Jam releasing device and method for hydraulic fracturing packer of underground long drill hole in coal mine

A hydraulic fracturing and packer technology, applied in the field of hydraulic fracturing, can solve the problems of increasing the friction between the packer and the hole wall, interrupting the fracturing project, and high risk, so as to improve the hydraulic construction efficiency and reduce the hydraulic pressure. The effect of cracking project loss and high success rate of unblocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the technical solution of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are for more clearly illustrative of the technical solutions of the present invention, and therefore only examples are as follows, and without limiting the scope of the invention.

[0027] It should be noted that the technical terms or scientific terms used in the art will be understood by those skilled in the art of the present invention, unless otherwise stated.

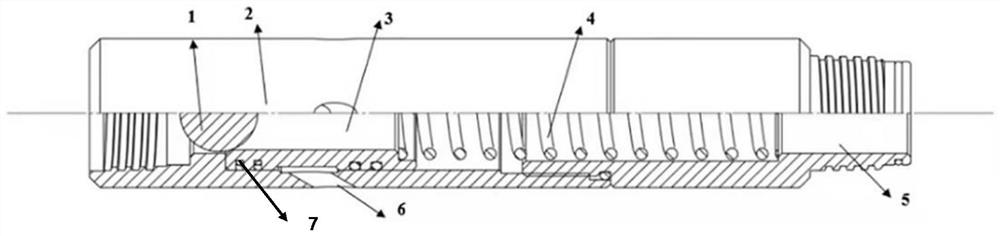

[0028] Such as figure 1 As shown, the embodiment of the present invention provides the present invention provides a hydraulic fracture clipper solution for a coal mine well, including a valve body 2, a plunger base 3, a low density ball 1, a lower joint 5 and The spring 4 is connected to the valve body 2, and the other end is connected to the sealing member, and 4 outlet 6 is opened at the position of the plunger 2. 4 out of the nozzle 6 is distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com