Layering water injection flow intelligent adjusting system under pit

A technology of intelligent adjustment and layered water injection, which is applied in the direction of production fluid, wellbore/well components, wellbore/well valve device, etc., which can solve the problems of heavy monitoring and adjustment workload of layered water injection, and real-time adjustment of water injection volume, etc. , to achieve the effect of reducing the risk of getting stuck and getting stuck, reducing the workload and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

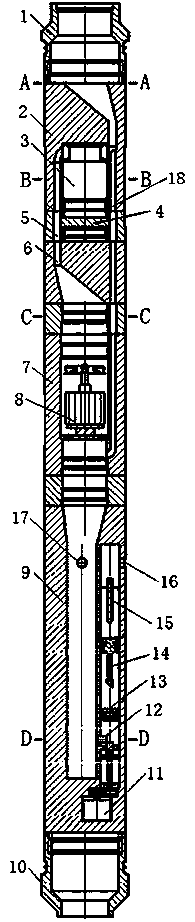

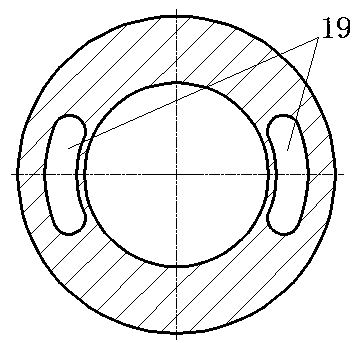

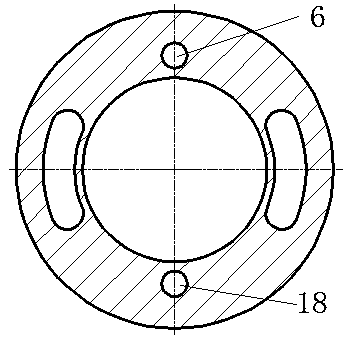

[0026] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, this downhole layered water injection flow intelligent adjustment system includes an upper joint 1, a tapered flow channel conversion pipe 2, a power generation unit 7, an intelligent water distributor 9, a lower joint 10 and a PCL control unit connected sequentially from top to bottom. There are two partial holes 19 arranged on both sides of the tapered hole flow channel conversion pipe 2, and the upper circular tapered hole is located between the two partial holes 19. Road 6 communicates with water injection branch 18, and a solenoid valve 3 is installed in the middle of the cone-hole flow channel conversion pipe 2. Connect the lower circular cone hole, the lower circular cone hole is narrow at the top and wide at the bottom. The lower circular cone hole communicates with the power gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com