Controllable track lateral drilling tool and method

A drilling tool and trajectory technology, applied in the field of controllable trajectory lateral drilling tools, can solve the problems of small borehole diameter, poor borehole trajectory accuracy, borehole buckling, etc., to ensure communication quality, improve safety and stability , Reduce the effect of falling well loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

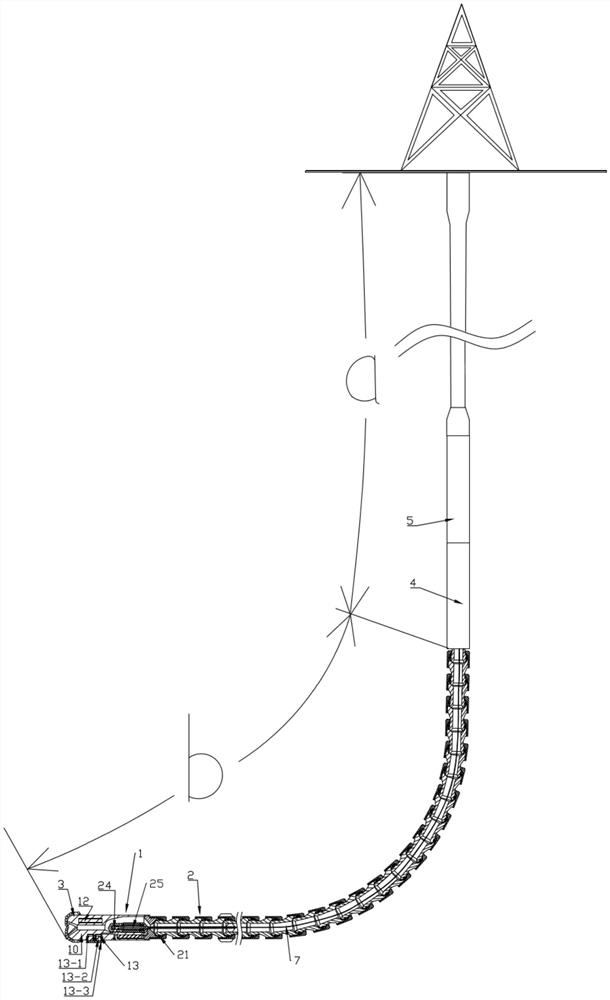

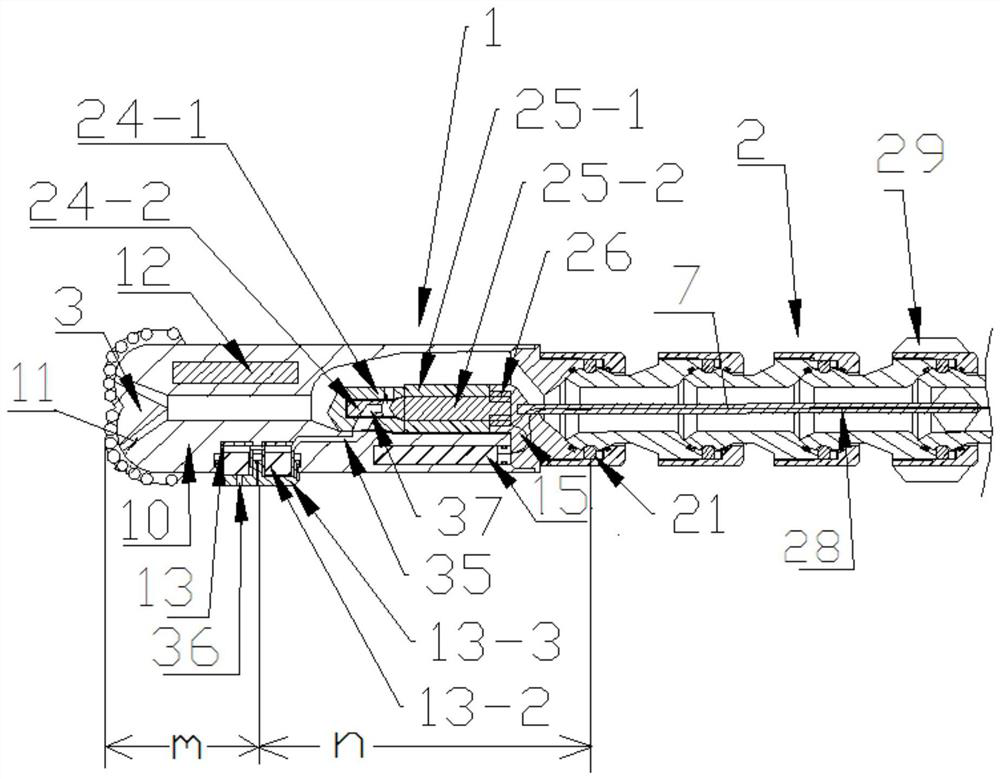

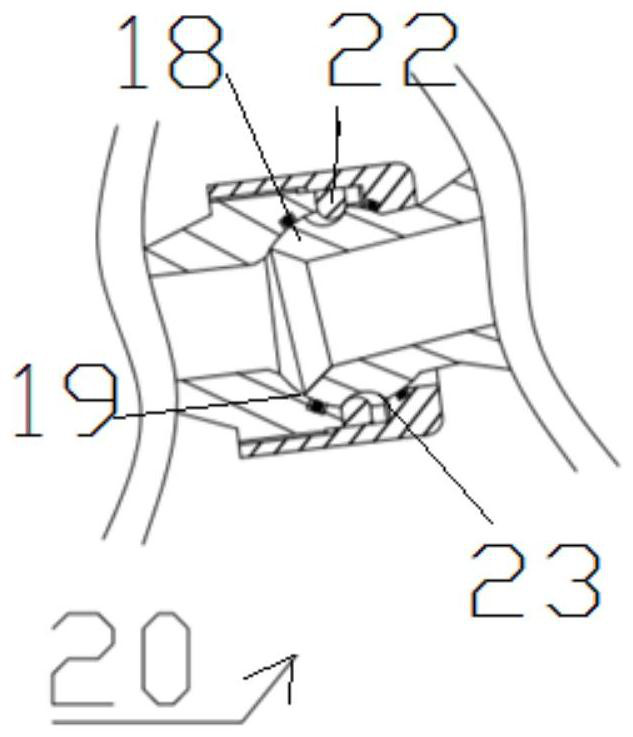

[0058] Example: see attached Figure 1-5 , the present invention provides a technical solution: a controllable trajectory lateral drilling tool, which includes a high-pass lateral drilling section b and a drilling power transmission section a, wherein the high-pass lateral drilling section b can Drilling of the extended well section e of the short-very short radius well section d is realized through the short-very short radius well section d extending laterally from the main wellbore c, and the high-passability lateral drilling section b includes the drill bit 3 in sequence from front to back , a high-passage guiding execution sub-joint 1 and a high-passage transmission sub-joint array 2, the high-passage transmission sub-joint array 2 is composed of several transmission sub-joints 20 for bearing torque, and the transmission sub-joints 20 can transmit the drill bit 3 Rotary drilling power, and there is a preset deflection limit angle between adjacent transmission nipples 20, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com