Spraying device for supplementary coating of rivet of easy-open cover and spraying method of spraying device

The technology of spraying device and easy-opening cover is applied to the device for coating liquid on the surface, conveyor control device, coating and other directions, which can solve the problem of the disclosure of drying device and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

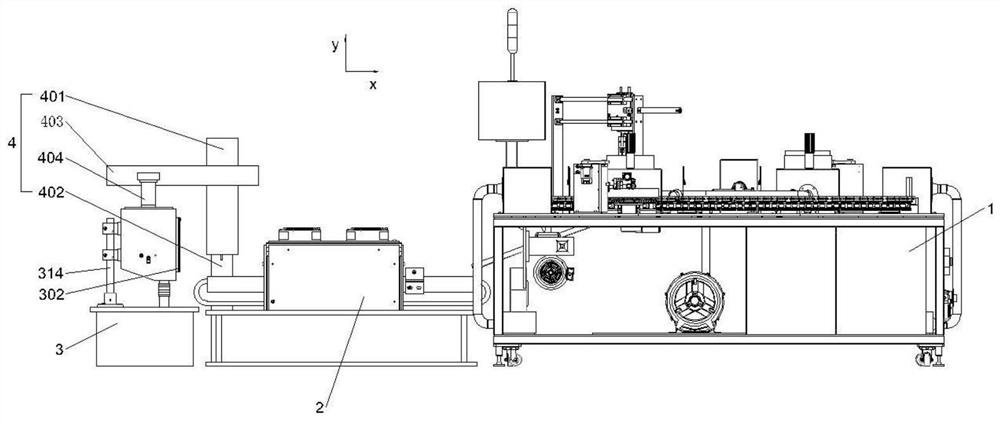

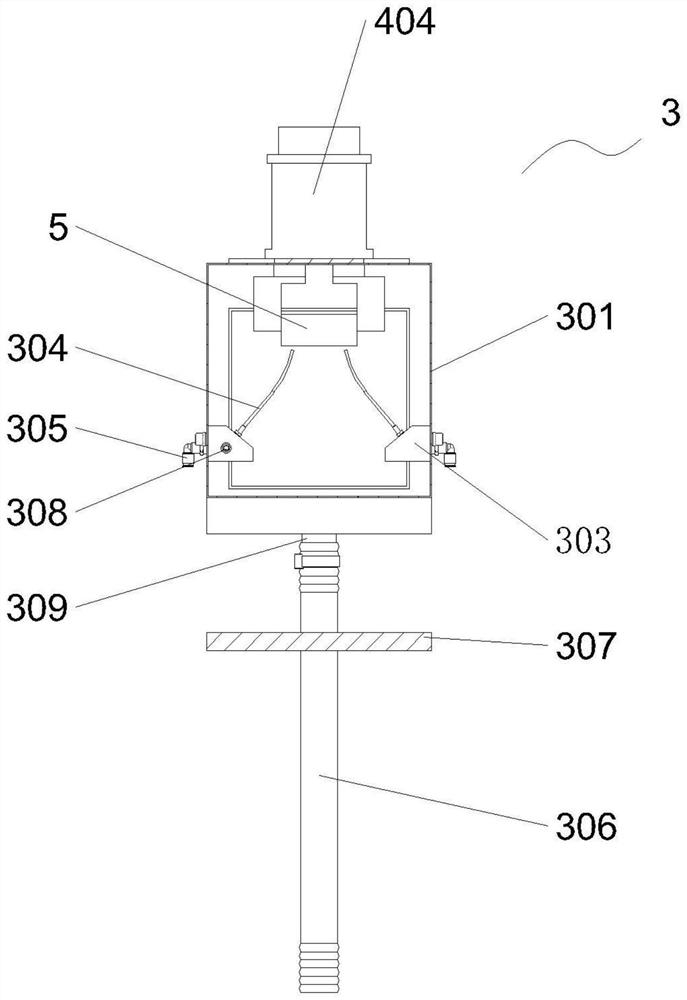

[0035] like figure 1 As shown, the present invention provides a spraying device for repairing rivets with an easy-open cover, comprising a repairing machine 1, a preliminary air-drying conveying device 2 installed at the outlet end of the repairing machine 1, and a drying device 3 installed at the outlet end of the preliminary air-drying conveying device 2, The grabbing device 4 installed on one side of the drying device 3 is used to grab the workpiece 5 from the preliminary air-drying conveying device 2 into the drying device 3 . The repairing machine 1 is in the prior art, and is not the technical problem solved by the present invention, so it will not be described in detail.

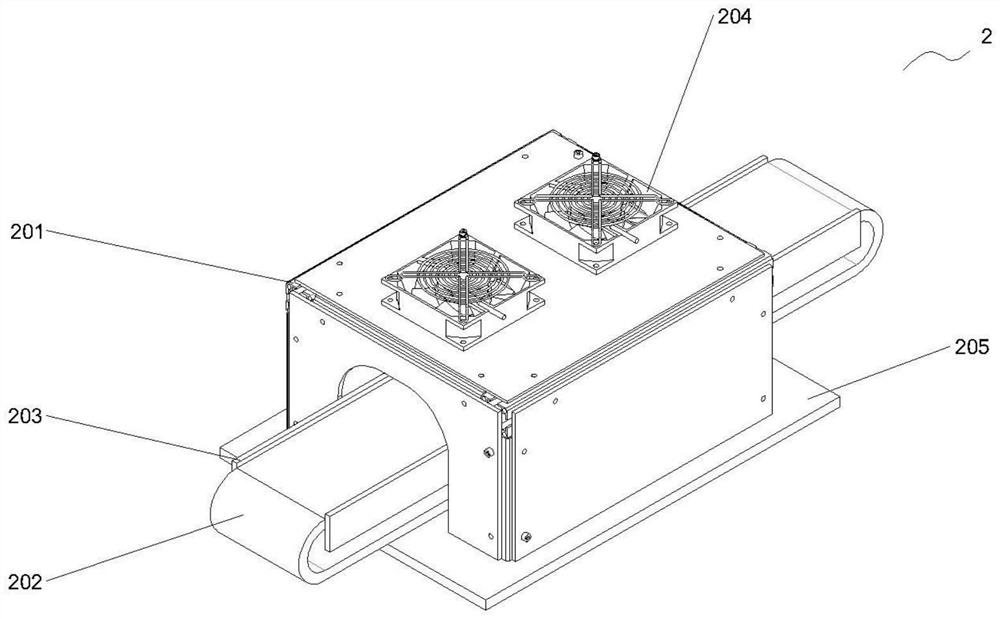

[0036] Please refer to figure 2 , the preliminary air-drying conveying device 2 includes a bottom plate 205, a conveying unit 202 installed on the bottom plate 205, side rails 203 installed on both sides of the conveying unit 202, and an air collecting frame 201 covering the conveying unit 202. The...

Embodiment 2

[0053] like Figure 5 As shown, the spraying device also includes an indexing device 6 located between the drying device 3 and the preliminary air-drying conveying device 2, and the grabbing device 4 is used to grab the workpiece 5 from the indexing device 6 into the drying unit 3.

[0054] Since the positions of the workpieces 5 are different when they reach the preliminary air-drying conveying device 2 , the indexing device 6 is used to facilitate the grasping device 4 to grasp the workpiece 5 to reach the drying device 3 .

[0055] Please refer to Figures 6 to 7 , the indexing device 6 includes a plate 601, a base 602 installed in the middle of the plate 601, a worktable 603 is movably installed on the base 602 through a bearing 604, and a groove 608 is evenly provided on the worktable 603 for resting The workpiece 5, the deceleration device 606 and the stop device 607 respectively located on both sides of the base 602 and mounted on the plate 601, and the sensing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com