Construction method of foundation pit slope supported independent pile tower crane foundation

A tower crane foundation and construction method technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of being unable to be used as a tower crane, low axial bearing capacity and anti-overturning capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

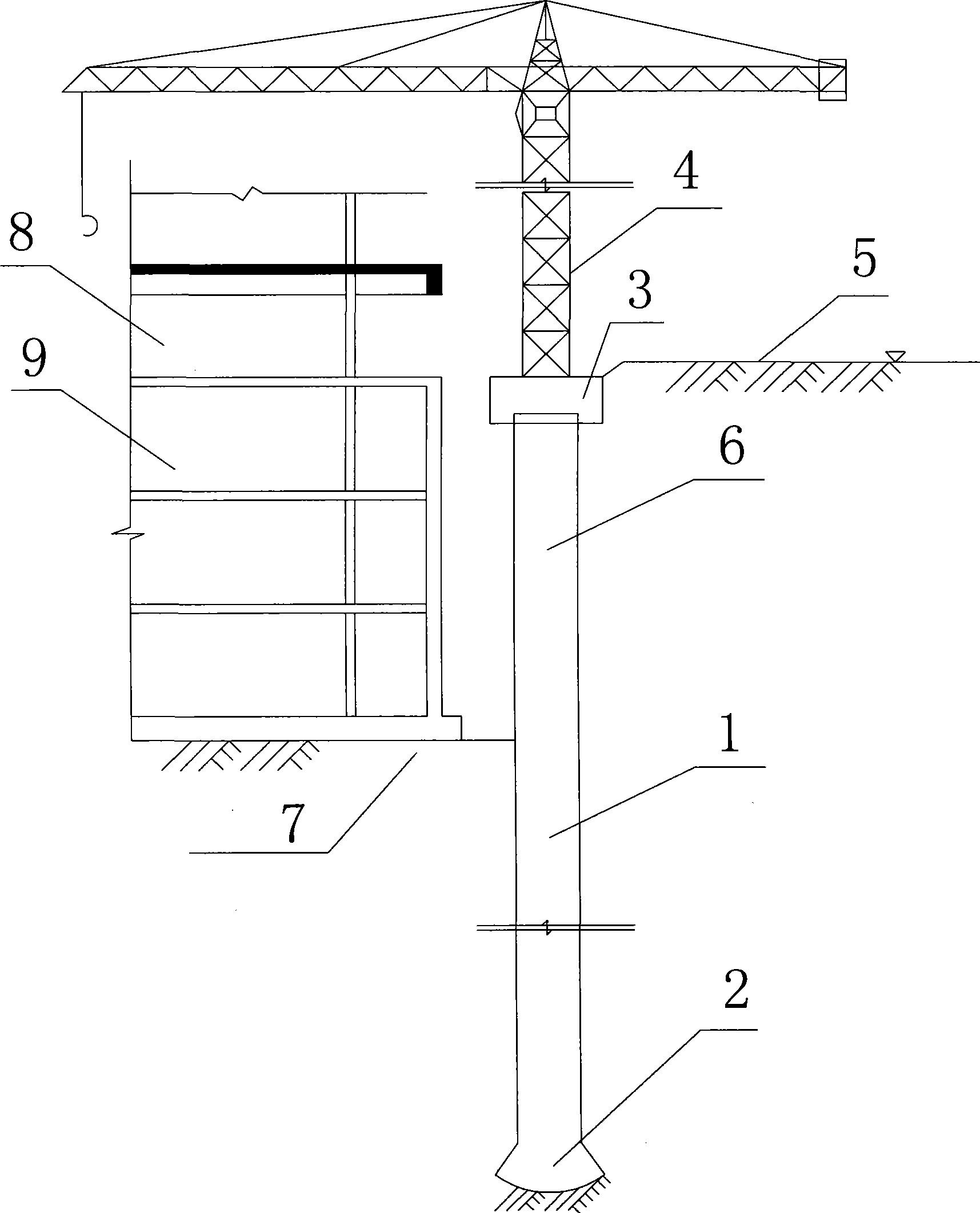

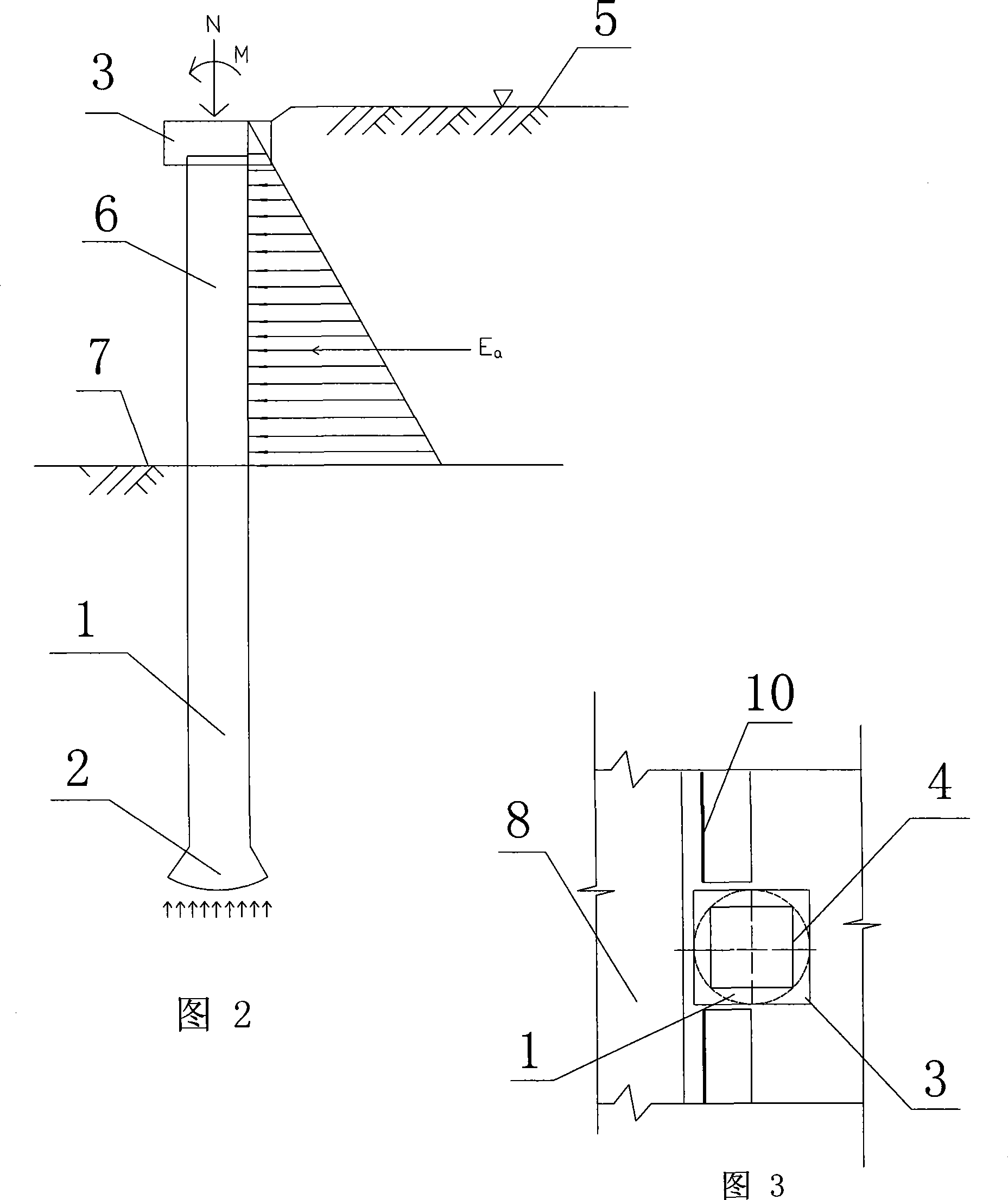

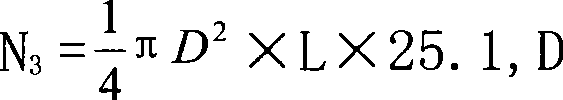

[0014] Such as figure 1 , shown in Fig. 2, Fig. 3, first carry out geological drilling analysis at 10 places of the foundation pit slope of building 8 and basement 9, formulate the construction plan; dig holes at the foundation pit slope according to the plan, pump water while digging, support Retaining formwork, pouring concrete retaining wall; when the digging hole reaches the design depth, enlarge the diameter of the hole bottom, clean the bottom of the hole, drain the water, pour the bottom concrete to form the enlarged head 2; pour concrete into the independent support pile from the bottom 1. On the top of the independent support piles, pour the tower crane 4 cap foundation 3, the diameter of the independent support piles is equal to or greater than 1.42 times the side length of the standard section of the tower body, and the depth of the independent support piles is equal to or greater than the pile foundation 1.5 times of the height of the cantilever 6 ensures that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com