Drill string element with fluid activation area

A drill pipe string and activation zone technology, applied in the field of oil and gas reservoir exploration and development, can solve problems such as low rigidity, achieve good lift capacity, improve turbulent flow dynamics, and reduce wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

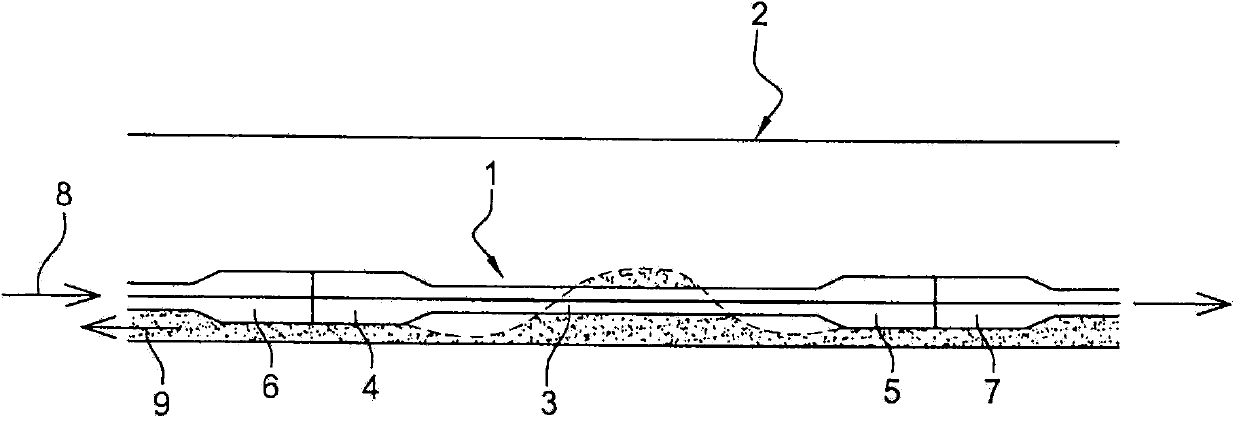

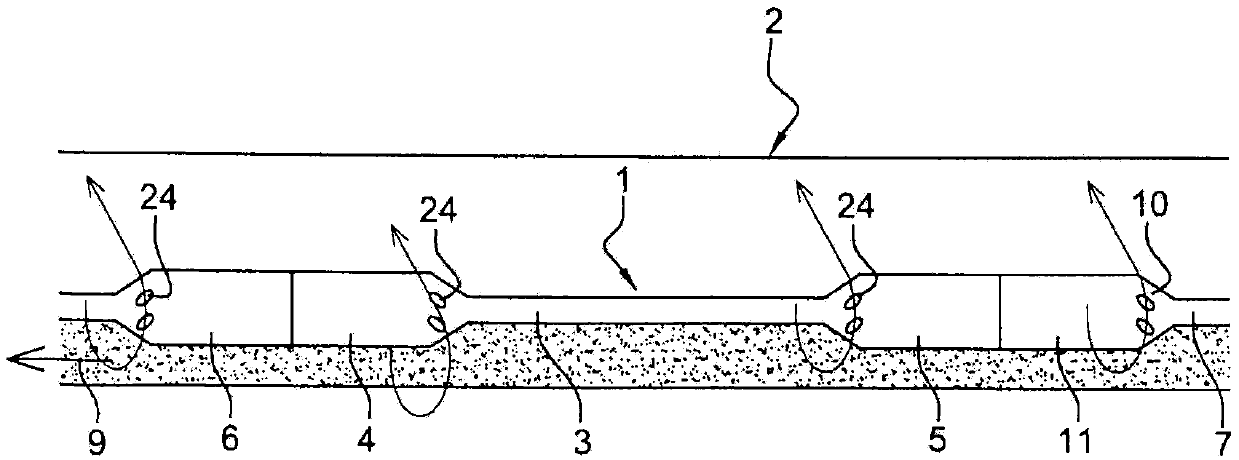

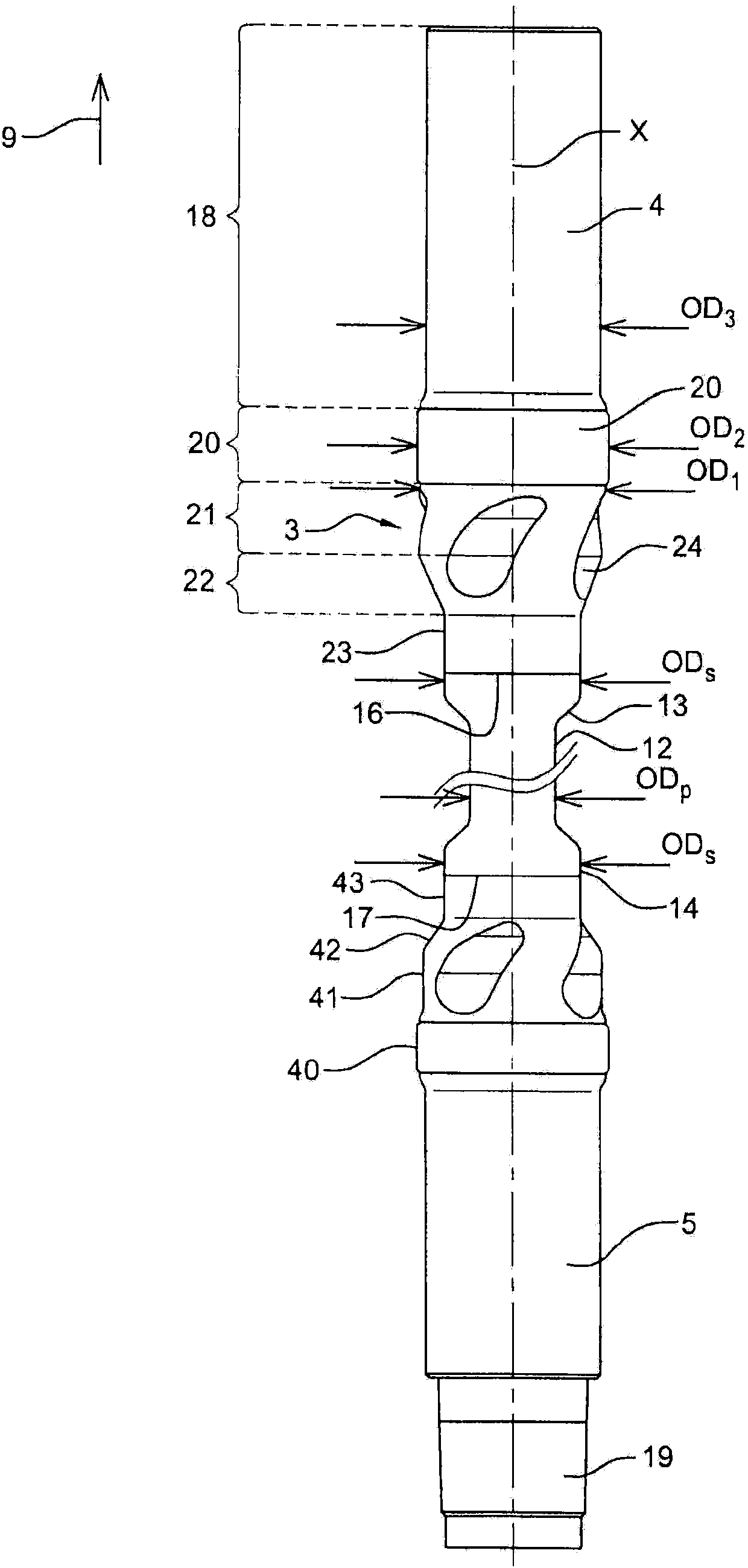

[0043] figure 1 A portion of a drill string 1 in an almost horizontal portion 2 of a formation well is shown. The drill string 1 is shown in part by a hollow tubular element 3 comprising two joints 4 and 5, by which each end of the element 3 is connected to complementary tubular elements 6 and 7 of the drill string. The drill string 1 defines a continuous central space for the flow of drilling fluid as indicated by arrows 8 . A drilling tool such as a drill bit works at the bottom of the borehole, then drilling fluid or drilling mud rises in the annular space between the borehole wall and the outer surface of the drill string 1 , see arrow 9 .

[0044] As the drilling fluid rises over the drill pipe, it carries debris from the formation traversed by the drilling tool to the surface from which the well is being drilled. The operation of the drill pipe according to the prior art is shown in figure 1 . exist figure 1 It was observed that debris carried by the drilling fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com