Insertion pipe type release separate-layer water injection string and operation process thereof

A layered water injection and intubation technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problem of not fundamentally eliminating the influence of sealing, the damage of the packer rubber tube, the pipe string Creep and other problems, to achieve the effect of reducing the risk of jamming, reducing operating costs, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

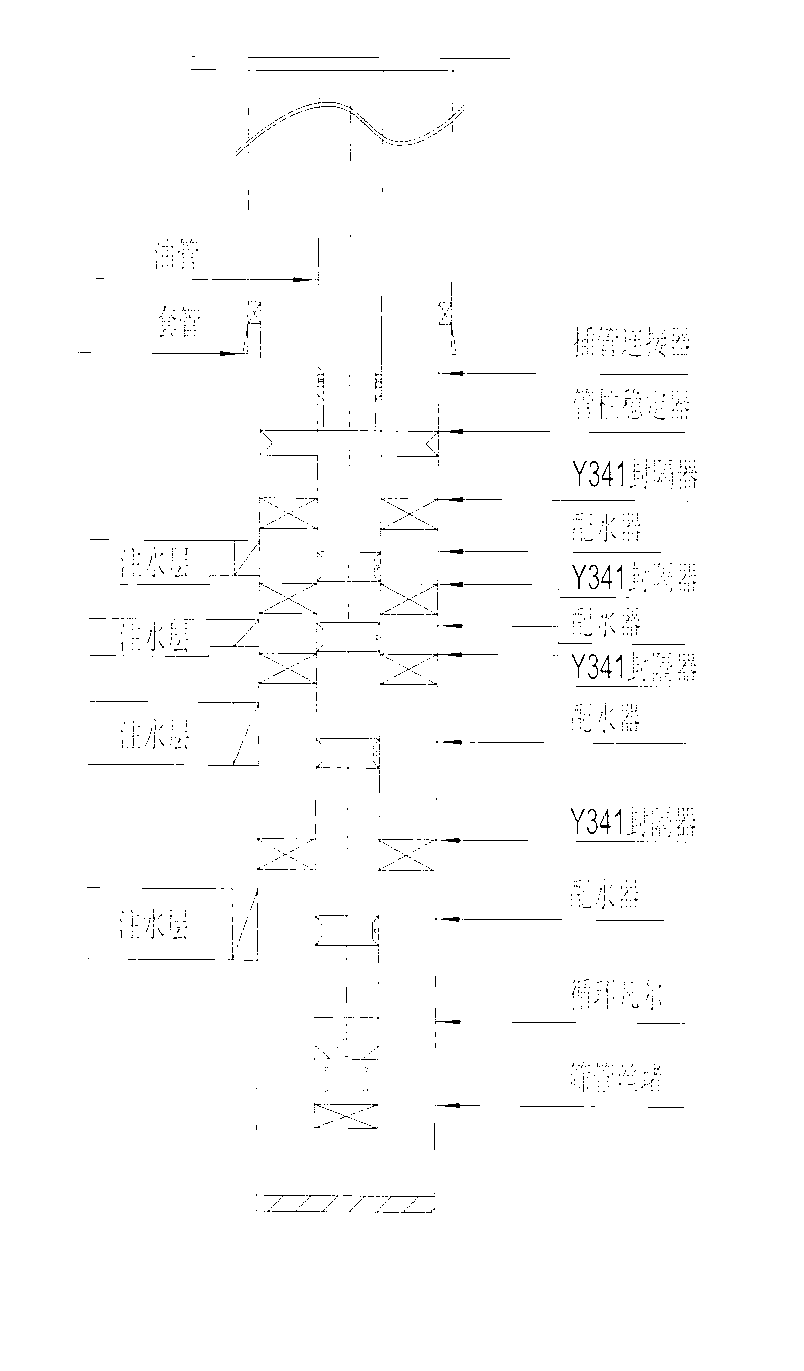

[0036] The following is a detailed description of the intubation-type drop-hand layered water injection string and its operation process in combination with the accompanying drawings:

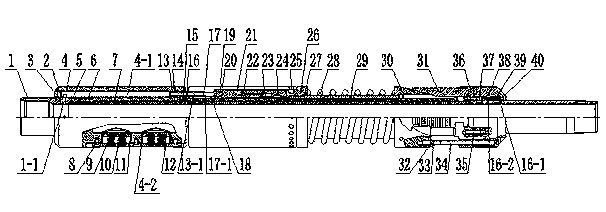

[0037] The intubation-type hands-off layered water injection string is composed of a conventional dispensing tool string, an intubation connector and a pipe string stabilizer. At least one cannula connector and a tubing string stabilizer are added to the upper part to form a dispensing string of "oil pipe + cannula connector + tubing string stabilizer + dispensing tool string".

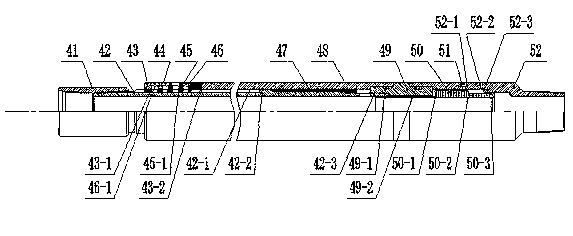

[0038] The intubation connector is composed of three parts: a hand-off assembly, an intubation seal assembly and a connection key assembly, wherein the hand-off assembly consists of a lower joint 52, a short joint 49, a piston sliding sleeve 50, an inner tube 42, The shear pin 51 and the sealing packing are composed; the intubation sealing assembly is composed of the upper joint 41, the inner pipe 42, the outer pipe 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com