Cutter edge modification method for processing helicoid of screw rotor

A helical surface and rotor technology, which is applied in the design and correction of the cutter blade shape, can solve the problems that the rotor cannot mesh normally, the application occasions are few, and the energy consumption of the compressor is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

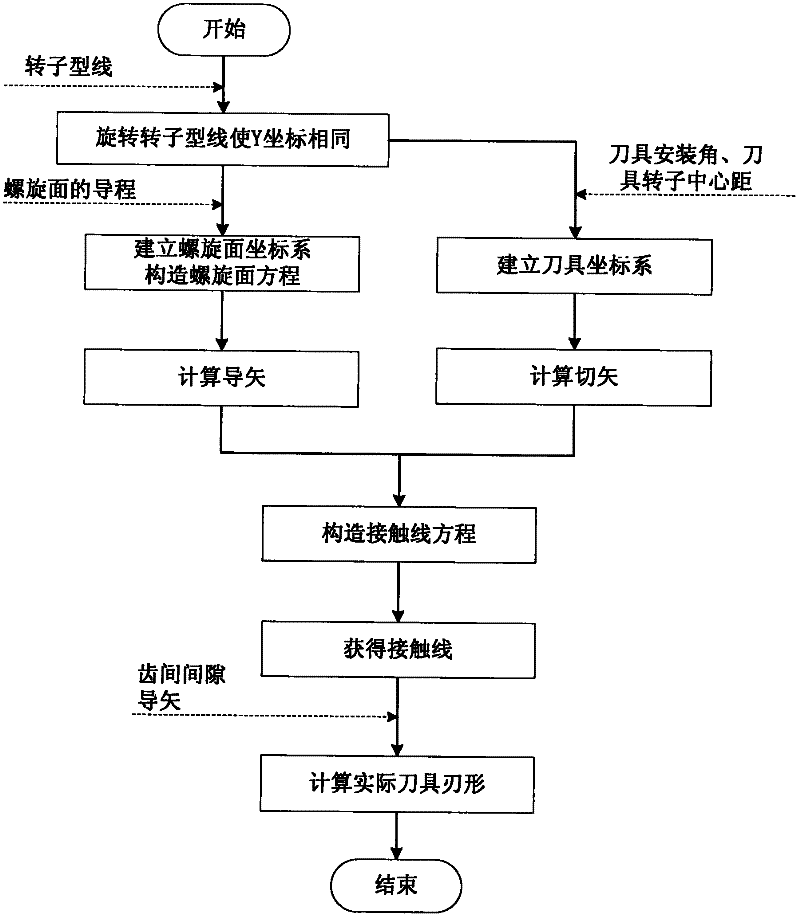

Method used

Image

Examples

Embodiment Construction

[0095] Describe the present invention below in conjunction with specific embodiment:

[0096] In this embodiment, the LG7.5 / 8 oil-injected screw air compressor is taken as an example. The rotor length of the compressor is 100 mm, and the male rotor has a torsion angle τ 1z is 300°, the female rotor torsion angle τ 2z is 240°; male rotor lead T 1 120mm, female rotor lead T 2 150mm; center distance A between male rotor and cutter 1c is 267.25mm, the center distance A between the female rotor and the cutter 2c 260.5mm; installation angle Both are 43.7°.

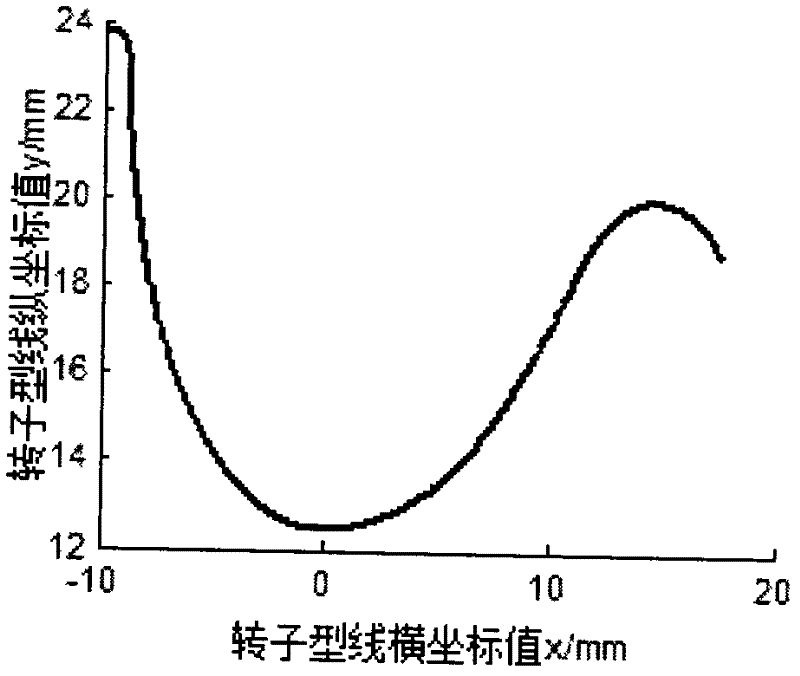

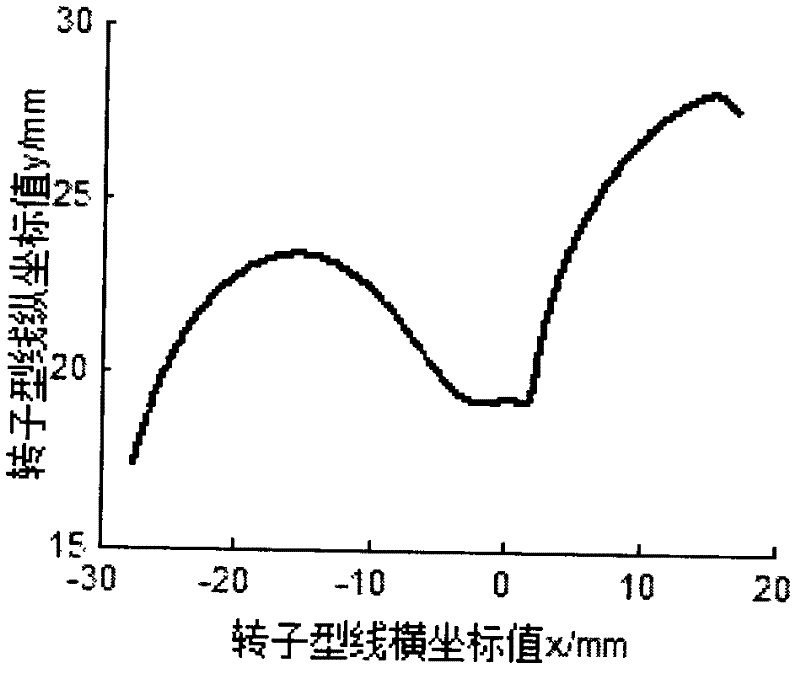

[0097] The rotor profile is given in the form of discrete points, and the corresponding coordinates of the discrete points starting from one end of the rotor profile in the initial coordinate system OOXXYY are ( xxx 1 , yy 1 ), ( xxx 2 , yy 2 ),...,( xxx n , yy n ), as attached figure 2 And attached image 3 shown. attached figure 2 And attached image 3 Corresponding to the molded lines of the female...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com