Control device for automatically drying sludge in solar greenhouse

A control device and solar energy technology, applied in dehydration/drying/concentrated sludge treatment, electric speed/acceleration control, water treatment parameter control, etc., can solve the problems of artificially judging the drying degree of sludge, and achieve automatic drying , low operating cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

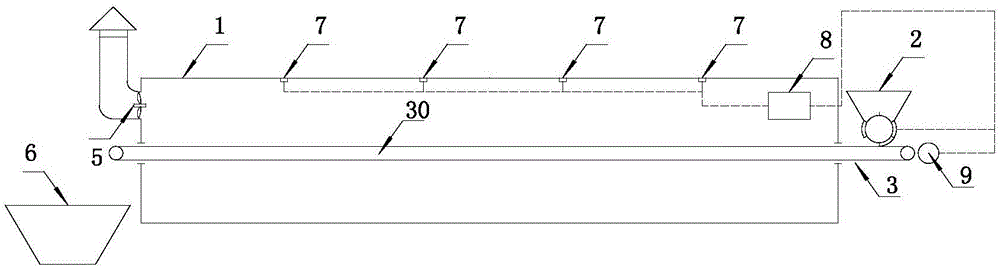

[0031] Such as figure 1 As shown, a solar greenhouse automatic drying sludge control device includes a solar greenhouse 1, a feeder 2, a conveyor belt mechanism 3, an exhaust fan 5, a storage bin 6, a heat flow meter 7, and a regulator 8,

[0032] The main body of the conveyor belt mechanism 3 is located in the solar greenhouse 1, and includes a first conveyor belt 30 driven by a motor 9, the motor 9 is connected to the regulator 8 circuit, and the feed end and the discharge end of the first conveyor belt 30 are Both extend to the outside of the solar greenhouse 1, and the feeder 2 is arranged directly above the feeding end of the first conveyor belt 30 outside the solar greenhouse 1, and the feeding amount is controlled by a regulator 8, and the staff regularly adds sludge to the feeder 2 . The storage bin 6 is arranged directly below the discharge end of the first conveyor belt 30 outside the solar greenhouse 1, and the exhaust fan 5 is arranged on one side of the solar gre...

Embodiment 2

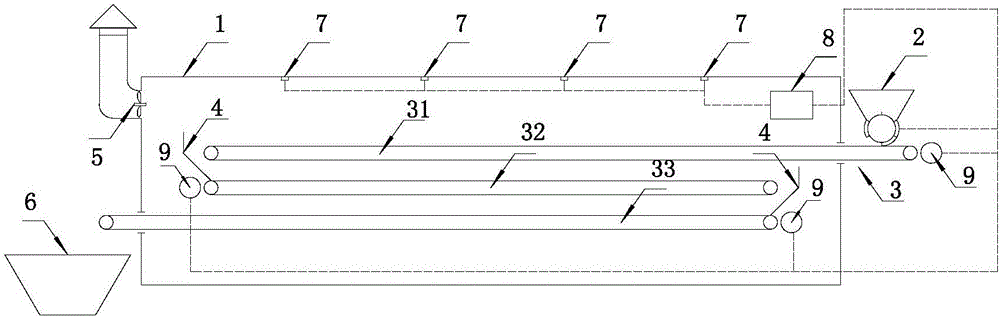

[0042] Such as figure 2 As shown, a solar greenhouse automatic drying sludge control device includes a solar greenhouse 1, a feeder 2, a conveyor belt mechanism 3, an exhaust fan 5, a storage bin 6, a heat flow meter 7, and a regulator 8,

[0043] The main body of the conveyor belt mechanism 3 is located at the solar greenhouse 1, and the conveyor belt mechanism 3 includes more than three conveyor belts driven by the motor 9, namely the second conveyor belt 31, the third conveyor belt 32, and the fourth conveyor belt 33. Each conveyor belt runs from top to bottom. The sludge is arranged in parallel with a certain distance apart, and the sludge is gradually transferred to the third conveyor belt 32 and the fourth conveyor belt 33 from the feeding end of the second conveyor belt 31 along the broken line track by gravity, and finally flows out from the outlet of the fourth conveyor belt 33. , the motor 9 is connected to the regulator 8 circuit.

[0044]The feed end of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com