Expanding-type large head anchor rod

A head-expanding and expansion-type technology, applied in construction, sheet pile wall, infrastructure engineering, etc., can solve the problems of difficulty in opening, inconvenient operation, complex structure, etc., and achieve easy failure, simple structure and high energy conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

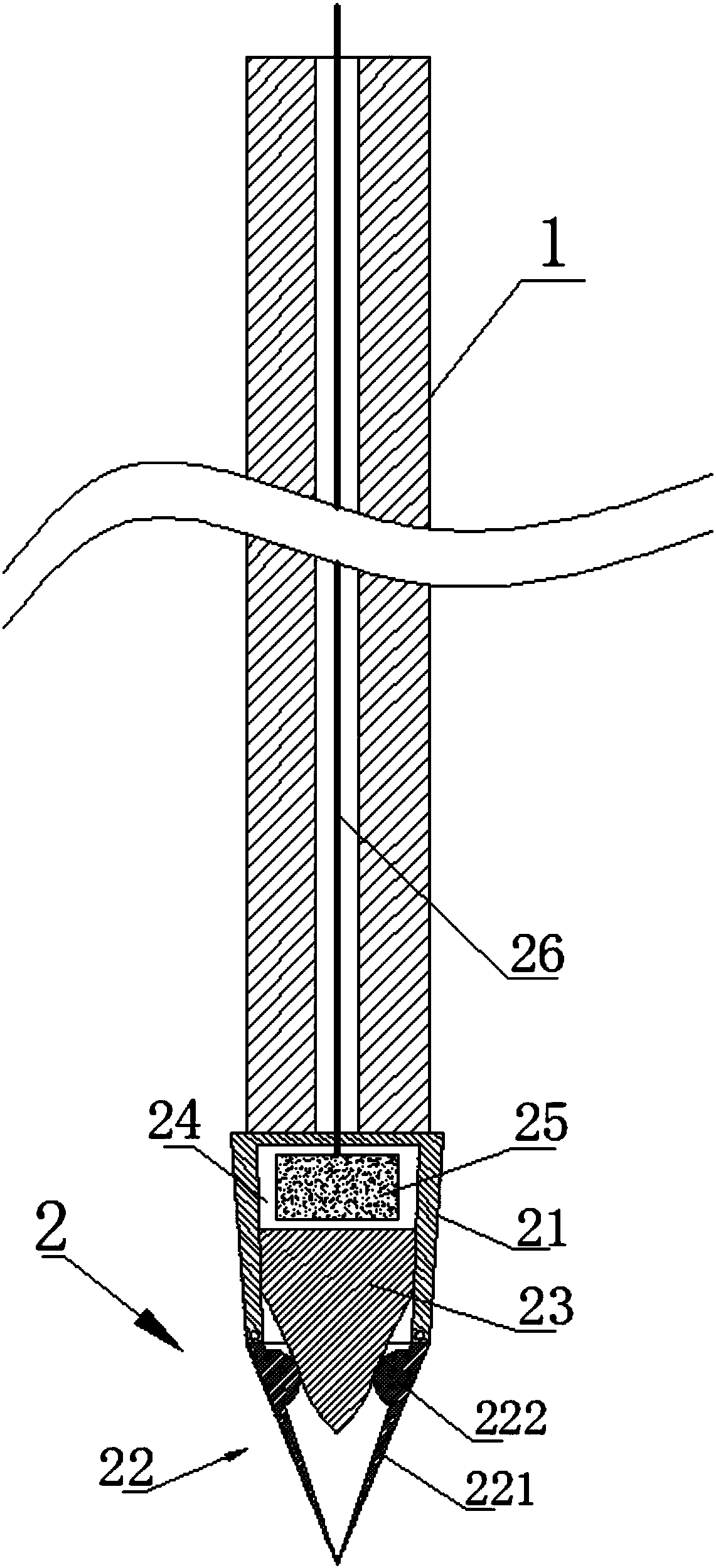

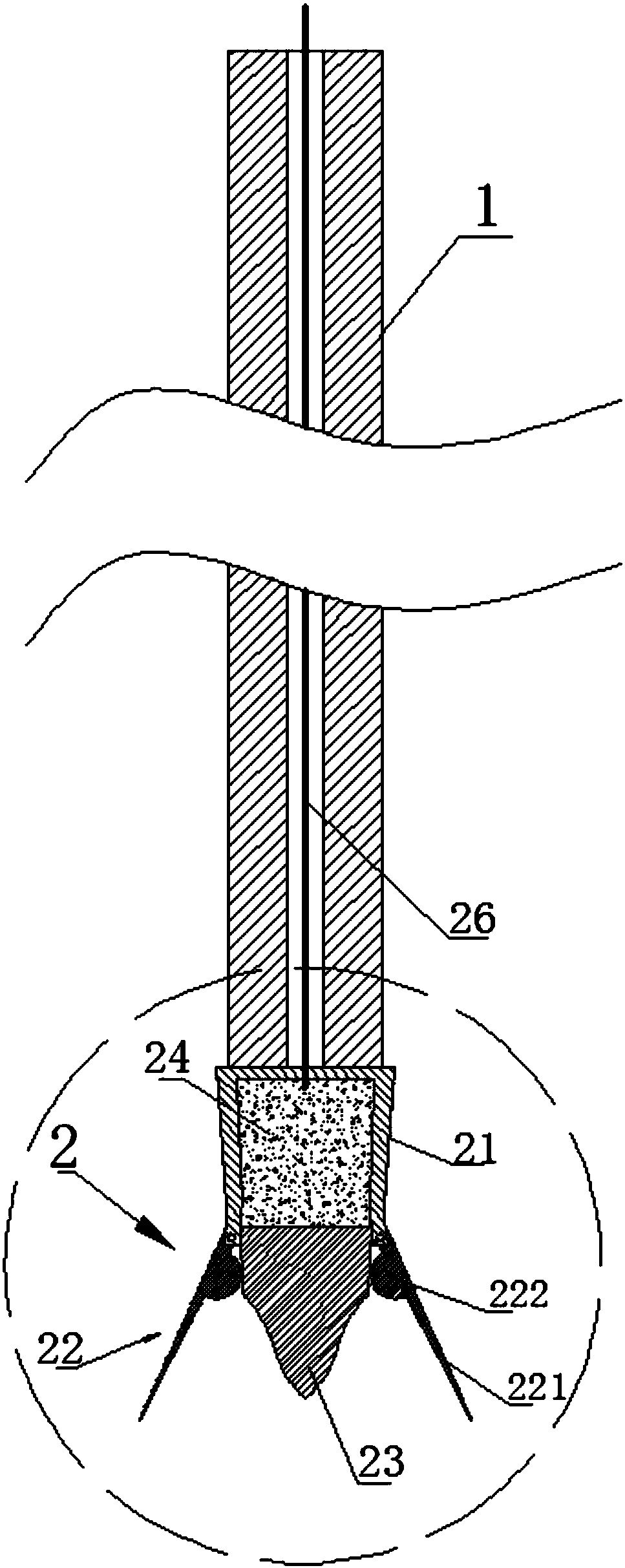

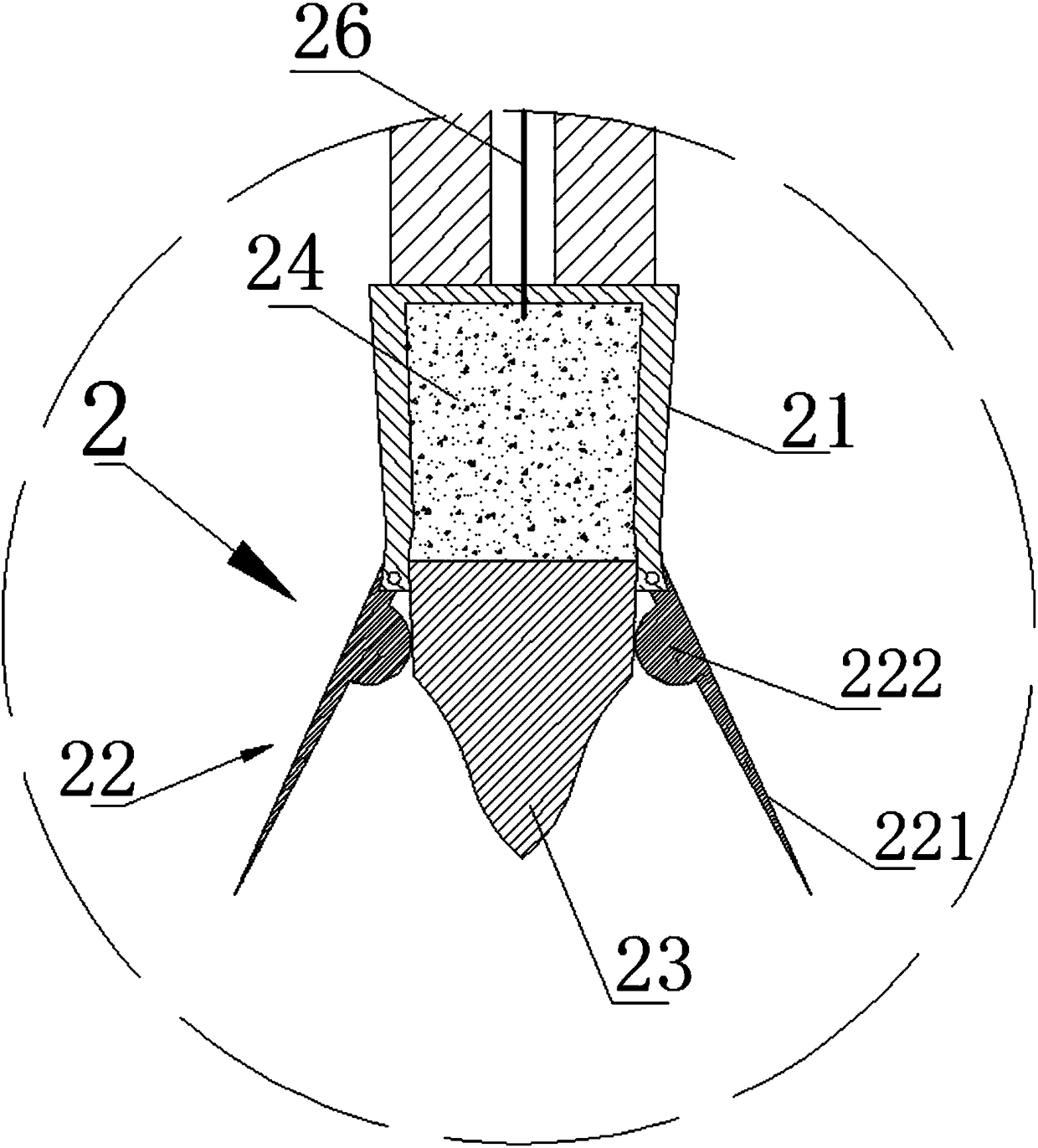

[0026] see Figures 1 to 3 , an expansion-type enlarged head anchor rod, including a rod body 1 and a bullet-shaped hollow enlarged part 2 arranged at the front end of the rod body 1; the enlarged part 2 is composed of a cylindrical part 21 and a tapered part 22; the cylindrical part 21 One end is fixedly connected to the front end of the rod body 1; the tapered part 22 is surrounded by a plurality of fan-shaped single pieces 221; the fan-shaped single piece 221 is rotatably connected to the other end of the cylindrical part 21; the inner seal of the cylindrical part 21 The sliding sleeve is provided with a bullet-shaped push block 23; the push block 23 and the cylindrical part 21 surround an explosion chamber 24; the explosion chamber 24 is filled with gunpowder; The inner side of the fan-shaped single piece 221 is provided with a protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com