Tunnel type wood veneer drying production line

A wood veneer and tunnel-type technology, applied in the direction of veneer drying, drying, drying machine, etc., can solve the problems of different drying efficiency and drying effect of hot air drying devices, and achieve ingenious structure setting and uniform heating , the effect of not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

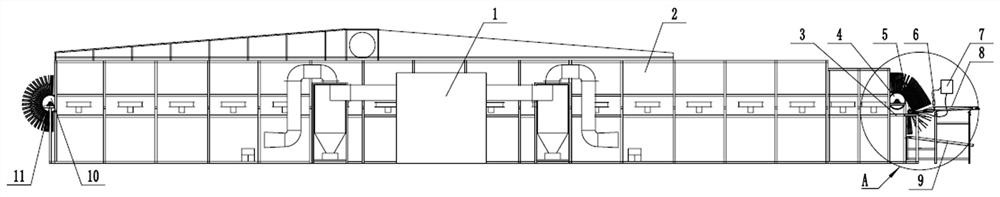

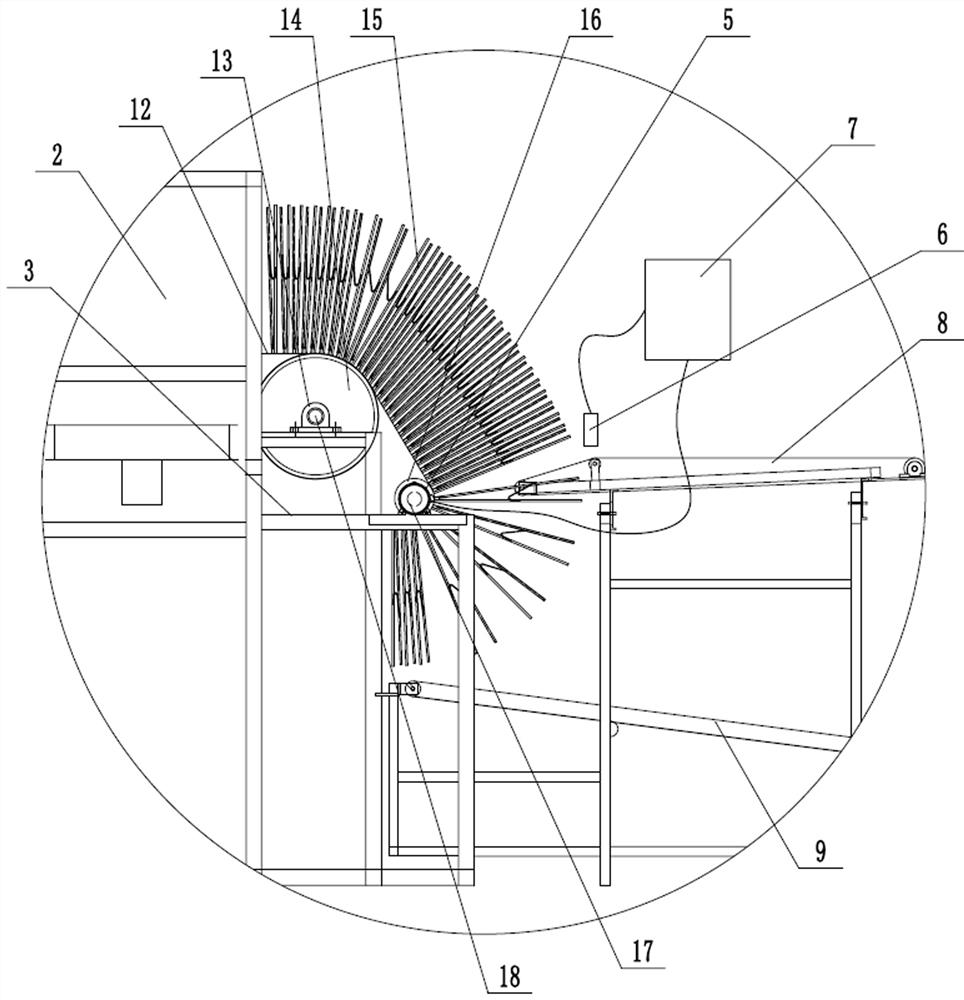

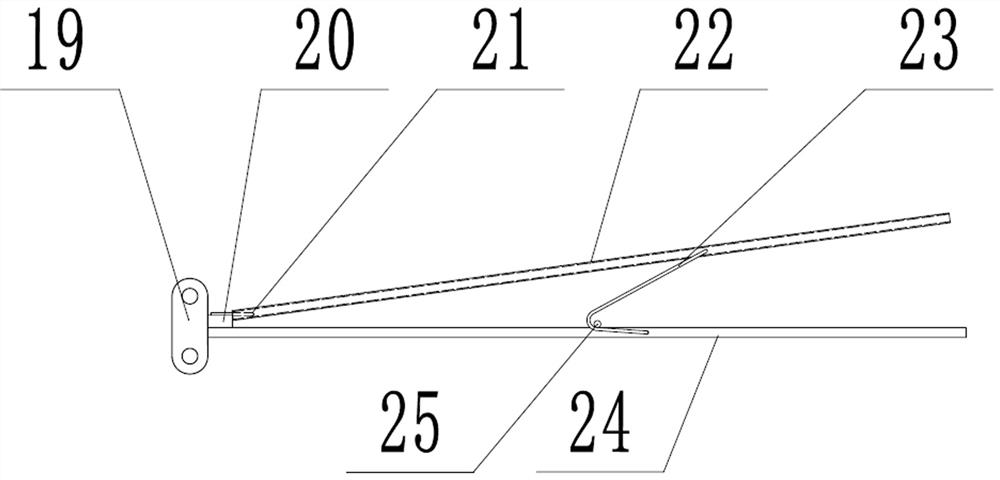

[0024]A tunnel-type wood veneer drying production line, including a hot blast stove 1, a tunnel-type drying room body 2 and a chain conveying device 4, the hot-blast stove 1 is connected to the tunnel-type drying room body 2 through an air duct to form a tunnel The drying room 2 provides hot air, and the chain conveying device 4 is installed through the tunnel drying room 2 for transporting wood veneers. The chain conveying device 4 includes a frame 3, and the two sides of the frame 3 A No. I driven shaft 18 and a No. II driven shaft 11 are respectively installed in parallel through bearings with seat 13, and a No. I driven sprocket 14 is respectively installed on both ends of the No. I driven shaft 18, and No. II driven shaft A No. Ⅱ driven sprocket 10 is installed at both ends of the shaft 11, and a driving shaft 17 is installed in parallel on the front upper or lower part of the No. 1 driven shaft 18 through a bearing 13, and the two ends of the driving shaft 17 are respecti...

Embodiment 2

[0026] A tunnel-type wood veneer drying production line, including a hot blast stove 1, a tunnel-type drying room body 2 and a chain conveying device 4, the hot-blast stove 1 is connected to the tunnel-type drying room body 2 through an air duct to form a tunnel The drying room 2 provides hot air, and the chain conveying device 4 is installed through the tunnel drying room 2 for transporting wood veneers. The chain conveying device 4 includes a frame 3, and the two sides of the frame 3 A No. I driven shaft 18 and a No. II driven shaft 11 are respectively installed in parallel through bearings with seat 13, and a No. I driven sprocket 14 is respectively installed on both ends of the No. I driven shaft 18, and No. II driven shaft A No. Ⅱ driven sprocket 10 is installed at both ends of the shaft 11, and a driving shaft 17 is installed in parallel on the front upper or lower part of the No. 1 driven shaft 18 through a bearing 13, and the two ends of the driving shaft 17 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com