Spinning machine with compressing apparatus

A compression device and spinning machine technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problem that the fiber structure is not fully guided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

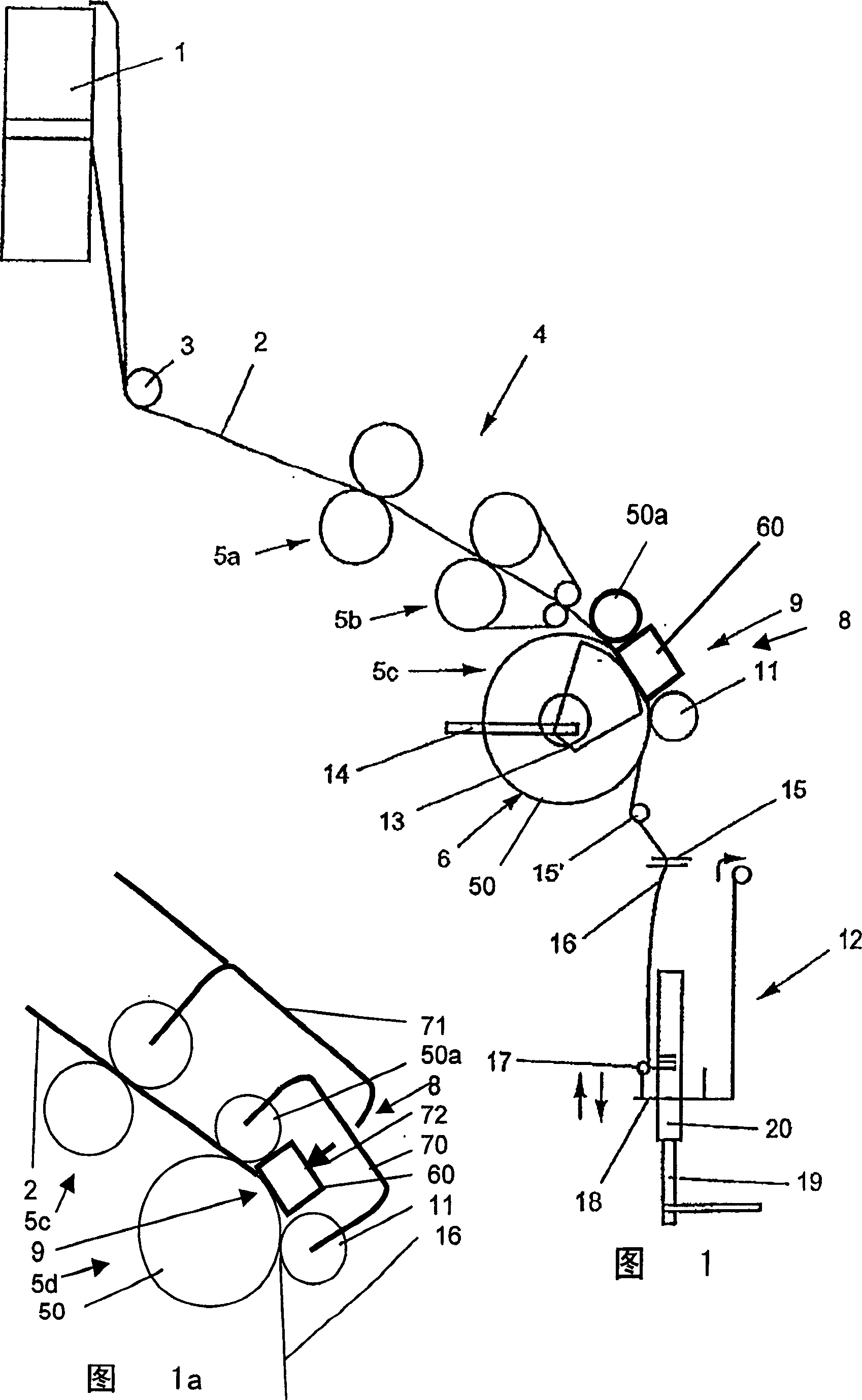

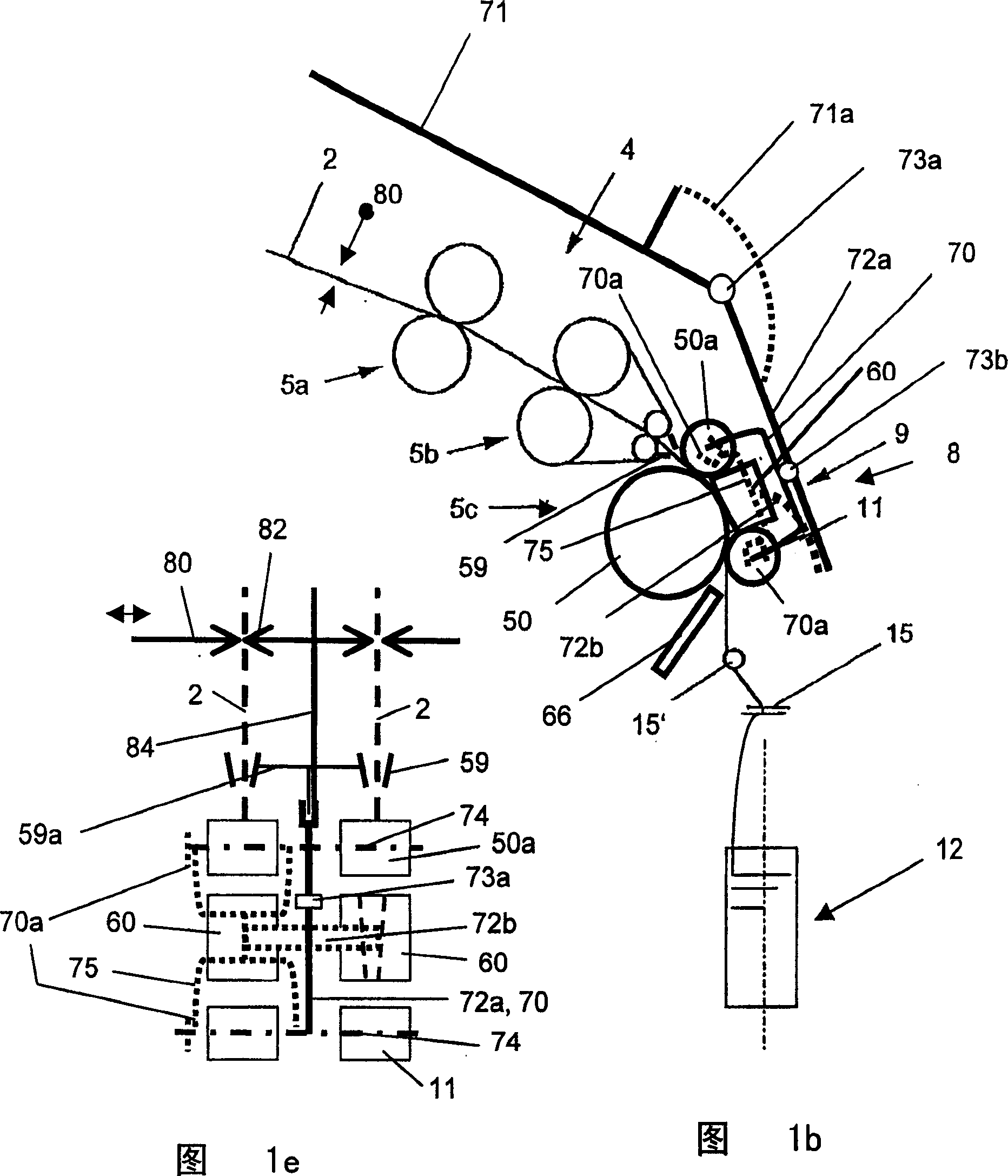

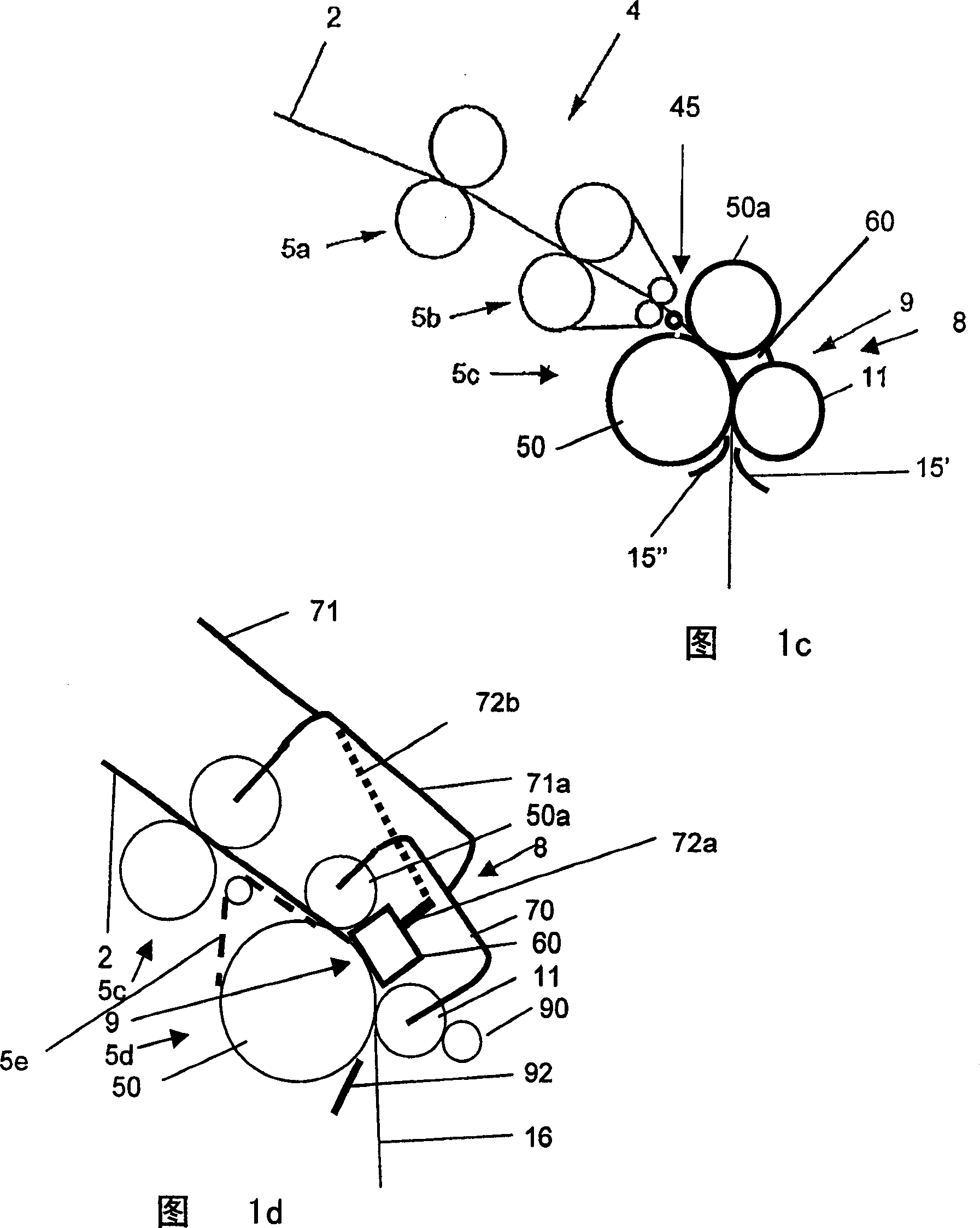

[0052] In a conventional spinning machine, the material supply 1 of FIG. 1 consists of cans or roving bobbins or rubbing bobbins. The fiber structure 2 is guided from the can to the drafting device. In the case of roving bobbins or rubbed bobbins, the roving is drawn from the circumference of the bobbins. The fiber structure, ie the roving yarn or fiber structure, enters the region of the drafting device 4 via a deflection device. The drafting unit consists of pairs of conveyor rollers, some of which are belted. The fibrous structure 2 is drafted only weakly between the first and second pair of delivery rollers 5a and 5b, and strongly between the second and subsequent pair of rollers 5c, so that a draft ratio of more than 100 can be achieved.

[0053] The drawn fiber structure is gripped between the gripping roller 50 a and the roller 6 and then compressed on the compression device 8 . The width of the fibrous structure leaving the drafting device 1 gradually decreases duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com