Power transmission line ice coating real-time distribution module calculation method

A distribution model and transmission line technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems that the model cannot achieve accuracy, the real-time meteorological consideration is insufficient, and the transmission line icing information cannot be controlled in real time. Achieve the effect of improving security, reliability, and reliable technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A calculation method for a real-time distribution model of icing on transmission lines, comprising:

[0034] Step 1. Screening of real-time meteorological data: collect real-time meteorological observation data of meteorological stations in various provinces in the study area on an hourly basis, process and summarize them, and obtain meteorological data related to ice covering, including minimum temperature, average temperature, maximum temperature, and precipitation volume, mean relative humidity and wind speed;

[0035]Step 2. Real-time meteorological data identification: By analyzing meteorological conditions, find out all icing processes, and effectively identify the entire process of icing initiation, growth, maintenance, interruption and end;

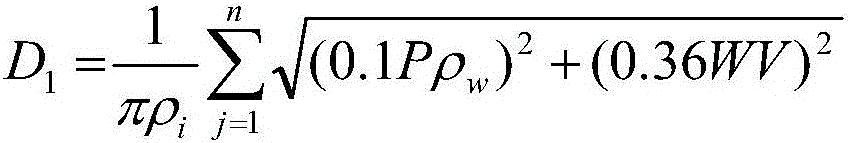

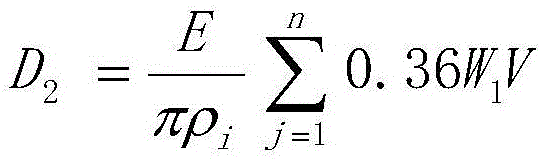

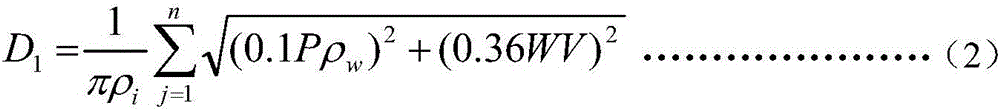

[0036] Step 3. Establish a real-time icing model: According to the capture coefficient of the supercooled fog droplets and the liquid water content of the fog droplets, combined with the rime Kathleen.F.Jones model, a real-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com