Patents

Literature

89results about How to "Realize automatic drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

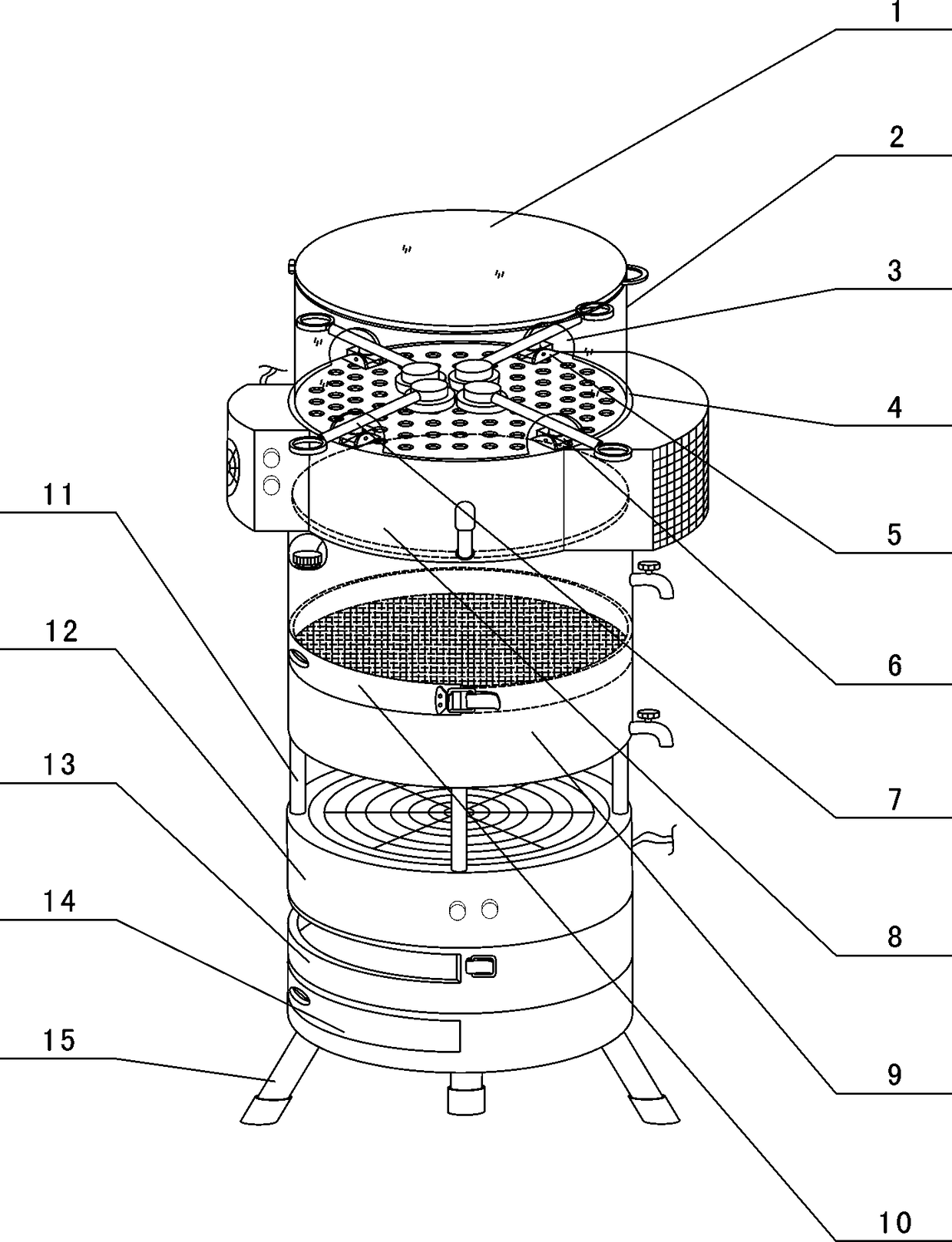

Grain intelligent baking storing integrated device

InactiveCN105341148AHigh degree of automationRealize automatic feedingAgriculture tools and machinesSeed preservation by dryingAgricultural engineeringIntelligent control

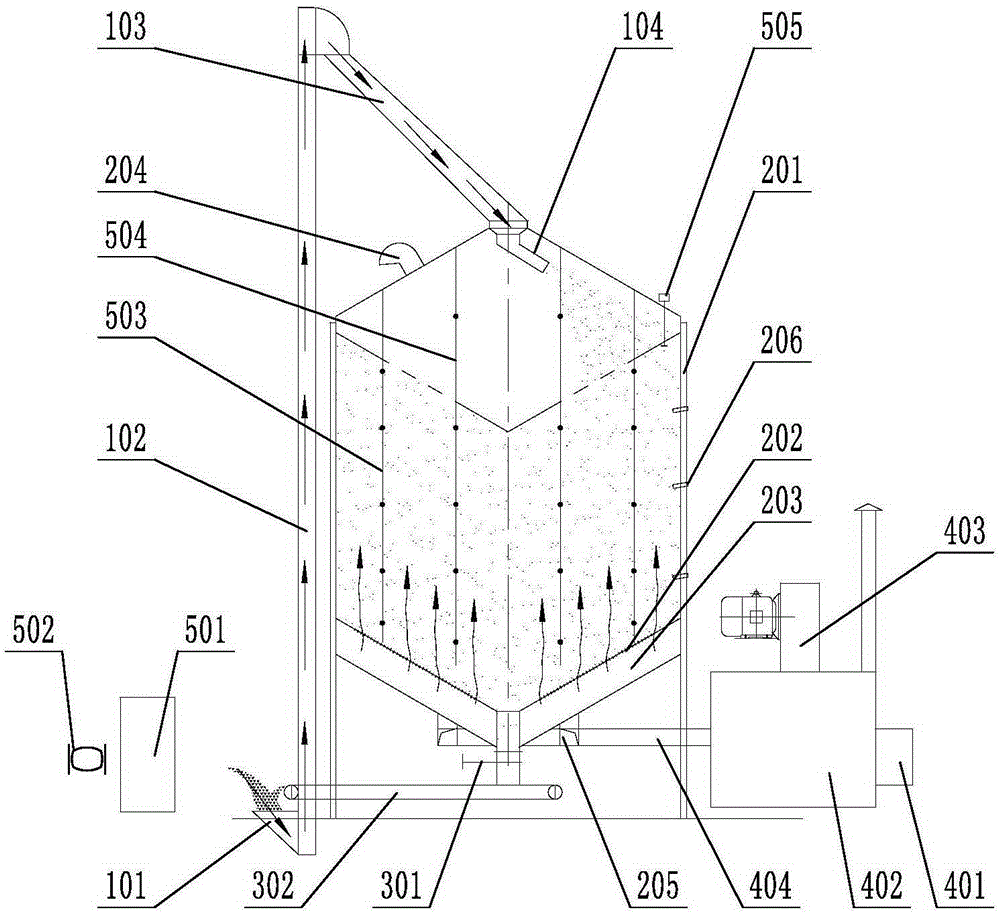

The invention relates to a grain intelligent baking storing integrated device with intelligent drying and storing functions, and belongs to the field of agricultural machinery grain drying and storing. The grain intelligent baking storing integrated device comprises a feeding unit, a storage unit, a discharging unit, an aeration-drying unit, and an intelligent control unit; the storage unit comprises a silo cell; the feed inlet of the silo cell is connected with the feeding unit; the feed outlet of the silo cell is connected with the discharging unit; the bottom of the silo cell is provided with an air passage; a wind chamber is arranged below the bottom of the silo cell; the wind chamber is communicated with the inner part of the silo cell via the air passage; the wind chamber is communicated with the aeration-drying unit via a wind passage; and the upper part of the silo cell is provided with an air exhausting device. According to the grain intelligent baking storing integrated device, grain drying and storing function are combined; automatic degree is high; the grain intelligent baking storing integrated device is safe and reliable to use; cost is reduced; grain drying and storing are not influenced by air factors; and the grain intelligent baking storing integrated device is suitable for small and medium-sized farmers, and big grain production households.

Owner:SHANDONG QUANGUAN MASCH TECH CO LTD

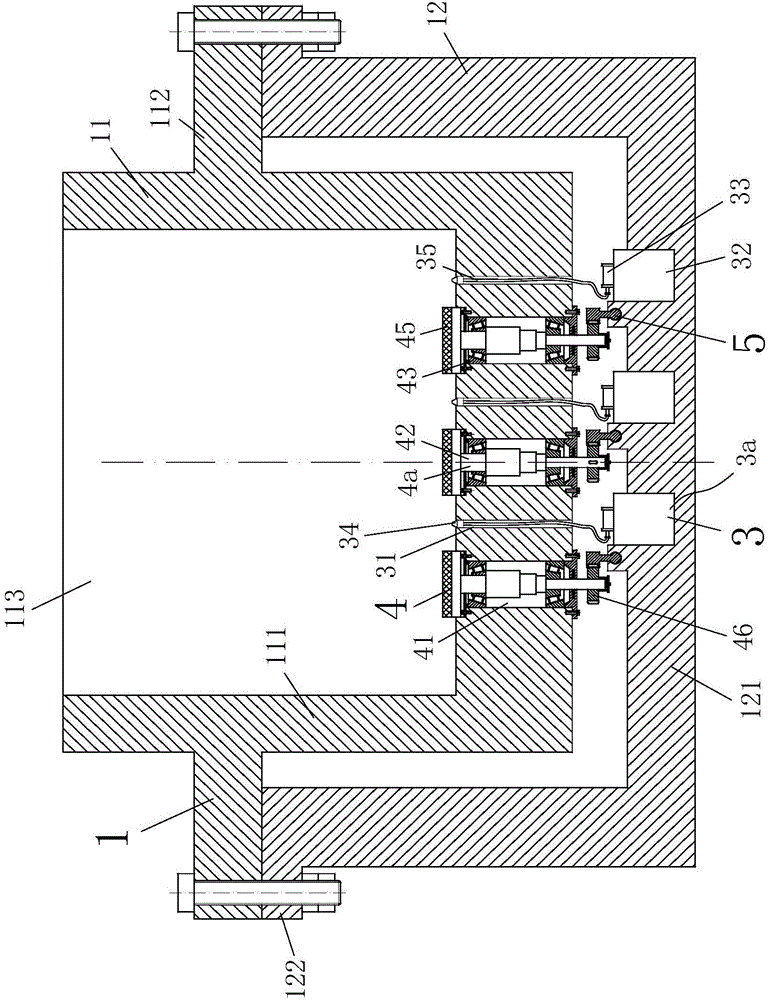

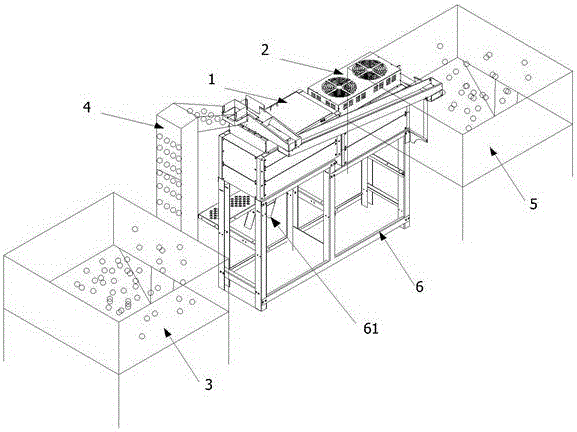

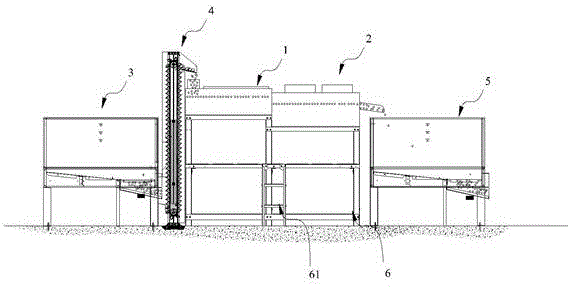

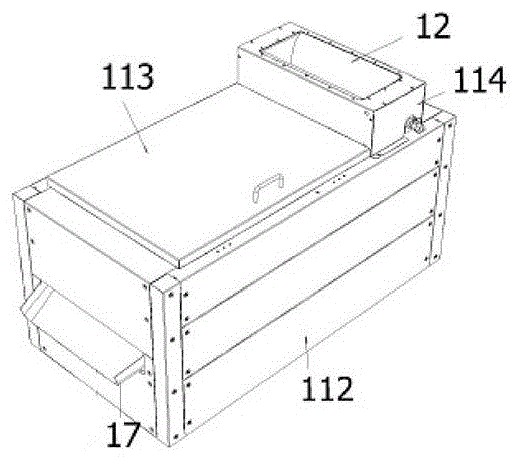

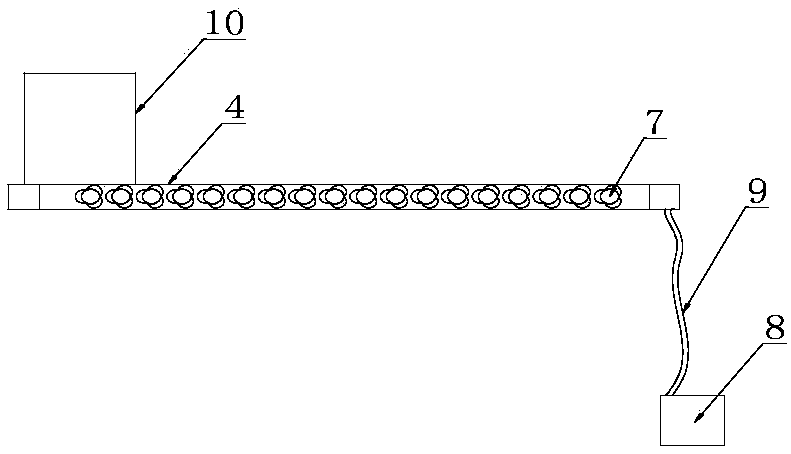

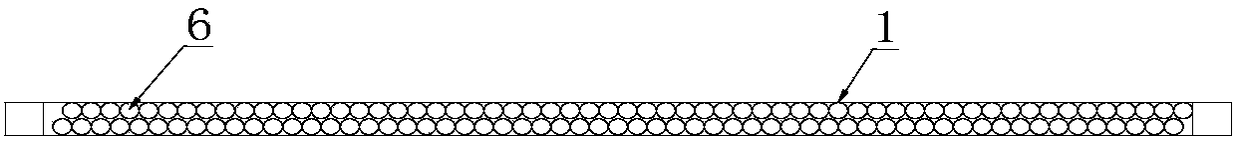

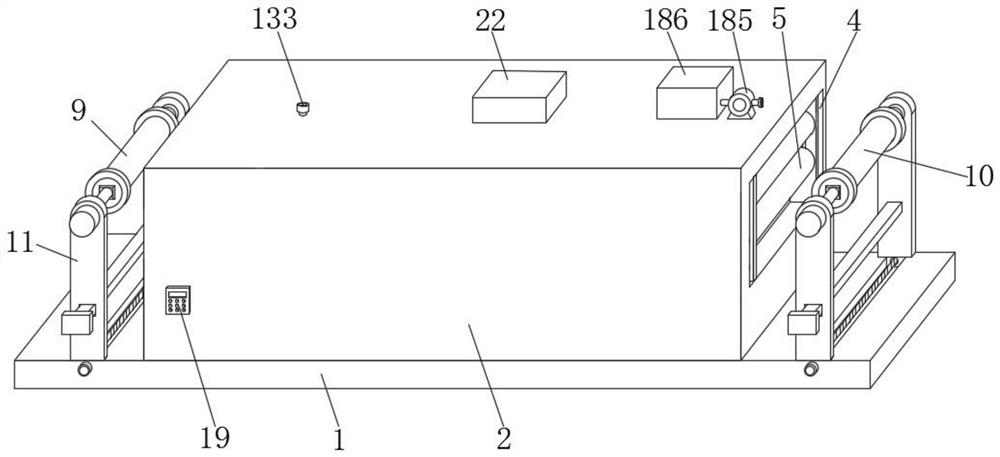

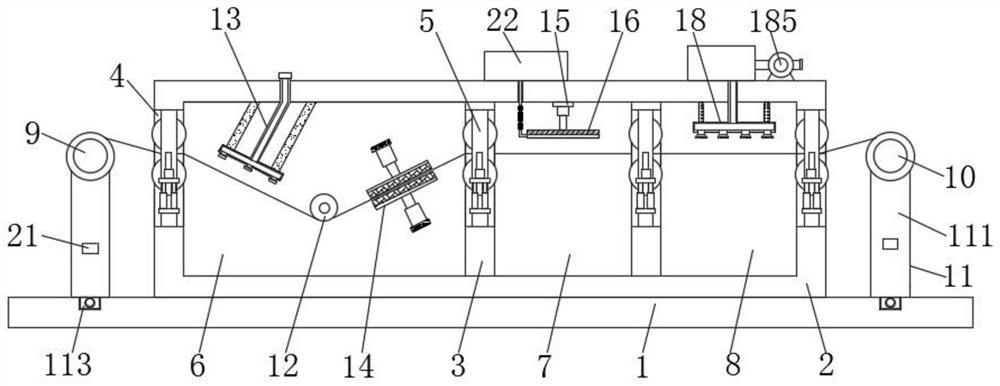

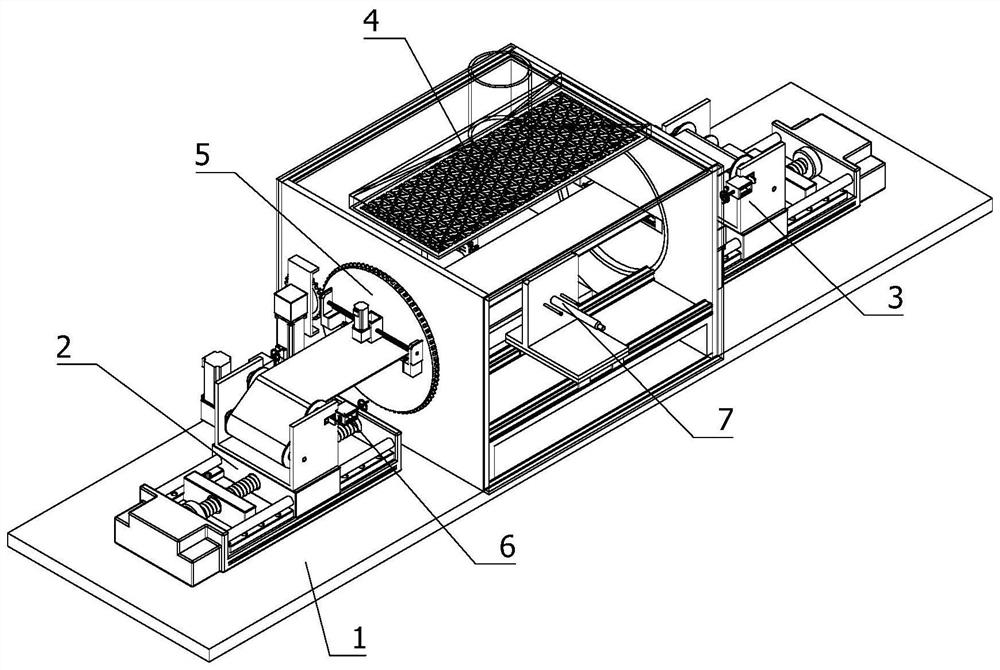

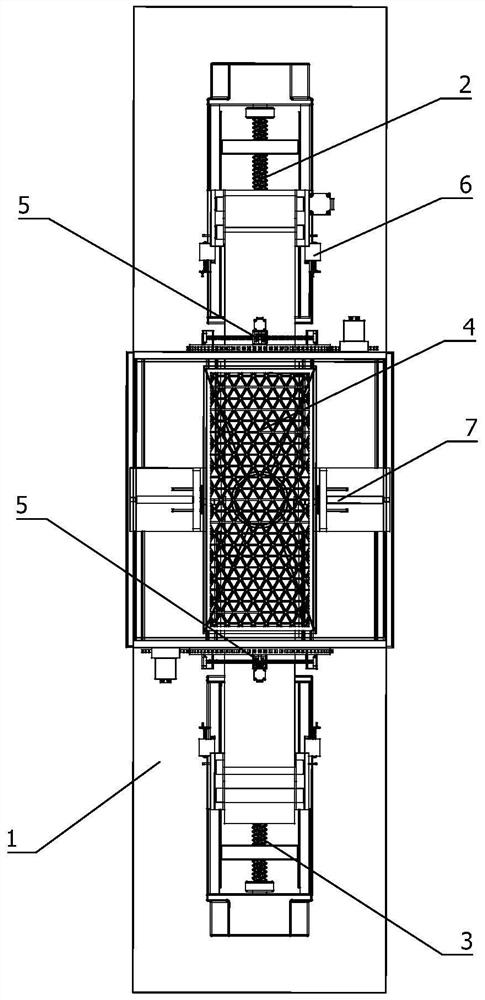

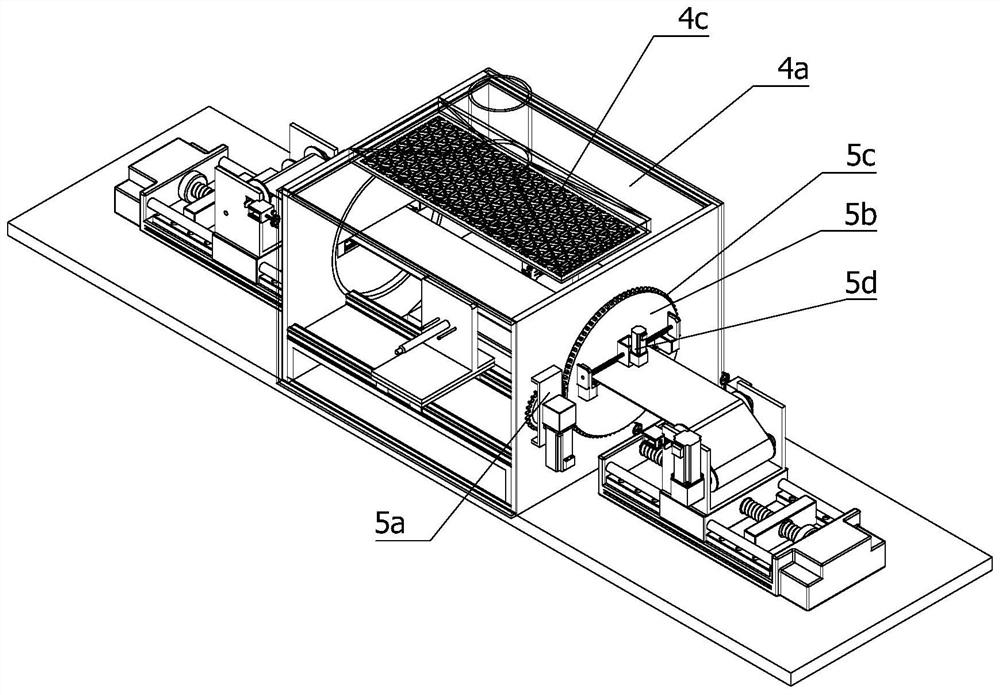

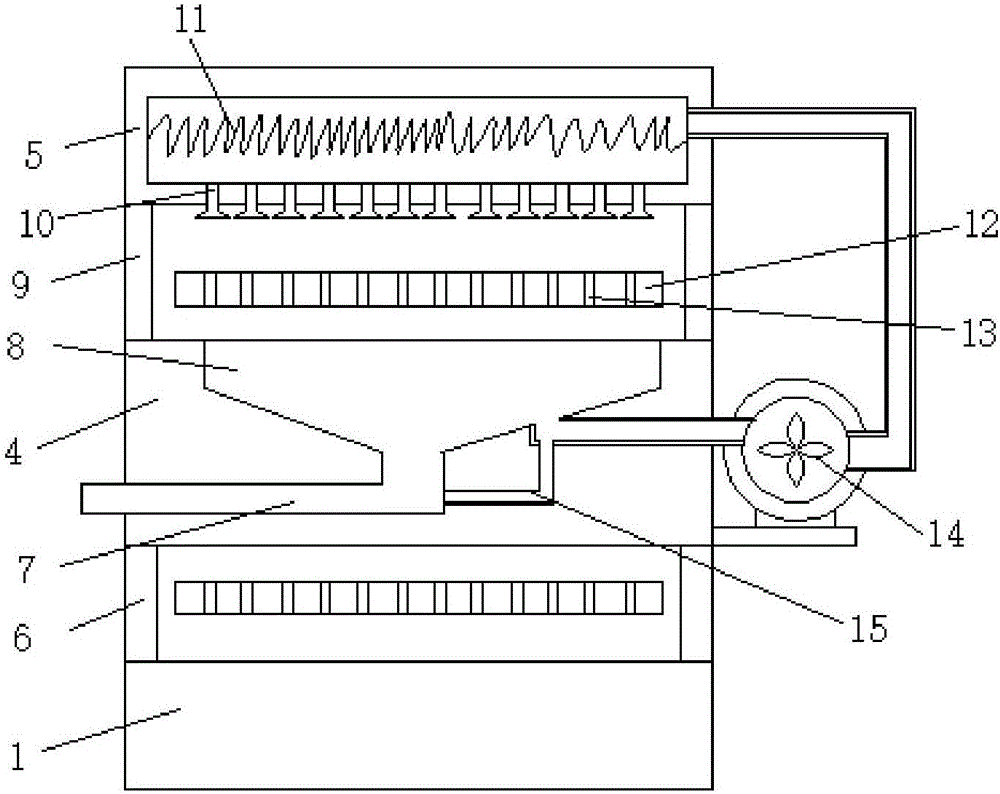

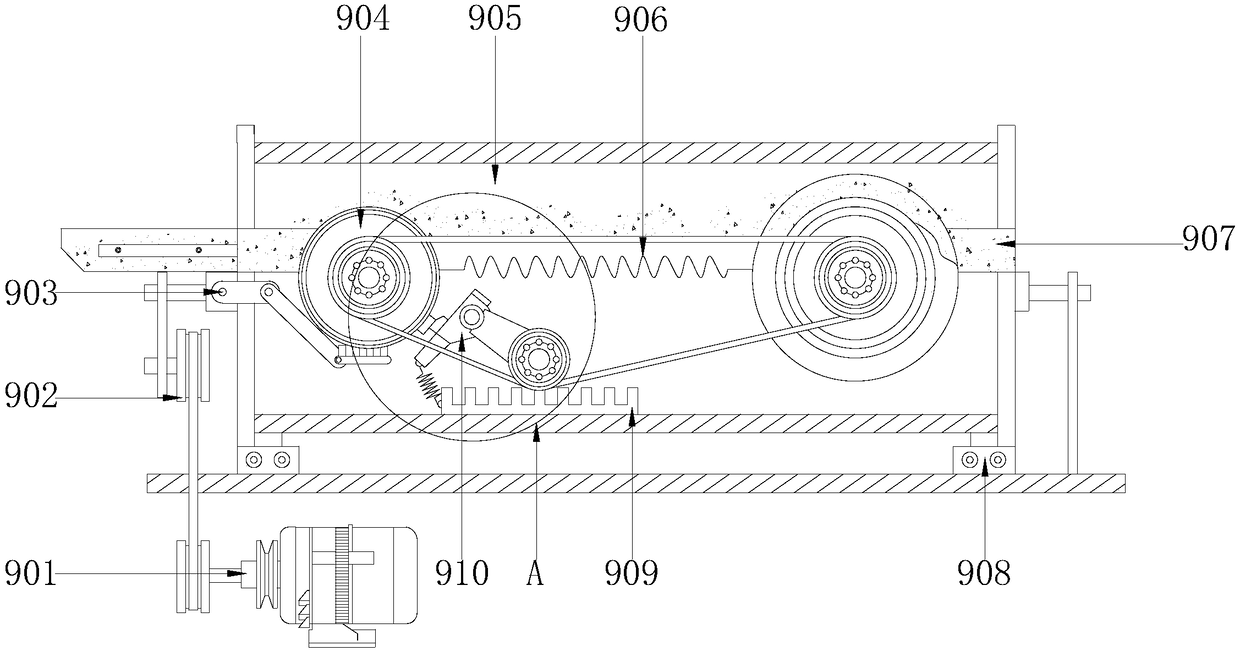

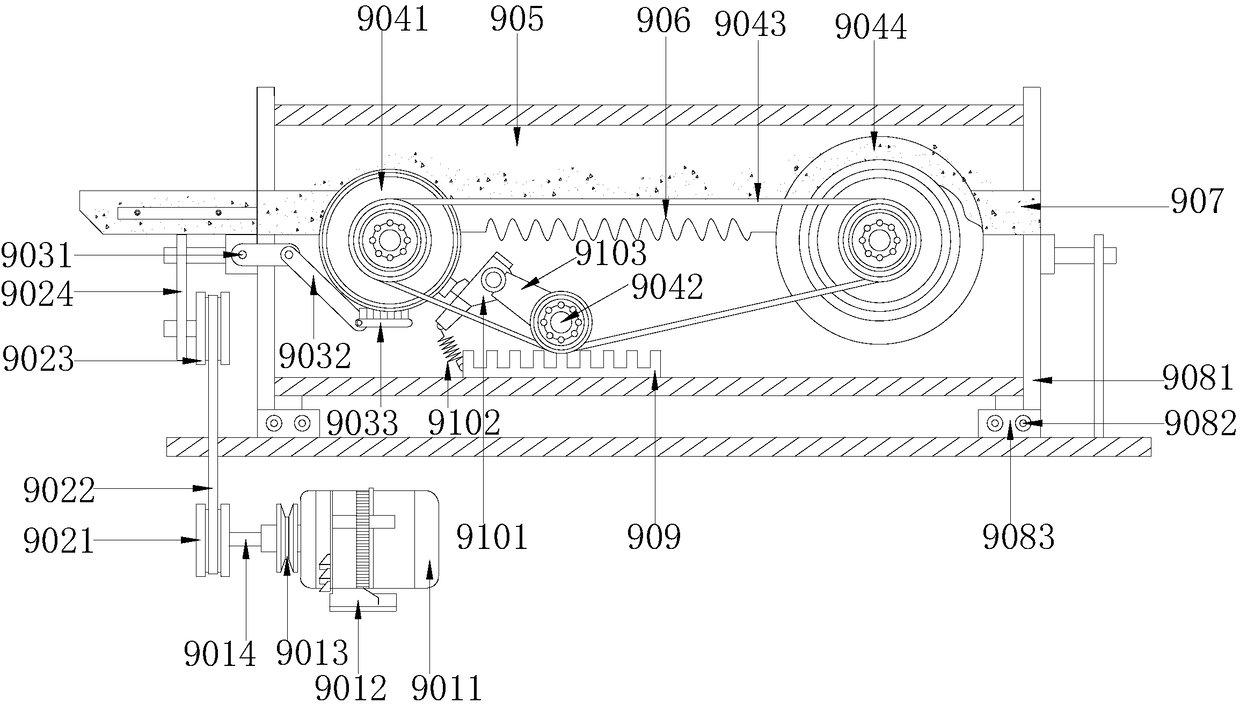

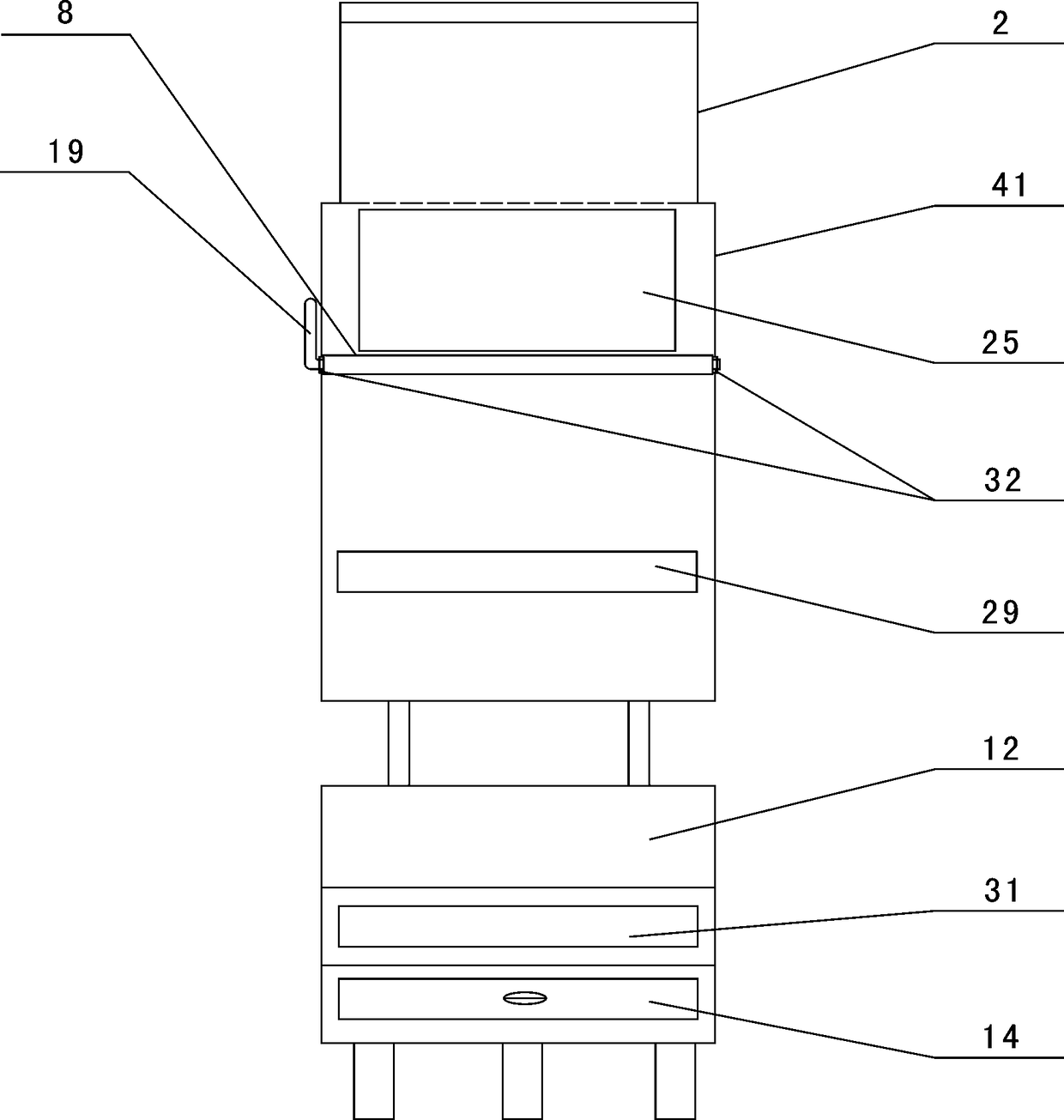

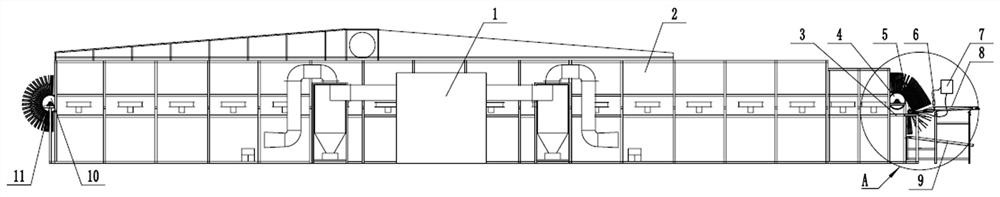

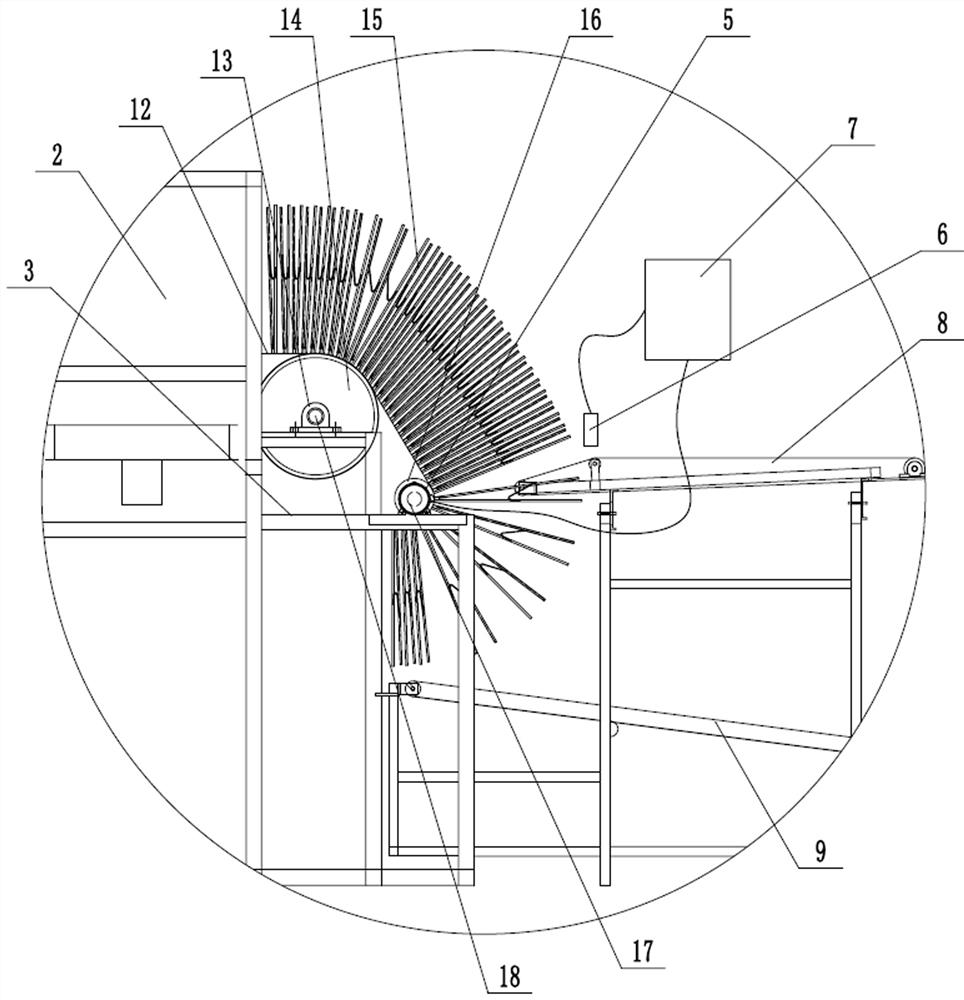

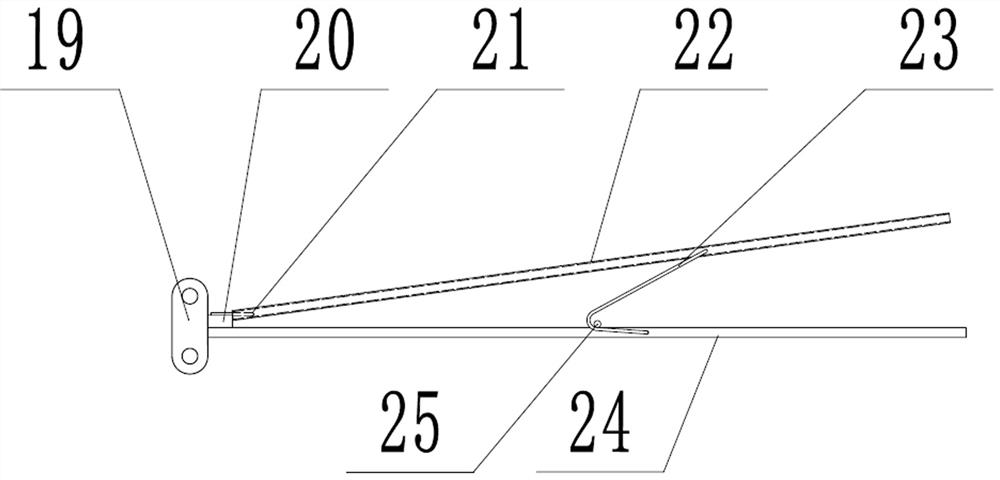

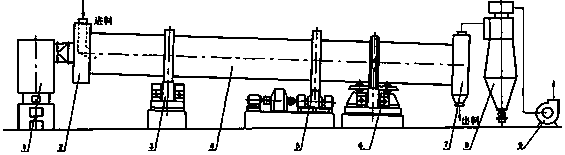

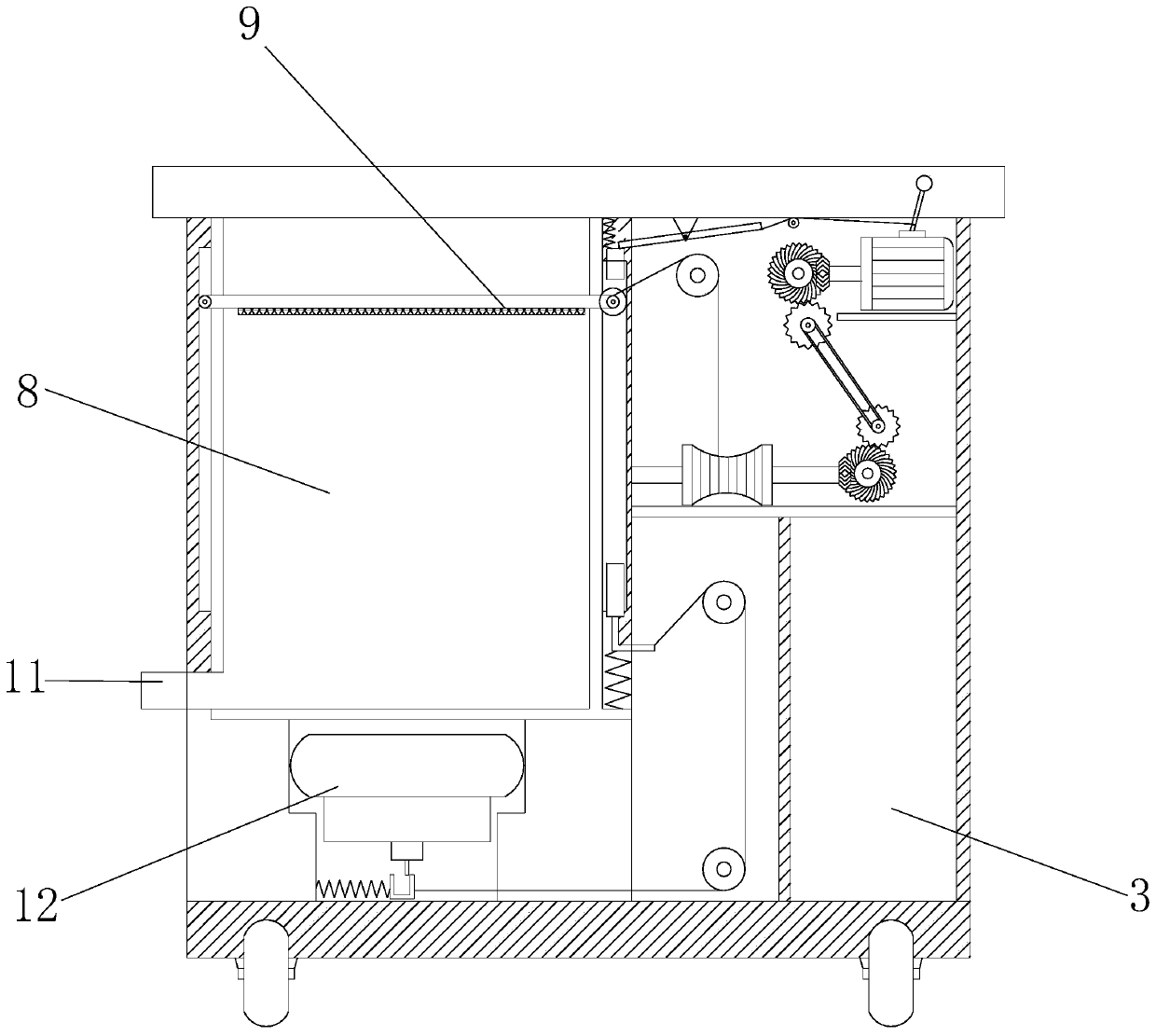

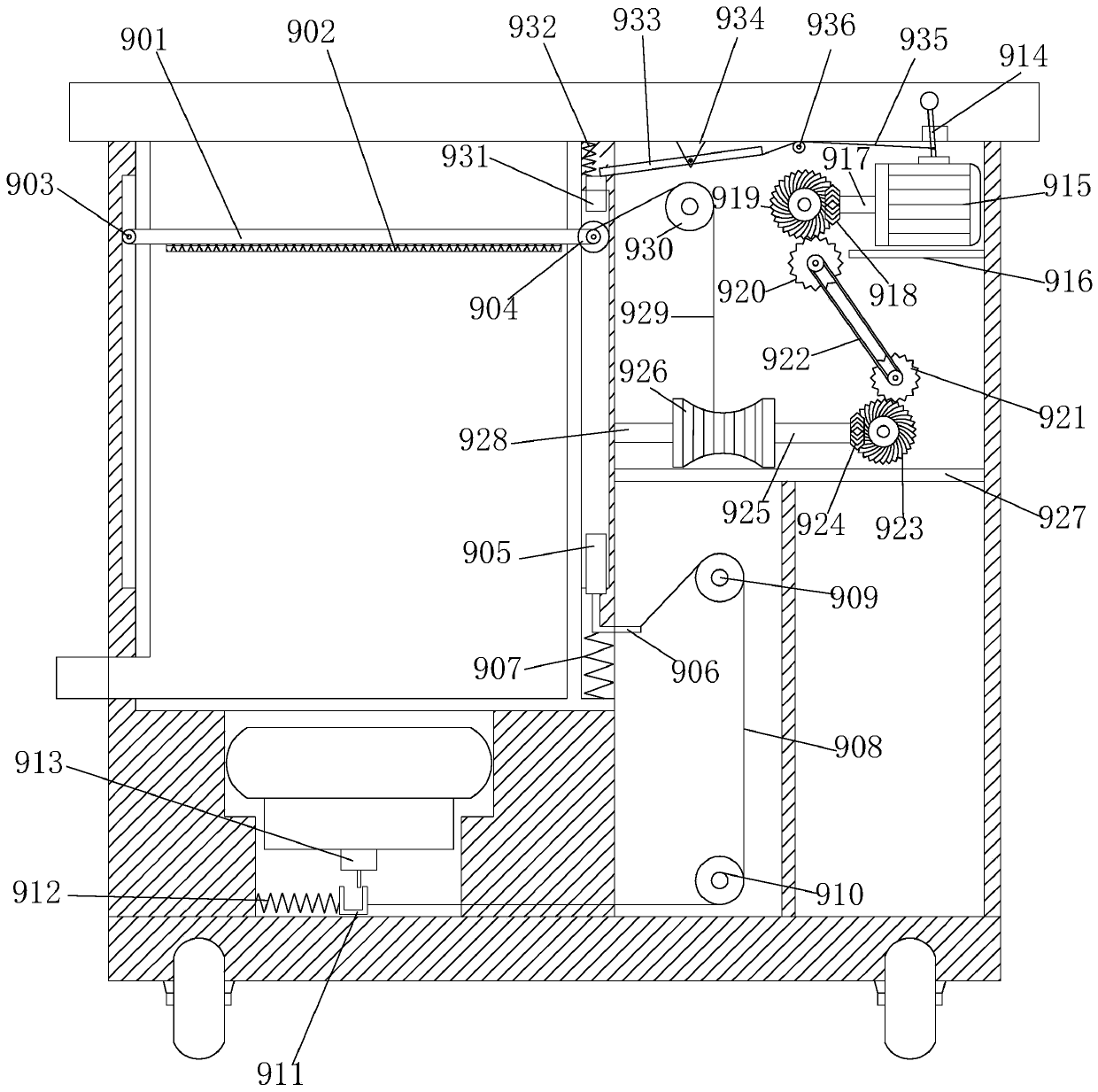

Multifunctional rotary type drying system and method for automated operation

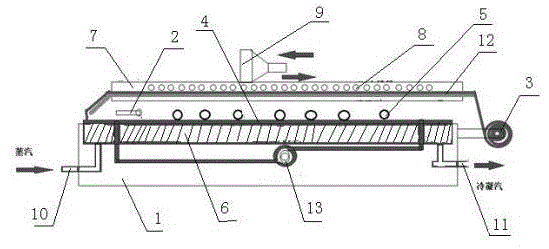

InactiveCN104075547ARealize automatic dryingImprove drying efficiencyDrying chambers/containersDrying solid materialsProcess engineeringPower unit

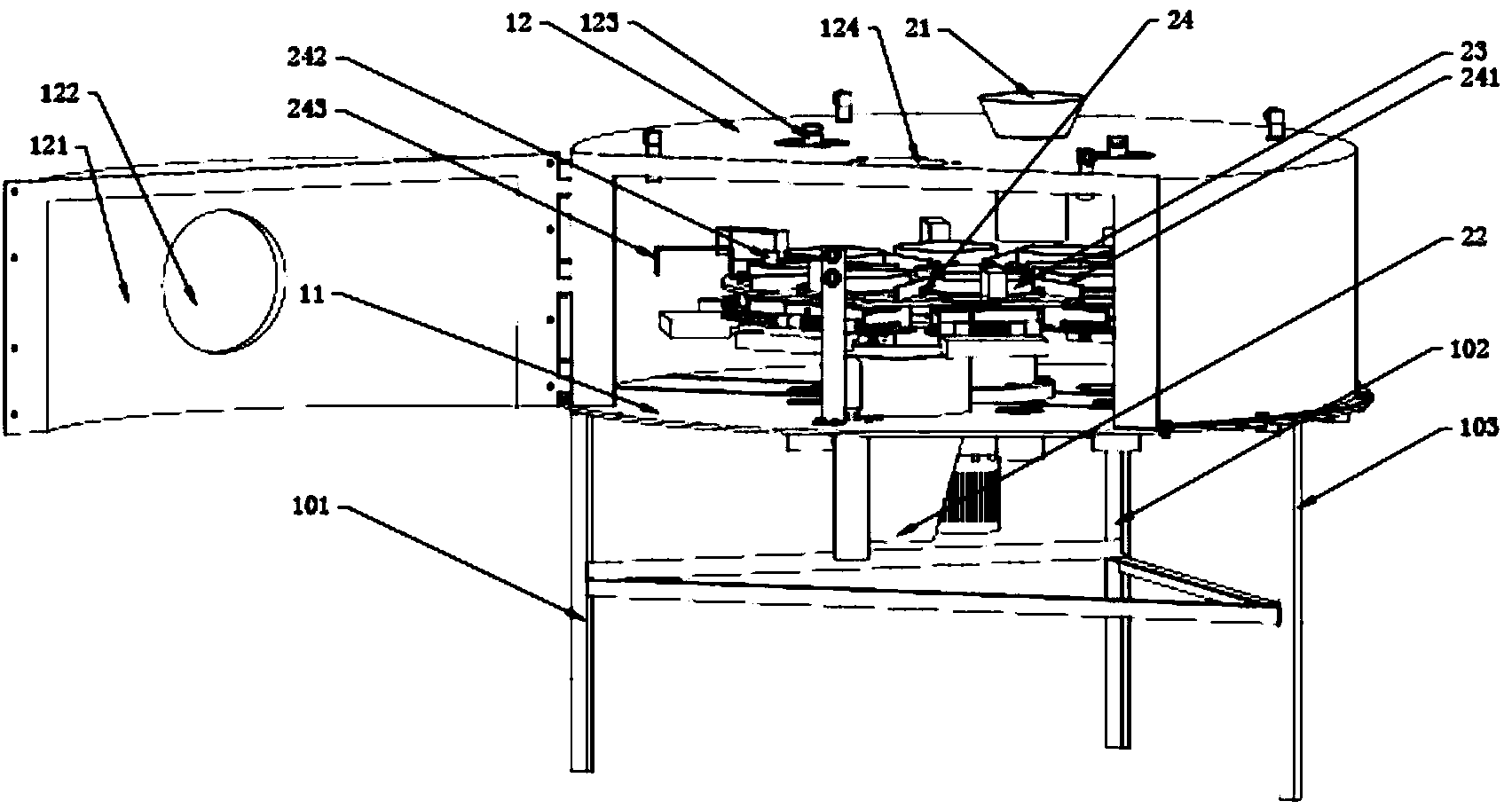

The invention relates to a multifunctional rotary type drying system and method for automated operation. The drying system comprises a box body, a material conveying unit, a power unit, a discharging unit and a control unit. According to the method, drying operation is carried out by utilizing the system. The multifunctional rotary type drying system and method for the automated operation can achieve continuous automatic drying of a large number of materials.

Owner:远光智和卓源(北京)科技有限公司

Fully automatic dried beancurd stick and skin machine

InactiveCN105053241ARealize manufacturingEasy to operateCheese manufactureFood scienceMicrocomputerFrequency conversion

The present invention belongs to the technical field of food processing equipments, and particularly relates to a fully automatic dried beancurd stick and skin machine. The fully automatic dried beancurd stick and skin machine includes a body which is provided with a new pulp filling point, and is characterized as follows: the body comprises a heating and cooling device and a conveyer; a drying device is arranged on the top of the heating and cooling device, and one side of the drying device is connected to a collecting device. The fully automatic dried beancurd stick and skin machine is controlled by a microcomputer with frequency conversion, is easy to be operated, can rapidly coagulate beancurd skins, automatically supplement pulp, circulate old pulp with microflow, automatically uncover the beancurd skins, and realize the production of thin beancurd skins, thick beancurd skins, double-layer beancurd skins, small dried beancurd sticks, and large dried beancurd sticks; the machine is designed to have the heat exchange and dehumidification functions, can realize automatic drying during the production process, and ensure the produced products to meet hygienic requirements.

Owner:王风宜

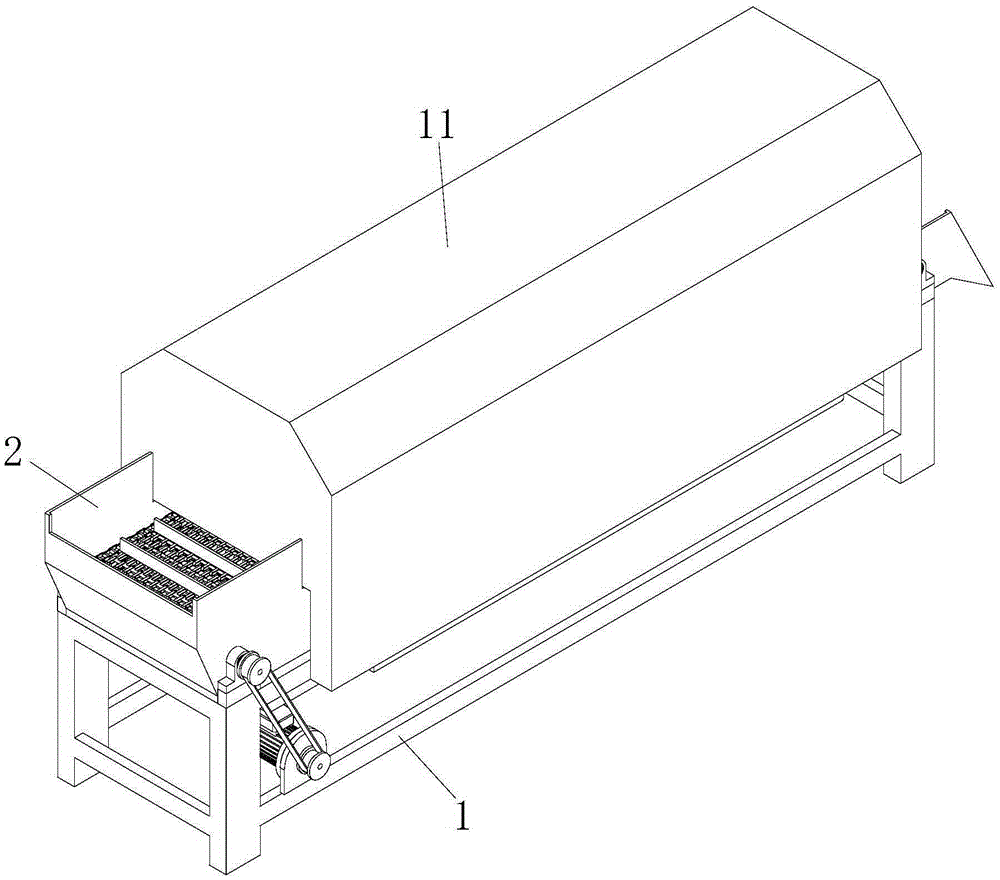

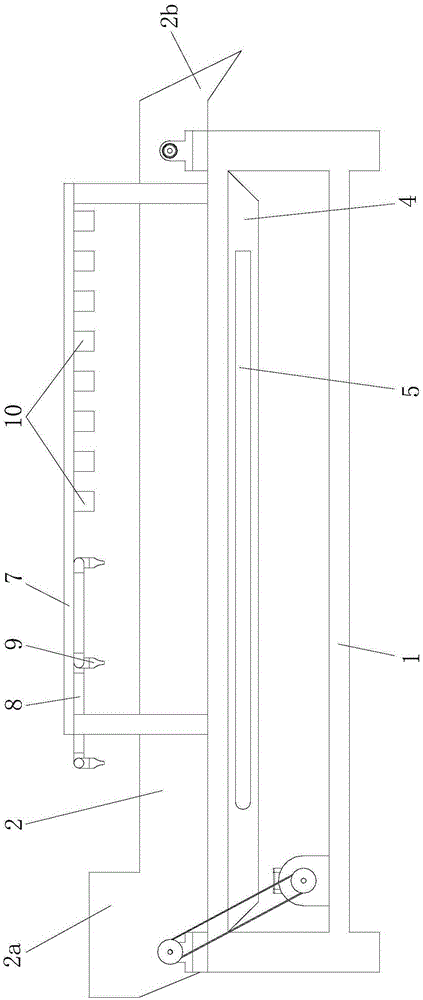

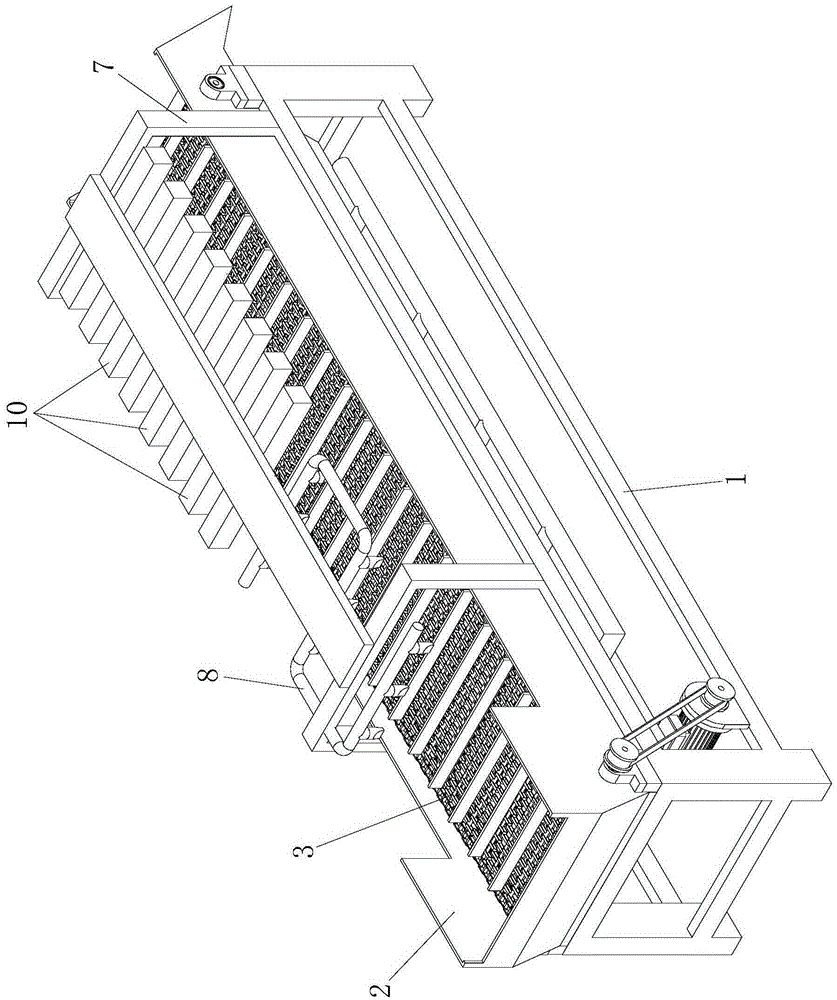

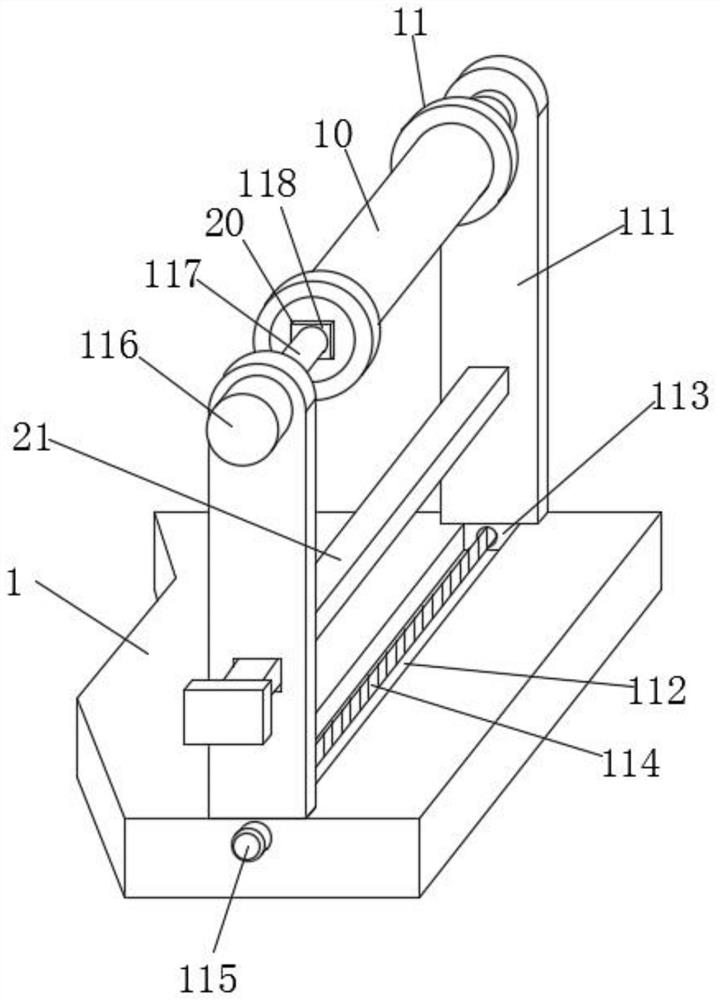

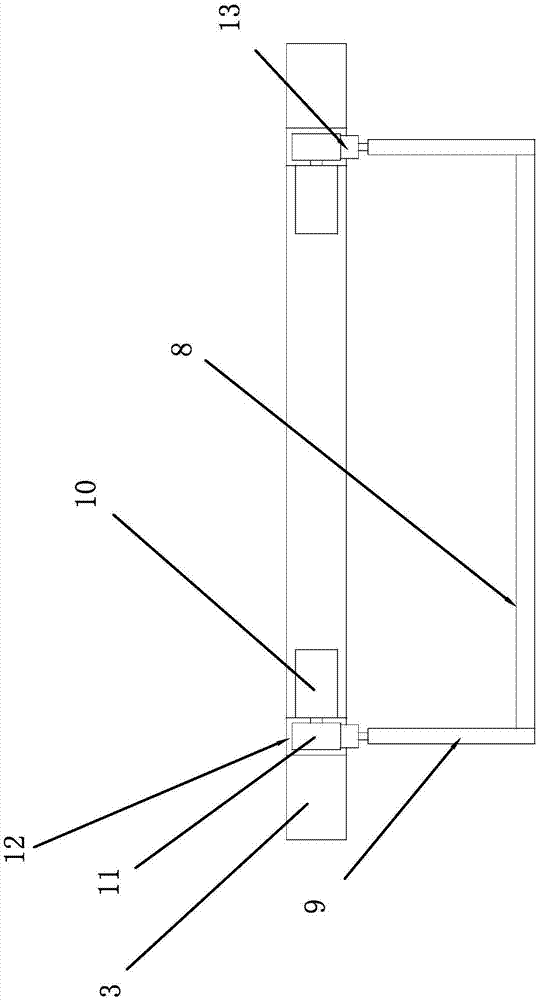

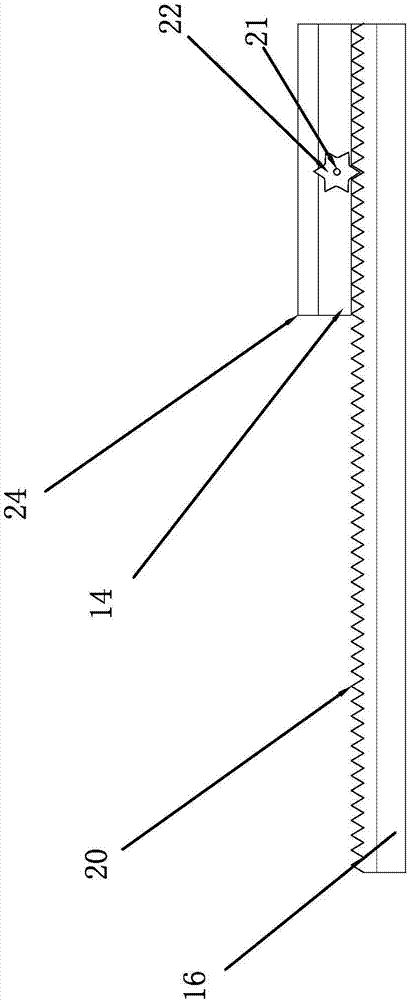

Shaft sleeve part drying machine

InactiveCN105258475ARealize automatic dryingSimple structural designDrying gas arrangementsDrying machines with progressive movementsFixed frameAgricultural engineering

The invention discloses a shaft sleeve part drying machine which comprises a rack. A drying tank is arranged at the upper end of the rack. A conveyor belt is installed in the drying tank. A water collection tank is installed at the lower end of the drying tank. Air pipes are fixed to the left end and the right end of the water collection tank and evenly provided with first air nozzles. A fixing frame is arranged above the drying tank. An S-shaped pipe is fixed to the front portion of the fixing frame. Second air nozzles are evenly installed at the lower end of the S-shaped pipe. Heating lamps are evenly installed at the rear portion of the fixing frame. A shell is arranged above the fixing frame. The shaft sleeve part drying machine has the beneficial effects that the structural design is simple and use is convenient; and shaft sleeves can be automatically dried, the automation degree is high, the production cost is saved, the labor intensity is relieved, and manpower and material resources are saved.

Owner:无为县鑫发盛汽车零部件有限公司

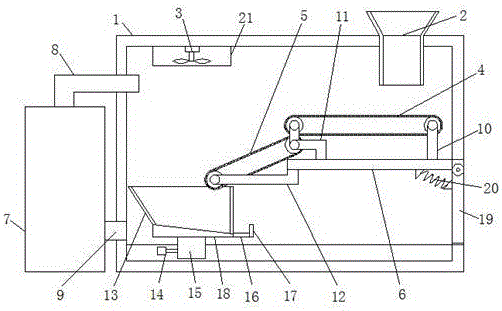

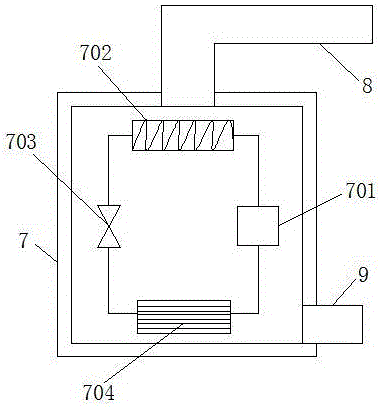

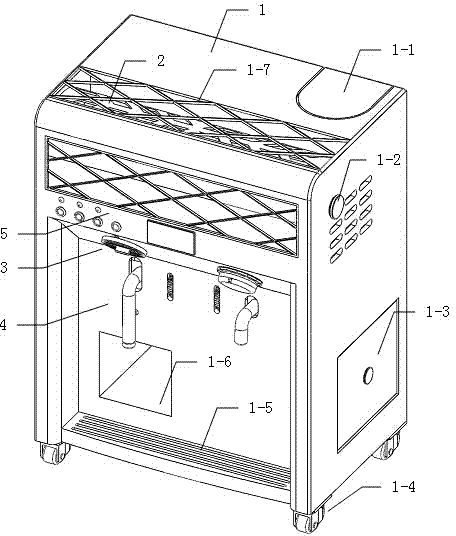

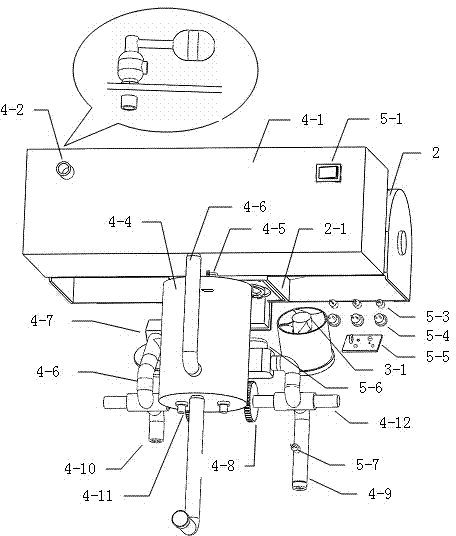

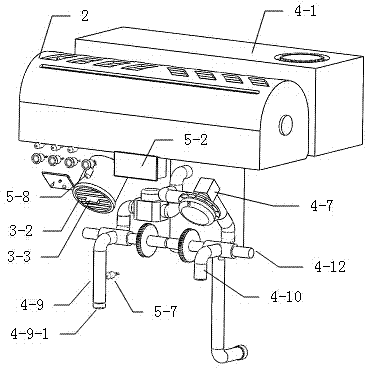

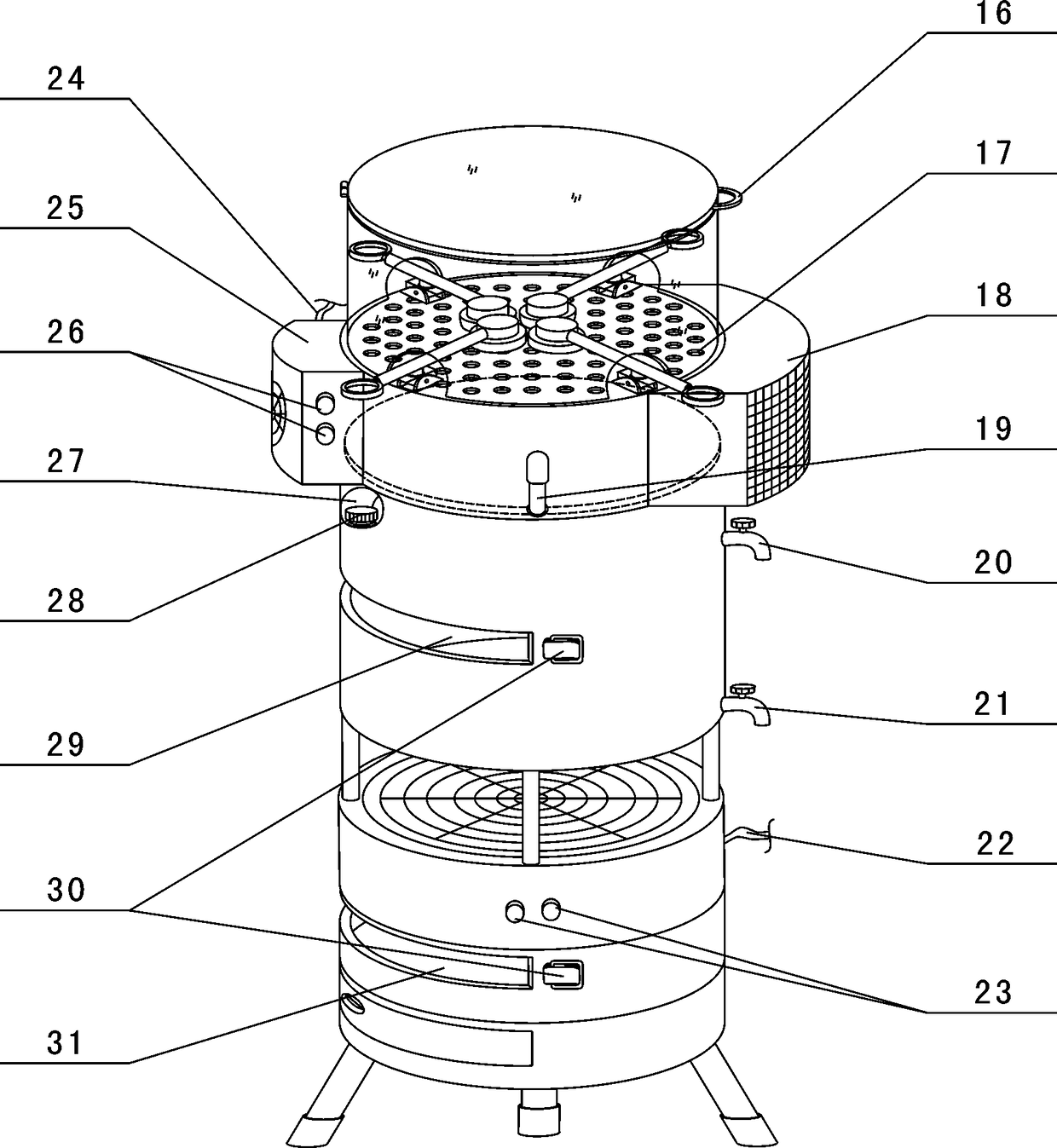

Automatic air energy dryer for grain drying

InactiveCN106482487ASimple structureEasy to operateDrying gas arrangementsSeed preservation by dryingEngineeringGrain drying

The invention discloses an automatic air energy dryer for grain drying. The dryer comprises a body housing, wherein a feed hopper is arranged at the upper end of the body housing; a support plate is arranged on one side of the inner wall of the body housing; a first transmission device is arranged between a first support column and a connecting shaft; a second transmission device is arranged at the end, far away from the first transmission device, of the connecting shaft; a collection box is arranged at one end of the second transmission device; an inclined block is arranged at the bottom of the collection box; a sliding block is fixedly connected to the lower end of the inclined block; a box door is connected to one side of the outer wall of the body housing in a rotating manner; a spring is fixedly connected between one side of the box door and the bottom of the support plate; an air outlet pipe is arranged on the other side of the outer wall of the body housing; a drying device is arranged at the end, far away from the body housing, of the air outlet pipe. The dryer is simple in structure, easy to operate, convenient and ingenious in use and suitable for wide popularization, and has good drying effects, and grains can be automatically dried.

Owner:HUBEI KEYANG ENERGY SAVING EQUIP

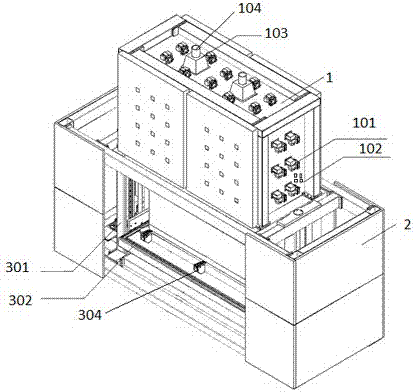

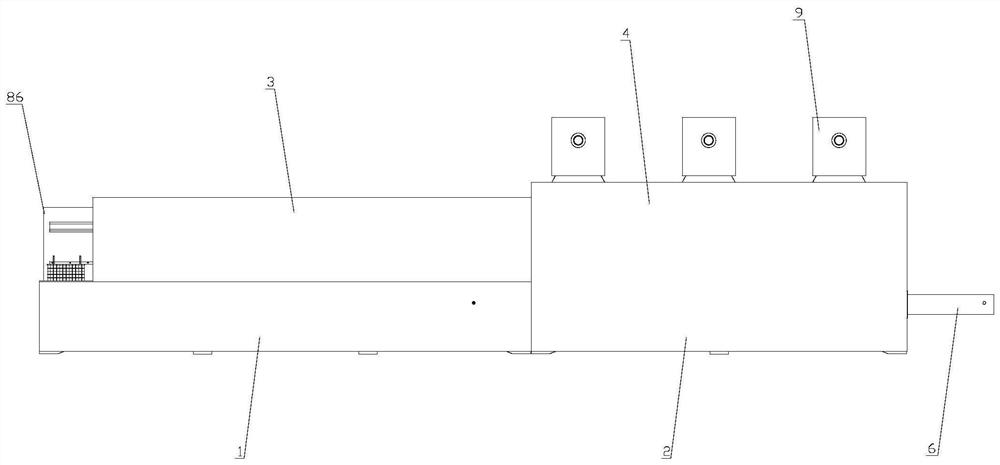

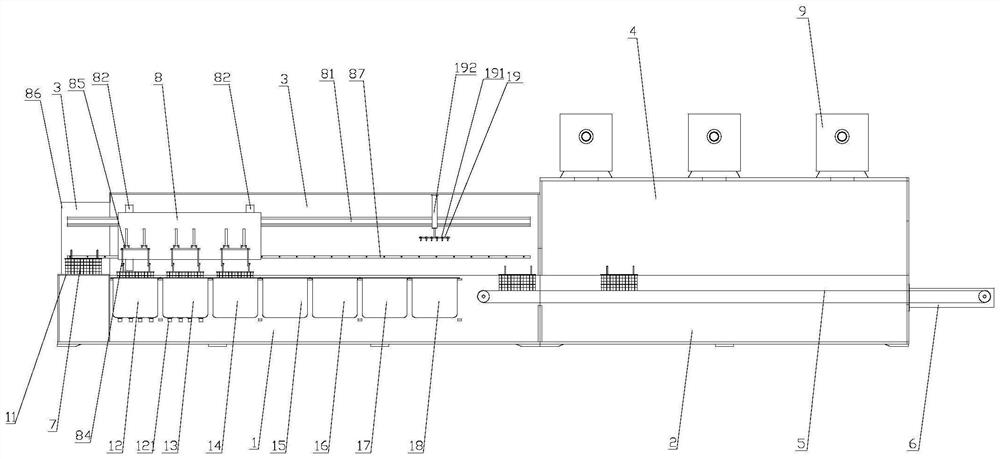

Ceramic microwave automatic forming line and ceramic forming method

InactiveCN108608567AAvoid crackingReduce labor costsCeramic shaping plantsFeeding arrangmentsProduction lineMicrowave

The invention relates to the field of ceramic microwave automatic forming lines and ceramic forming methods, in particular to a ceramic microwave automatic forming line and a ceramic forming method. The ceramic microwave automatic forming line and the ceramic forming method are characterized by comprising a circulated conveying line, an automatic pugging machine and an automatic forming machine, the circulated conveying line is sequentially provided with an automatic mud putting machine, an automatic mold clamping machine and a microwave drying box, the automatic pugging machine is connected with the circulated conveying line through the automatic mud putting machine, and the automatic forming machine is connected with the circulated conveying line through the automatic mold clamping machine. Manual transferring labor is not needed for joining parts between equipment of the ceramic microwave automatic forming line, the automatic degree is high, the production efficiency is high, and the space occupied by the equipment is small; by means of the ceramic forming method, the labor cost is saved, the operation accuracy is high, and the finished product rate is improved; and compared with a traditional drying manner, the microwave drying manner is good in drying uniformity, a blank body is not prone to cracking, the drying time is short, and the energy consumption is low.

Owner:福建省德化博龙陶瓷有限公司

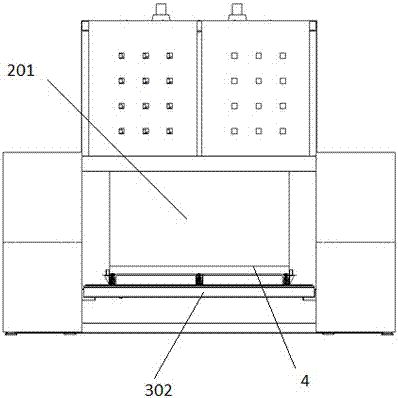

Jacking type sand core microwave drying device

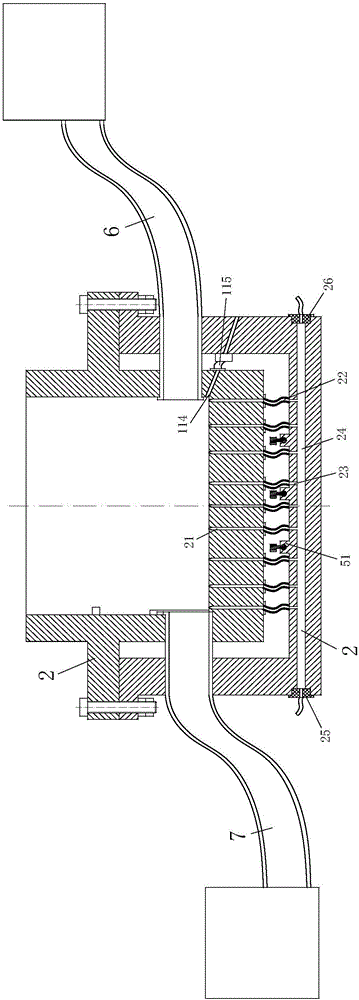

InactiveCN108007096AAvoid Sealing DefectsPrevent leakageSand dryingDrying solid materials with heatMicrowaveEngineering

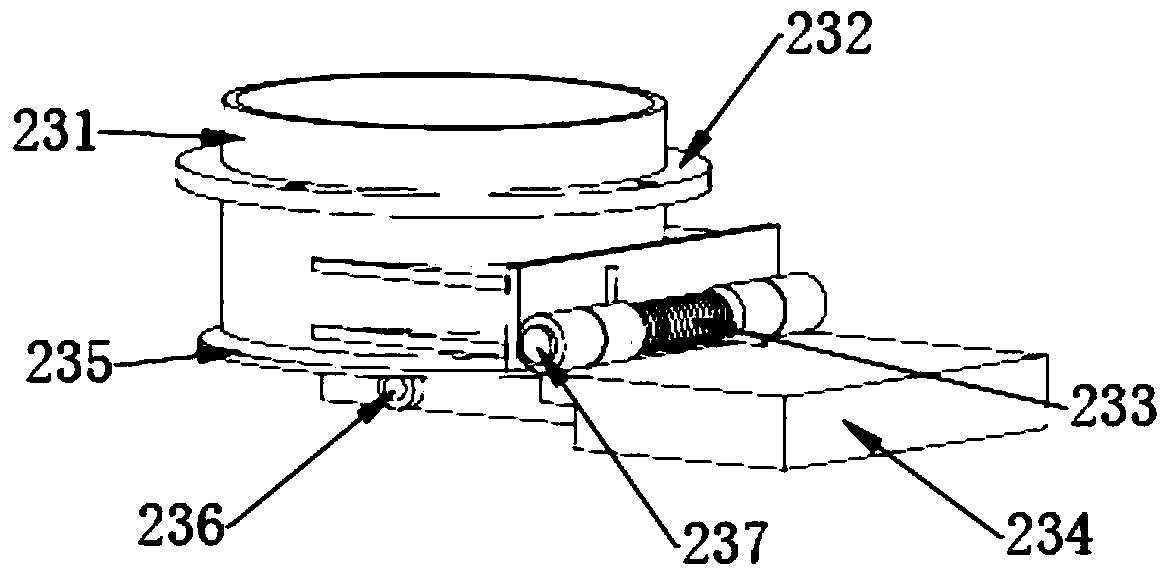

The invention relates to a jacking type sand core microwave drying device. The drying device mainly comprises a microwave drying cavity, a jacking assembly and a sand core tray, wherein the jacking assembly comprises two supporting stand columns and a jacking sealing bracket arranged between the two supporting stand columns; a vertical linear rail is arranged on each supporting stand column; the jacking sealing bracket is jacked and descended on the supporting stand columns through the vertical linear rails; an inner roller way is arranged on the jacking sealing bracket, and is used for beingmatched with a outer roller way to carry and transport the sand core tray; the microwave drying cavity is located above the supporting stand columns; the bottom of the microwave drying cavity is provided with a feeding opening; when the jacking sealing bracket ascends, the jacking sealing bracket is in sealing connection with the feeding opening. Through matching and sealing of the jacking sealingbracket and the upper microwave drying cavity, microwave leakage prevention is carried out, the problem of microwave leakage is effectively solved, and 3D printing sand core flow coating and automatic drying after dip coating are efficiently realized.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

Automatic traditional Chinese medicinal material drying equipment

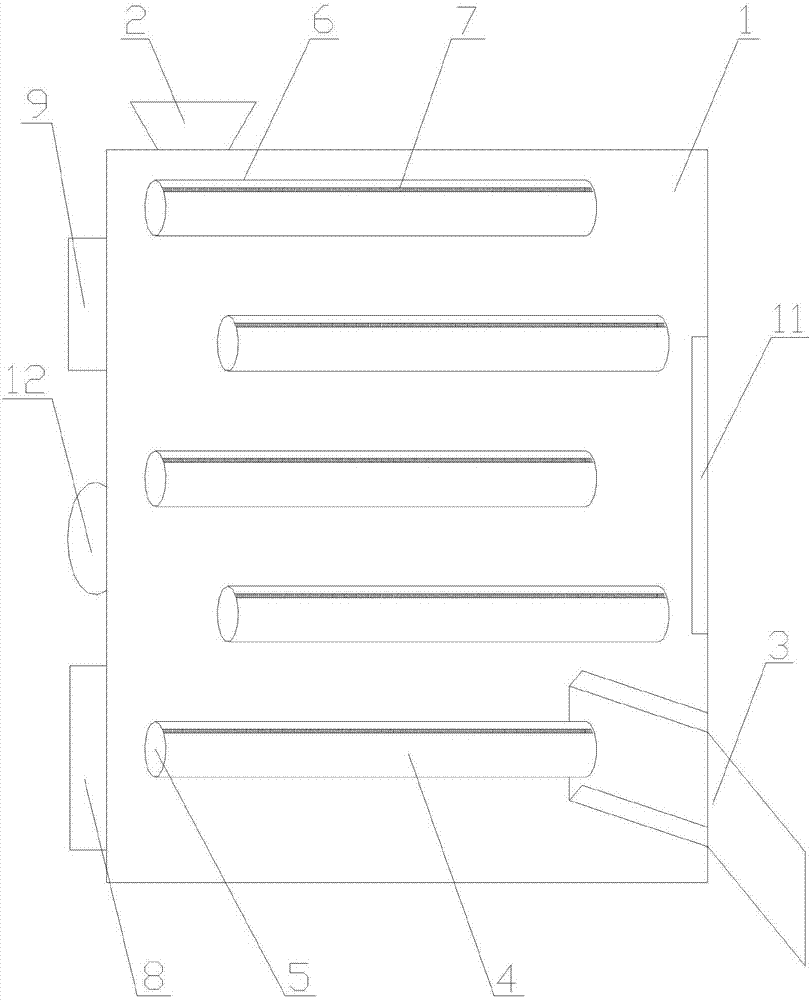

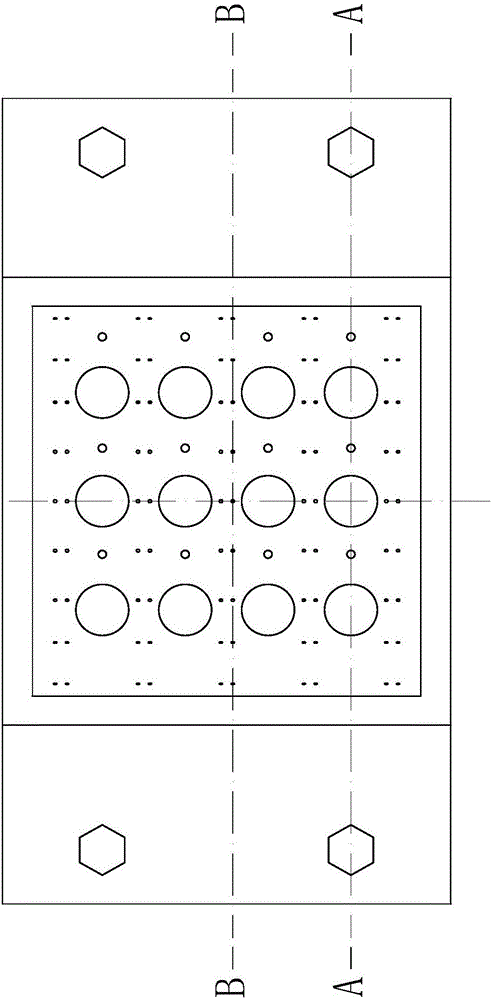

InactiveCN107036422AGuaranteed cleanlinessSmall footprintDrying gas arrangementsDrying machines with progressive movementsProcess engineeringMoisture sensor

The invention discloses automatic traditional Chinese medicinal material drying equipment. The automatic traditional Chinese medicinal material drying equipment solves the problems that in the prior art, the drying efficiency is low, the drying effect is poor, and using is troublesome. The automatic traditional Chinese medicinal material drying equipment comprises a closed square drying equipment body, a feeding port, a discharging port, five layers of conveying frames, an air heater and an exhaust fan, wherein the feeding port and the discharging port are formed in the top and the lower portion of the drying equipment body correspondingly, the five layers of conveying frames are arranged in the square drying equipment body and are sequentially distributed from top to bottom, and the air heater is located on the outer side of the drying equipment body and communicates with the drying equipment body. Guiding wheels are arranged at the two ends of each conveying frame. Each conveying frame is provided with a conveying belt. The conveying belts rotate in cycles under the action of the guiding wheels so that dried traditional Chinese medicinal material conveying can be achieved. The upper surface of each conveying frame is provided with a vibration belt, and stop sheets preventing the traditional Chinese medicinal materials from falling to the bottom of the drying equipment body in the conveying and drying process are arranged on the two sides of the conveying belt. A temperature and humidity sensor is arranged on the inner wall of the drying equipment body, and the outer side wall is provided with a microprocessor. The automatic traditional Chinese medicinal material drying equipment is convenient to use, high in drying efficiency and good in effect.

Owner:成都璐城科技有限公司

Foot nursing device

ActiveCN106511063AEasy to cleanHigh degree of automationDevices for pressing relfex pointsMedical devicesMedical equipmentWarm water

The invention relates to the field of medical equipment, in particular to a foot nursing device. The foot nursing device comprises a nursing frame, a water feeding device, a cream extrusion device, a massage device and a linkage device. The water feeding device comprises a first water through cavity, a connection pipe, a lower vertical cavity, a lower transverse cavity, a water inlet plug and an air inlet plug. The cream extrusion device comprises a cream extrusion cavity, a cream storage groove, a cream storage pot, a cream extrusion hydraulic pump, a cream extrusion nozzle and a cream conveying pipe. The massage device comprises a storage cavity, a massage rotating shaft, a conical roller bearing, a supporting plate, a massage plate and a massage gear. The linkage device comprises a fixing block and a rack. The foot nursing device further comprises a fish feeding hose and a fish discharge hose. By means of the foot nursing device, integrated operation of automatic warm-water cleaning, automatic drying, automatic cream wiping, automatic massage and automatic constant-temperature fish pedicure can be achieved for the feet of users, and the automation degree is high.

Owner:山东哈维药业有限公司

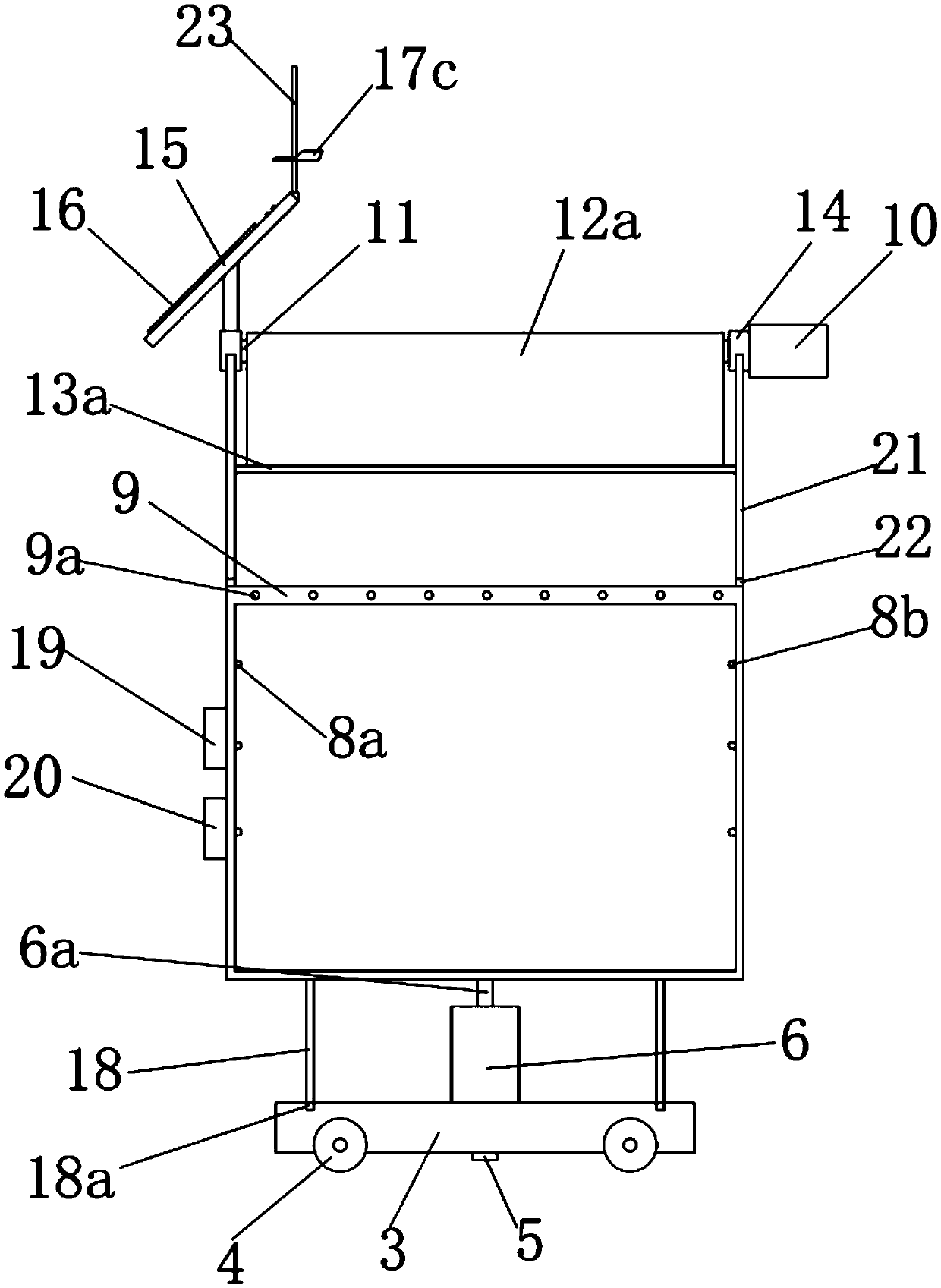

Outdoor airing robot based on Internet of Things

InactiveCN108677464ARealize automatic dryingNovel structureOther drying apparatusTextiles and paperEngineeringMoisture sensor

The invention relates to an outdoor airing robot based on Internet of Things. According to the scheme, a second motor is arranged on a chassis, the rotating shaft of the second motor extends upwards vertically and is fixedly connected with a bottom frame, the upper part of the bottom frame is provided with a horizontal clothes-airing rod, a top frame is arranged on the clothes-airing rod, the topframe comprises a bottom support fixed on the clothes airing rod and inclined supports which are vertically and symmetrically arranged on two sides of the bottom support; the upper part of each inclined support is provided with a fixing plate; a rotating drum is arranged between the two fixing plates; a third motor for driving the drum to rotate is arranged on one of the fixing plates; an collecting board is arranged above the fixing plates, a raindrop sensor, a temperature and humidity sensor, a wind direction sensor, a wind speed sensor, a light angle sensing device and a solar panel are respectively arranged on the collecting board, a plurality of sensors, such as the temperature and humidity sensor, raindrop sensor, light angle sensing device, are used for sensing the change of the external environment, and the automatic airing of the clothes is realized by controlling the rotation directions and the rotating speeds of different motors by the controller.

Owner:SHANGQIU NORMAL UNIVERSITY

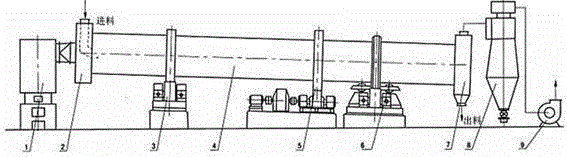

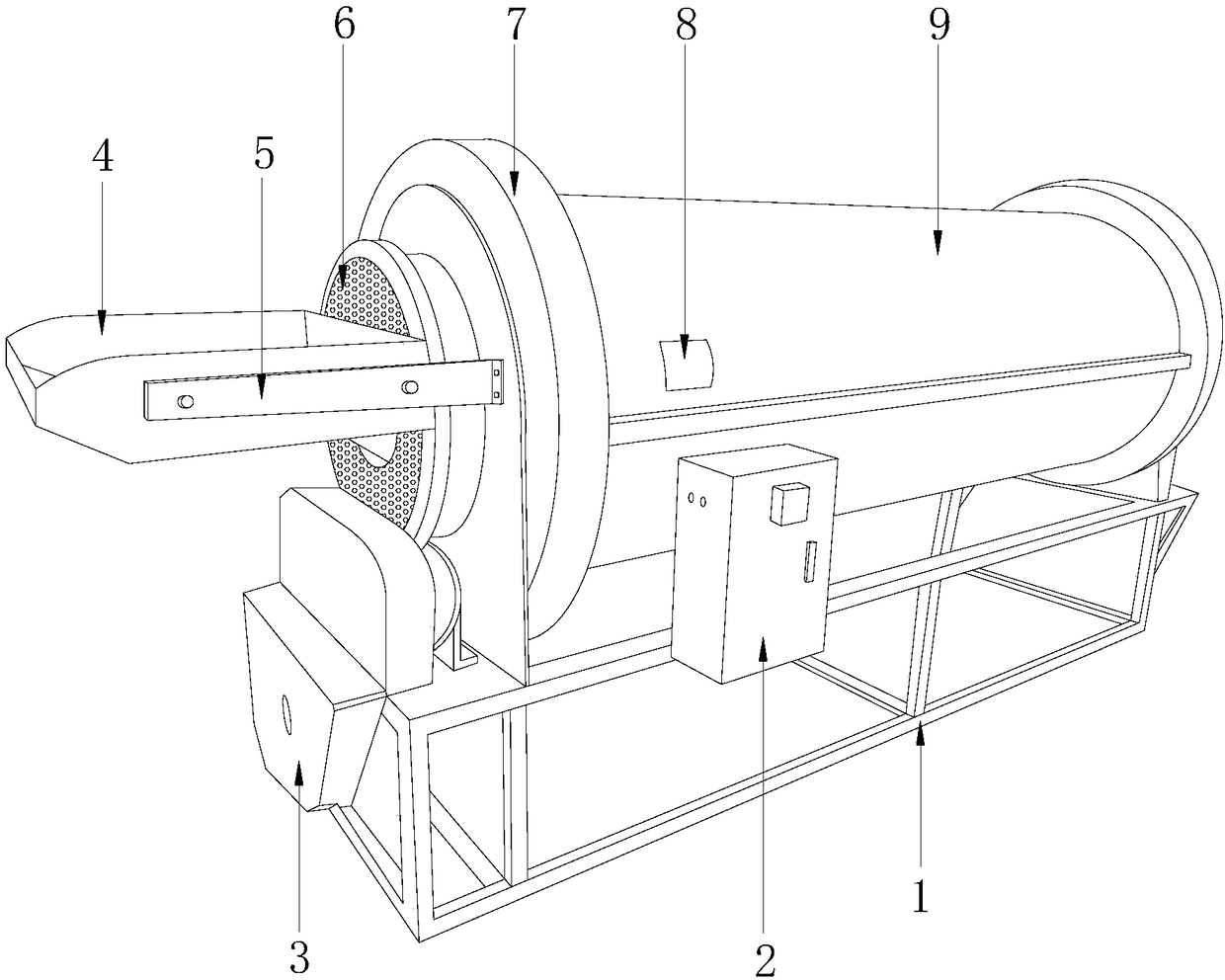

Fly ash drying machine

ActiveCN105157377AIncrease economic benefitsGuaranteed drynessDrying solid materialsDrying machines with non-progressive movementsAgricultural engineeringPollution

The invention discloses a fly ash drying machine. The fly ash drying machine comprises a drying kiln which is arranged in an inclined mode. The high end of the drying kiln is a feed end, and the low end of the drying kiln is a discharge end. A riding wheel device is arranged on the portion, close to the feed end, on the drying kiln. A riding wheel blocking device is arranged on the portion, close to the discharge end, on the drying kiln. A transmission device is arranged in the middle of the drying kiln. A heating device is connected to the feed end of the drying kiln. A discharge device is arranged at the discharge end of the drying kiln. The discharge device is connected with a cyclone separation device which is connected with an induced draught fan. Unique design is adopted for the fly ash drying machine according to the characteristics of fly ash, and the pollution and treatment problem of fly ash is solved; meanwhile, waste fly ash is turned into wealth, and economic benefits are increased.

Owner:陈宇捷

Golf washing and drying system

The invention relates to a golf washing and drying system. The golf washing and drying system comprises a golf inlet groove, a vertical conveyor, a golf washing machine, a drying machine and a golf outlet groove; after being conveyed into the golf inlet groove, golf is lifted through the vertical conveyor to an inlet of the golf washing machine, when the system is started, a cover plate of the inlet is opened, water is fed automatically through a solenoid valve, the golf falls onto a screw shaft in the golf washing machine, when the golf is conveyed through the screw shaft in a guiding mode, four rolling bushes rotate in opposite directions in pairs, and the golf is conveyed to an outlet through the inlet of the golf washing machine. After being washing, the golf automatically enters the air drying equipment which is formed by assembling seven rolling brushes in parallel so that the golf is turned over from an inlet to an outlet of the drying machine, a high-power fan at the top continuously blows air, when the golf reaches the outlet, a golf body is wholly blown dry, and the golf falls into the golf outlet groove. The golf washing and drying system can automatically wash the golf without manual blow-drying or natural air drying, and manpower and time are greatly reduced.

Owner:深圳市绿瑞高尔夫科技有限公司

Motor drying device and drying method

ActiveCN105846618ABurn out preventionImprove securityManufacturing dynamo-electric machinesCurrent sensorComputer module

The invention discloses a motor drying device which comprises a voltage regulating and transformation module, an infrared temperature measurement module, an insulation detection module, a first touch screen, a power supply, a first relay, a second relay and a third relay, wherein the voltage regulating and transformation module is respectively connected with the infrared temperature measurement module, the insulation detection module, the touch screen, the power supply, the coil of the first relay, the coil of the second relay and the coil of the third relay, the voltage regulating and transformation module is connected with a motor through a current sensor and the normally-opened node of the first relay, the motor is connected with the insulation detection module through the normally-opened node of the second relay, the normally-opened node of the second relay is grounded, the motor is connected with the insulation detection module through the normally-opened node of the third relay, and the power supply is connected with the insulation detection module through a switch. The invention further provides a motor drying method. Drying of a motor can be done without repeatedly dismounting wires, the operation is simple and convenient, and the safety of an operator is ensured.

Owner:CHINA FIRST METALLURGICAL GROUP

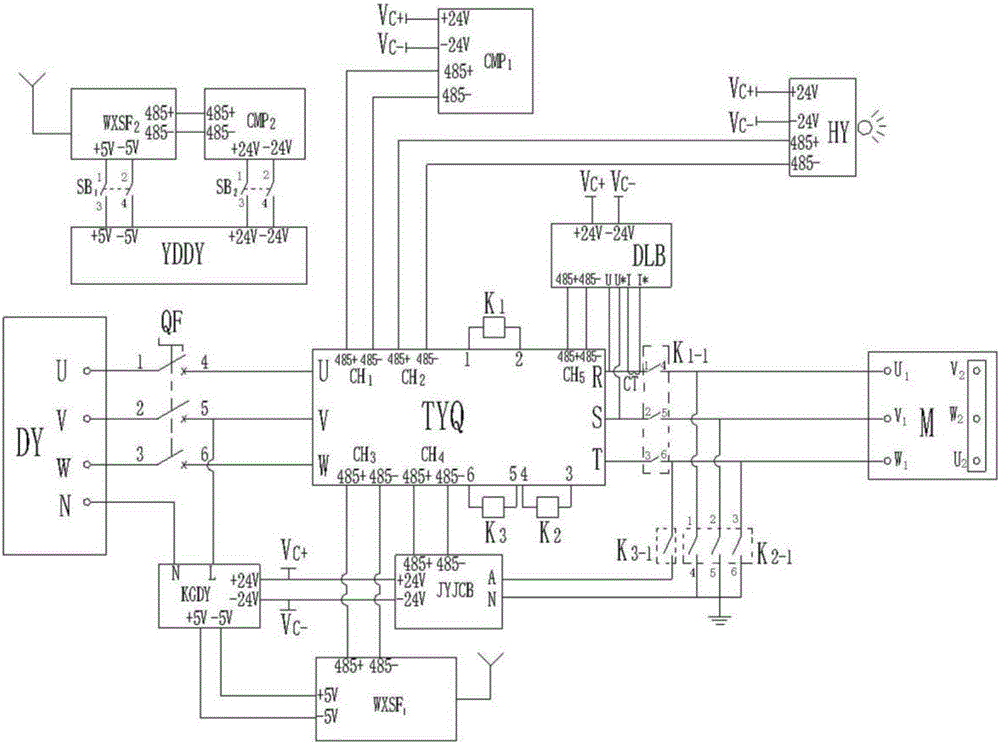

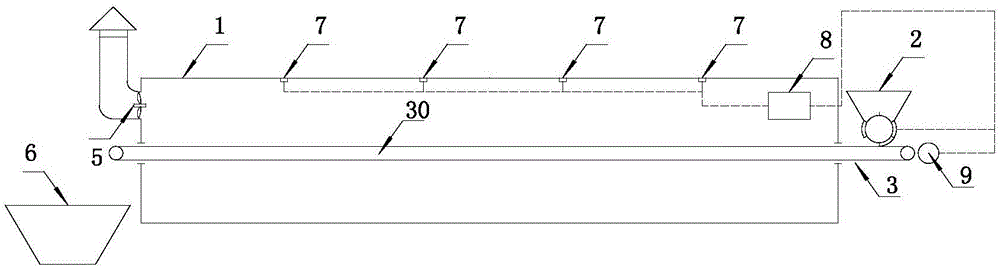

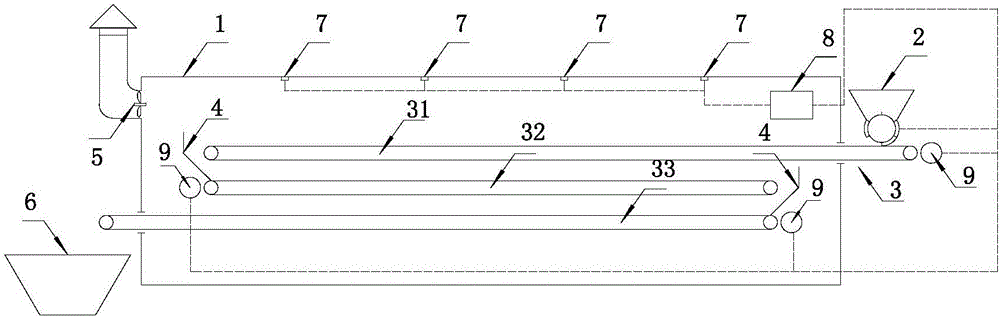

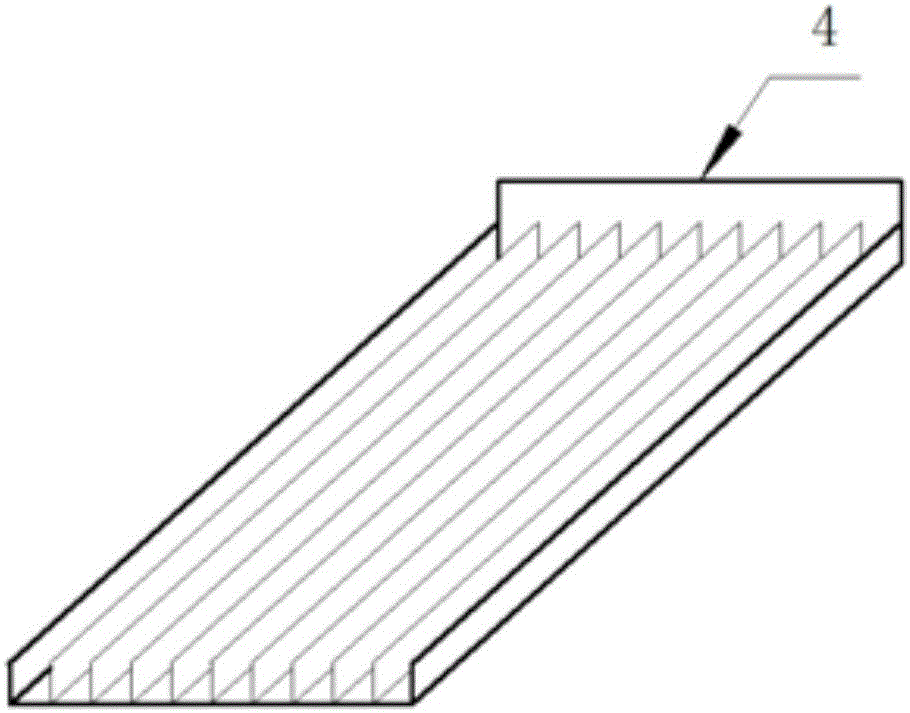

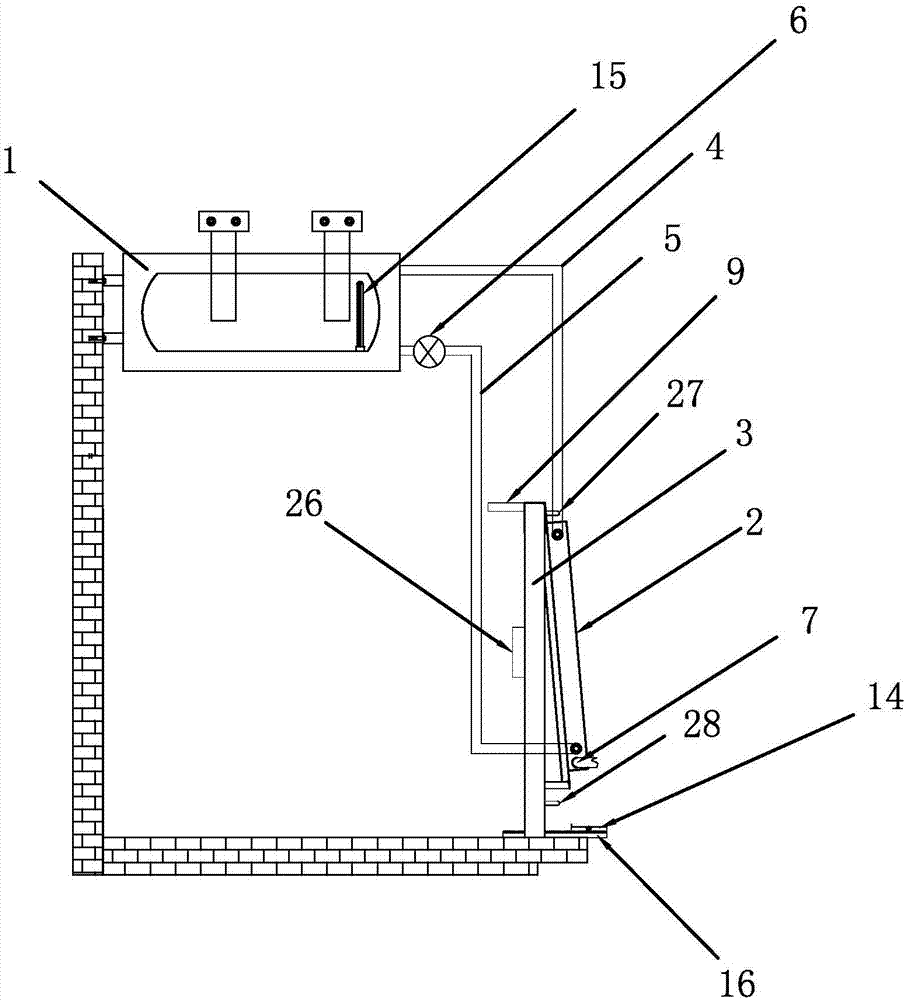

Control device for automatically drying sludge in solar greenhouse

PendingCN106517725AReduce investmentReduce drying costsWater treatment parameter controlSludge treatment by de-watering/drying/thickeningHeat flowControl system

The invention discloses a control device for automatically drying sludge in a solar greenhouse. The control device comprises the solar greenhouse, a feeder, a conveying belt mechanism, an exhaust fan, a storage bin, a heat-flow meter and an adjuster. According to the control device, the density value of heat flow entering the solar greenhouse is measured by the heat-flow meter, and then the adjuster controls the operation of a system according to the density value to achieve the purpose of automatic sludge drying; and the control device is simple to operate, a worker only needs to periodically add wet sludge into the feeder and recycle clean sludge from the storage bin and does not need to judge the drying degree of the sludge, the system can control the drying time of the sludge in the solar greenhouse according to the density value of the heat flow entering the solar greenhouse to realize automatic sludge drying, and the control device is high in degree of automation and low in operating cost.

Owner:SOUTH CHINA UNIV OF TECH

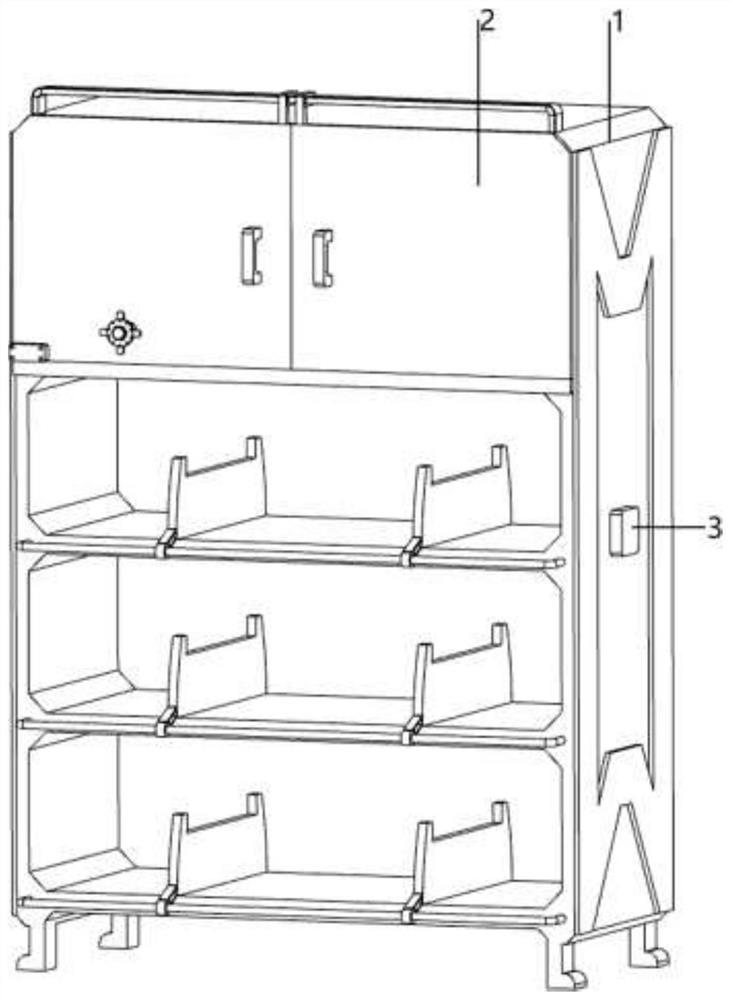

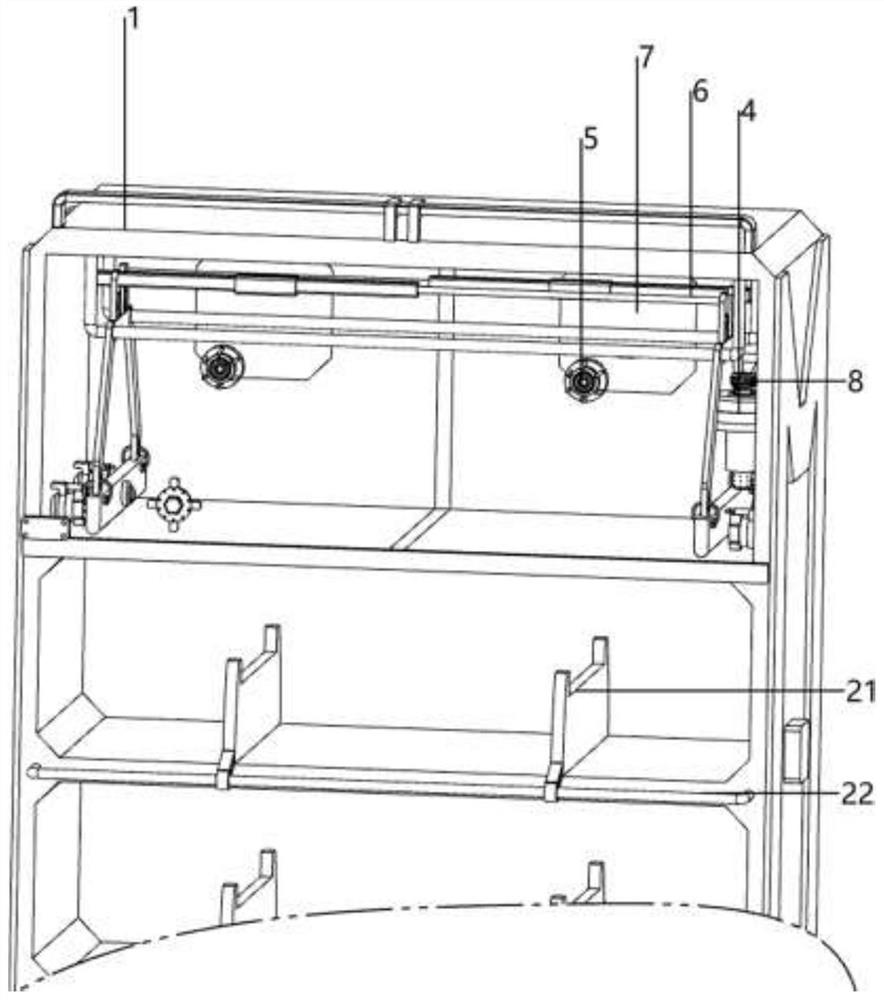

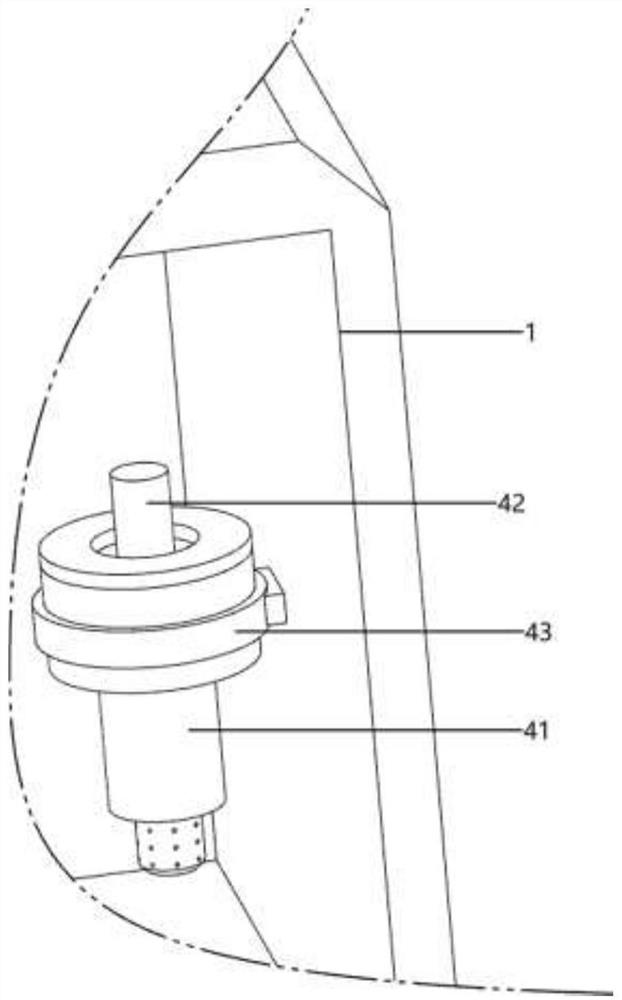

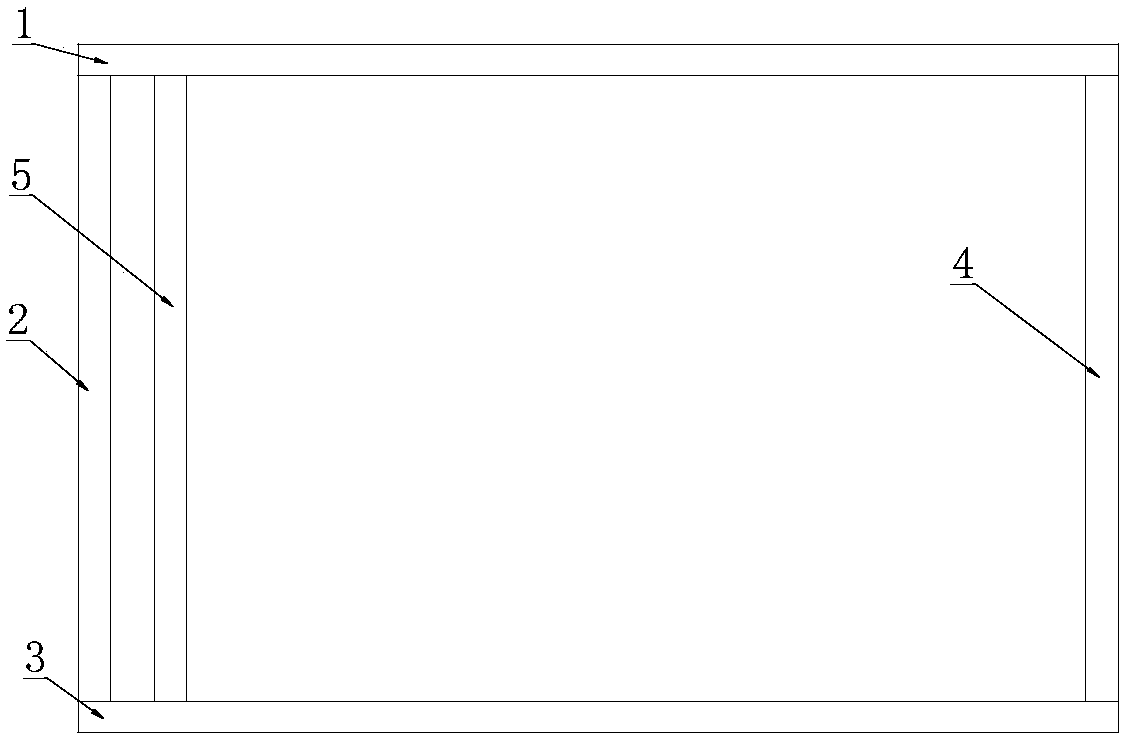

Intelligent bookcase capable of adjusting humidity

PendingCN112914260ARealize automatic dryingPrevent moistureBook cabinetsDrying gas arrangementsPhysicsEngineering

The invention relates to an intelligent bookcase, in particular to an intelligent bookcase capable of adjusting humidity. According to the intelligent bookcase capable of adjusting the humidity, automatic drying can be achieved, and books can be conveniently put in order. According to the technical scheme, the intelligent bookcase comprises a bookcase body, bookcase doors, partition plates, first U-shaped rods, a drying mechanism and a drying mechanism, the bookcase doors are rotationally connected to the two sides of the bookcase body, the three first U-shaped rods are arranged on one side of the bookcase body, the two partition plates are slidably connected to the first U-shaped rods, the drying mechanism is arranged on one side in the bookcase body, and the drying mechanism is arranged on the bookcase doors. And through cooperation of the drying mechanism and the drying mechanism, the bookcase can be automatically dried, and therefore books can be prevented from being affected with damp.

Owner:江西金橡木业有限公司

Sunlight room roof automatic cleaning device

InactiveCN109424128ARealize automatic collectionRealize automatic dryingRoof toolsCleaning using liquidsAgricultural engineeringWater spray

The invention discloses a sunlight room roof automatic cleaning device which comprises frame bodies, a water collecting tank, water spraying holes, a water outlet hose, fans and a power supply. The upper frame body, the lower frame body, the left frame body and the right frame body are distributed on the upper, lower, left and right sides of a glass roof respectively. The water spraying holes areformed in the upper frame body. The water outlet hose is connected with the lower frame body. The water collecting tank is connected with a water inlet pipe which is communicated with the upper framebody so that water in the water collecting tank can enter the upper frame body through the water inlet pipe. The fans are arranged in the left frame body and the right frame body. By means of the cleaning device, the automatic cleaning and air-drying of the terrace glass roof can be realized, the structure is simple, and use is convenient.

Owner:陈业祥

Textile fabric printing and dyeing device

PendingCN112323286APracticalRemove dustLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsEngineeringTextile printer

The invention belongs to the technical field of textile printing and dyeing, and discloses a textile fabric printing and dyeing device. The device comprises a supporting plate, wherein a printing anddyeing box is fixedly connected to the top of the supporting plate, and two partition plates arranged left and right are arranged in the printing and dyeing box. According to the scheme, a cloth feeding winding drum and a cloth collecting winding drum with different lengths can be clamped, fixed, unwound and wound, textile fabrics with different thicknesses can be conveyed through a cloth feedingassembly with an adjustable interval, practicability is high, an auxiliary roller can assist in conveying the fabrics, the functions of automatic wetting, dust removing and excessive moisture absorbing through extrusion can be achieved through mutual cooperation of the auxiliary roller, a water spraying assembly and a water absorbing assembly in a wet spraying cavity, the automatic printing and dyeing function can be achieved through mutual cooperation of a hydraulic telescopic rod, a connecting block, a printing and dyeing module, a telescopic pipe and a dyeing agent box in a printing and dyeing cavity, automatic drying can be achieved through a drying assembly in a drying cavity, finally, winding is conducted through the cloth collecting winding drum, the automation degree is high, and the working efficiency is high.

Owner:陈扬辉

Yarn drying equipment for producing Duntou blue cloth

InactiveCN112127074ARealize automatic dryingReduce labor costsLiquid/gas/vapor removal by squeezingTextile treatment carriersYarnPolymer science

The invention relates to the technical field of cloth dyeing and weaving, in particular to yarn drying equipment for producing Duntou blue cloth. The drying equipment comprises a drying mechanism, a material rolling mechanism, a material conveying mechanism, two twisting mechanisms, a rubbing and flattening mechanism and twisting force detection mechanisms, wherein the drying mechanism is arrangedon a machine frame and used for drying to-be-dried cloth with the rice milk removed; the material rolling mechanism is arranged on the machine frame, and the feeding end of the material rolling mechanism faces the discharging end of the drying mechanism; the material conveying mechanism is arranged on the machine frame, and the discharging end of the material conveying mechanism faces the feedingend of the drying mechanism; the two twisting mechanisms are correspondingly arranged at the feeding end and the discharging end of the drying mechanism, and the twisting mechanisms clamp the to-be-dried cloth and rotate in the reverse direction, and are used for wringing the to-be-dried cloth; the rubbing and flattening mechanism is arranged in the drying mechanism, symmetrically faces the direction of the to-be-dried cloth and is used for rubbing and flattening the to-be-dried cloth; and the twisting force detection mechanisms are arranged on the material rolling mechanism and the materialconveying mechanism and used for detecting the acting force applied to the to-be-dried cloth. According to the scheme of the yarn drying equipment for producing the Duntou blue cloth, the automation problem of the Duntou blue yarn drying process is solved, manpower is saved, and efficiency is improved.

Owner:马亚伟

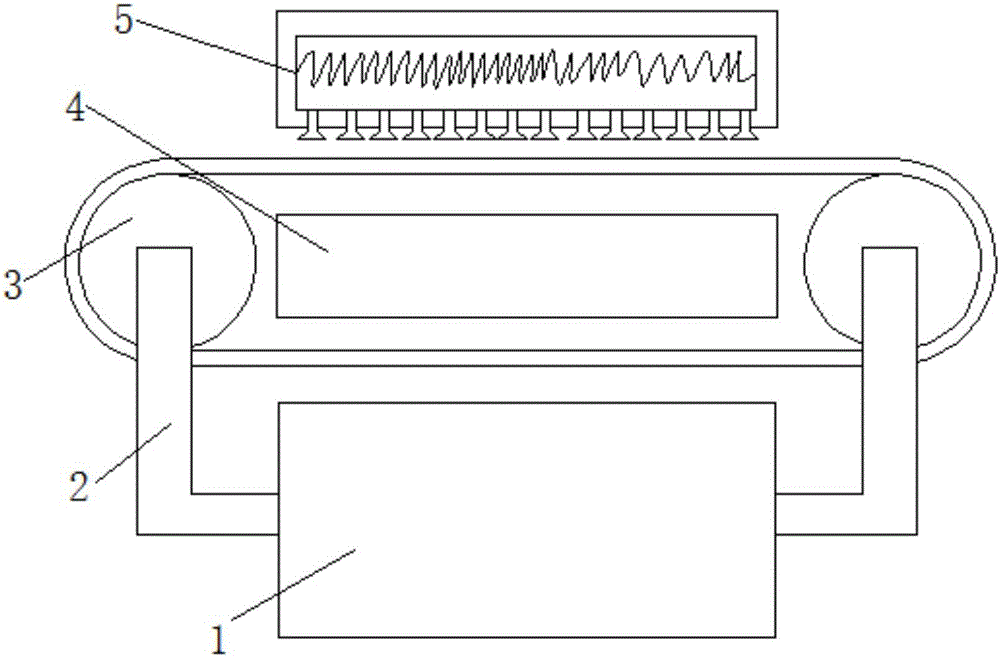

Heat insulation plate drying machine

InactiveCN106766803AImprove drying efficiencyReduce energy consumptionDrying gas arrangementsDrying machines with progressive movementsEnergy lossEngineering

The invention discloses a heat insulation plate drying machine which comprises a base, a bracket and a conveying device, wherein the conveying device is mounted at the top end of the base through the bracket; a heating box and a water discharging tank are arranged above the base; the water discharging tank is located between the base and the heating box; two first supporting plates are connected between the base and the water discharging tank; the first supporting plates are separately located on two sides of the top end of the base; two second supporting plates are connected between the water discharging tank and the heating box; the two second supporting plates are separately located on two sides of the top end of the water discharging tank; the conveying device comprises a conveying belt, a motor and two rollers; an output shaft of the motor is connected with the rollers; the conveying belt is connected between the two rollers; uniformly distributed ventilating holes are formed in the conveying belt; the heating box is located above the conveying belt; the water discharging tank is located at the middle position of the conveying belt. The heat insulation plate drying machine is simple in structure, high in automation degree and low in energy loss, and can realize recycling of heat and save the cost.

Owner:重庆市豫鹰保温材料有限公司

Drying equipment for tea production and processing

InactiveCN108375298ARealize automatic dryingOperational securityPre-extraction tea treatmentDrying gas arrangementsEngineering

The invention discloses drying equipment for tea production and processing. The drying equipment structurally comprises a machine frame, a control cabinet, supporting wheels, a feeding hopper, fixingrods, exhaust fans, turnover discs, a model mark and a drying mechanism, wherein the machine frame is vertically arranged at the lower end of the control cabinet and is welded to the turnover discs, the control cabinet is horizontally attached to the side end of the drying mechanism and is electrically connected to the supporting wheels, the supporting wheels are horizontally fixed to the side ends of the exhaust fans and are welded to the machine frame, the feeding hopper is horizontally arranged at the left end of one turnover disc and is fixed to one exhaust fan through nuts, and the two fixing rods are uniformly arranged at the left end and the right end of the feeding hopper and are welded together. The drying equipment has the advantages that tea can be automatically dried by the drying mechanism, the operation is simple and safe, meanwhile, the workload can be reduced, the labor amount can be decreased, the working efficiency can be greatly improved, and popularization can be facilitated.

Owner:福建聚云科技股份有限公司

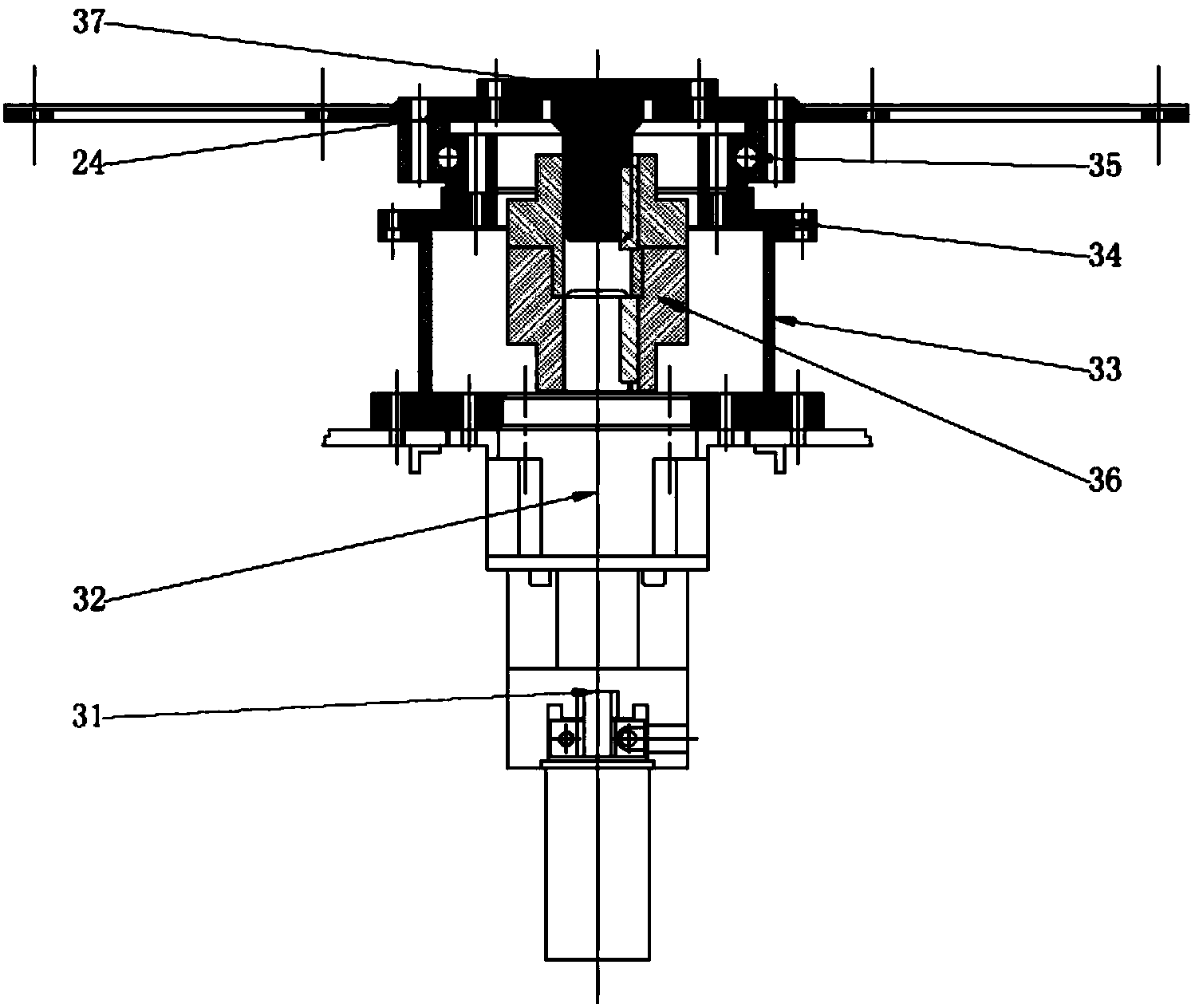

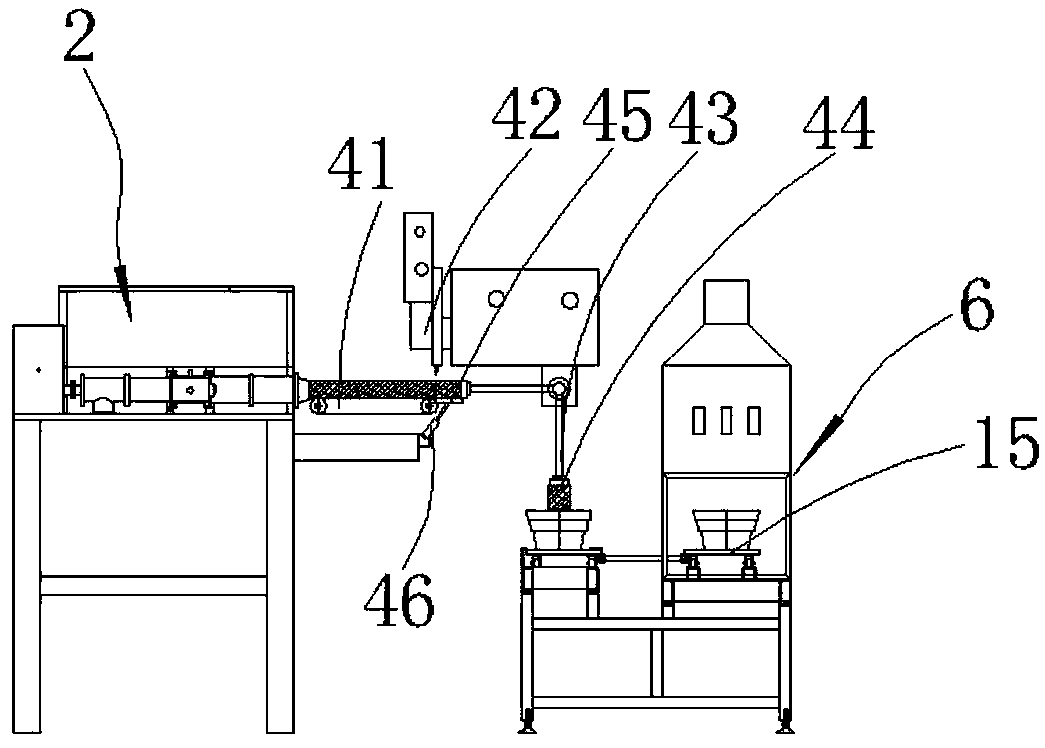

Improved structure of tablet press

The invention relates to an improved structure of a tablet press. The improved structure of the tablet press comprises a tablet pressing device and a feeding device. A lower punch die driving rod I and a lower punch die driving rod II are hinged to the bottom end of a lower punch die, the extending height of the lower punch die driving rod II is controlled to be larger than that of the lower punch die driving rod I, and therefore when the lower punch die protrudes out of a die hole, an inclined plane is formed to facilitate discharging of tablets. A guide groove and a die disc are in smooth transition, so the discharge rate of the tablets is improved, and the tablets are prevented from being blocked at the end of the die disc. The improved structure of the tablet press is provided with a rotary spray nozzle, and the spray nozzle is connected with a water inlet pipe and an air inlet pipe. Therefore, automatic washing and automatic drying of the inner wall of a feeding hopper are achieved, operations are simple and convenient, and the problem that it is difficult to clean the inner wall of the feeding hopper is avoided.

Owner:华康玫瑰(广东)生物技术研究有限公司

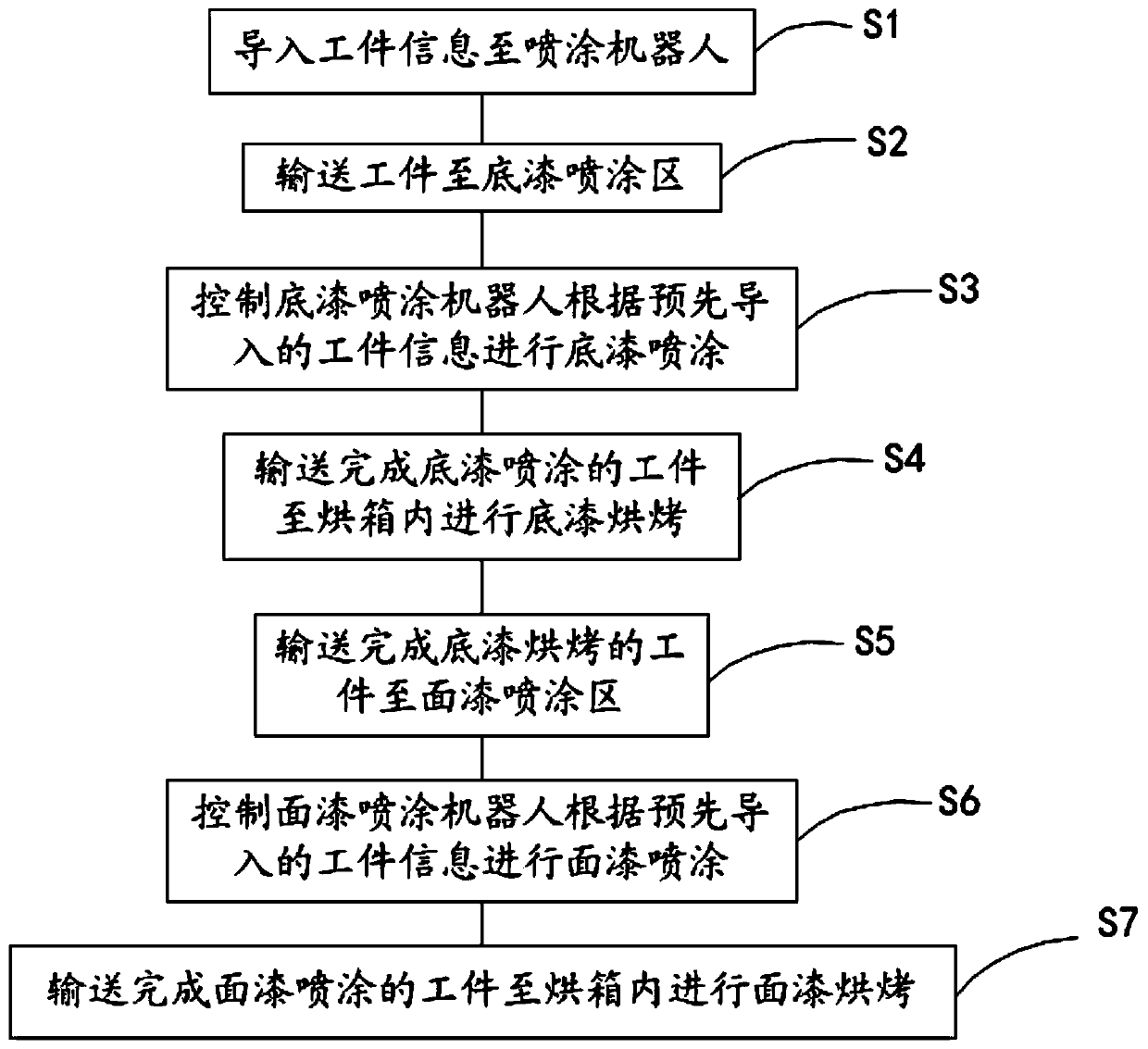

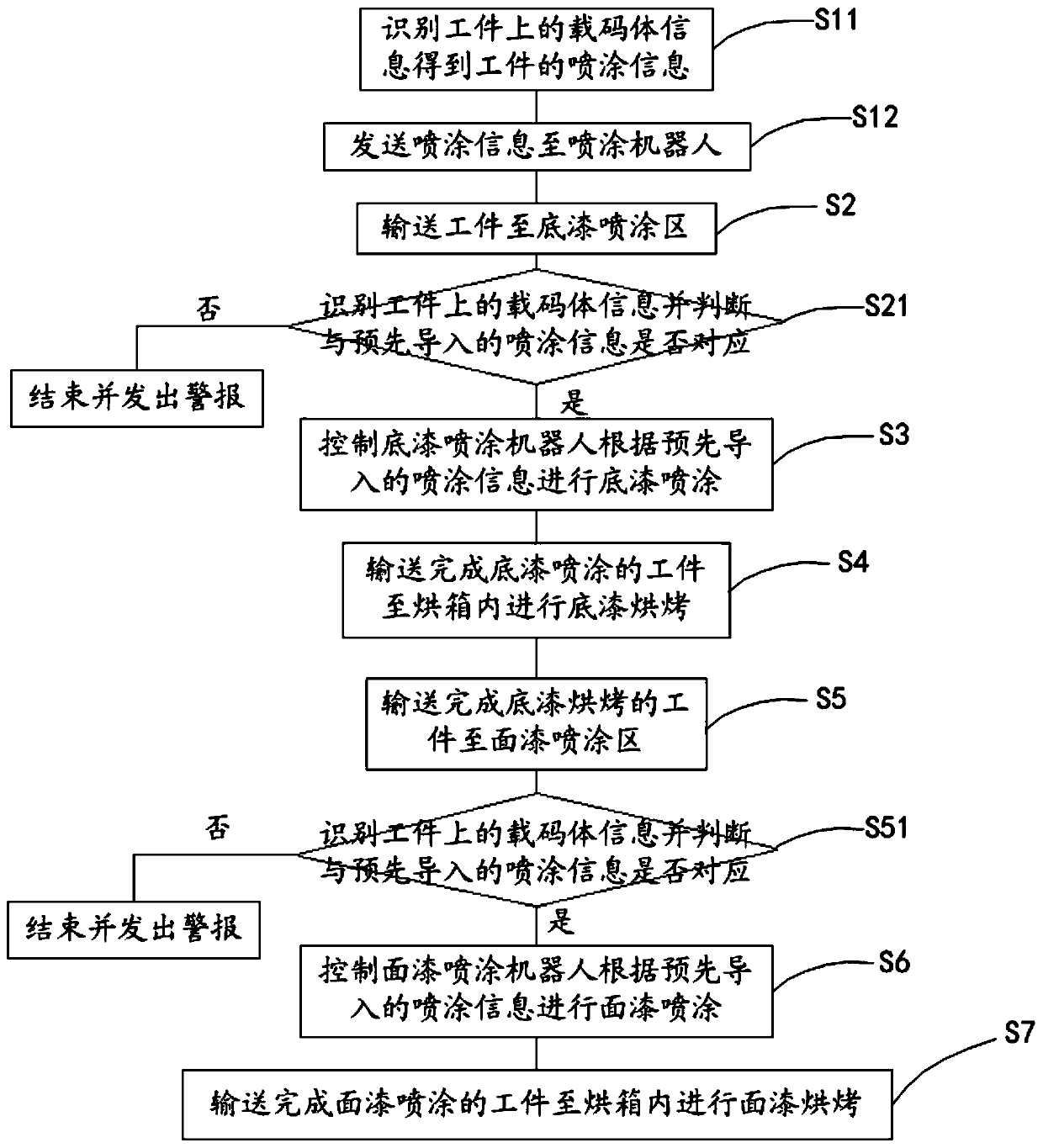

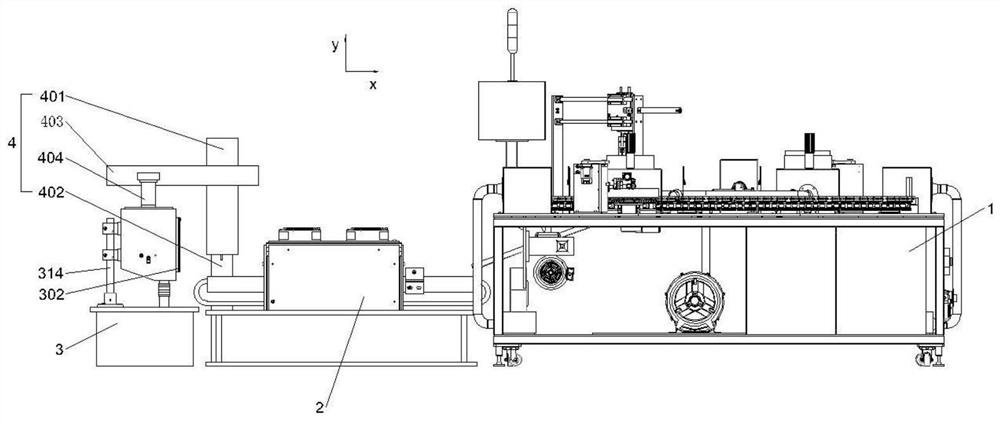

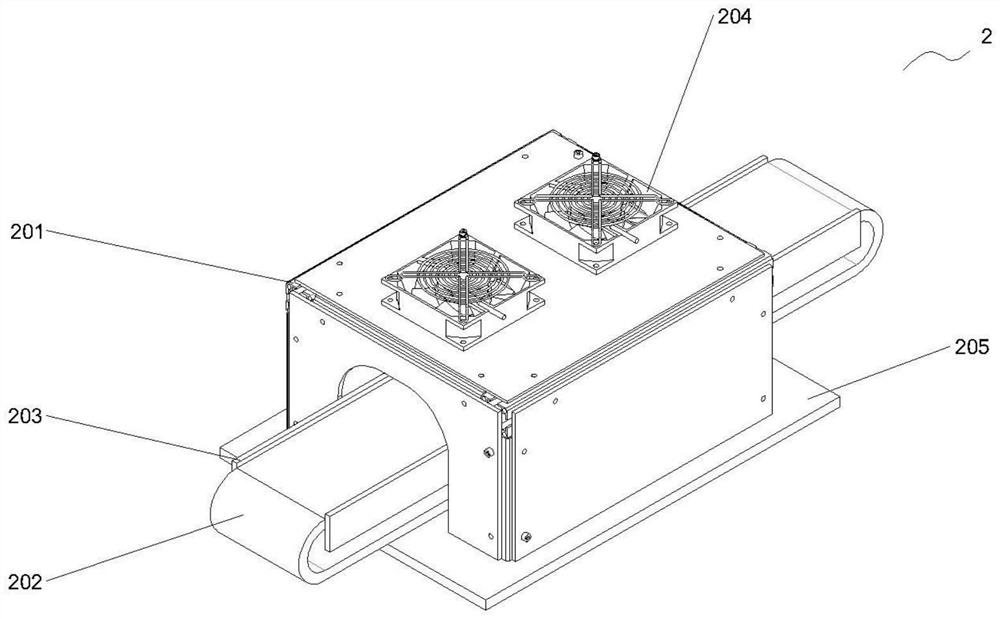

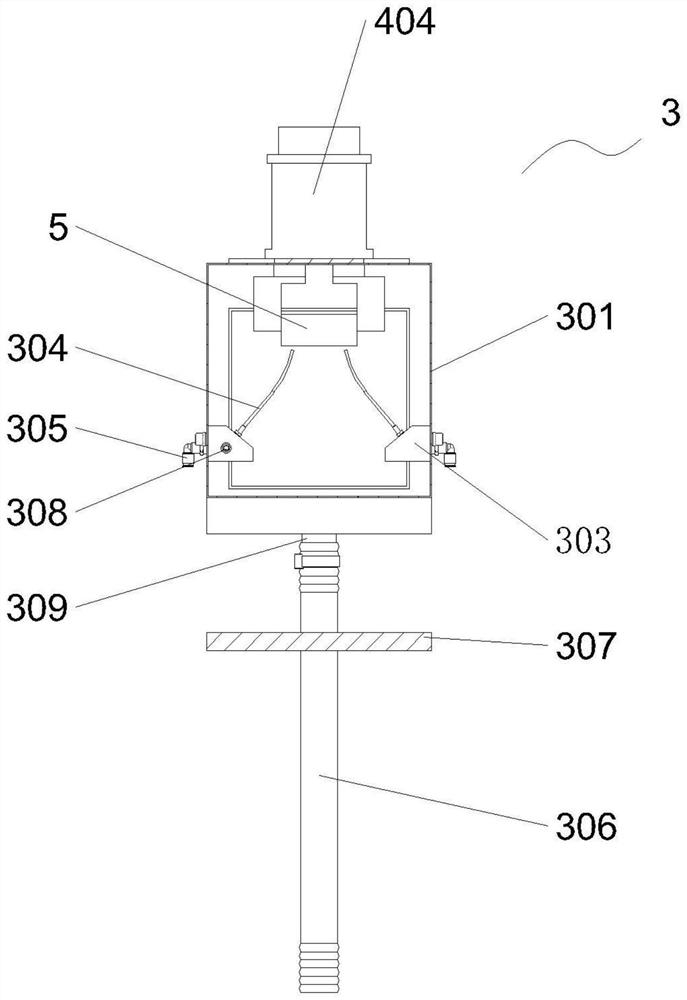

Engine coating spraying technology and system

InactiveCN109894338ARealization of automatic sprayingRealize automatic dryingLiquid surface applicatorsCoatingsAgricultural engineeringRobot

The invention discloses an engine coating spraying technology. The engine coating spraying technology comprises the steps that S1, workpiece information is guided to a primer spraying robot and a finishing coat spraying robot; S2, a workpiece is conveyed to the primer spraying area; S3, the primer spraying robot is controlled to conduct primer spraying according to the pre-guided-in workpiece information; fourthly, the workpiece obtained after primer spraying is conveyed into an oven, and the oven is controlled to conduct primer baking; S5, the workpiece obtained after primer baking is conveyed to the finishing coat spraying area; S6, the finishing coat spraying robot is controlled to conduct finishing coat spraying according to the pre-guided-in workpiece information; and S7, the workpiece obtained after finishing coat spraying is conveyed into the oven to be subjected to finishing coat baking. According to the provided engine coating spraying technology, full-automatic workpiece spraying can be achieved, hurt to bodies of spraying personnel in the spraying process is avoided, the spraying robots can conduct spraying according to the preset track and the preset scheme, and the paint painting rate can be greatly increased. The invention discloses an engine coating spraying system.

Owner:ANHUI HUALING AUTOMOBILE

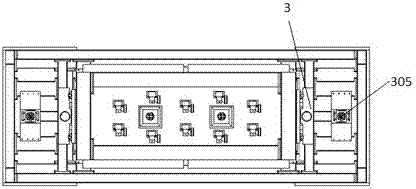

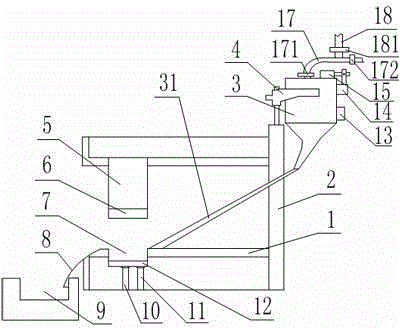

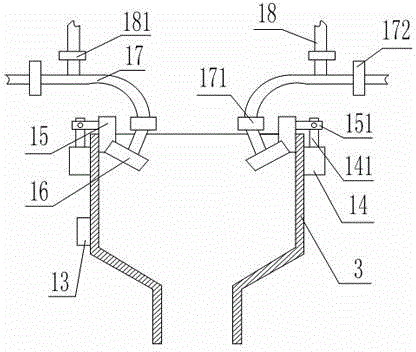

Spraying device for supplementary coating of rivet of easy-open cover and spraying method of spraying device

ActiveCN114669454ARealize automatic dryingPretreated surfacesControl devices for conveyorsRivetCoating

The invention discloses a spraying device for supplementary coating of rivets of easy-open caps, which comprises a repairing machine, a preliminary air-drying conveying device mounted at the outlet end of the repairing machine, a drying device mounted at the outlet end of the preliminary air-drying conveying device, and a grabbing device mounted on one side of the drying device and used for grabbing workpieces from the preliminary air-drying conveying device into the drying device. According to a spraying device disclosed in the prior art, a subsequent drying device is not disclosed, automatic drying after the continuous spraying step is achieved, meanwhile, in the drying step, due to the fact that the position distances are different when workpieces reach a preliminary air drying and conveying device, operation of a grabbing device is inconvenient, and the working efficiency is high. Therefore, the designed dividing device is used for facilitating the grabbing device to grab the workpiece to the drying device.

Owner:NANTONG INST OF TECH

Integrated multipurpose bathing device

ActiveCN104748395AWide range of applicationsLow costFluid heatersElectric heating systemTemperature controlHeat control

The invention discloses an integrated multipurpose bathing device. The integrated multipurpose bathing device is composed of a case part, a water heating part, a drying and heating part and a control part. A temperature control instrument and a heat switch are adopted by the water heating part for heating control over hot water and boiled water, the power of a heating wire is high enough to enable hot water at the temperature over 40 DEG C to be supplied continuously, and the continuous water outlet temperature is made to range from 40 DEG C to 60 DEG C by adjusting a water outlet switch; the water outlet which can rotate up and down is adopted on the aspect of structure connection, the water outlet direction can be adjusted conveniently through a human body sensor, and automatic water supplying and cleaning can be achieved through sensing; the drying and heating device can be used for automatic drying through sensing through the cooperation between the human body sensor and an air outlet used for adjusting the air outlet direction. According to the integrated multipurpose bathing device, boiled water or hot water at a set temperature can be supplied, the sensing type automatic water outlet function, the automatic drying function and the auxiliary heating function are integrated, the device can be moved freely through universal wheels on a case, and the bathing device is suitable for home life and particularly suitable for cleaning and bathing of infants.

Owner:浙江巨力宝纺织科技有限公司

Suaeda salsa grass seed extract beverage and preparation method thereof

PendingCN108740650AImprove qualityNutritionally completeFatty-oils/fats productionFood ingredient functionsFlavorAntioxidant

The invention provides a suaeda salsa grass seed extract beverage and a preparation method thereof, and relates to a beverage. The suaeda salsa grass seed extract beverage is prepared from the following raw materials in percentage by weight: 4-6% of white granulated sugar, 0.5-5% of suaeda salsa seed oil, 5-10% of black nightshade juice, 0.1-2% of starch, 0.005-0.06% of guar gum, 0.01-0.1% of xanthan gum, 0.0002-0.02% of an antioxidant, 0.01-0.1% of a food flavor and the balance of water. The suaeda salsa grass seed extract beverage disclosed by the invention makes up the vacancy of vegetablefat beverages in conventional market; and the suaeda salsa grass seed extract beverage produced and developed by the invention has health-care efficacy, so that pursuit of people for healthy life canbe met.

Owner:碱蓬先创科技(盘锦)有限公司

Automatic polycrystalline silicon washing device

PendingCN111804642AImprove cleaning efficiencyRealize automatic cleaningDrying gas arrangementsCleaning using liquidsMegasonic cleaningProcess engineering

The invention discloses an automatic polycrystalline silicon washing device which comprises a washing rack, a drying rack, a washing hood, a drying hood, a conveyor belt, a conveyor belt support sideplate, a plurality of washing baskets, a washing basket carrying device and a plurality of drying fans; the drying rack is connected with one end of the washing rack; the drying hood is transversely arranged at the upper end of the drying rack; the washing hood is transversely arranged at the upper end of the washing rack; the washing hood communicates with the drying hood; and the end, far away from the drying rack, of the washing rack extends out of the washing hood to be provided with a feeding platform. According to the automatic polycrystalline silicon washing device, the washing basket carrying device is cooperated with the washing baskets, a plurality of washing grooves and the conveyor belt to realize automatic feeding, automatic washing and automatic drying, improve the polycrystalline silicon washing efficiency and lower the manual labor intensity; and purified water is filled in the washing grooves, and the washing quality is improved through ultrasonic washing.

Owner:HAIYAN DESHENG CHEM EQUIP

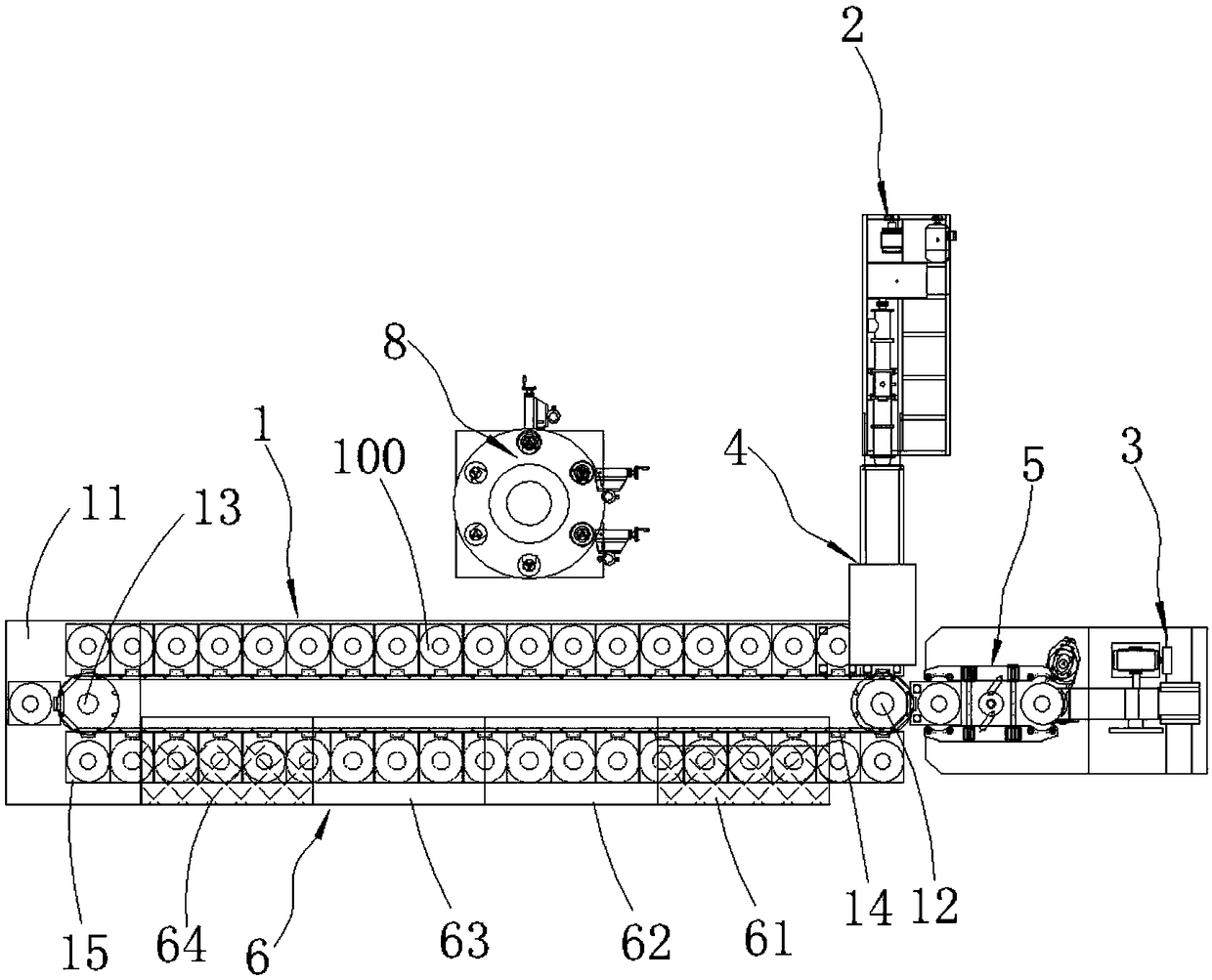

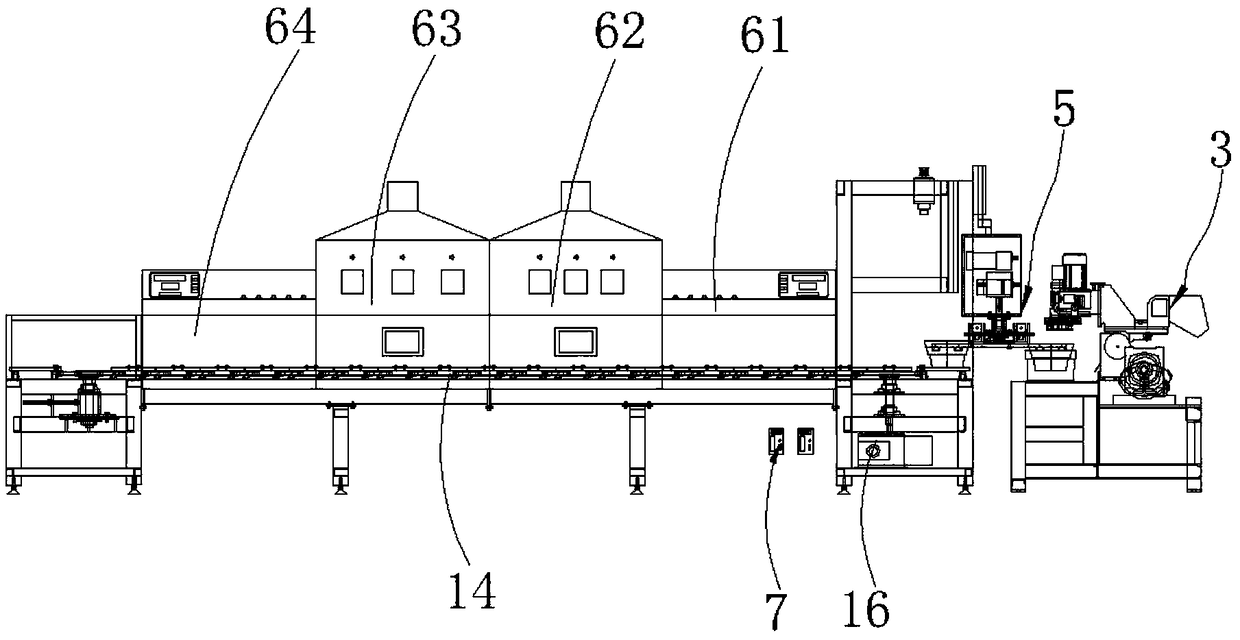

Tunnel type wood veneer drying production line

PendingCN114485122AEvenly heatedAvoid deformationDrying machines with progressive movementsDrying solid materialsWood veneerHot air oven

A tunnel type wood veneer drying production line comprises a hot blast stove, a tunnel type drying room body and a chain conveying device, the hot blast stove provides hot air, the chain conveying device conveys wood veneers, the chain conveying device comprises a machine frame, and a first driven shaft and a second driven shaft are installed at the two ends of the machine frame respectively. A first driven chain wheel and a second driven chain wheel are installed at the two ends of the first driven shaft and the two ends of the second driven shaft respectively, a driving shaft with small driving chain wheels at the two ends is installed on the upper portion or the lower portion in front of the first driven shaft, and the small driving chain wheels, the first driven chain wheels and the second driven chain wheels at the corresponding ends are connected in a closed-loop mode through plate type conveying chains. And an automatic clamp for clamping a wood veneer is arranged between chain plates corresponding to each section of chain of the two plate type conveying chains. According to the drying production line, the wood veneers can be vertically conveyed into the tunnel drying room to be dried, the plate type conveying chain circularly rotates in the tunnel drying room, discharging is conducted when the plate type conveying chain rotates to the inlet end, and continuous flow drying operation is achieved.

Owner:广西青松木业有限公司

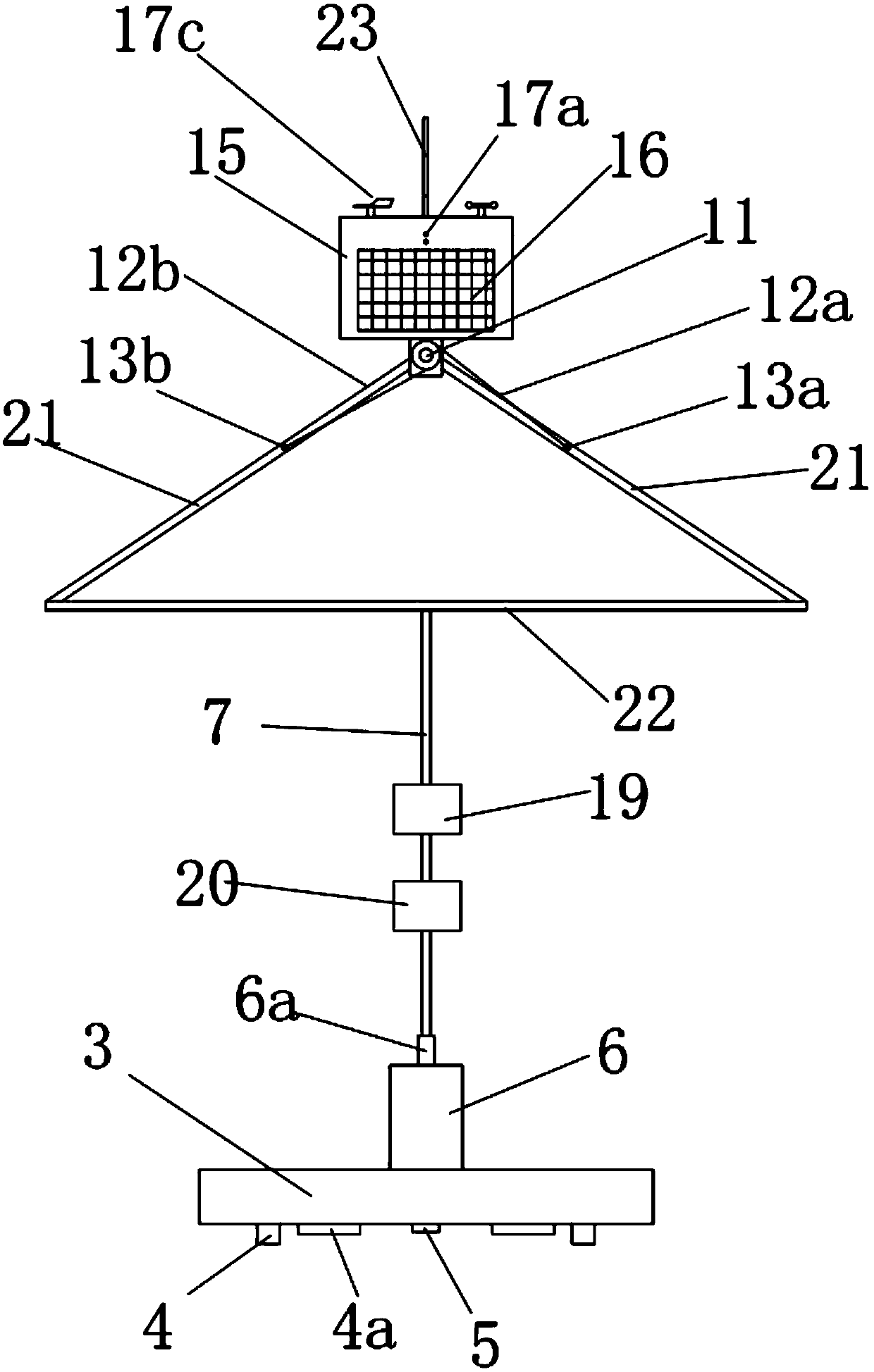

Balcony combined with wall-mounted solar water heater

InactiveCN107218728ADoes not take up spaceEasy to useBalustradesSolar heat devicesSolar waterEngineering

The invention provides a balcony combined with a wall-mounted solar water heater, which belongs to the technical field of solar energy. The balcony combined with a wall-mounted solar water heater includes a water tank, a solar heat collector and a balcony guardrail. The lower end of the water tank is provided with a cold water output pipe, the cold water output pipe is provided with a circulation pump, the hot water input pipe and the cold water output pipe are respectively connected to the solar collector, and the solar collector is also connected to a water inlet pipe, and the upper end of the balcony guardrail has a A drying device, a potted plant care device is provided at the lower end of the balcony guardrail, and the potted plant care device includes a platform for placing potted plants and a pushing structure for pushing the platform to the outside of the balcony guardrail. The invention not only integrates the solar heat collector with the building, but also makes the solar heat collector not occupy space, and has multiple functions and strong applicability.

Owner:HAINING JIANENG SOLAR ENERGY IND

Fly Ash Dryer

ActiveCN105157377BSolve pollutionSolving Disposal ProblemsDrying solid materialsDrying machines with non-progressive movementsAgricultural engineeringEconomic benefits

The invention discloses a fly ash drying machine. The fly ash drying machine comprises a drying kiln which is arranged in an inclined mode. The high end of the drying kiln is a feed end, and the low end of the drying kiln is a discharge end. A riding wheel device is arranged on the portion, close to the feed end, on the drying kiln. A riding wheel blocking device is arranged on the portion, close to the discharge end, on the drying kiln. A transmission device is arranged in the middle of the drying kiln. A heating device is connected to the feed end of the drying kiln. A discharge device is arranged at the discharge end of the drying kiln. The discharge device is connected with a cyclone separation device which is connected with an induced draught fan. Unique design is adopted for the fly ash drying machine according to the characteristics of fly ash, and the pollution and treatment problem of fly ash is solved; meanwhile, waste fly ash is turned into wealth, and economic benefits are increased.

Owner:陈宇捷

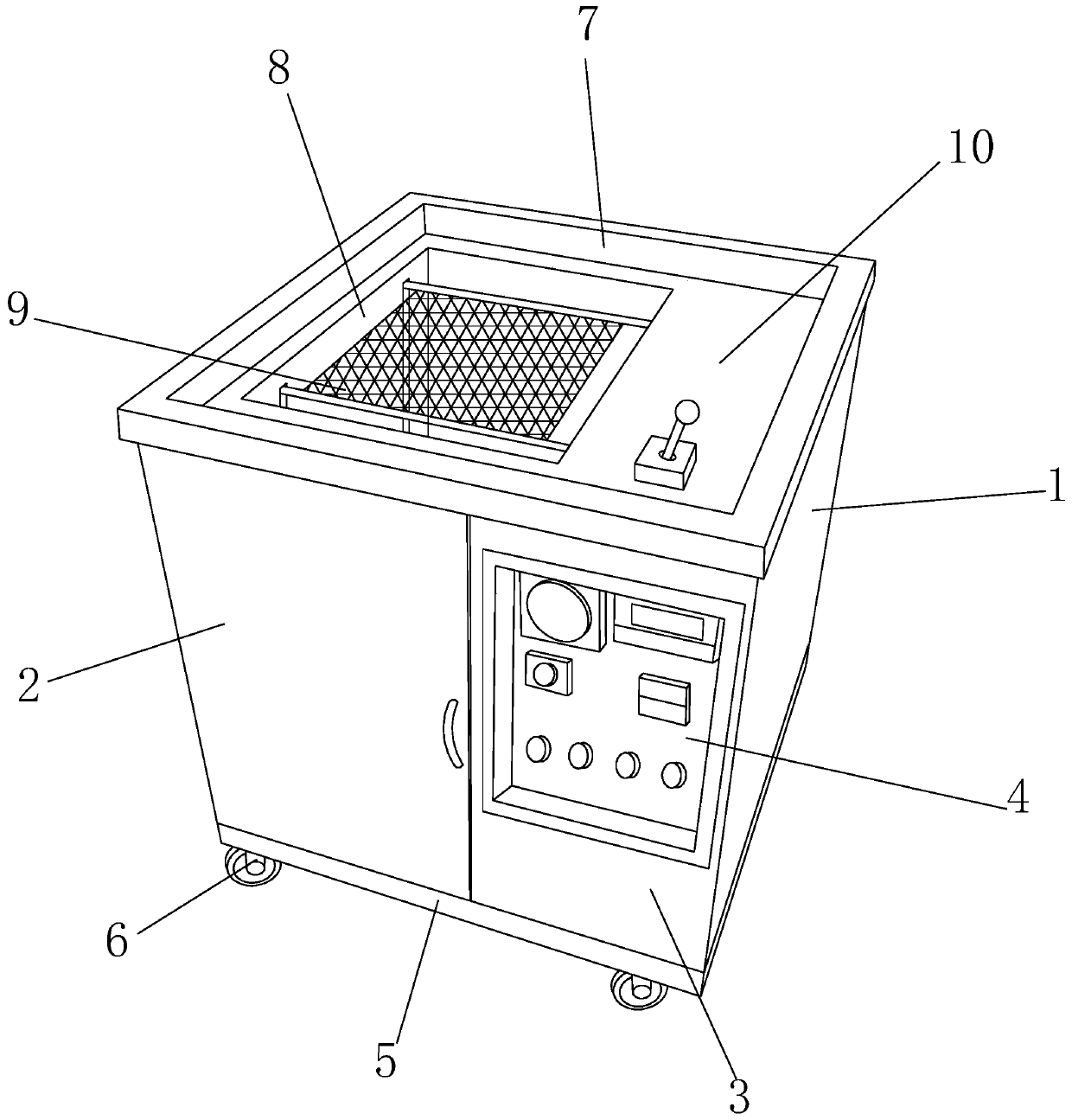

Cleaning device for plastic mold

ActiveCN107696353BImprove automationIncreased versatilityCleaning using liquidsFiltrationElectric power

The invention discloses a cleaning device for a plastic mold. The device structurally comprises a device main body, a maintenance door, a power chassis, a control panel, a base, movable idle wheels, an anti-overflow edge, a cleaning water tank, a cleaning auxiliary mechanism, a worktable, a water outlet pipe and an ultrasonic cleaner. The maintenance door is arranged on the left side of the frontsurface of the device main body and is movably connected to the device main body through a hinge; the power chassis is arranged in the right side of the device main body and is of an integral formingstructure with the device main body. The device disclosed by the invention has the beneficial effects that the cleaning auxiliary mechanism is arranged, the plastic mold can be fed into the cleaning tank; when the plastic mold is available in the cleaning tank, the ultrasonic cleaner is automatically started to clean the plastic mold ultrasonically; then the plastic mold is sent out by means of anoperating handspike; meanwhile, the ultrasonic cleaner is automatically closed to save power and energy; the mold is placed on a storage net, so that automatic filtration is achieved; automation andfunctionalization of the cleaning device for the plastic mold are enhanced effectively, and the environment-friendly and energy-saving effects are achieved.

Owner:TANGSHAN WEISEN NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com