Cable digital layering injection ground control system

A ground control and ground controller technology, which is applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc. problems, to achieve the stability of the communication process, reduce the risk of blocking the card, and realize the effect of direct data reading and real-time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

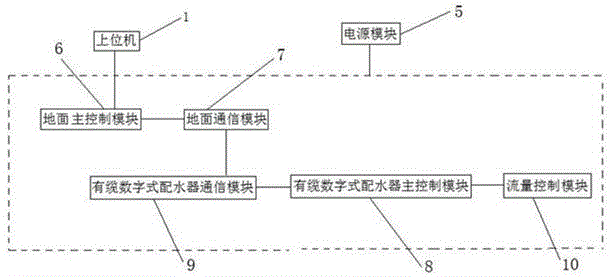

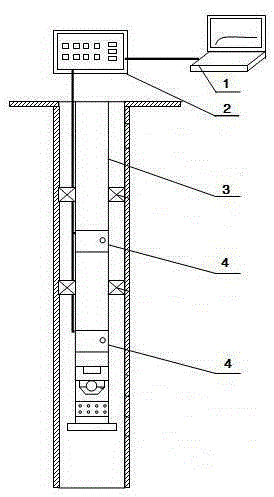

[0023] Such as figure 1 and figure 2 As shown, the present invention provides a cabled digital dispensing ground control system, comprising an oil pipe 3 and a cabled digital water distributor 4 connected to the oil pipe 3, and the cabled digital water distributor 4 communicates with the ground through a cable. The ground controller 2 on the ground is electrically connected, and the ground controller 2 is electrically connected with the upper computer 1;

[0024] The cable digital water distributor 4 is provided with a cable digital water distributor communication module 9, a cable digital water distributor main control module 8, and a flow control module 10, which are electrically connected in sequence;

[0025] The ground controller 2 includes a power supply module 5, a ground main control module 6, and a ground communication module 7, and the upper computer 1, the ground main control module 6, the ground communication module 7, and the cable digital water distributor comm...

Embodiment 2

[0036] The main control module 6 on the ground and the main control module 8 of the cable digital water distributor all adopt the SM201 type main control module. The flow control module 10 is a DG4V3S-2A-MUH5-60 type flow control module. The ground communication module 7 and the cable digital water distributor communication module 9 all adopt one of WLAN, NFC, WIFI-Dircet, bump, 2G, 4G, Bluetooth, wifi, zige-bee, GPRS, 3G, and USB modules .

[0037] The cabled digital injection ground control system provided by the present invention has the functions of automatic adjustment of the injection volume of each layer, real-time monitoring and storage of downhole pressure, temperature and flow parameters, and automatic downhole sealing inspection. The ground controller is connected to the cabled digital water distributor through a cable, and the cable is used for two-way transmission of data and instructions to realize direct data reading and real-time control. At the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com