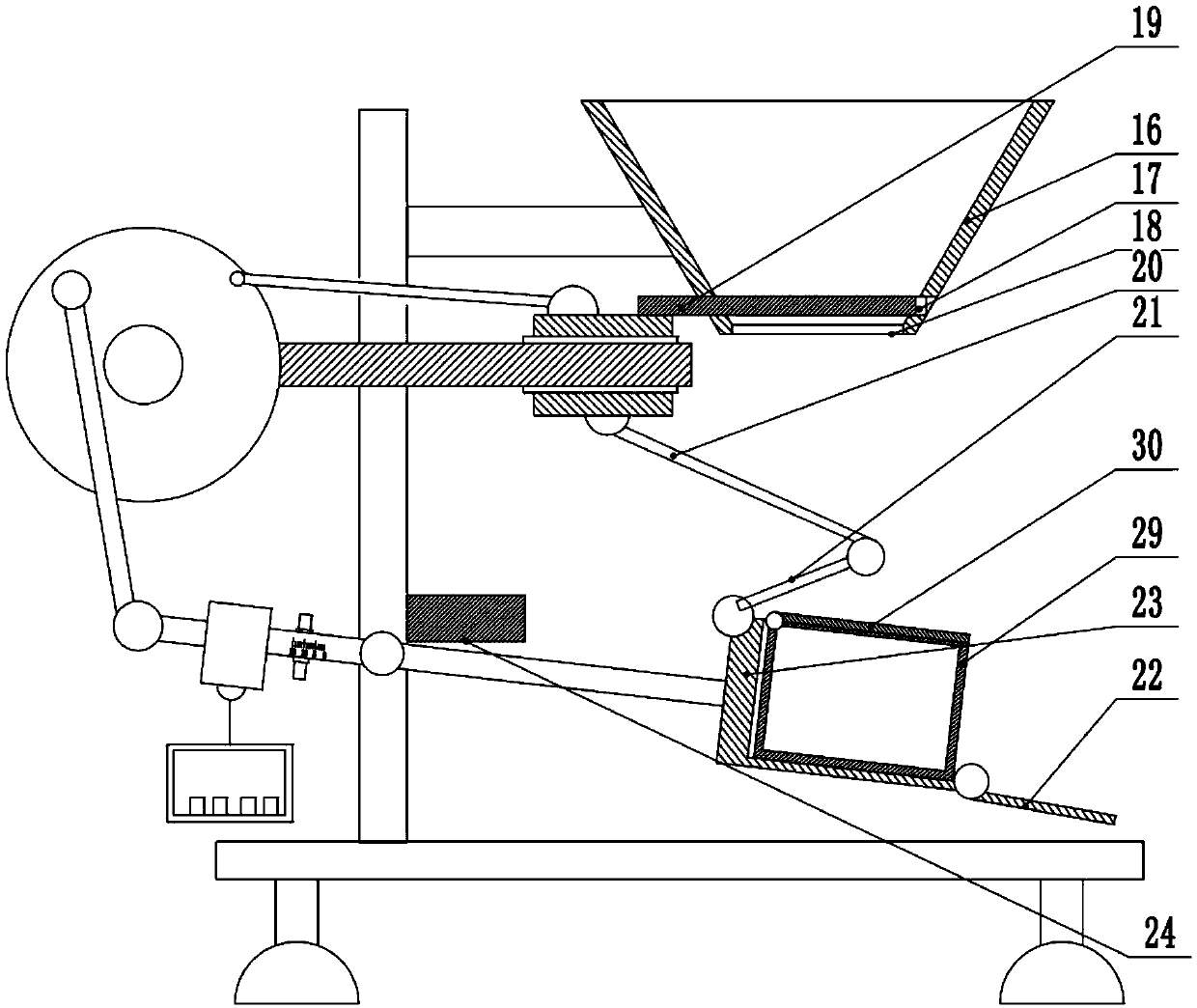

[0028] see Figure 4 Embodiment 2 is improved on the basis of Embodiment 1. The side wall of the storage tank 16 is fixedly connected to the first pressure sensor 27, and the first pressure sensor 27 can detect whether the material in the storage tank 16 is sufficient. When the detected numerical value is relatively low, the material in the material storage box 16 can be replenished in time to ensure that the device can operate normally; the bottom of the packing box 23 is provided with a second pressure sensor 28. During long-term use, mechanical wear may affect the adjustment accuracy. The second pressure sensor 28 can be used to detect whether the material filled in the actual packaging box 29 is the same as the value we set. When it is different, you can adjust the fine-tuning weight 25 offset mechanical errors.

[0029] In the present invention, during use, at first the packing box 29 is put into the packing box 23, the box cover 30 is leaned against the second connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com