Patents

Literature

34results about How to "Avoid Sealing Defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

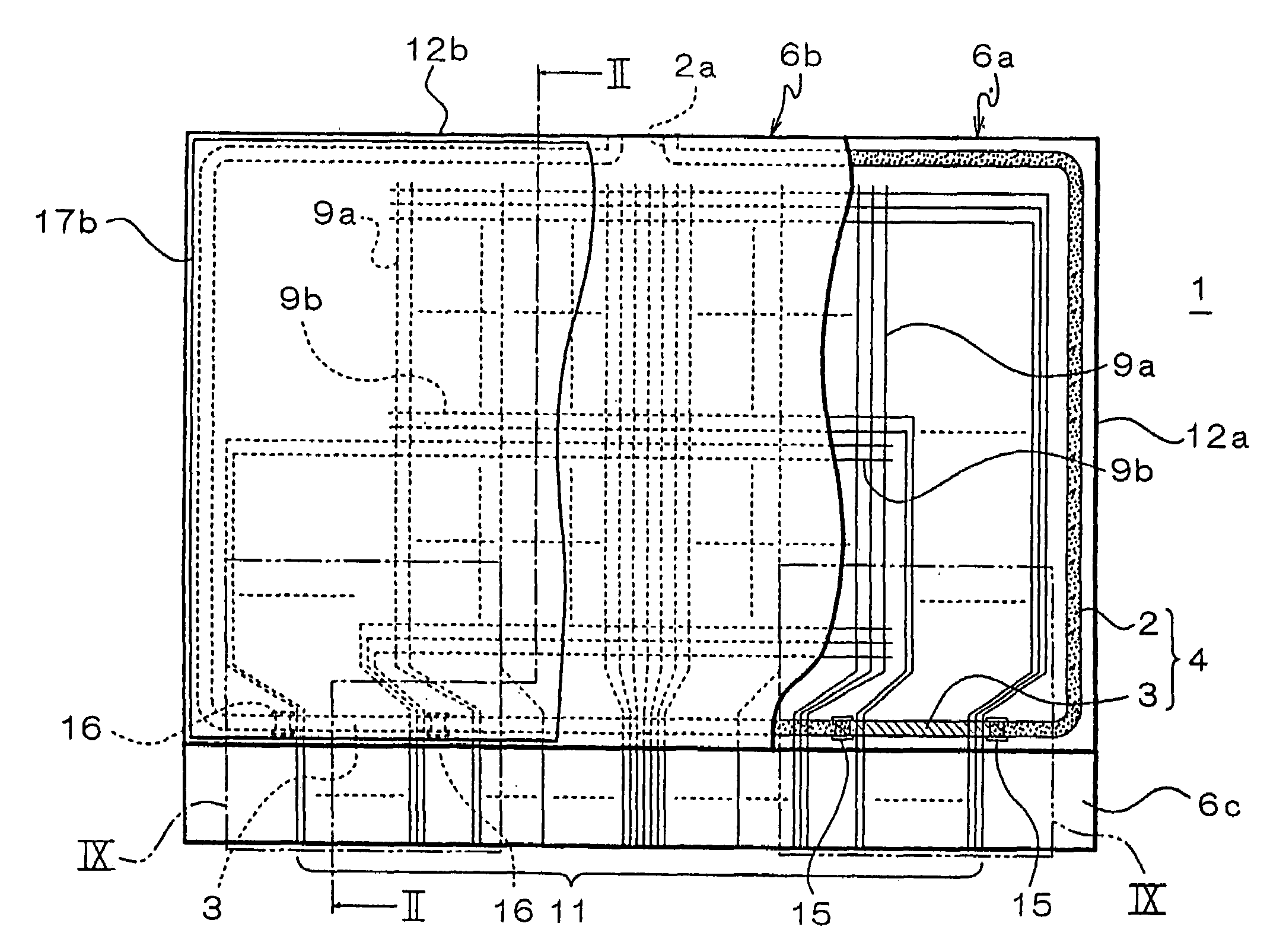

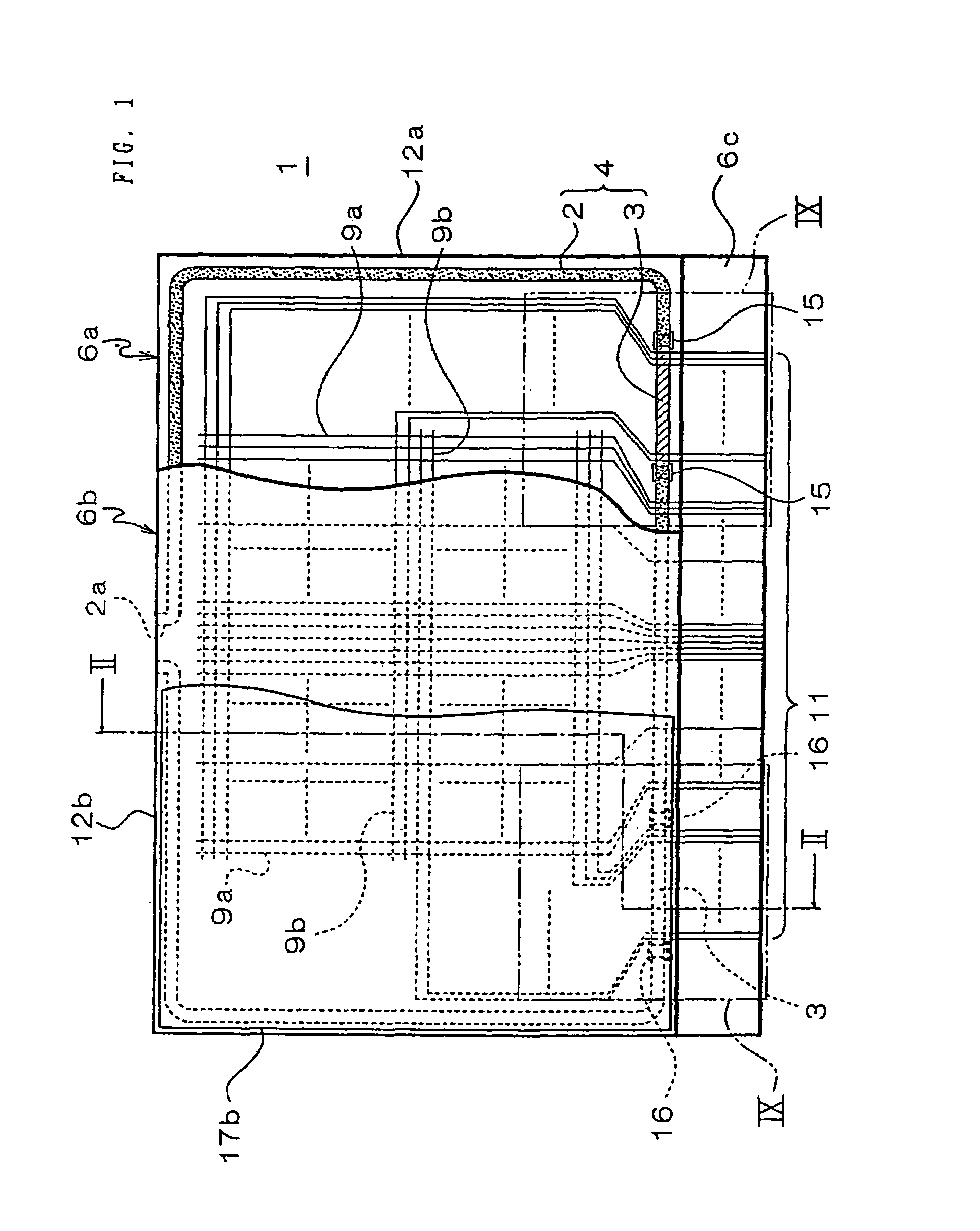

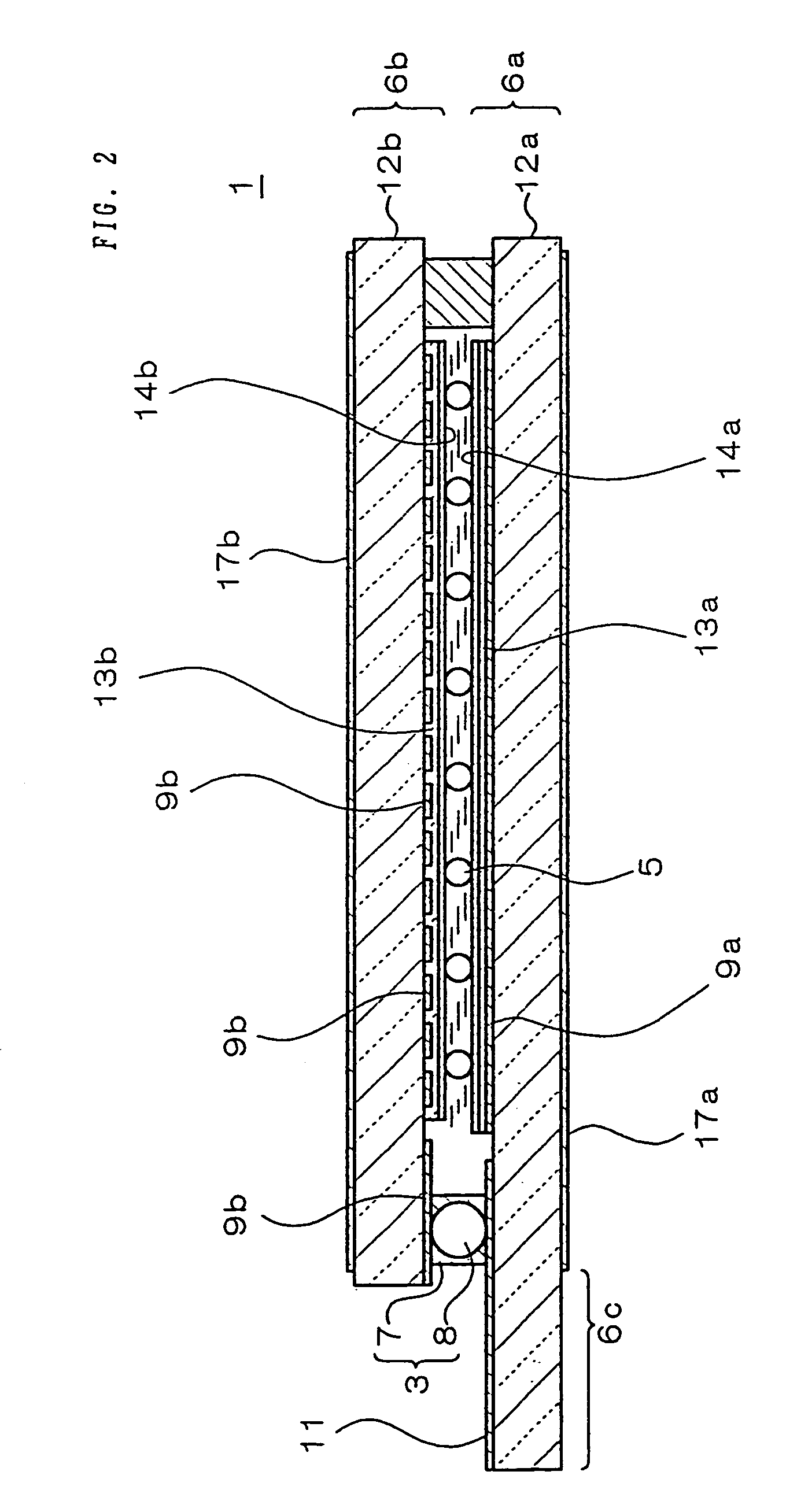

LCD and method of manufacture thereof

InactiveUS6930745B1Precise positioningAvoid Sealing DefectsNon-linear opticsConductive materialsMaterials science

Owner:BOE TECH GRP CO LTD

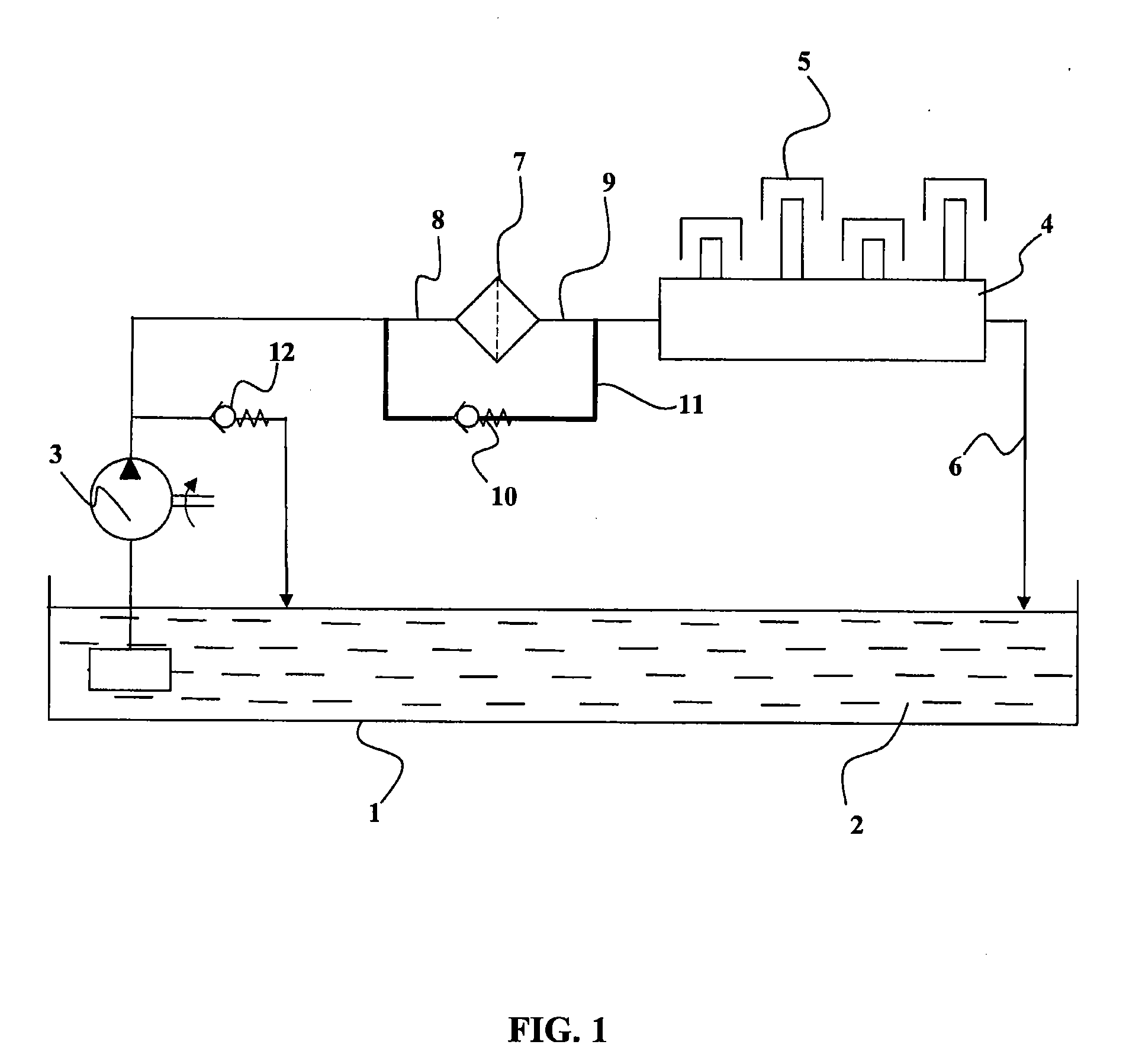

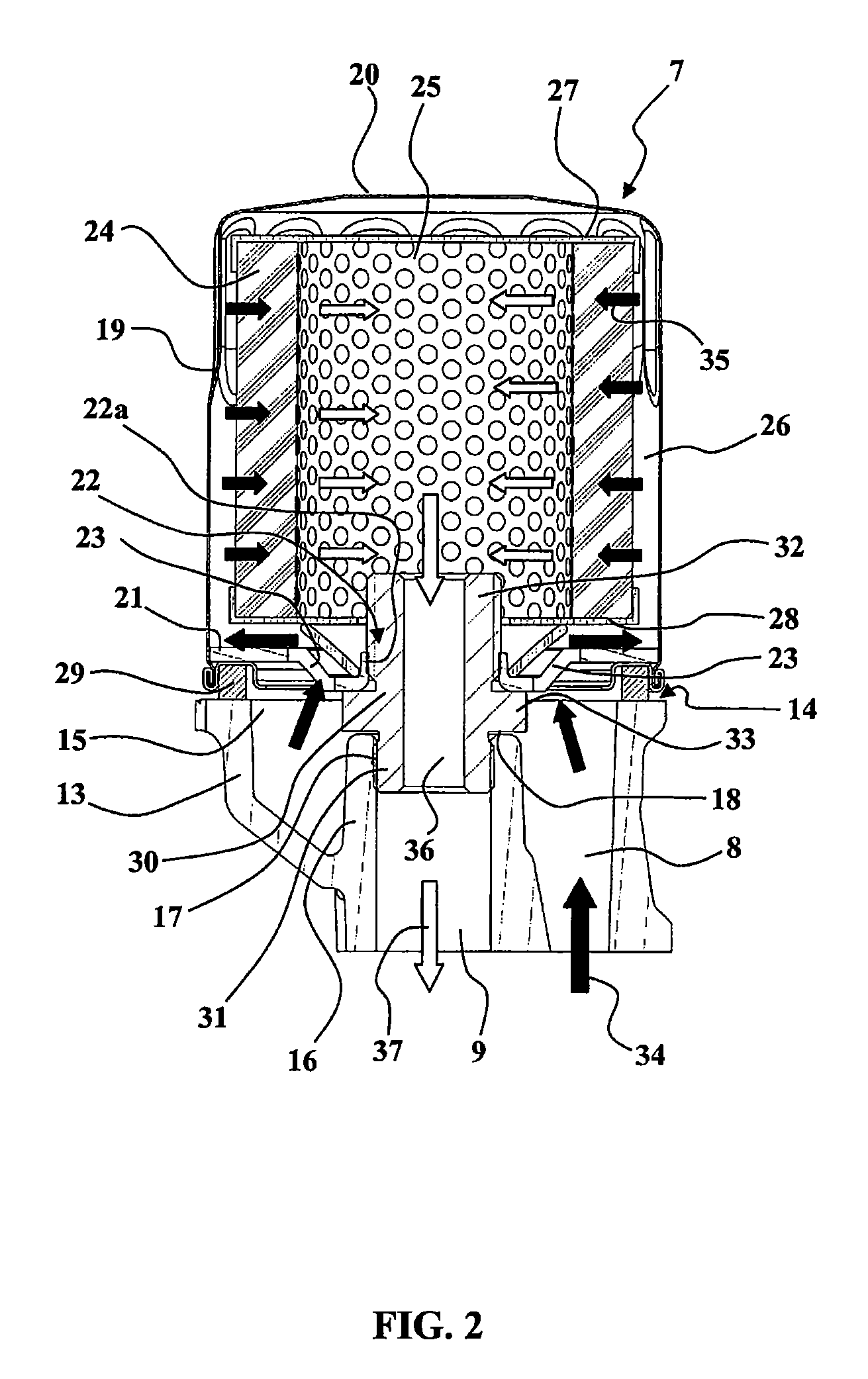

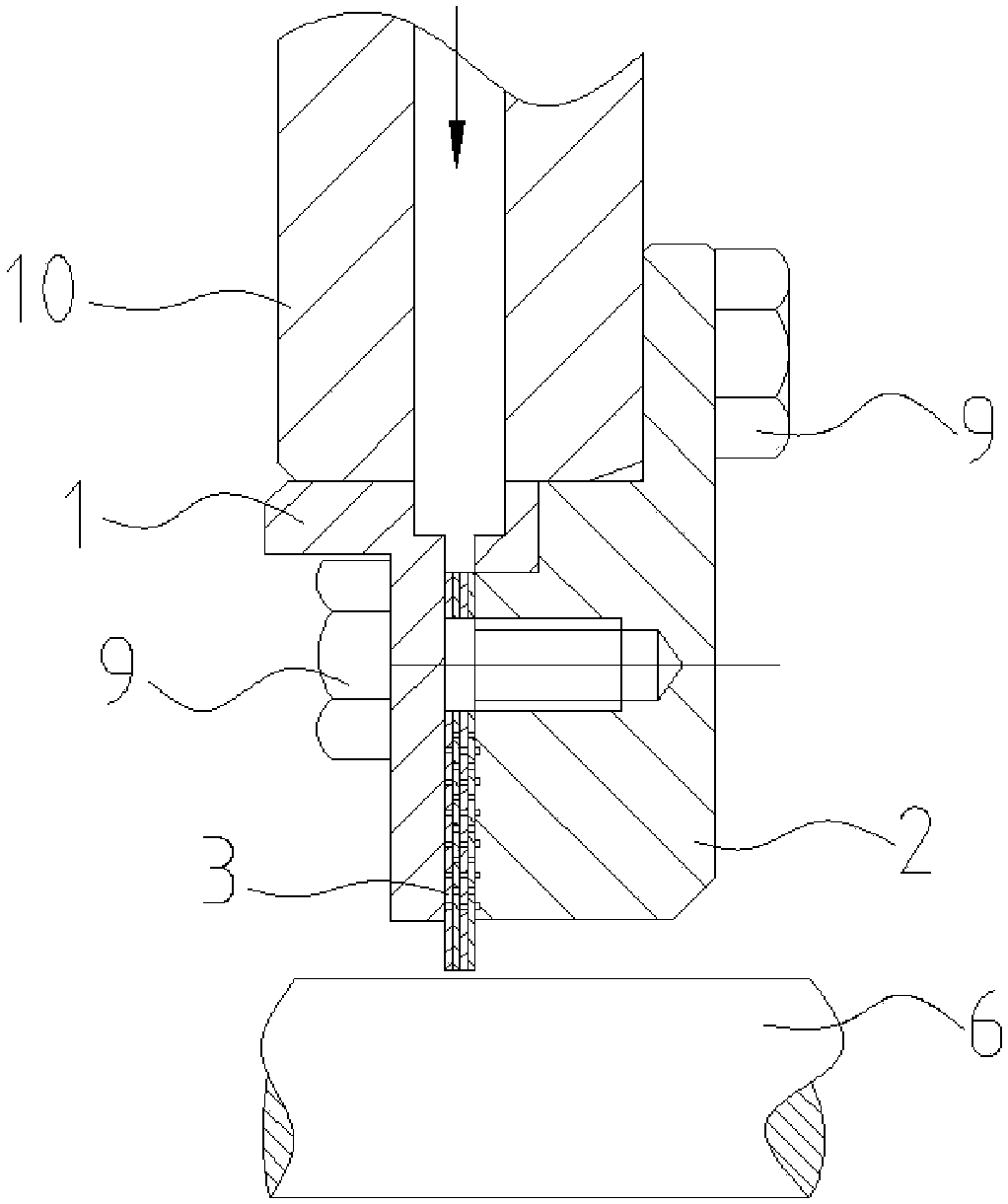

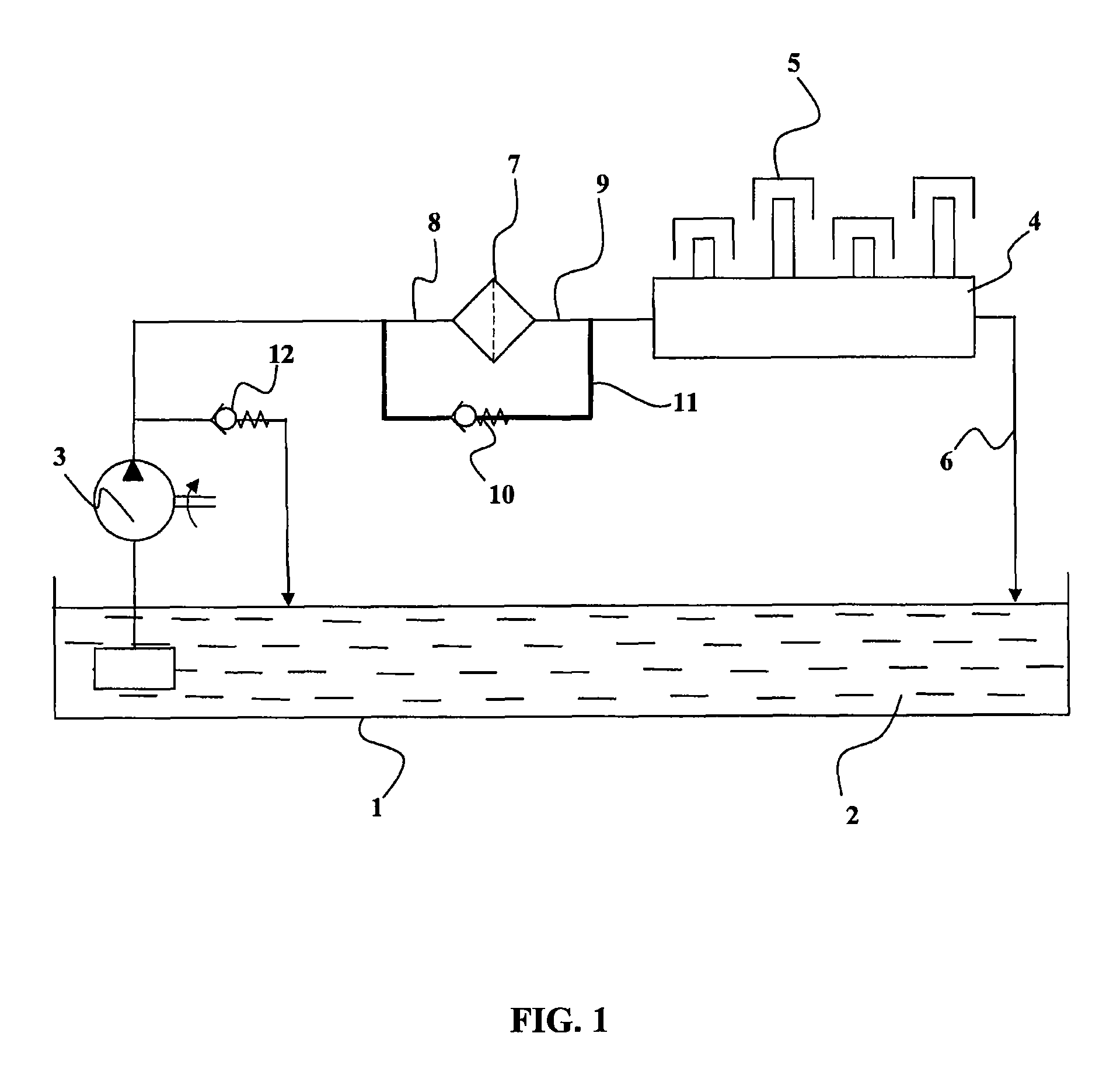

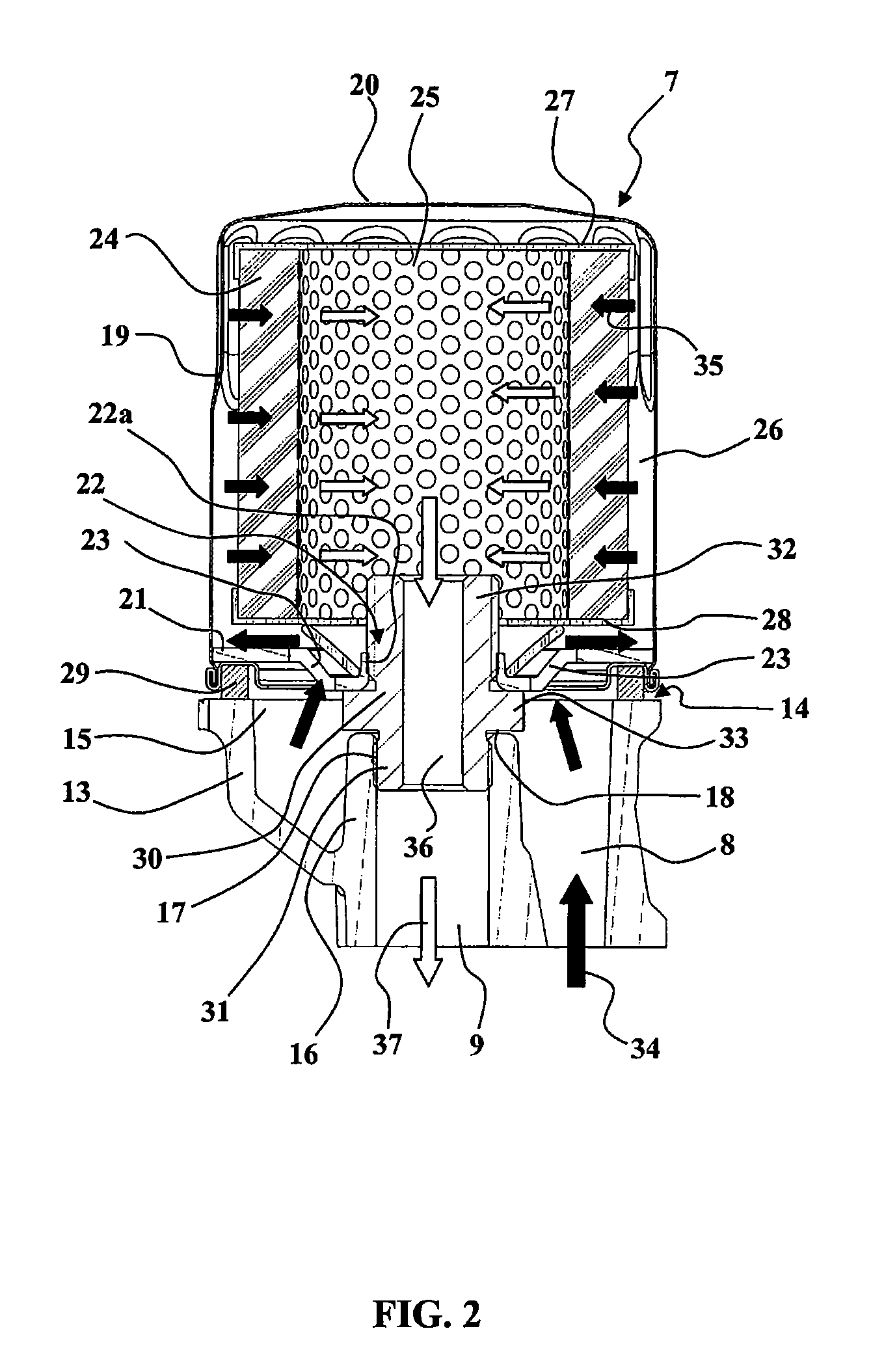

Oil bypass device, and engine fitted with such a device

ActiveUS20080083664A1Improve reliabilityAvoid risk of failurePipe heating/coolingLubricant conduit arrangementsPressure riseEngineering

According to the invention, the filter is fixed to the engine block by screwing it to an attached connecting sleeve. The connecting sleeve contains a bypass valve, in the form of a tubular piston sliding in a through-passage and pushed against an intermediate shoulder by a spring. By sliding, the piston opens or closes a radial passage establishing direct communication between the inlet passage and the through-passage of the device. If the filter element of the filter is clogged, the pressure rise in the inlet passage causes the piston to move and the radial passage to open to reduce the pressure rise and ensure a satisfactory flow of oil. This reduces pressure rises upstream of the filter and ensures sufficient lubrication of the engine even in the case of clogging of the filter.

Owner:BONTAZ CENT

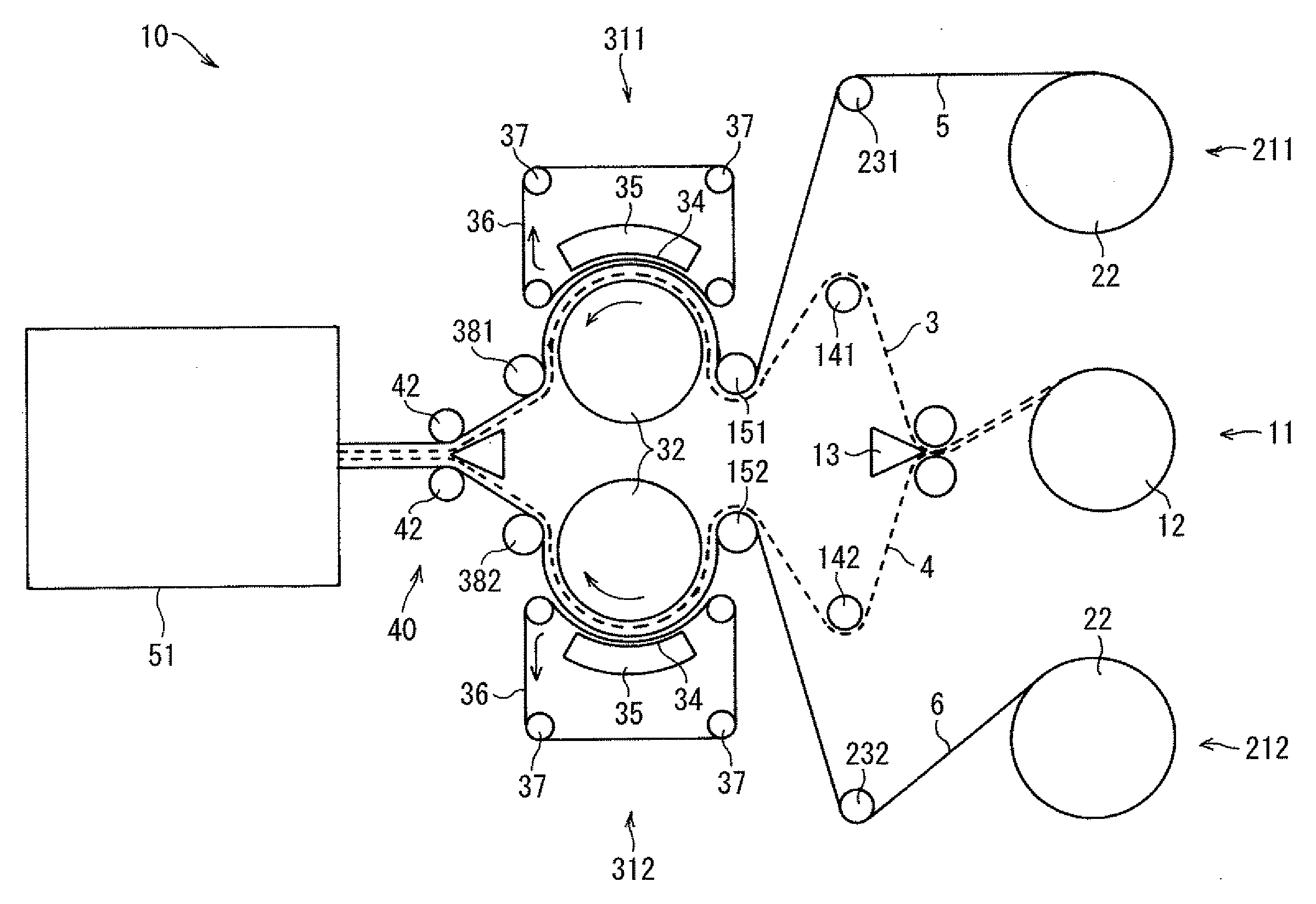

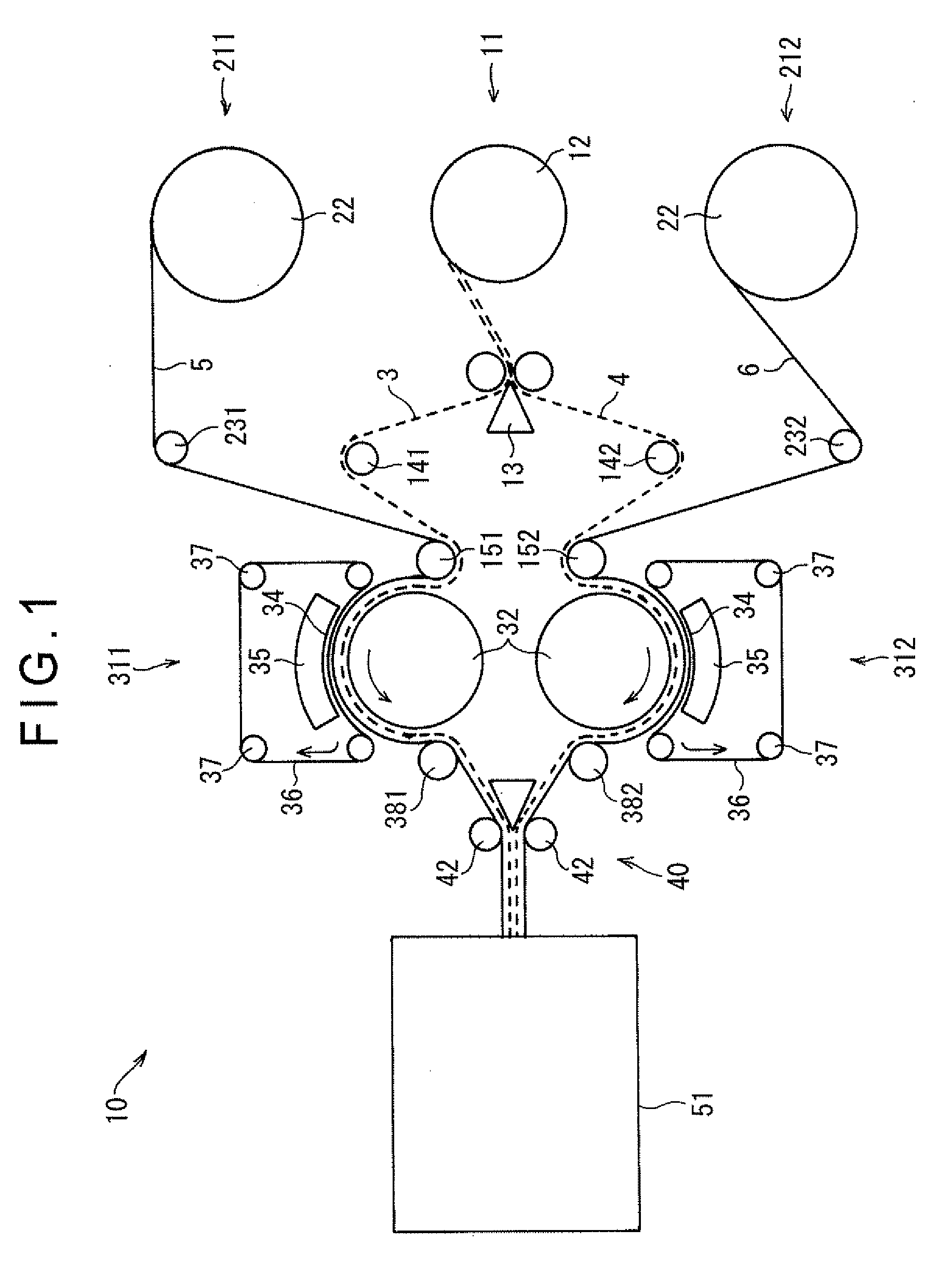

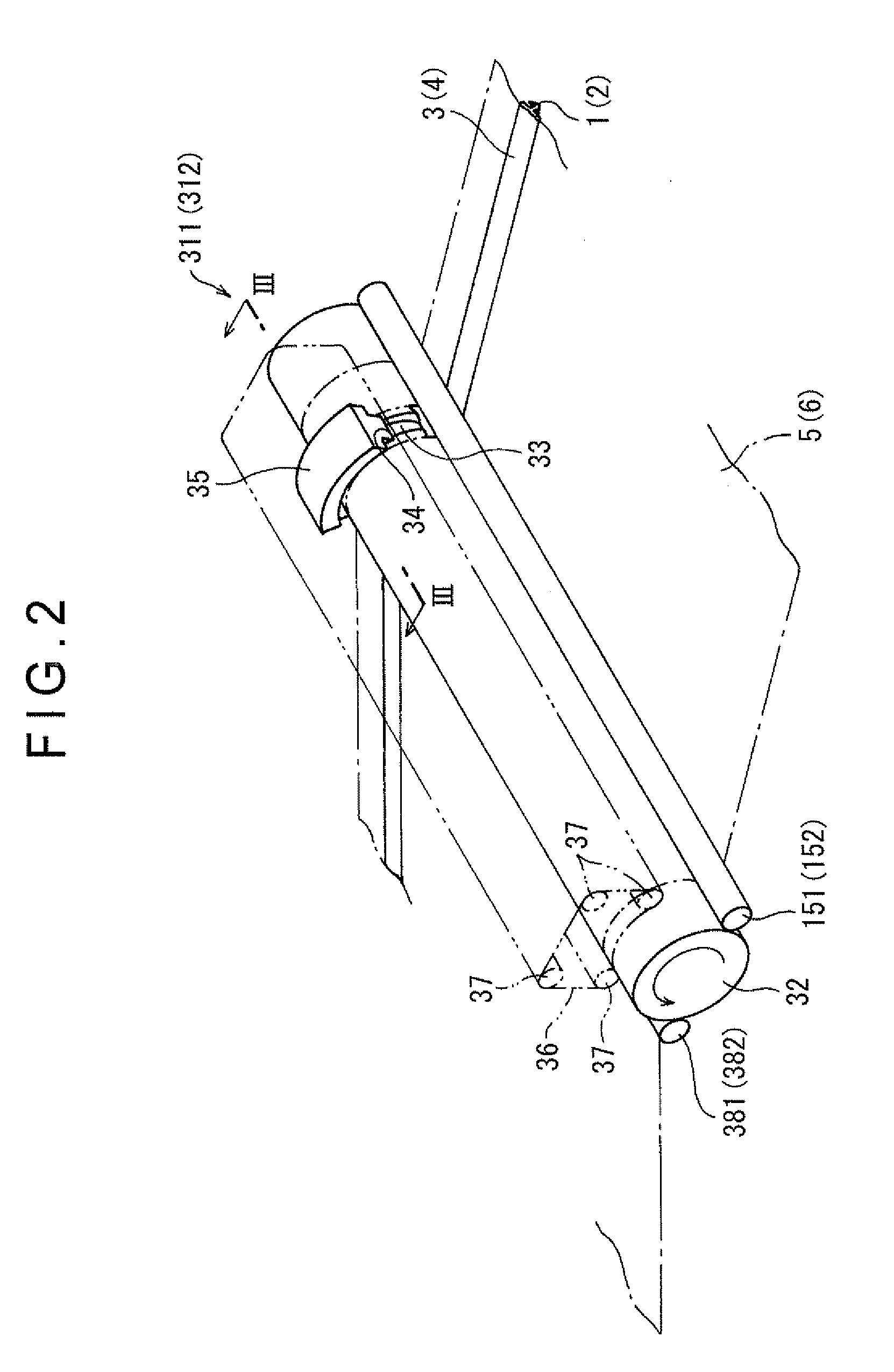

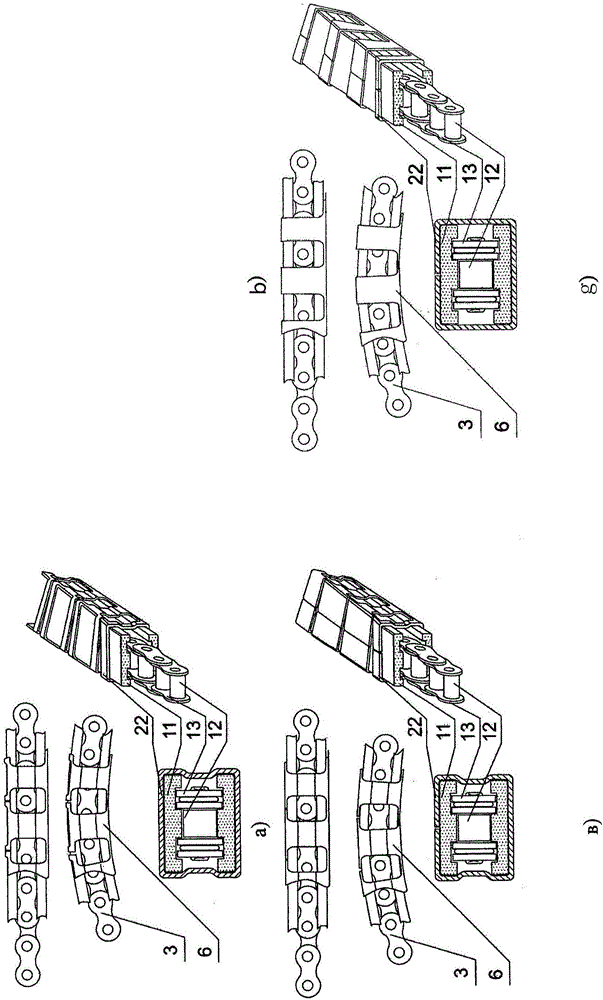

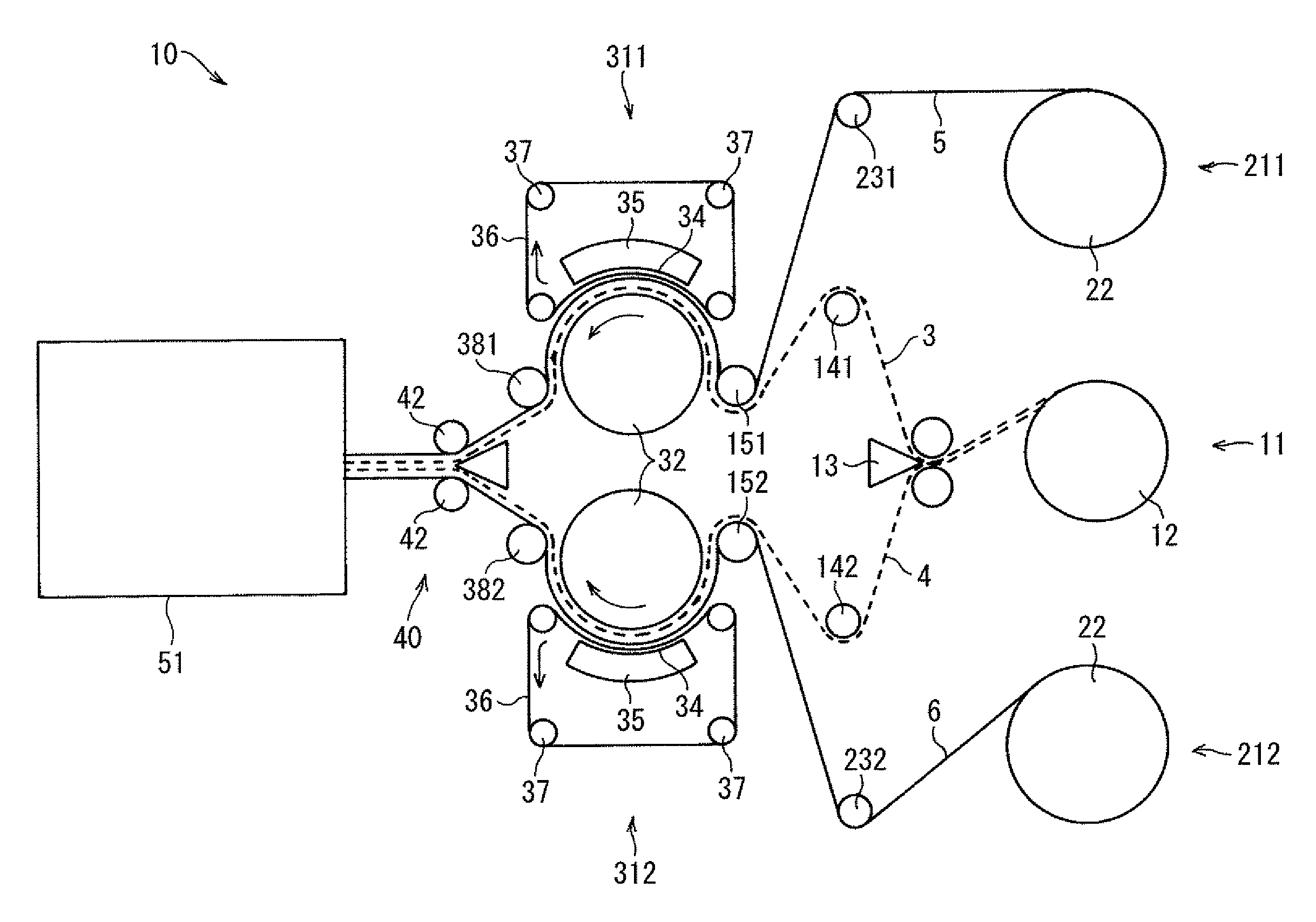

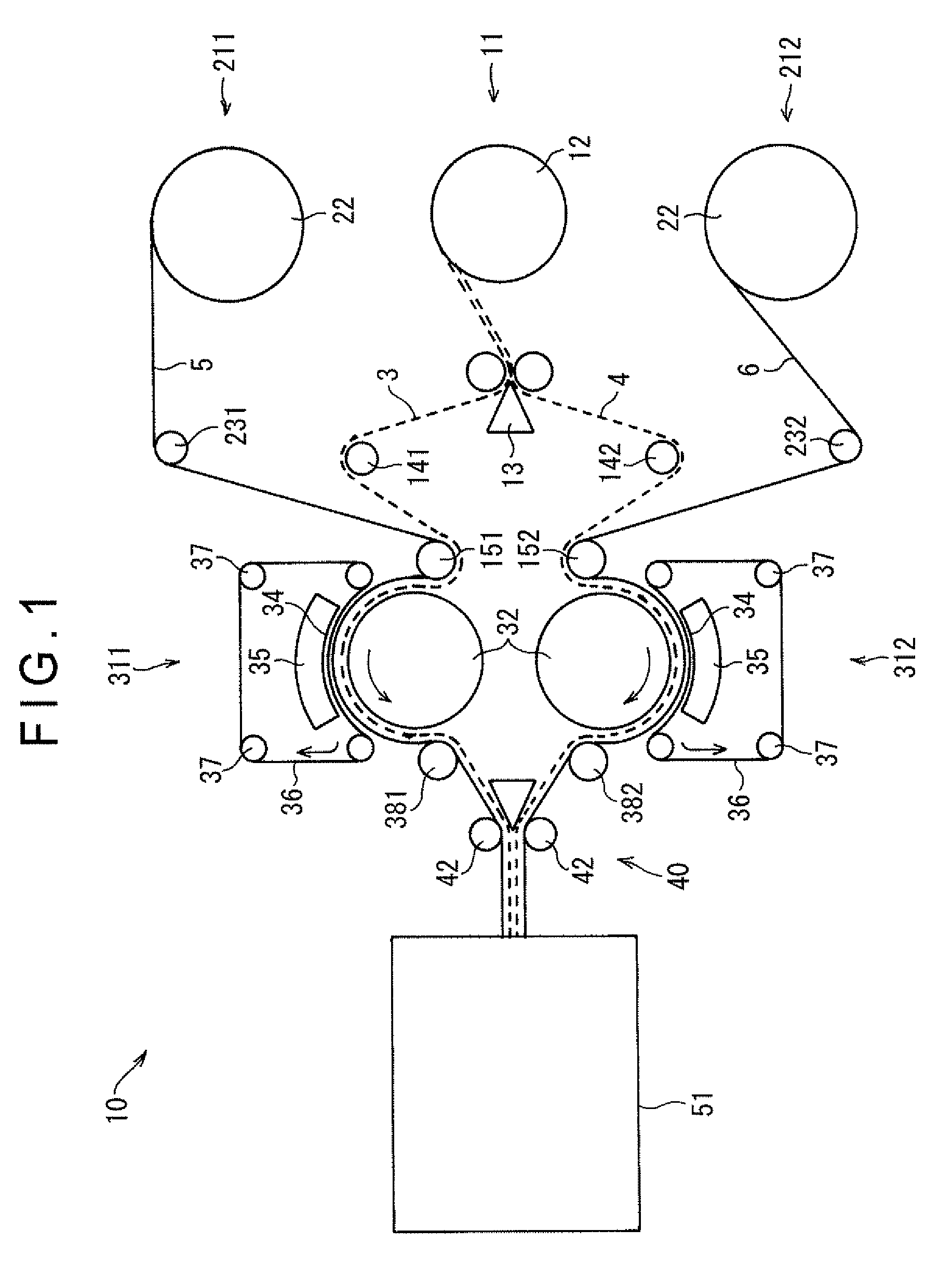

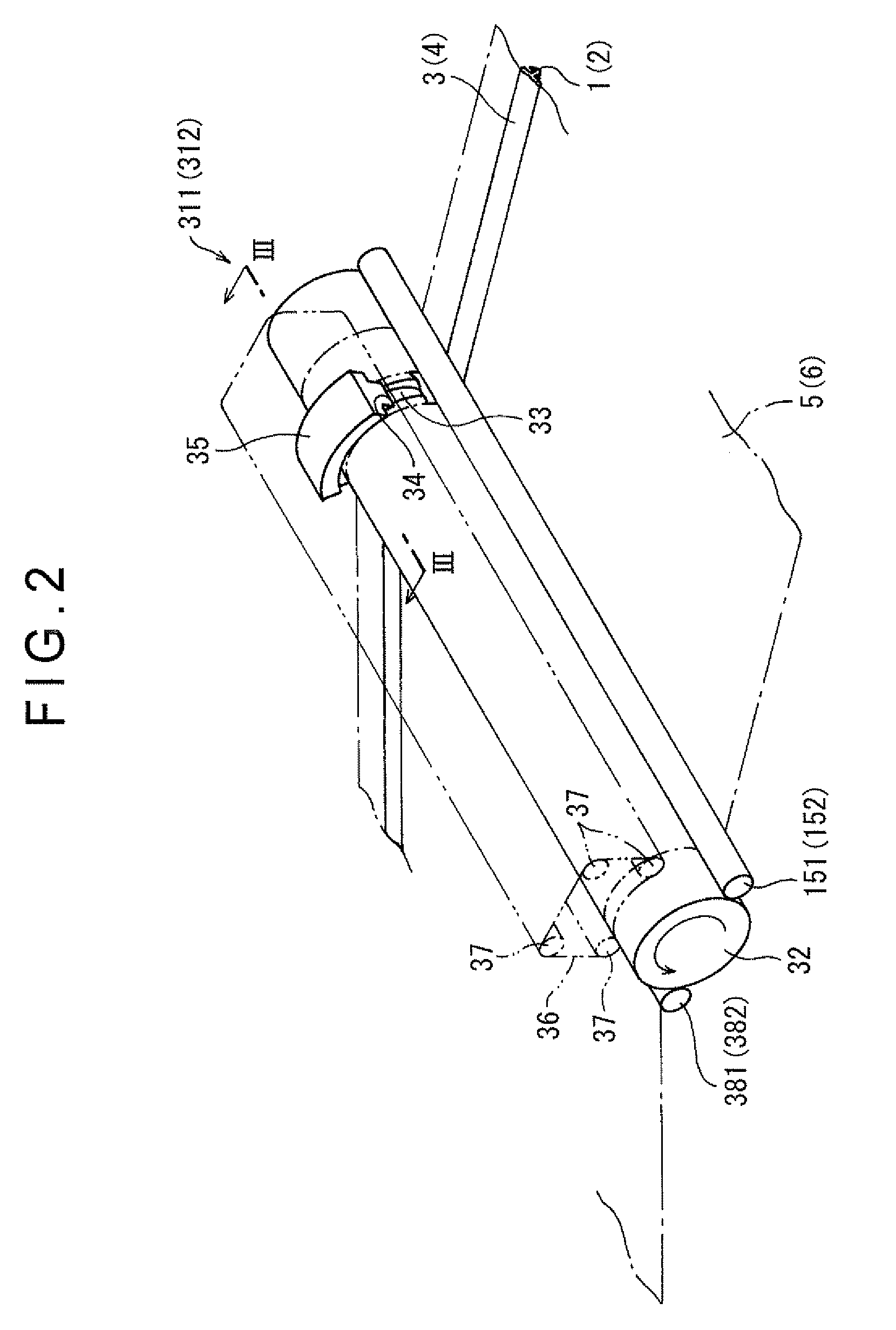

Method and Device for Manufacturing Bag with Clamping Device

ActiveUS20090005228A1Inhibit transferAvoid Sealing DefectsEnvelopes/bags making machineryMechanical working/deformationEngineeringMechanical engineering

A tape 3, 4 with a zipper member and a bag film 5,6 are continuously moved by rotation of a rotary drum 32 while being overlaid with each other such that the tape 3, 4 travels in a tape introducing groove 33 for a tape with a zipper member, the groove formed along a circumferential direction of the rotary drum 32. The tape 3, 4 with the zipper member is continuously welded to the bag film 5, 6 on a circumferential surface of the rotary drum 32 by a seal bar 35 that has a welding surface 34 in a curved shape corresponding to a circumferential surface shape of the rotary drum 32. The whole tape 3, 4 with the zipper member is accommodated in the tape introducing groove 33 for the tape with the zipper member and a seal surface of a tape body 31, 41 is adapted to be substantially flush with the circumferential surface of the rotary drum 32, so that heat applied from the seal bar 35 to the tape 3, 4 with the zipper member is restrained from transferring to the rotary drum 32.

Owner:IDEMITSU UNITECH CO LTD

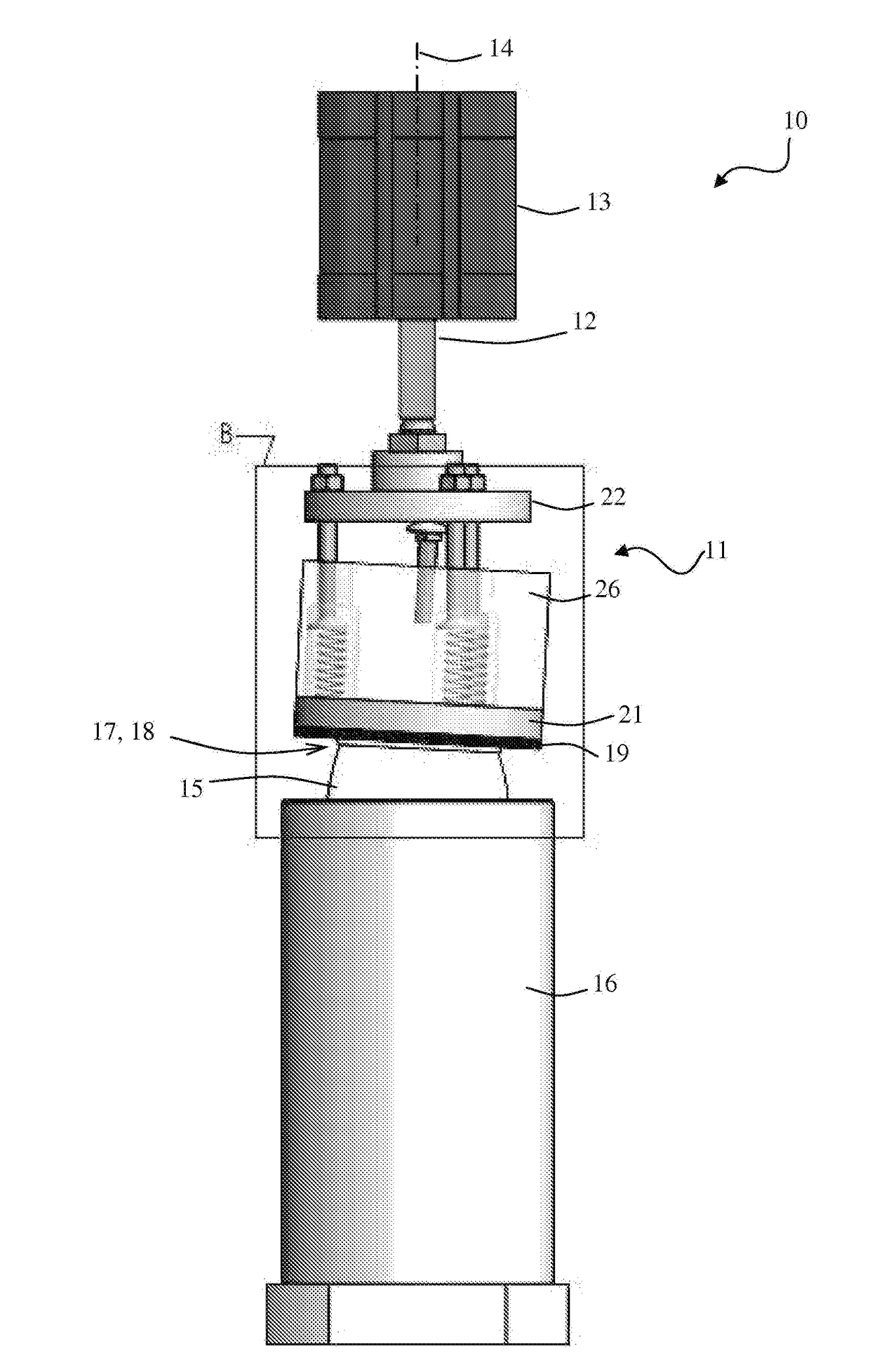

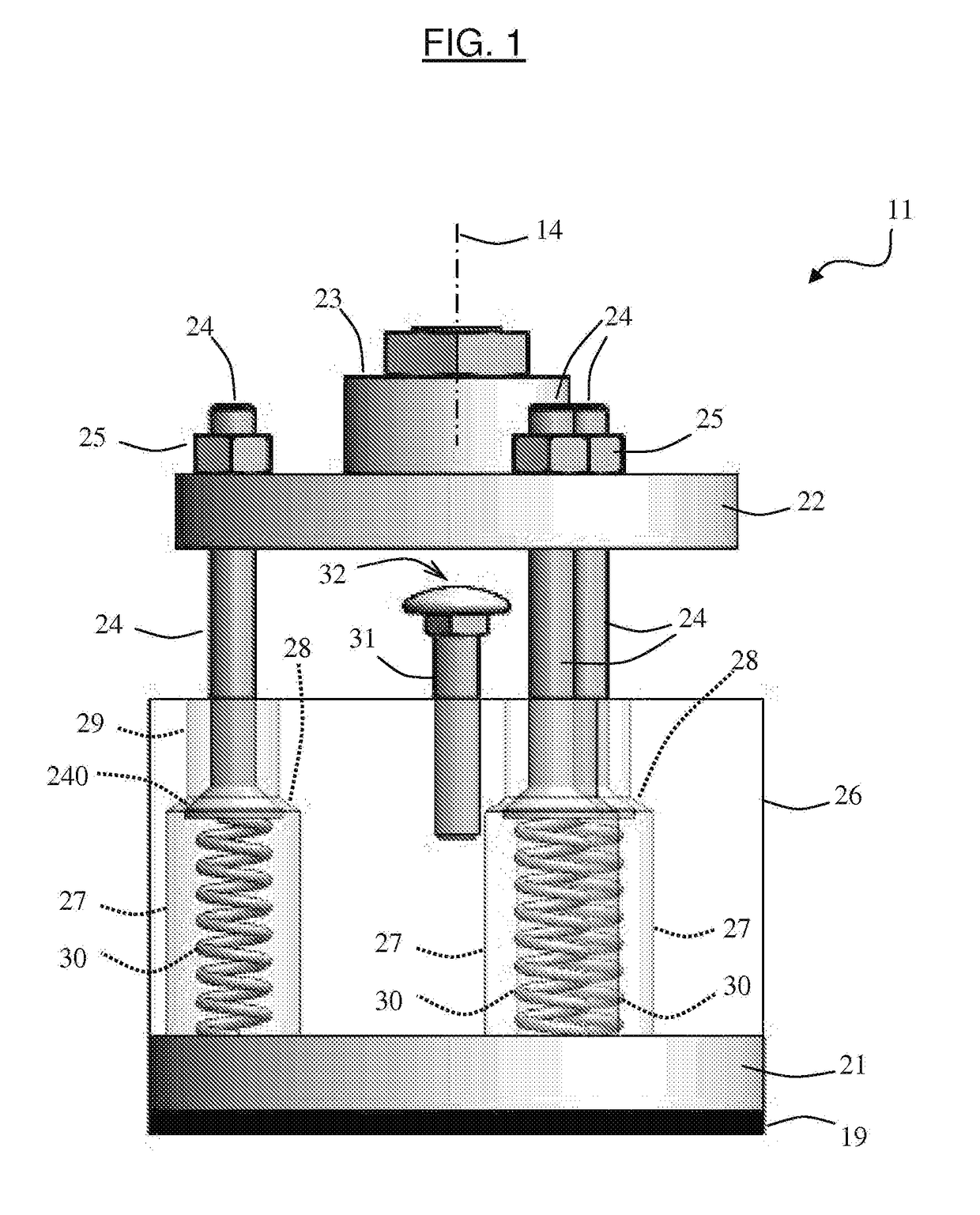

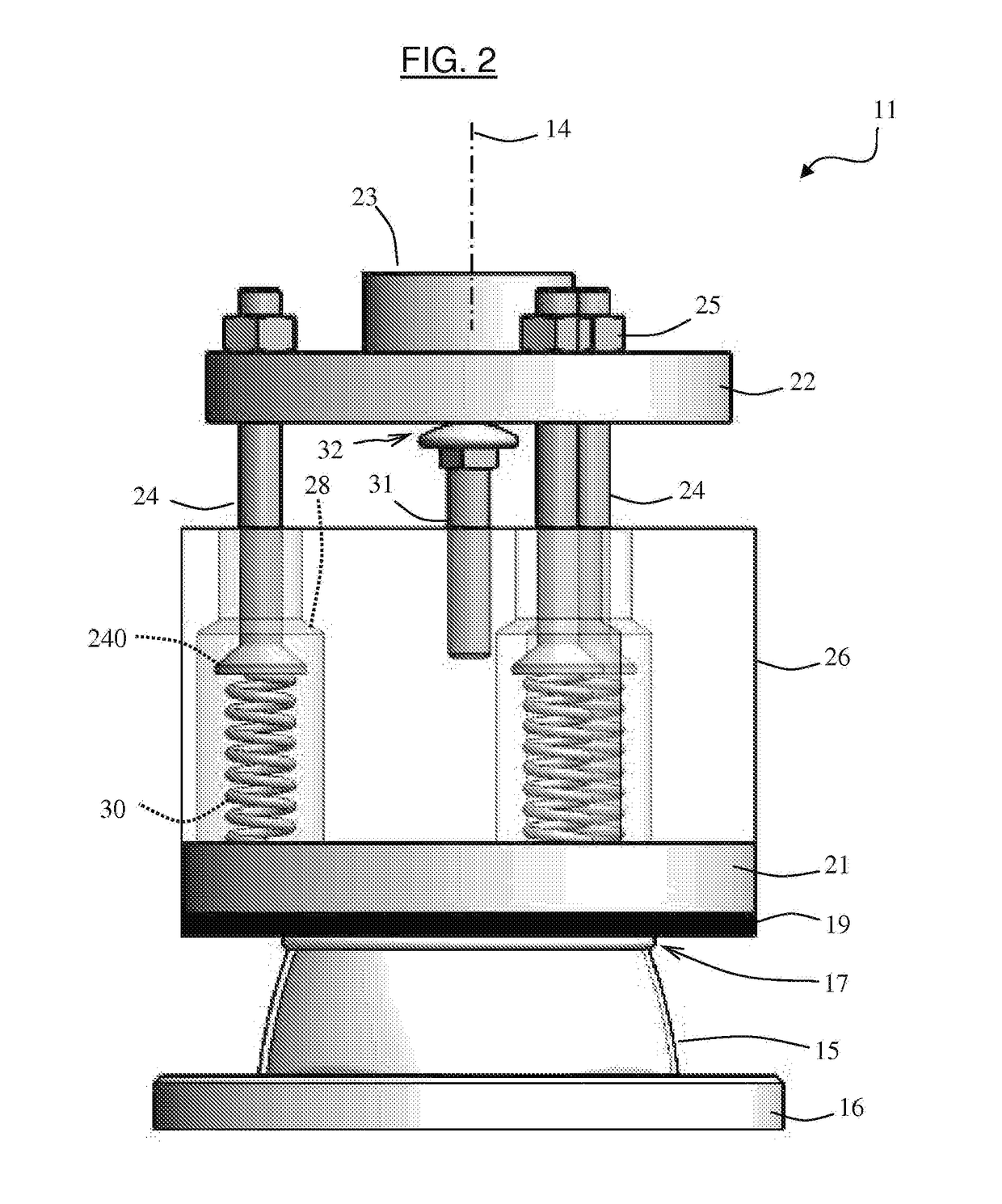

Method and device for heat-sealing a lid onto the rim of a glass

InactiveUS20170197741A1Avoid Sealing DefectsQuality improvementPackaging by pressurising/gasifyingWrapper twisting/gatheringActuatorThin membrane

The invention relates to a device for heat sealing a film lid placed on the rim of a glass, the device comprising a deformable and thermally conductive element designed to press against the film lid and the rim and to heat the film lid and the rim. A peripheral portion of the conductive element is arranged to extend beyond the rim. The device has means for hinging and suspending the conductive element, and means for transmitting a pressure force exerted by an actuator to the conductive element, which force transmission means are distinct from the means for hinging and suspending the conductive element.

Owner:1 4 VIN

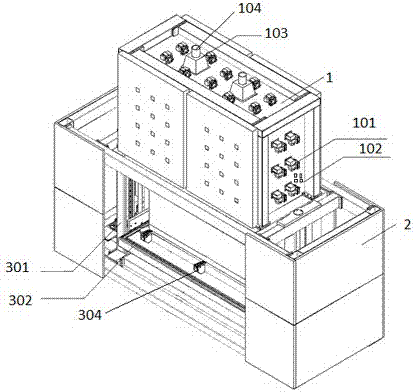

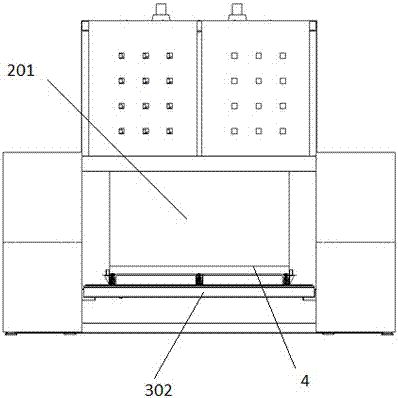

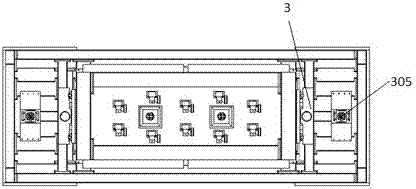

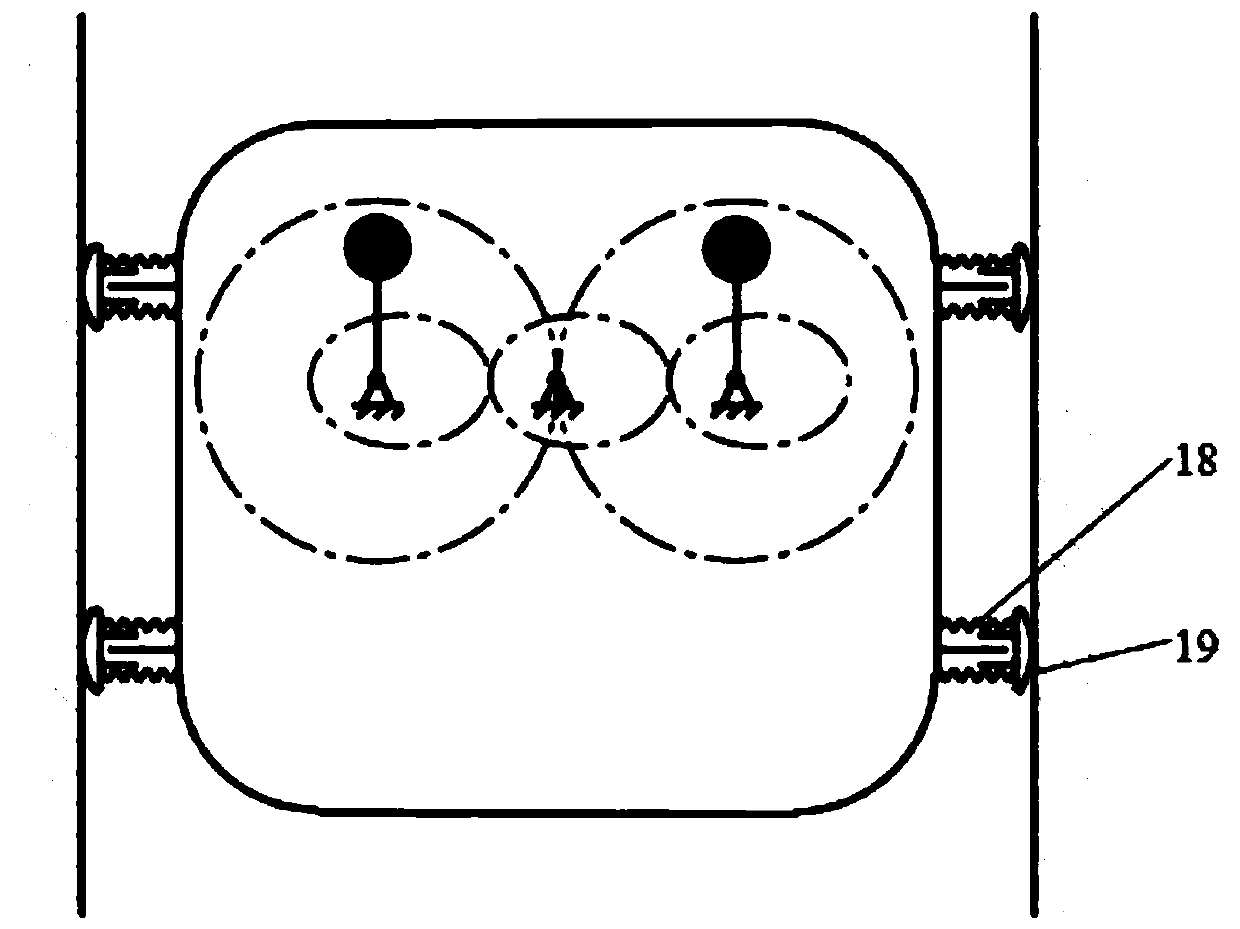

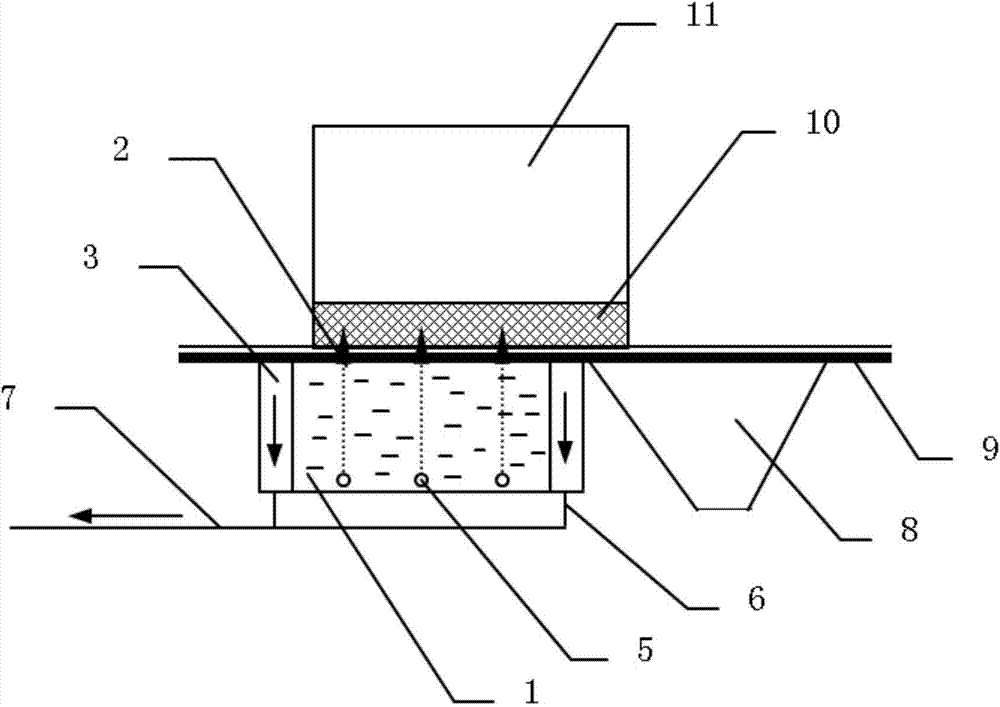

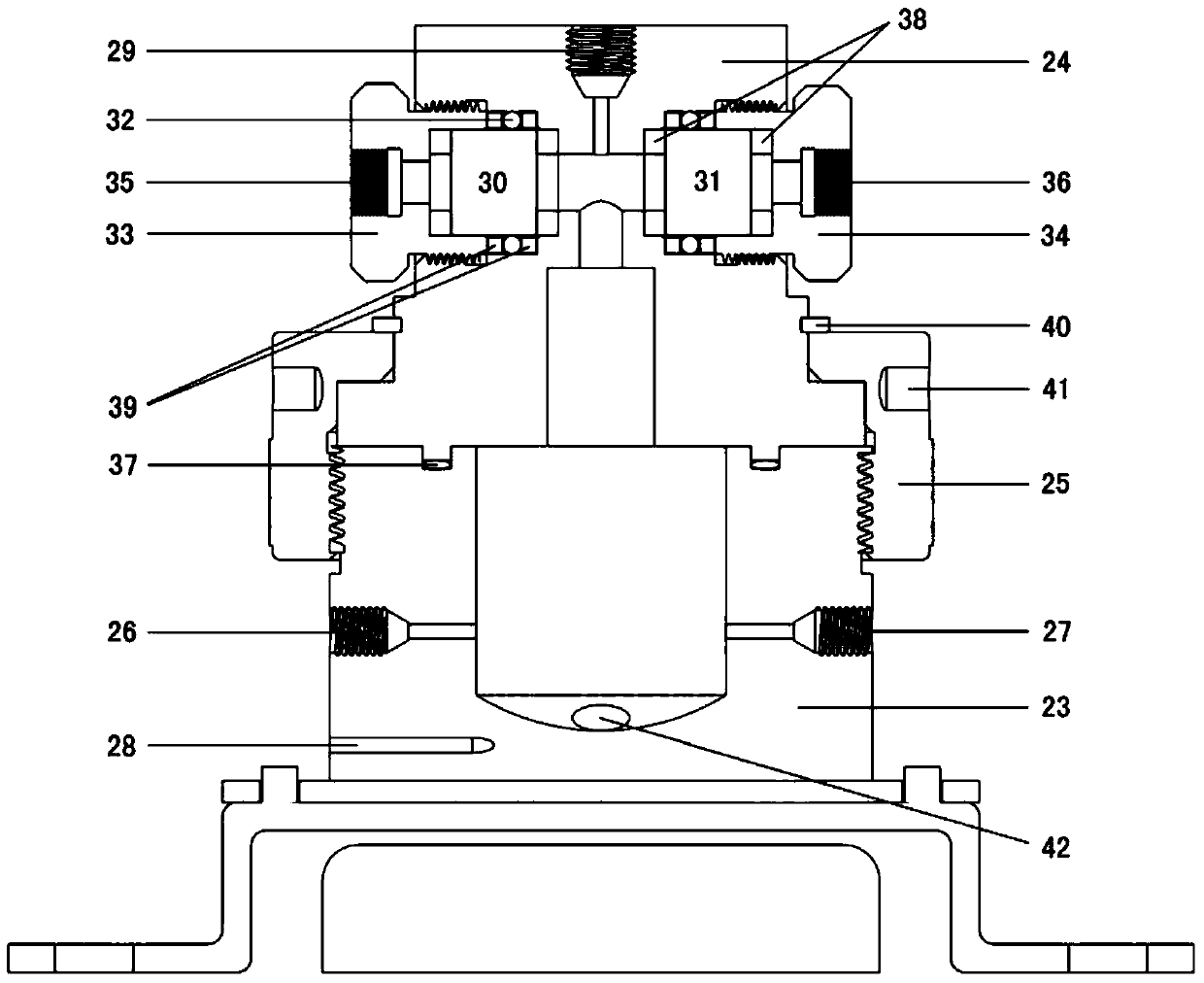

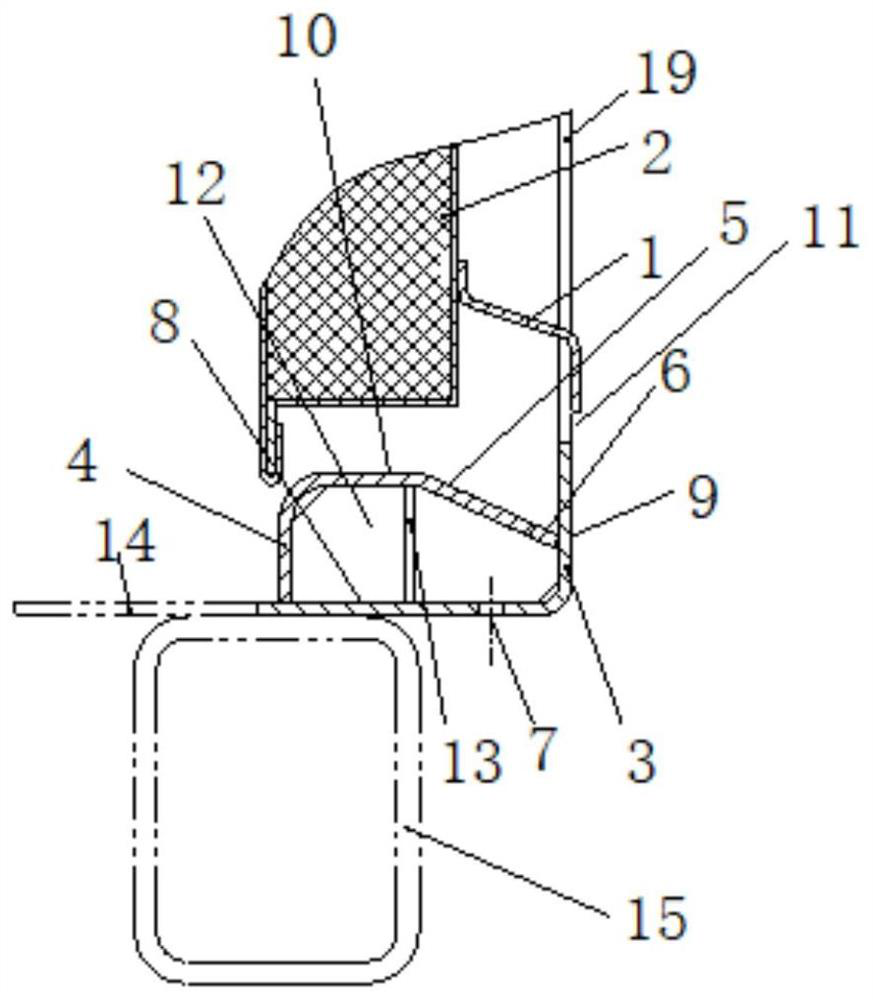

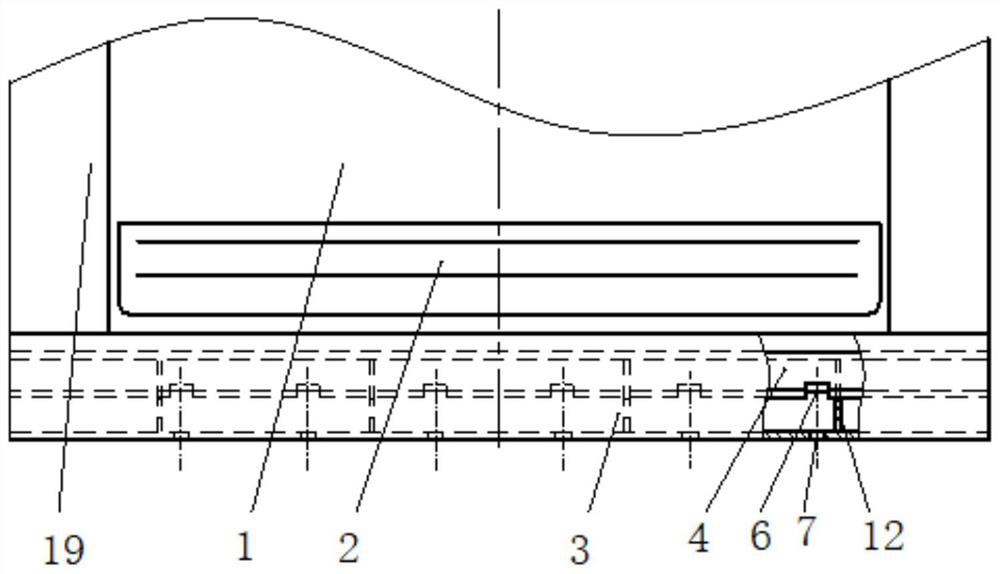

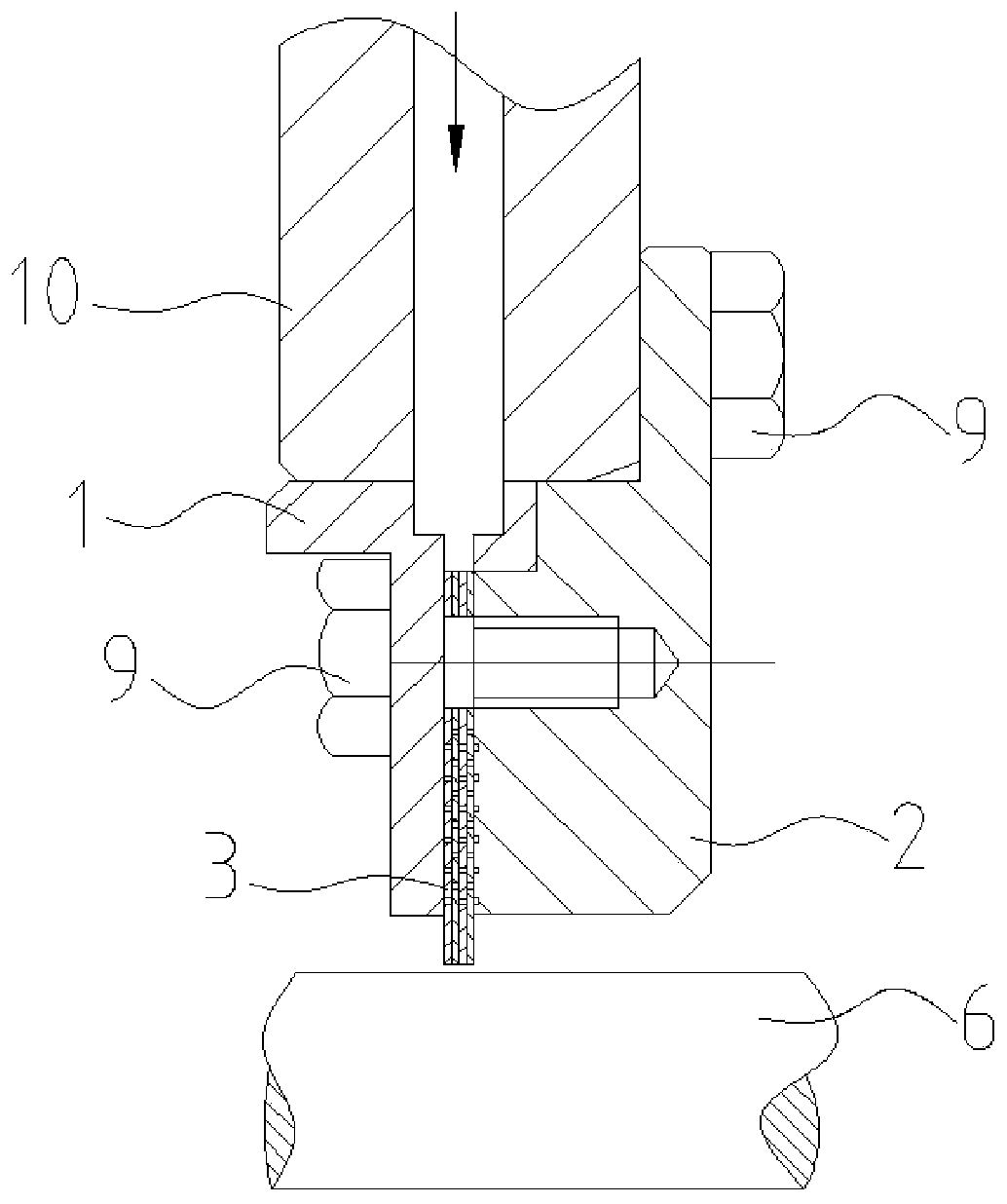

Jacking type sand core microwave drying device

InactiveCN108007096AAvoid Sealing DefectsPrevent leakageSand dryingDrying solid materials with heatMicrowaveEngineering

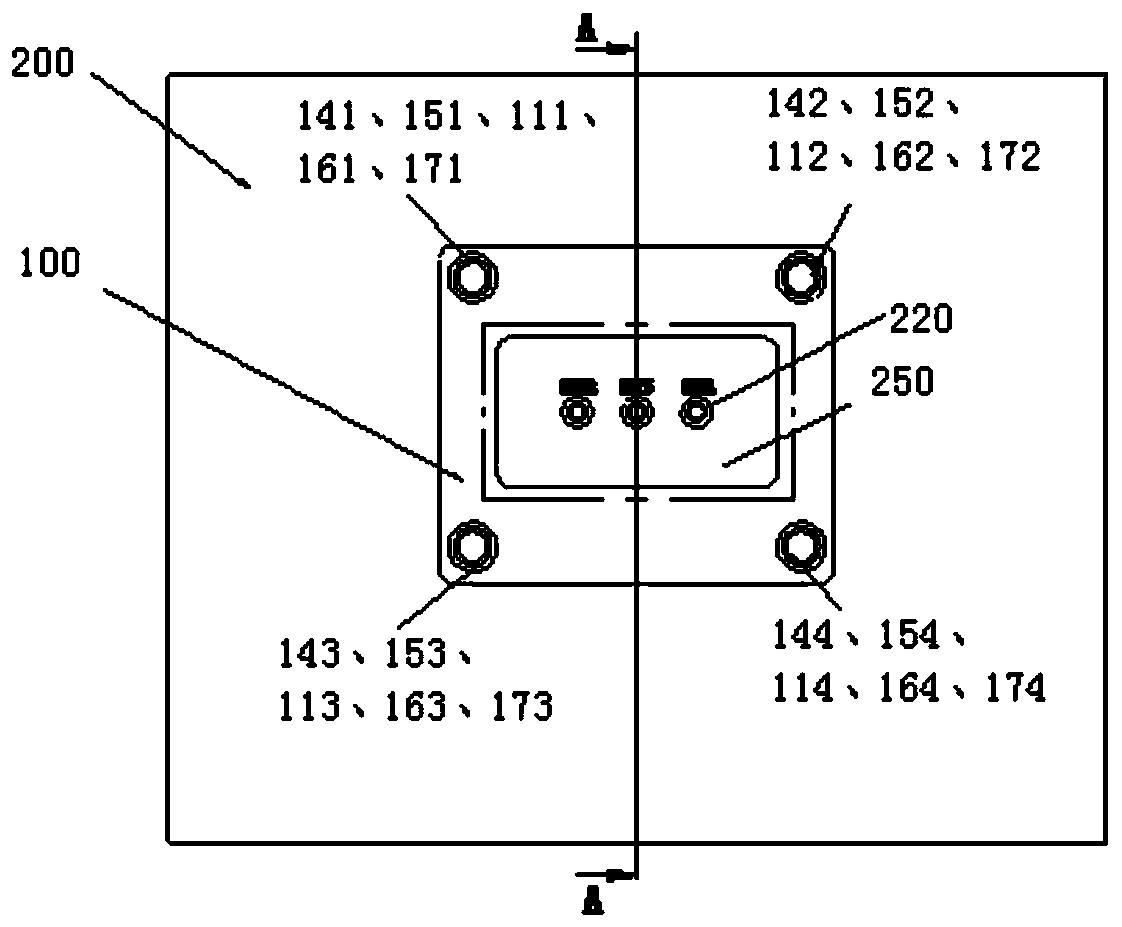

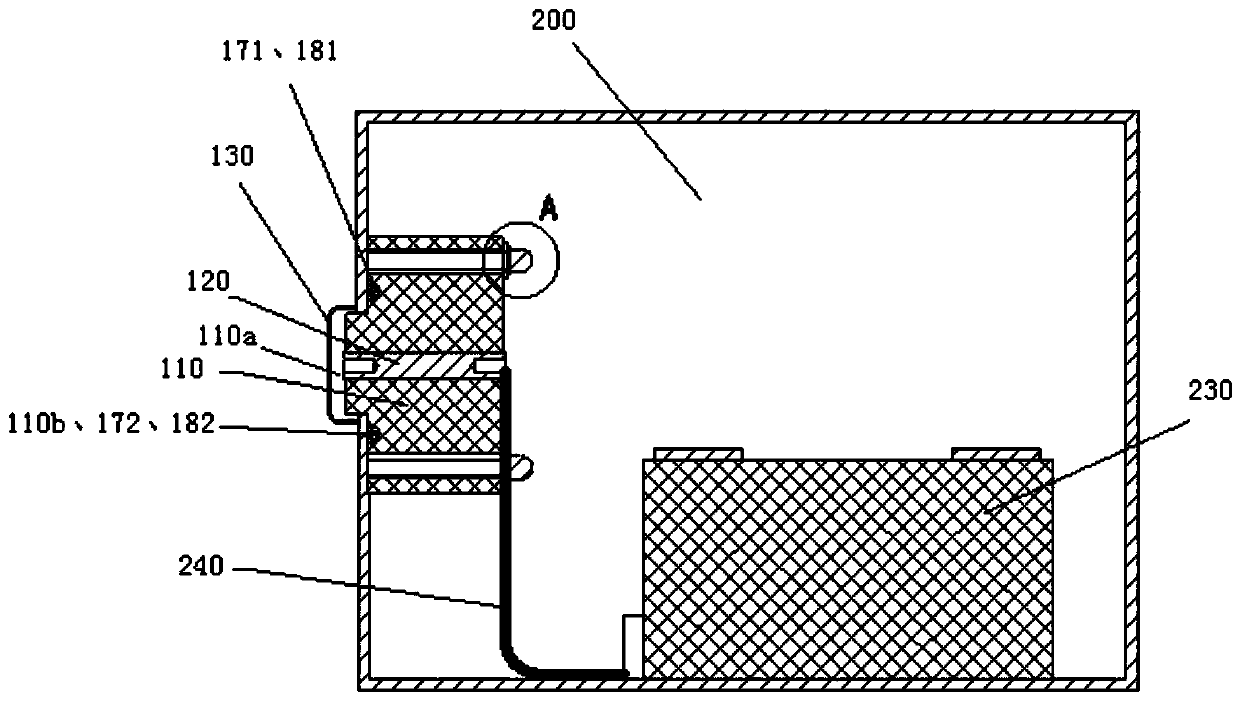

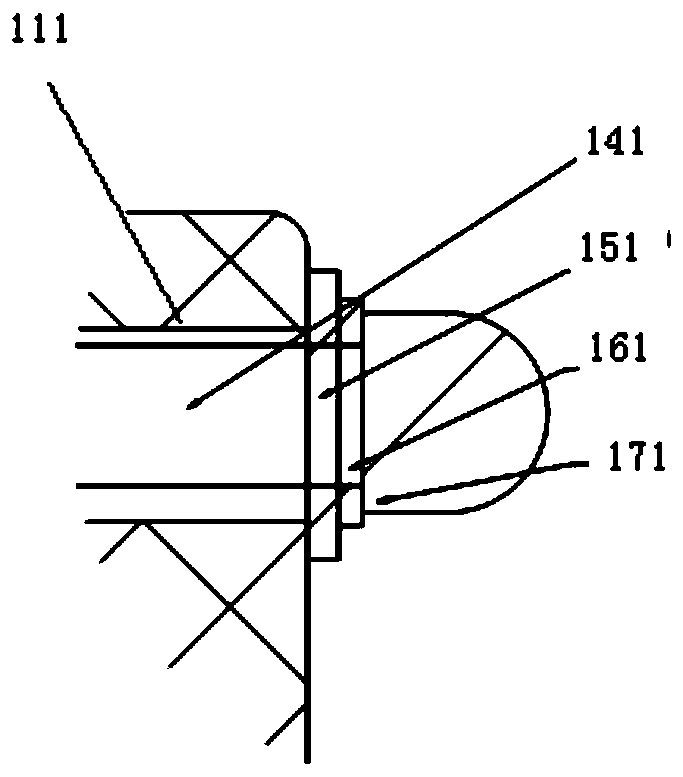

The invention relates to a jacking type sand core microwave drying device. The drying device mainly comprises a microwave drying cavity, a jacking assembly and a sand core tray, wherein the jacking assembly comprises two supporting stand columns and a jacking sealing bracket arranged between the two supporting stand columns; a vertical linear rail is arranged on each supporting stand column; the jacking sealing bracket is jacked and descended on the supporting stand columns through the vertical linear rails; an inner roller way is arranged on the jacking sealing bracket, and is used for beingmatched with a outer roller way to carry and transport the sand core tray; the microwave drying cavity is located above the supporting stand columns; the bottom of the microwave drying cavity is provided with a feeding opening; when the jacking sealing bracket ascends, the jacking sealing bracket is in sealing connection with the feeding opening. Through matching and sealing of the jacking sealingbracket and the upper microwave drying cavity, microwave leakage prevention is carried out, the problem of microwave leakage is effectively solved, and 3D printing sand core flow coating and automatic drying after dip coating are efficiently realized.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

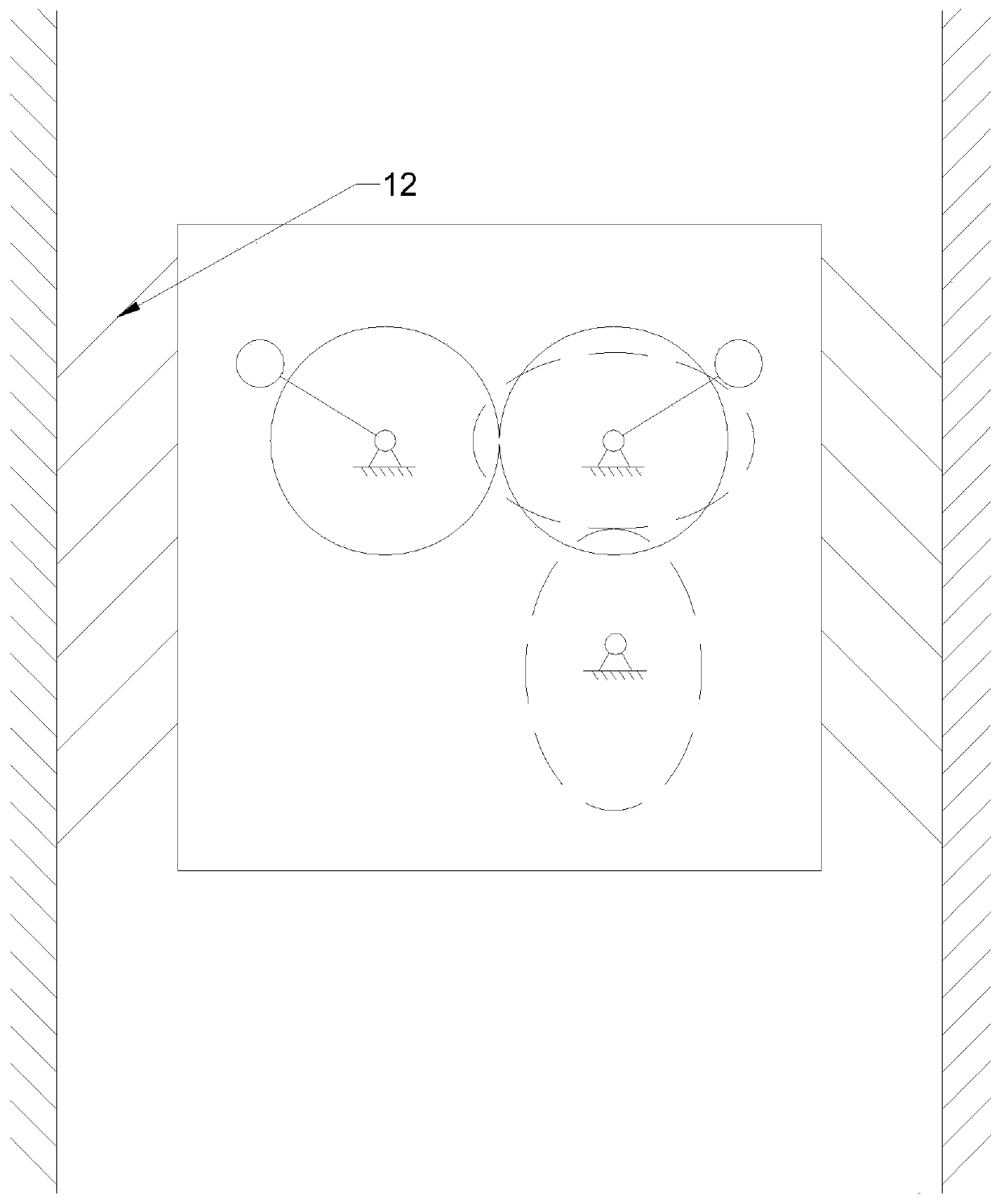

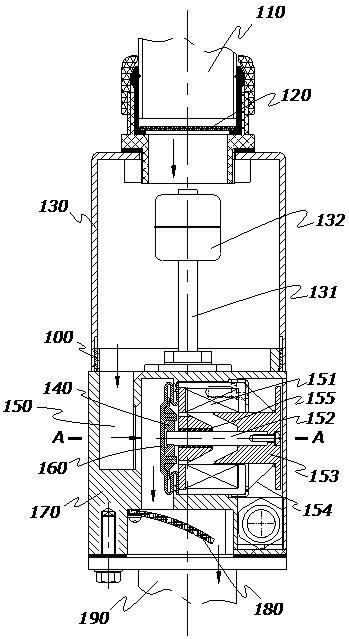

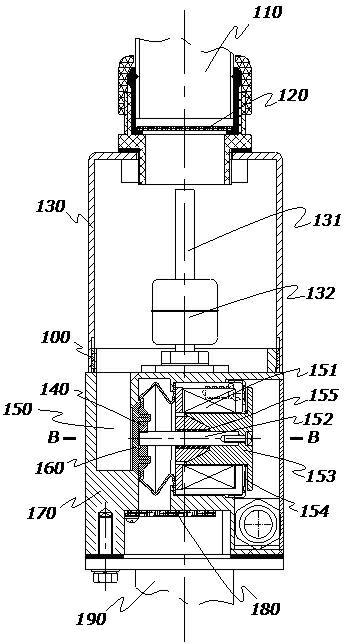

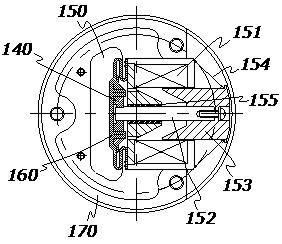

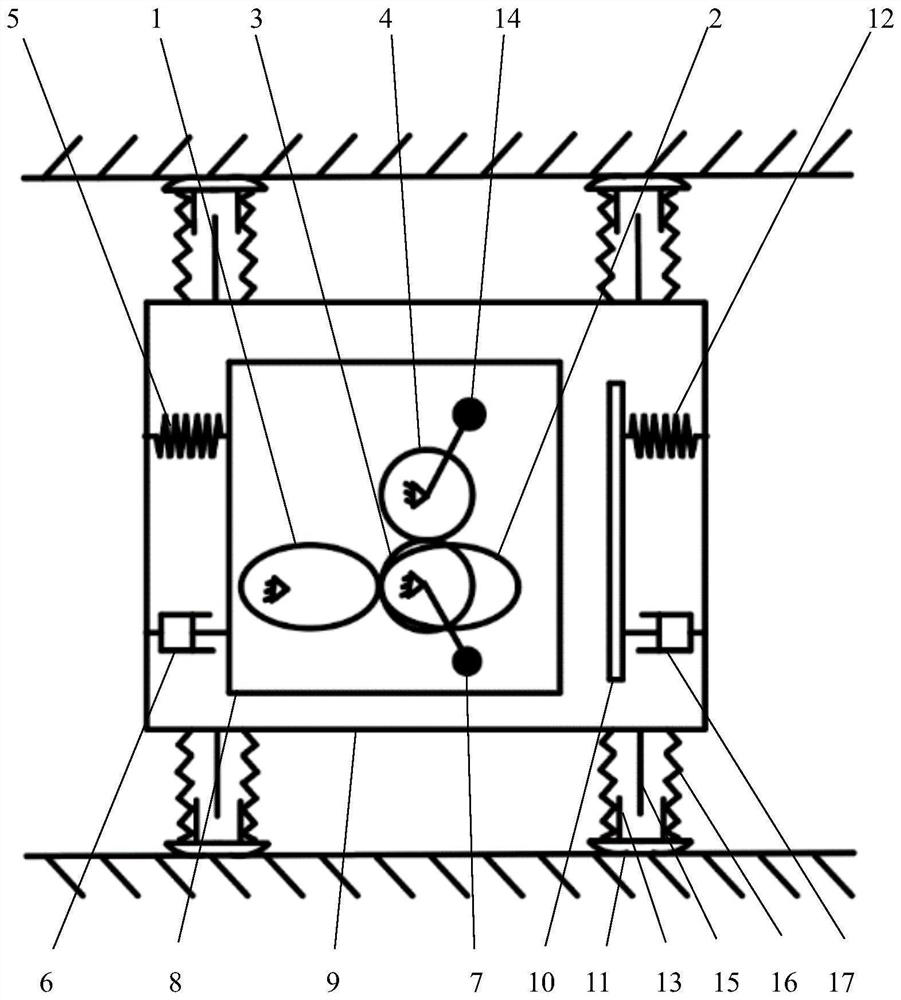

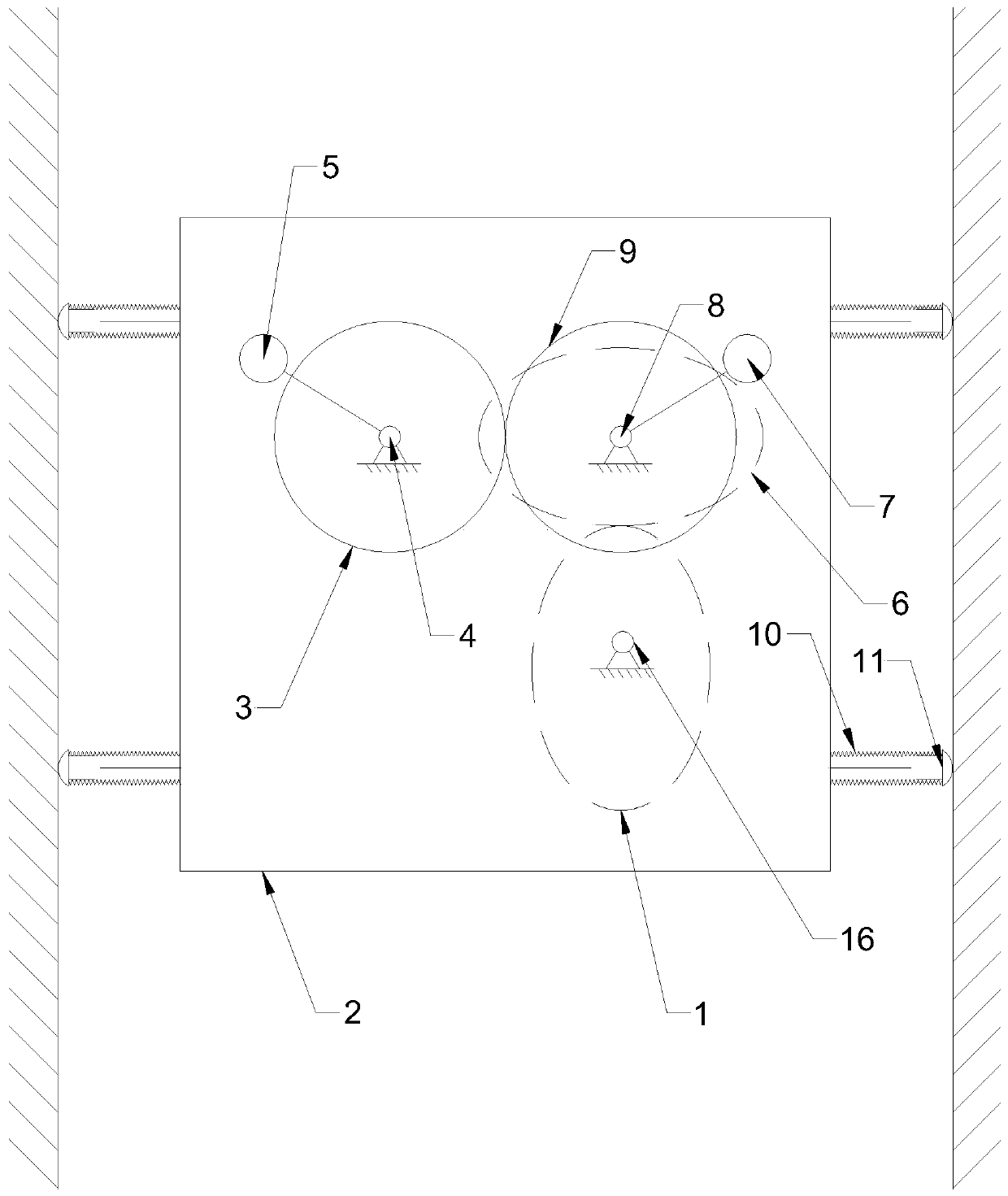

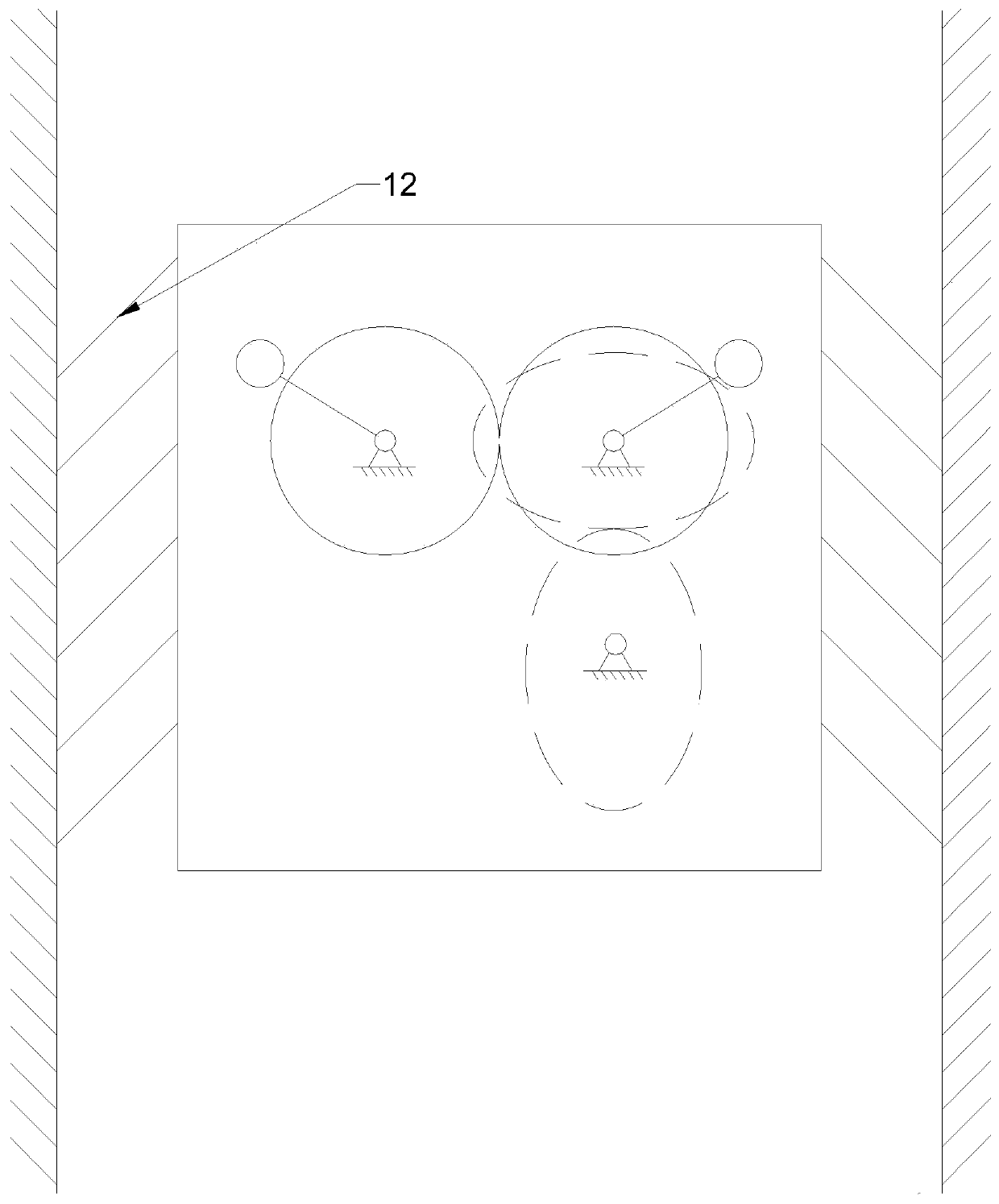

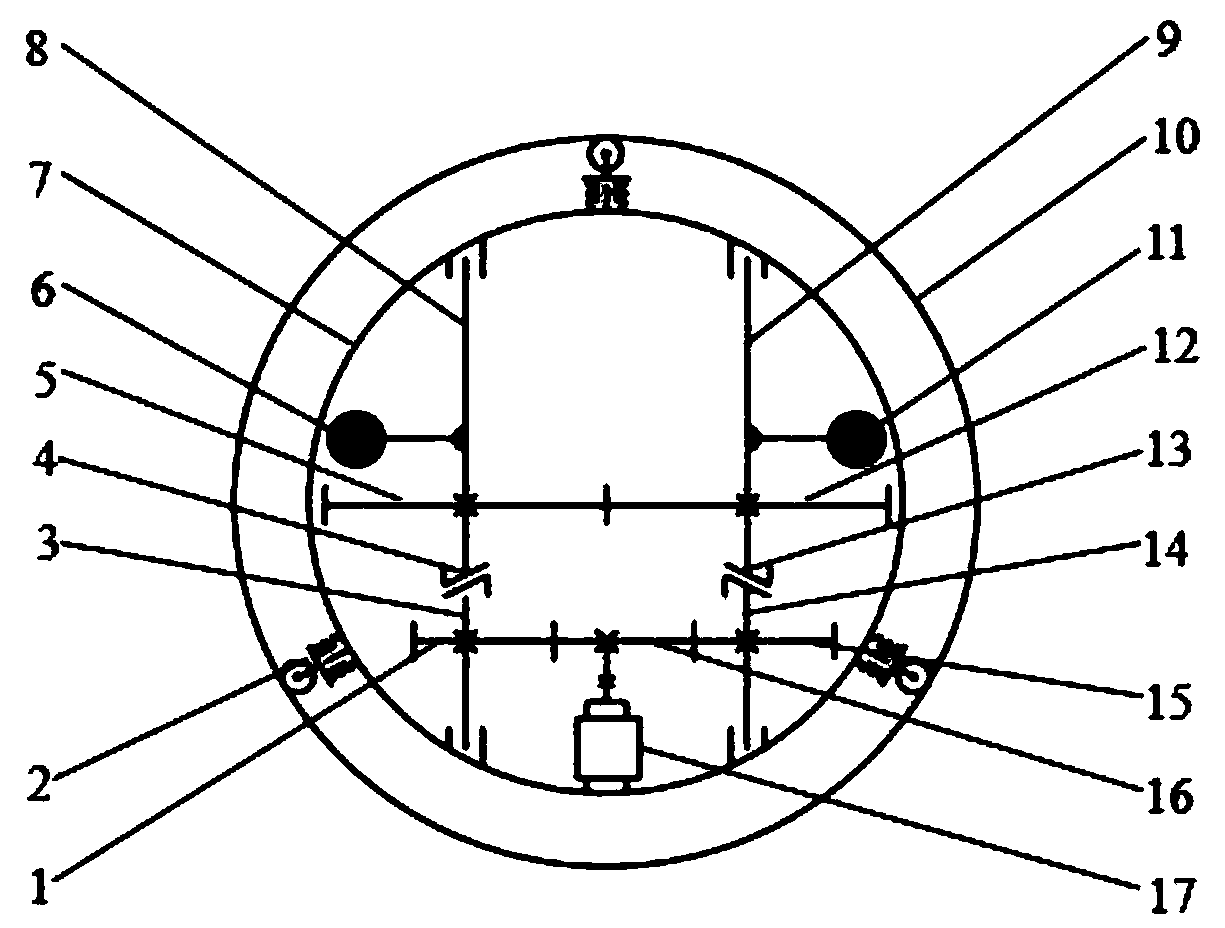

Bidirectional moving inertia pipeline robot

The invention provides a bidirectional moving inertia pipeline robot. At present, due to the structure, most pipeline robots can not work bidirectionally in high pressure, flammable and explosive, corrosive and other severe environments. The bidirectional moving inertia pipeline robot mainly comprises a shell and an inertia excitation mechanism. The inertia excitation mechanism comprises a rotation power source, three non-circular gear connected in series and two identical eccentric mechanisms, and the inertia excitation mechanism is arranged inside the robot shell. The two eccentric mechanisms are transmitted through a pair of synchronous cylindrical gears, revolving shafts of the two non-circular gears are connected with revolving shafts of the synchronous cylindrical gears respectivelythrough two overrun clutches, and the work directions of the two overrun clutches are opposite. The inertia pipeline robot moves through the mutual action of interior inertia and environment frictionforce, the defect that movable sealing must be arranged between a traditional power source and main driving feet can be overcome fundamentally by means of the driving mode, and the bidirectional moving inertia pipeline robot is suitable for small, high pressure, corrosive, flammable, high temperature and other extreme severe pipeline work environments.

Owner:上海乔智科技有限公司

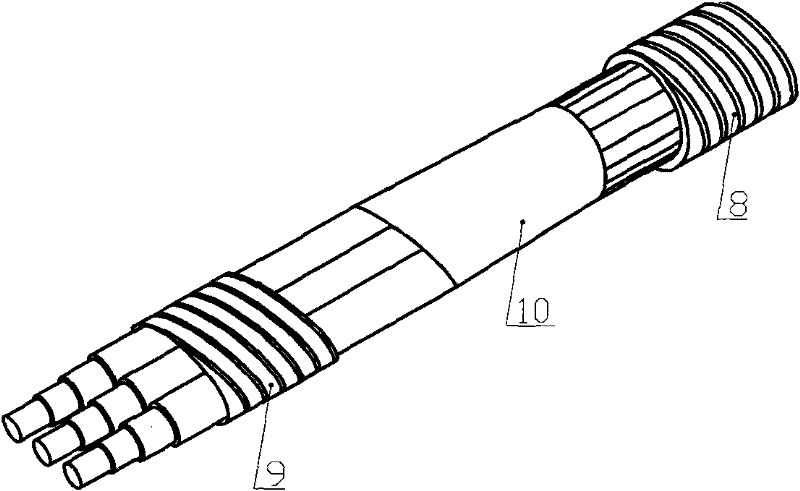

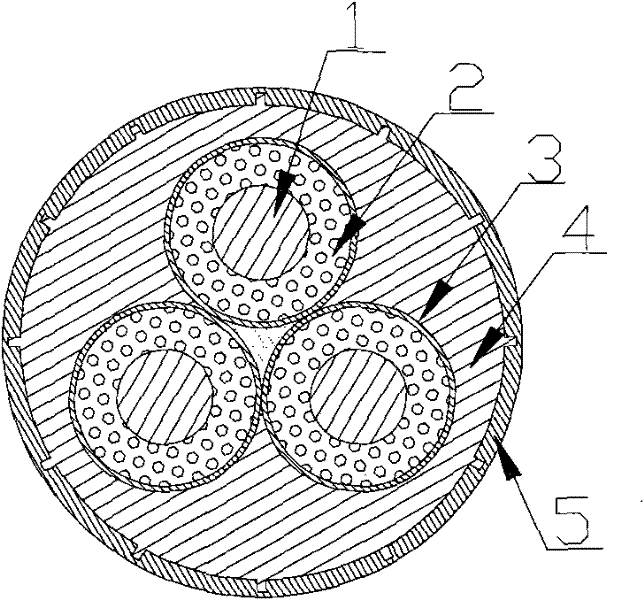

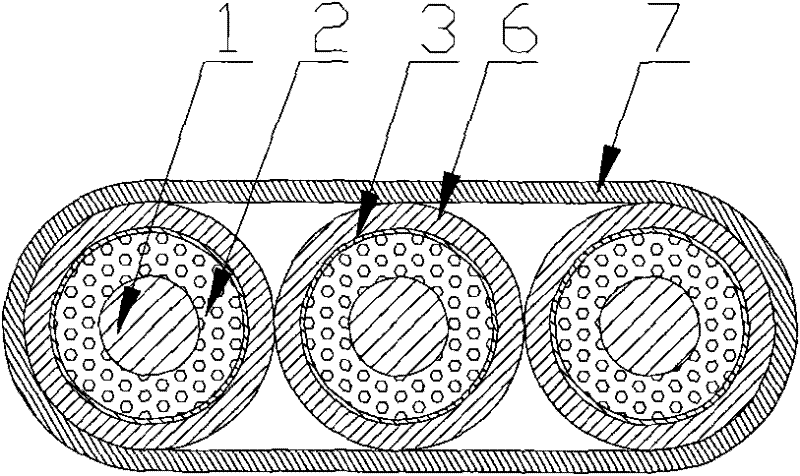

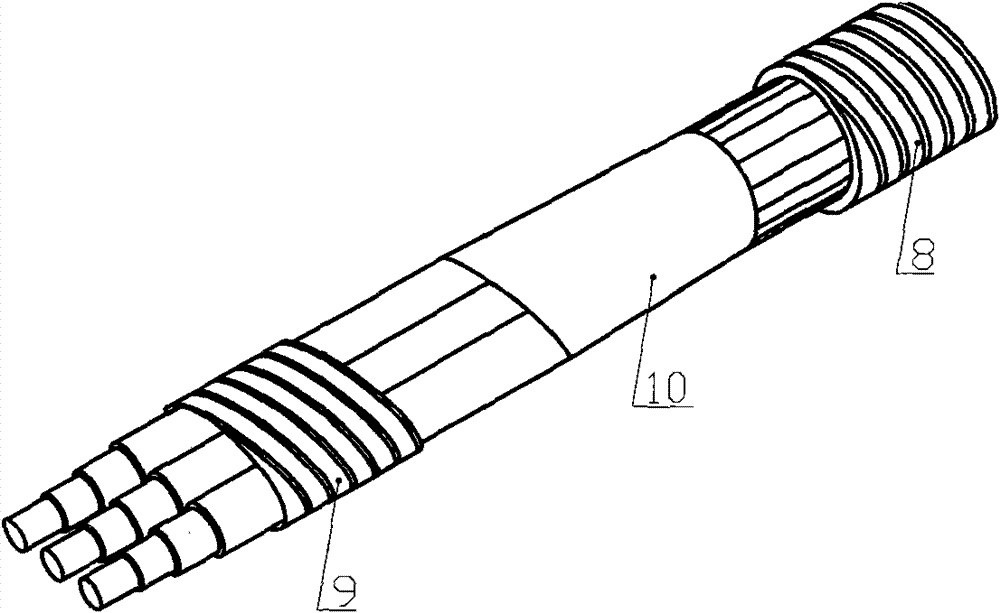

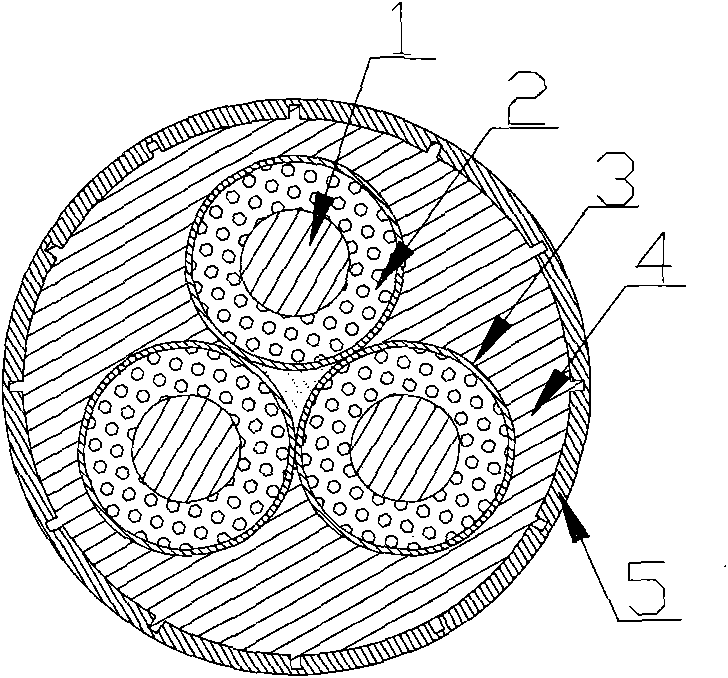

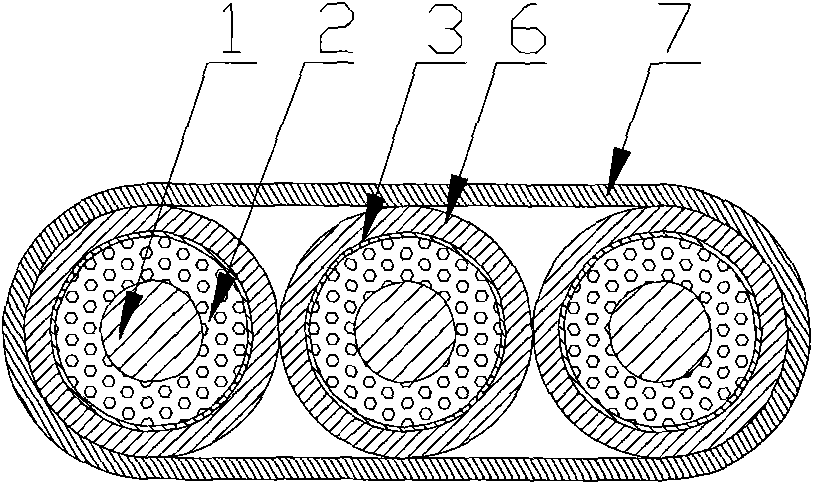

Circular-flat integrated cable for electric submersible pump

ActiveCN102456431AExtend your lifeAvoid Sealing DefectsInsulated cablesConnections effected by permanent deformationVulcanizationElectrical conductor

A circular-flat integrated cable for an electric submersible pump is disclosed. In order to overcome the disadvantage that the present belting method is hard to ensure the sealing performance at the connected place of a circular cable and a flat cable, so that an insulating layer is corroded by an underground oil-gas environment, and thus the cables are failed in advance, an insulating layer and an oil-resisting layer are orderly covered outside the conductor disclosed by the invention to be a core, the three cores of the circular cable are covered by a jacket layer after being arrayed in a triangle, and an armour layer is disposed outside the jacket layer; the armour layer, the jacket layer and the oil-resisting layer on the end part of the circular cable are orderly peeled off to exposethe insulating layer, and after the conductors of the three cores on the end part of the circular cable are twisted with the conductors of the three cores of the flat cable, a moulding and a vulcanization for the transition belt rubber jacket layer of the circular cable and the flat cable are finished on a rubber processing device; and an armour layer is covered outside the transition belt rubberjacket layer of the circular cable and the flat cable by a steel belt to form a circular-flat integrated cable. The circular-flat integrated cable for an electric submersible pump has the advantage that the connected place of a circular cable and a flat cable is moulded once, so that a sealing defect existing during a connection process is efficiently avoided, and the lives of the cables are efficiently prolonged.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

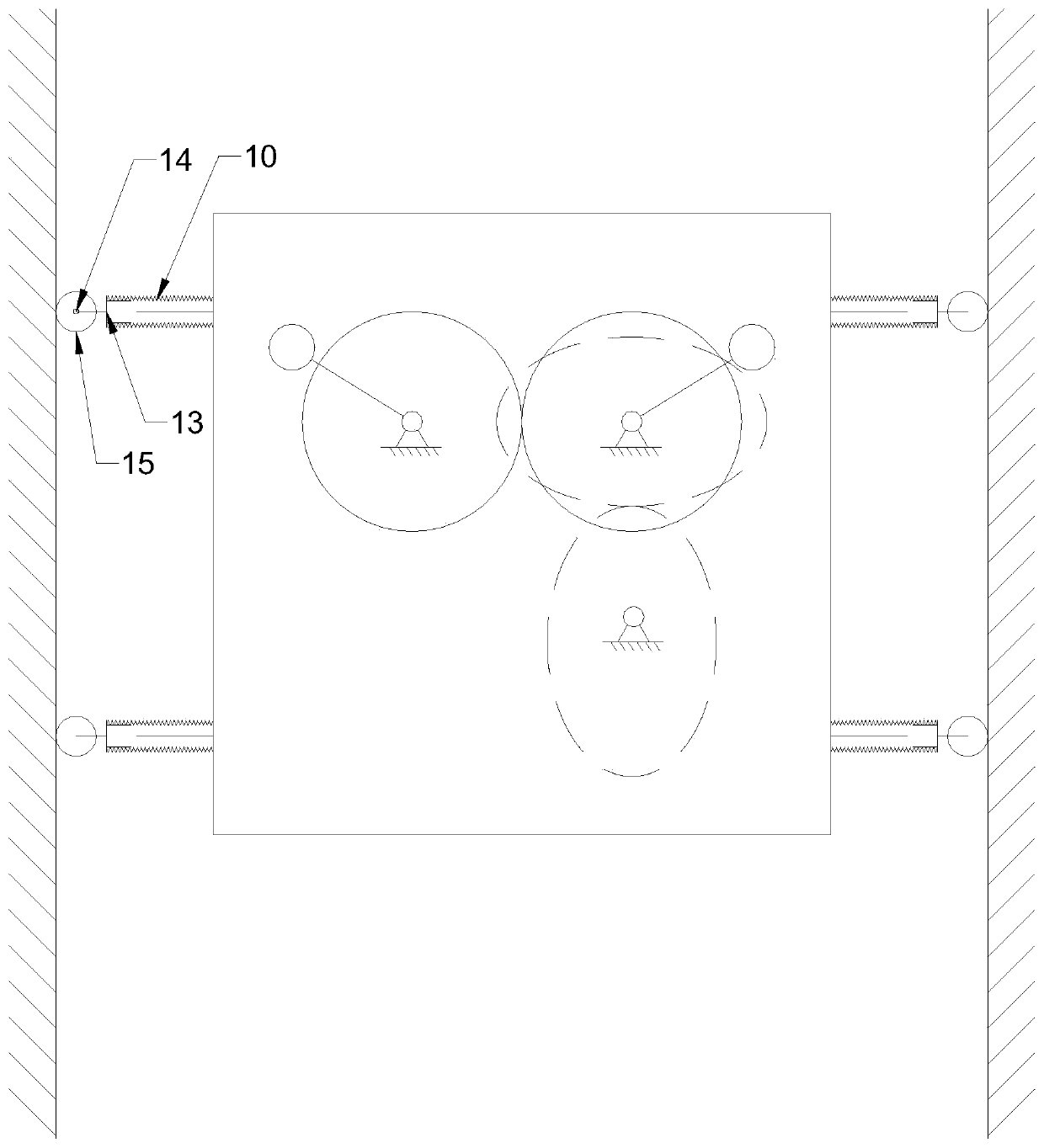

Pipeline robot

The invention relates to a pipeline robot and belongs to the technical field of robots. The pipeline robot comprises an inertial excitation mechanism which comprises a rotary power source, a non-circular gear transmission mechanism and at least two same eccentric mechanisms, and all eccentric mechanisms are uniformly distributed circumferentially on a plane; each eccentric mechanism comprises an eccentric mass block which rotates around a rotating shaft; the rotary power source drives the eccentric mass block to rotate around the rotating shaft through the non-circular gear transmission mechanism; the rotating speeds of the eccentric mass blocks are consistent and the component forces of a resultant force of eccentric forces generated by all the eccentric mass blocks are zero. The pipelinerobot moves by means of joint action of an inner inertial force and an environmental friction force. By adopting the driving mode, the defect that a driving device and an executing device in a conventional driving mode must be sealed is overcome fundamentally, so that the pipeline robot is suitable for extremely severe pipeline operating environments such as narrow, corrosive, inflammable and high-temperature environments, and has a huge potential in the aspect of miniaturization.

Owner:大庆市大广测绘服务有限公司

Electromagnetic pressure protection water discharge valve

ActiveCN102095012AReduce connection pointsSmall footprintOperating means/releasing devices for valvesValve members for heating/coolingWater dischargeWater leakage

The invention discloses an electromagnetic pressure protection water discharge valve. The valve is connected between a water discharge inlet and a water discharge outlet, and comprises a valve body and a valve, wherein a water discharge passage is formed in the valve body; the valve is movably arranged in the water discharge passage; the valve body is provided with an electromagnetic valve; and the valve is arranged on the electromagnetic valve and is opened and closed through the action of an armature of the electromagnetic valve. Due to the adoption of the electromagnetic valve, the water discharge valve is opened and closed through the action of the electromagnetic valve, so that water is not required to be discharged by squeezing by using the gravity of the water to prevent the phenomenon of water logging due to incapable discharge of a small amount of water when the water is available, and the valve is not required to be sealed through air pressure to overcome the defect of difficulty in sealing of the valve in the presence of insufficient air pressure when the water is not available, and the valve is not influenced by vibration produced during running of a train to prevent water leakage and air leakage phenomena caused by the vibration; and the valve fills the blank in the technology of the pressure protection water discharge valve of a domestic high speed train of China and has great practical value for the domestication of the China high-speed multiple units.

Owner:深圳市垅运照明电器有限公司

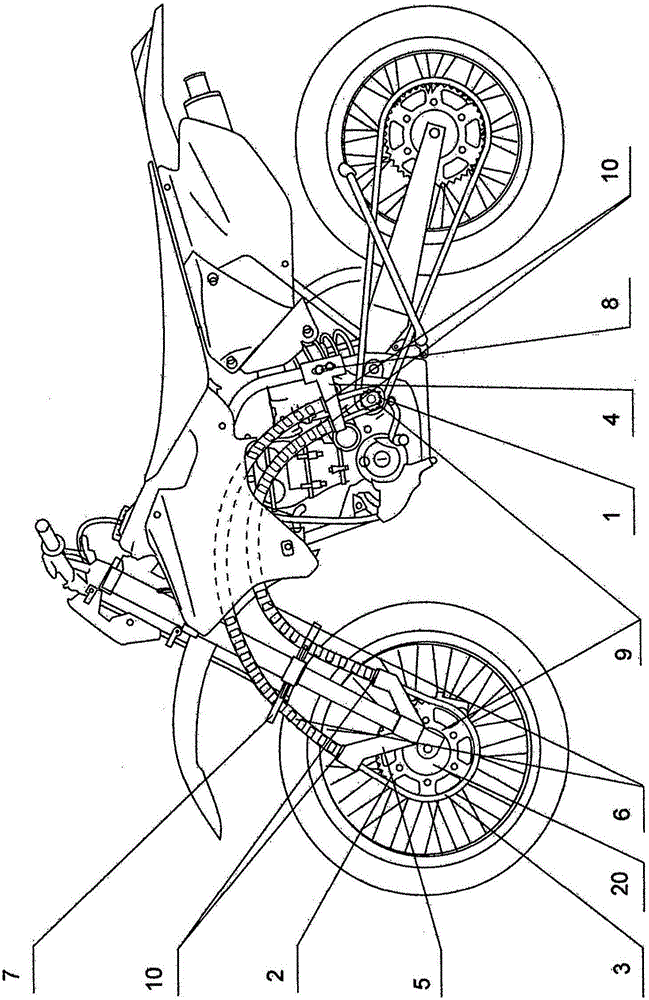

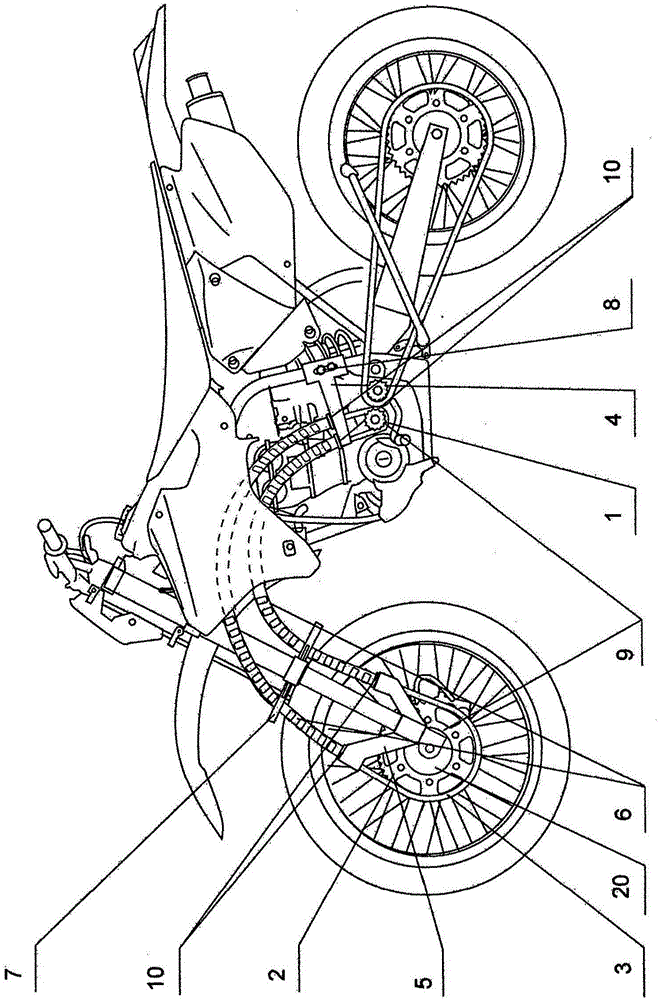

Motorcycle front wheel drive

InactiveCN106103262AImprove reliabilitySimplified front-wheel drive mechanismChain/belt transmissionGearingSteering wheelRoller chain

The invention belongs to the field of machinery manufacturing, and the front wheels of two-wheel and three-wheel vehicles are driven. The technical result of the invention is to improve the reliability of the front wheel drive of the motorcycle and simplify the structure. The result of this technology realizes the front wheel drive design of the motorcycle. The structure includes a driving sprocket associated with the engine shaft and a driven sprocket associated with the front wheel. The driving sprocket and the driven sprocket are The roller chains in the flexible casing are connected.

Owner:斯坦尼斯拉夫·维克托罗维奇·莫兹哥夫

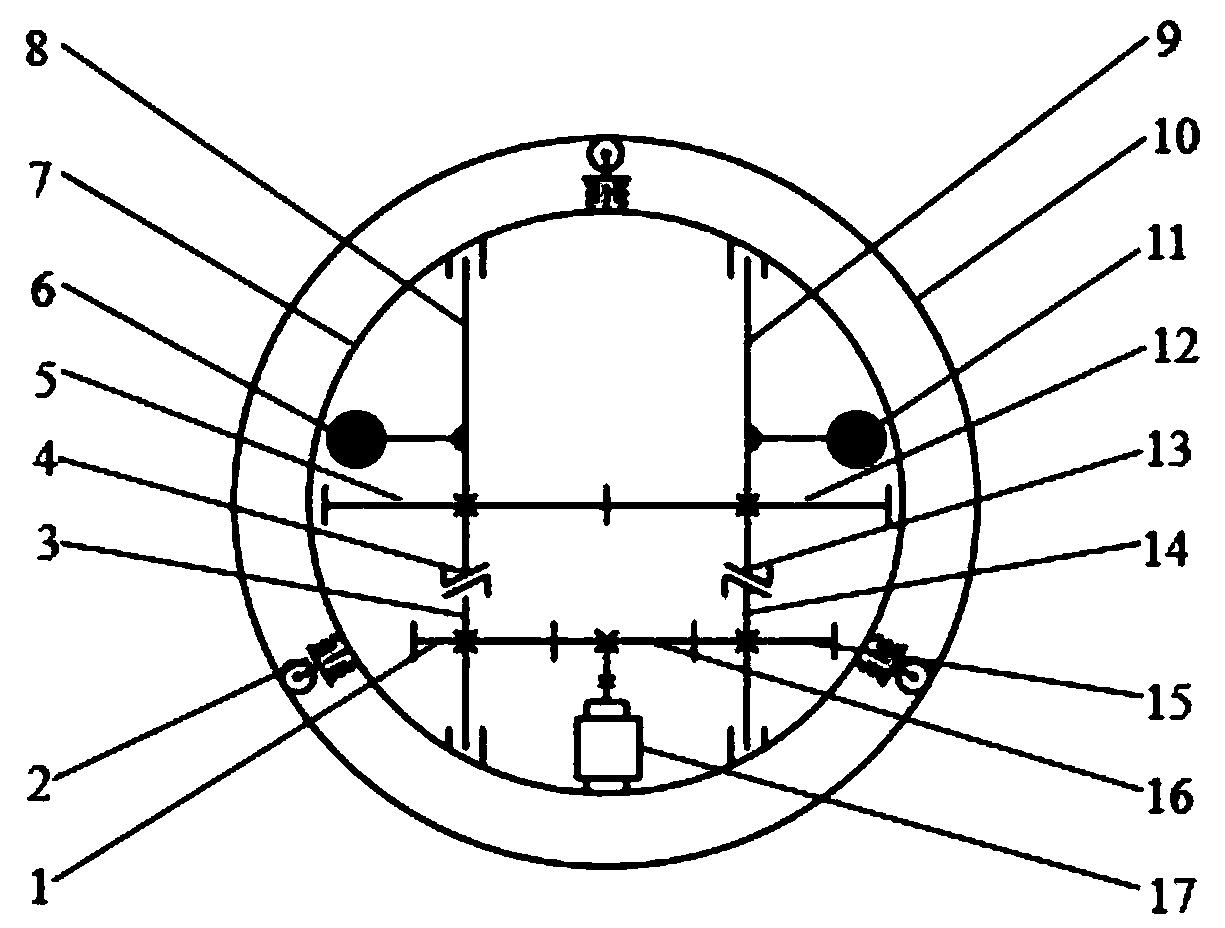

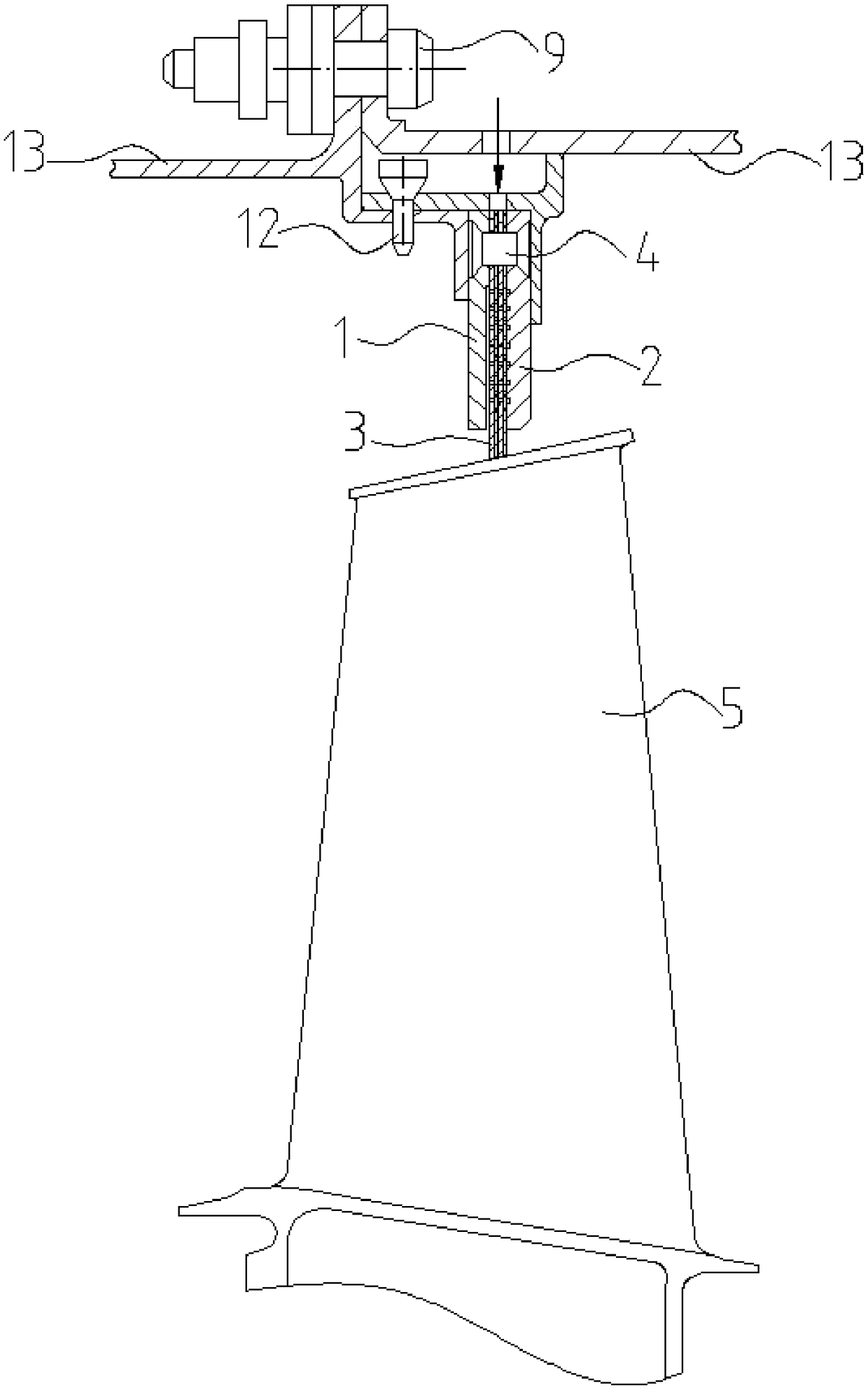

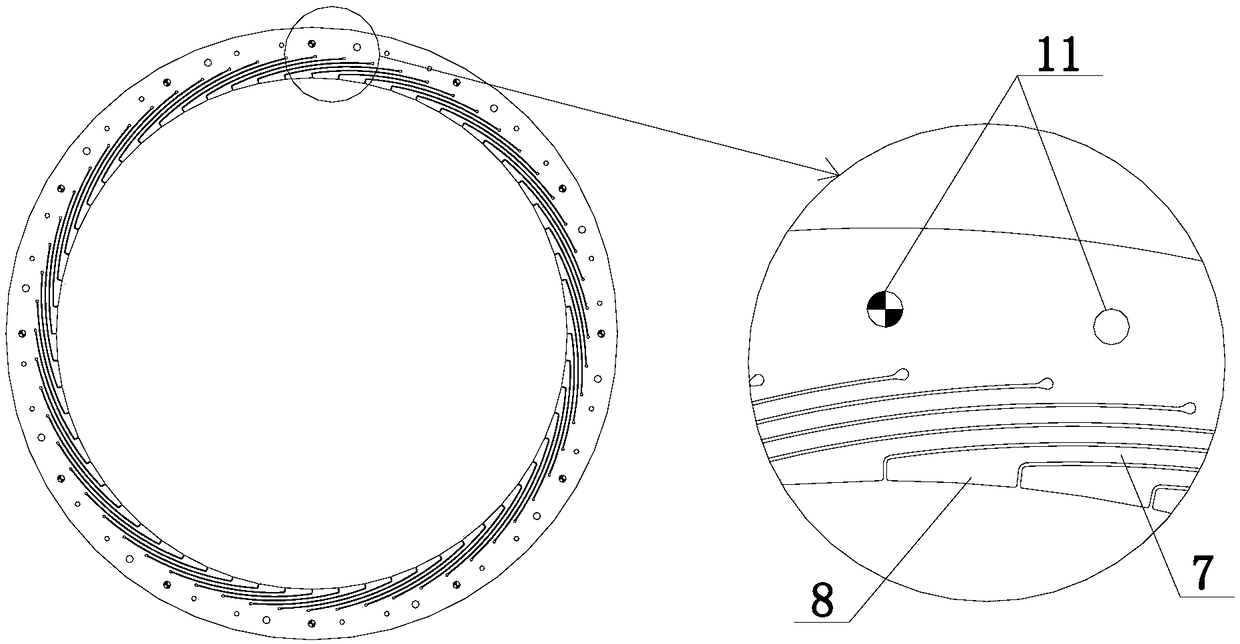

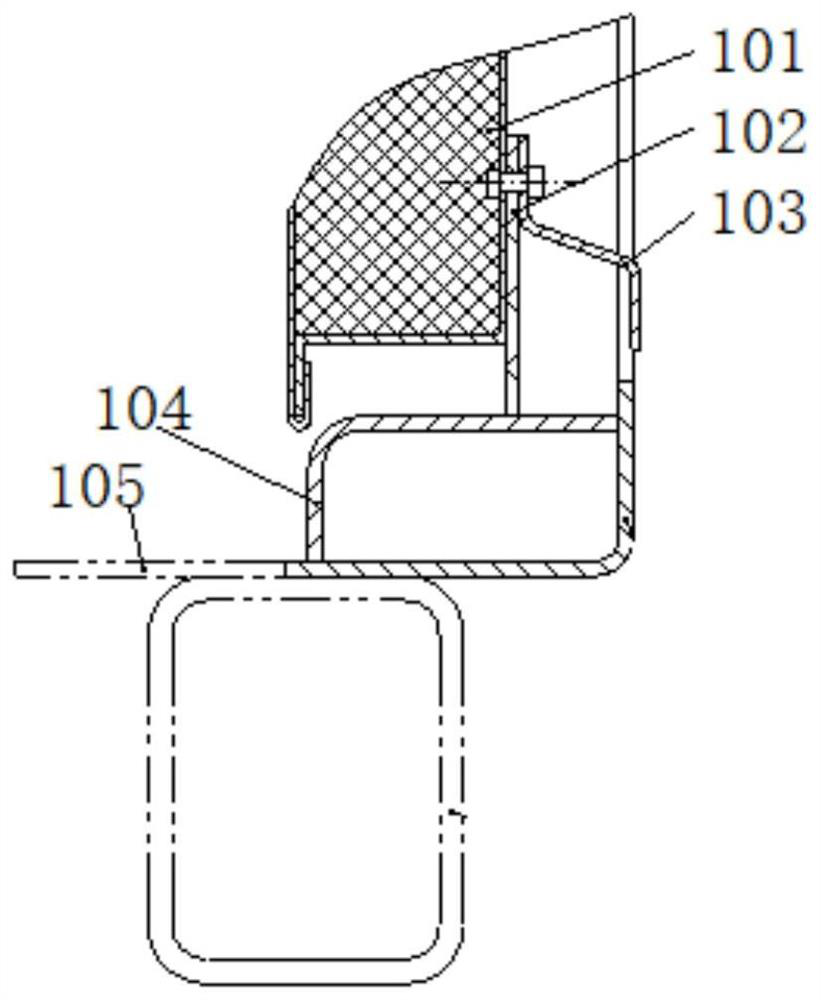

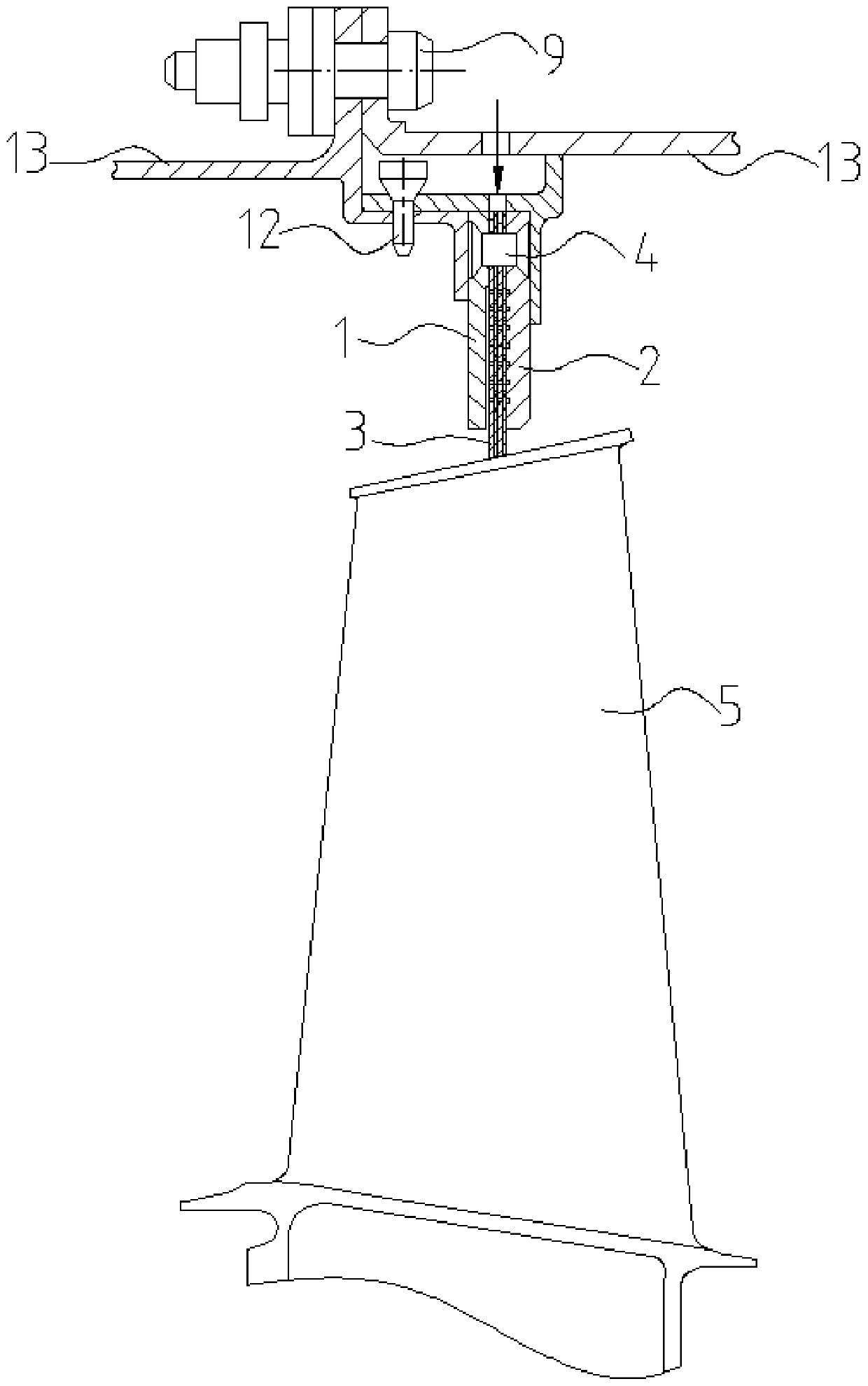

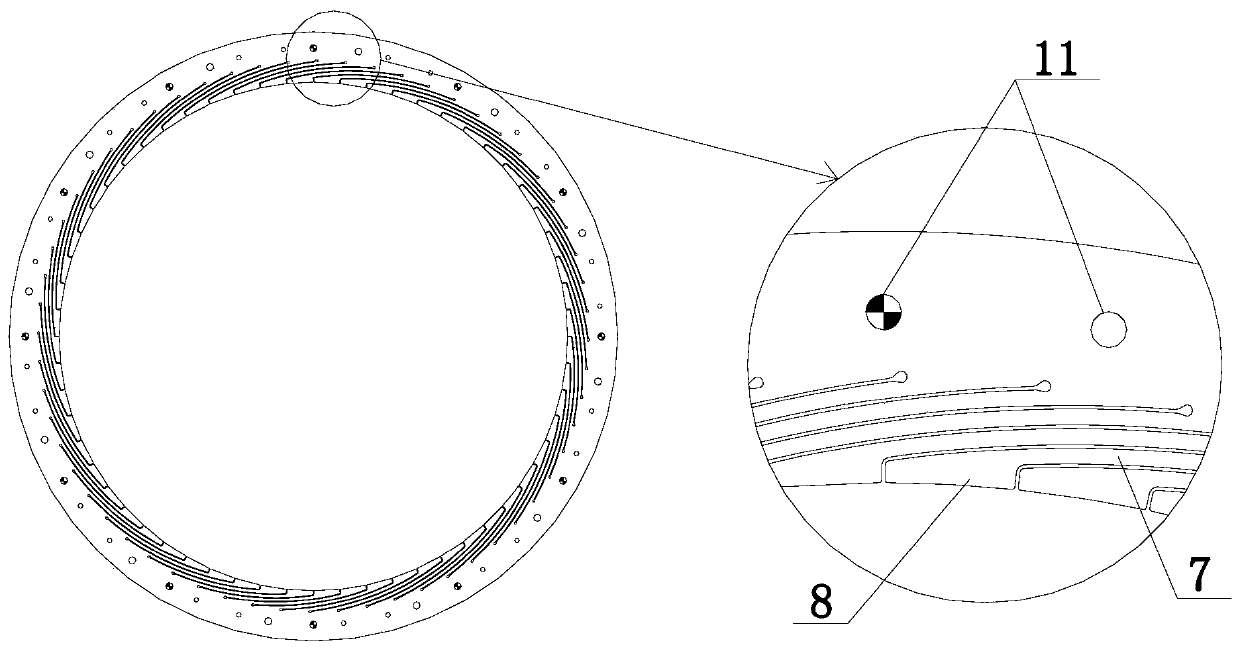

Finger seal device with core hollowed-out finger piece

ActiveCN108223798AImprove the high temperature performance of the sealReduce leakageEngine sealsEngineeringAero engine

The invention belongs to the field of aircraft engine design, and relates to a gas sealing device for an engine main flow path and a secondary flow path. The finger seal device is composed of a frontbaffle (1), a rear baffle (2) and the core hollowed-out finger piece (3). A gap is formed in the core hollowed-out finger piece (3) from the inner diameter, a finger body (7) and a seal shoe (8) are arranged in the gap, and the core of the finger body (7) and the core of the seal shoe (8) are hollowed out. Frictional wear between the seal shoe and a rotator is reduced, the high temperature resistance performance of finger seal is improved, and besides, the optimal performance of conventional finger seal is basically maintained.

Owner:AECC SICHUAN GAS TURBINE RES INST

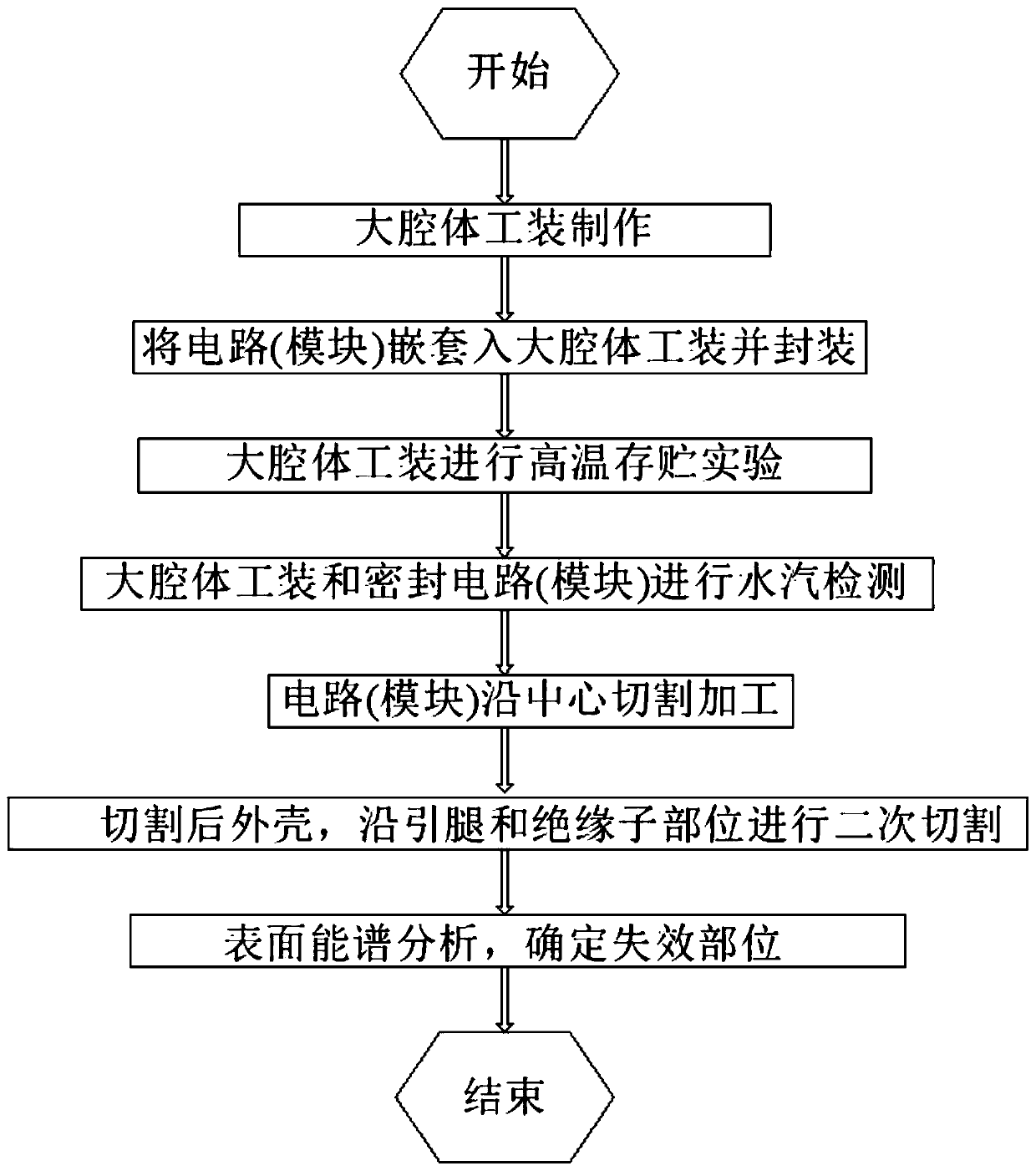

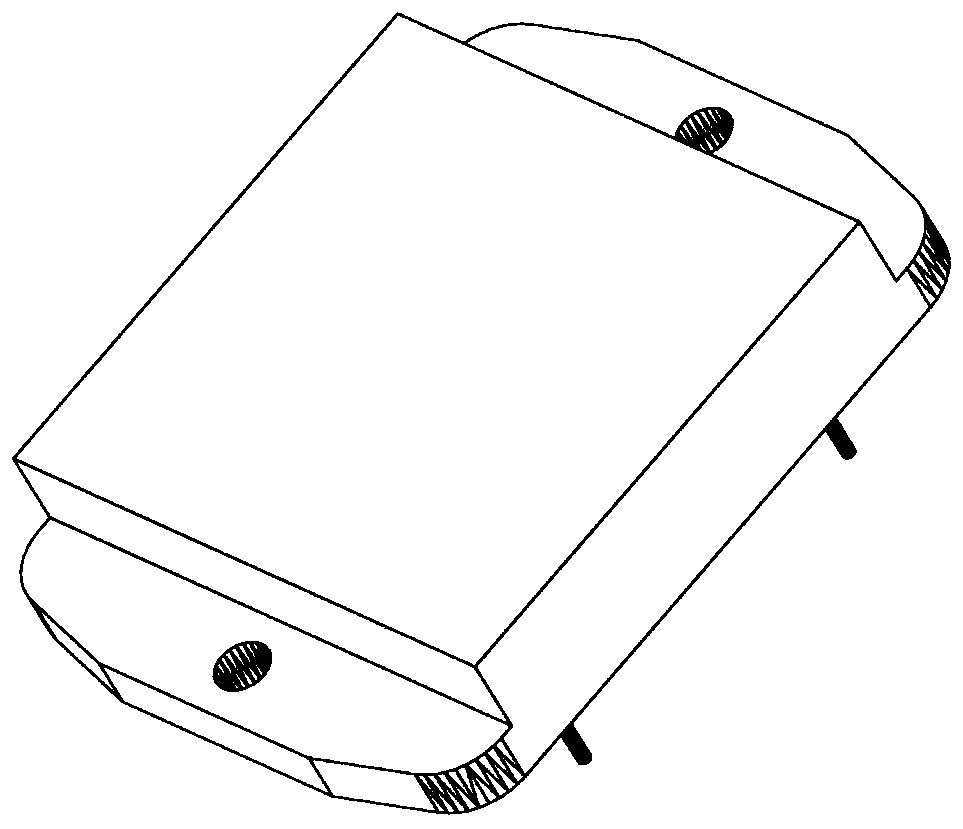

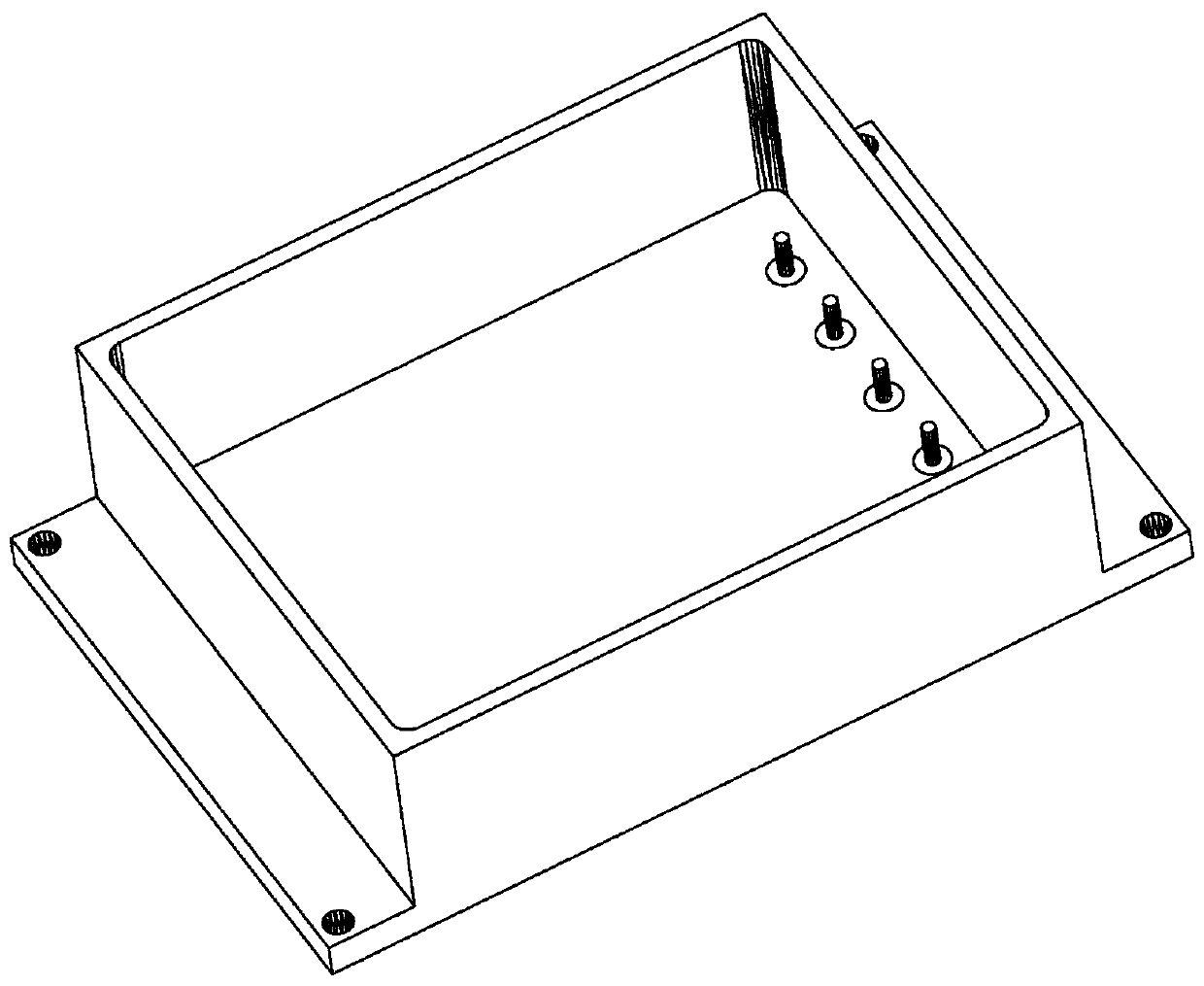

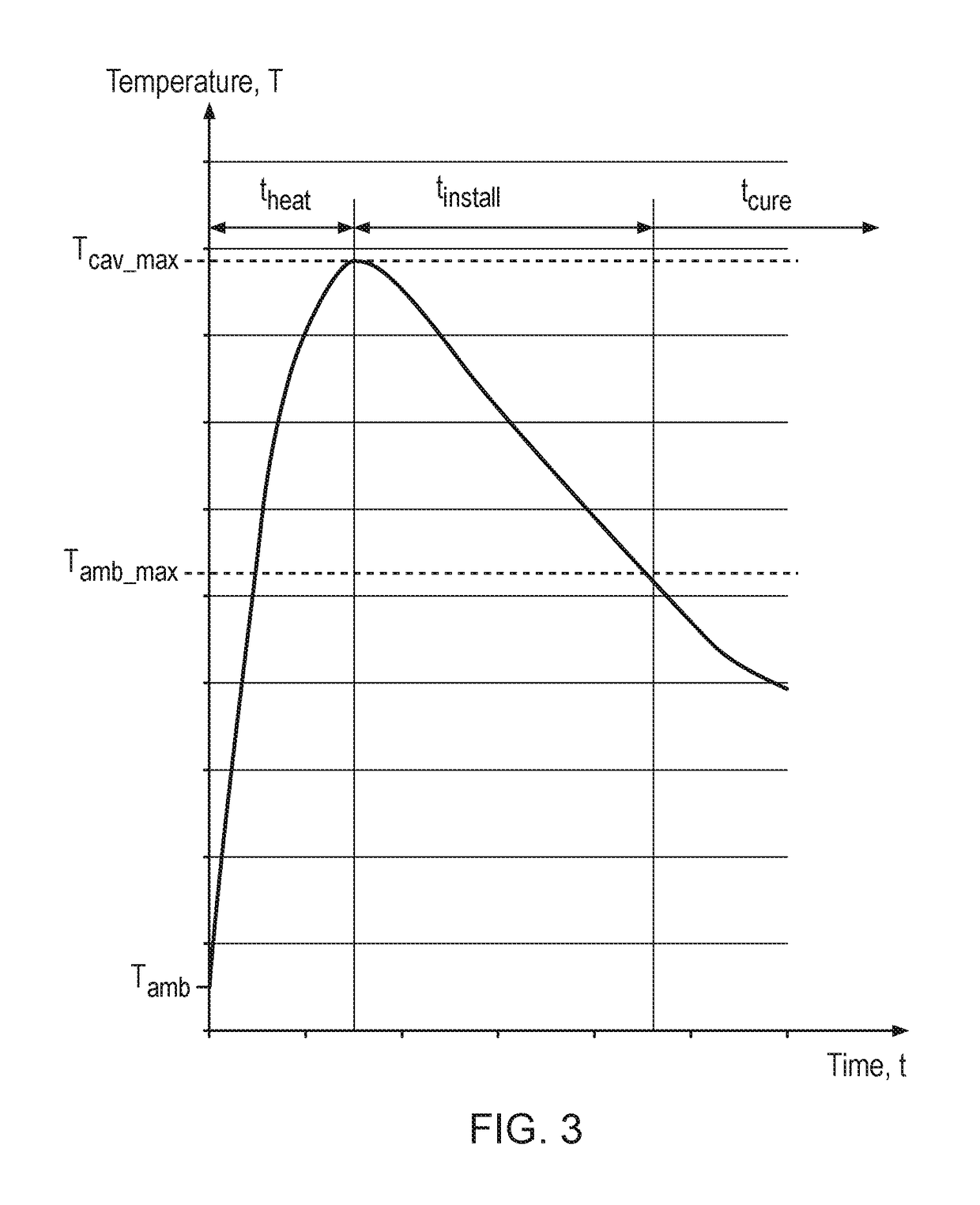

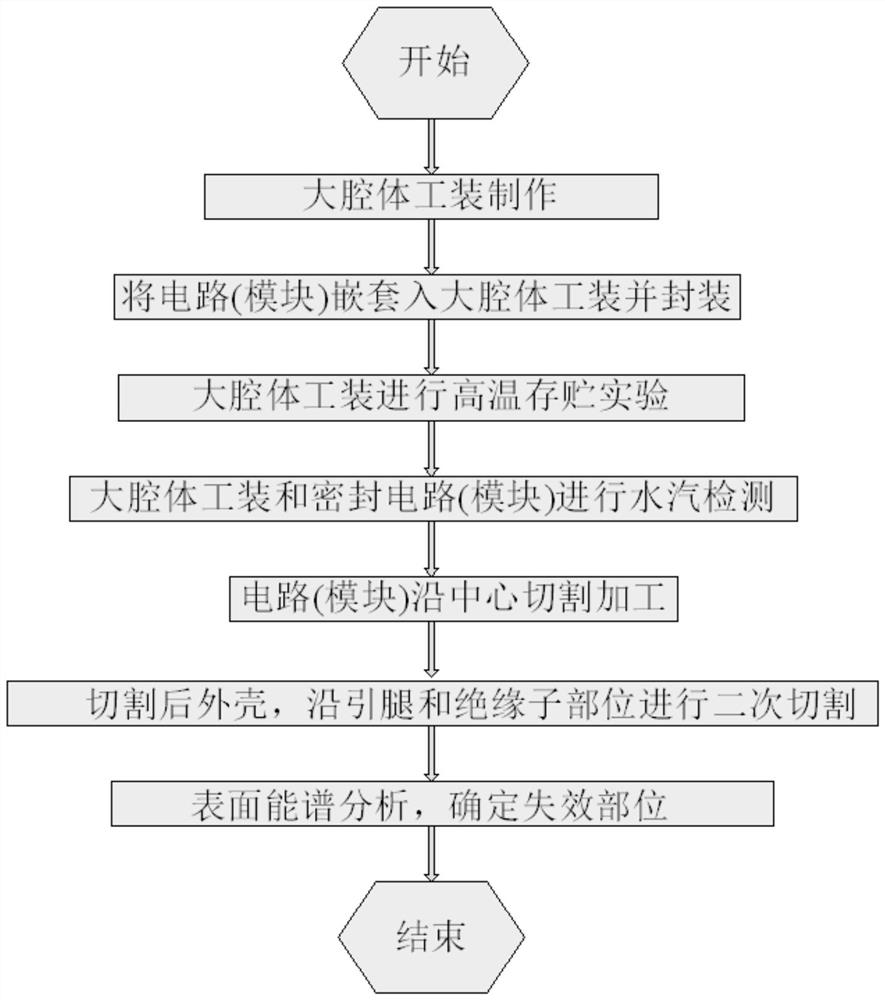

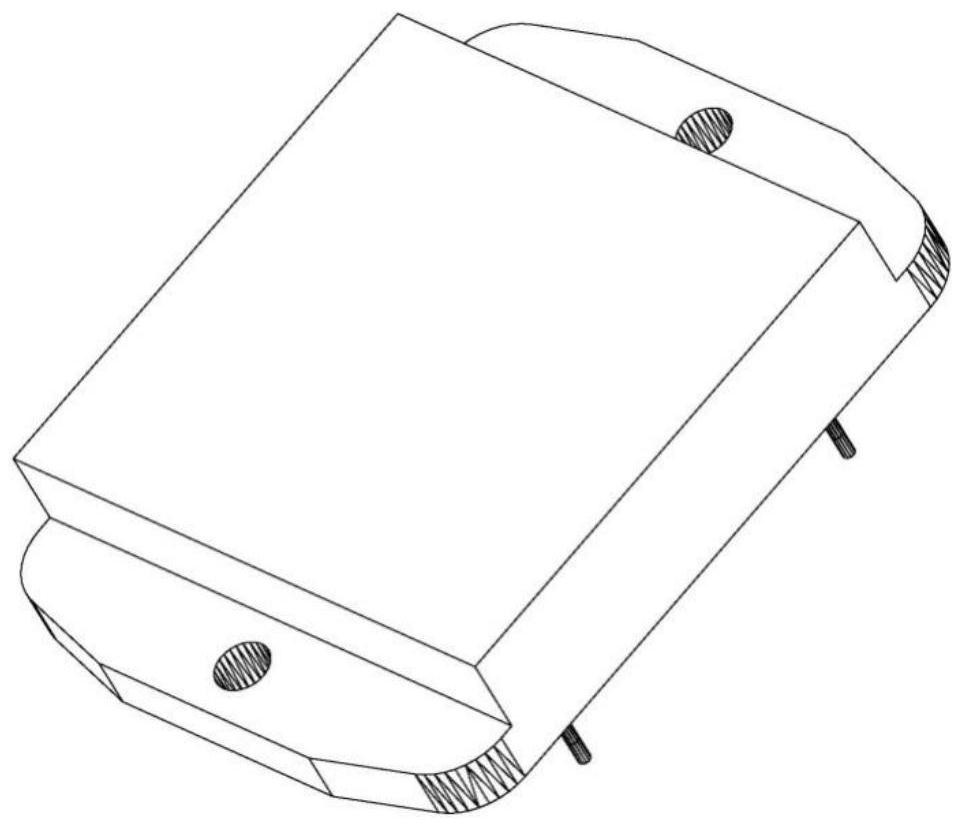

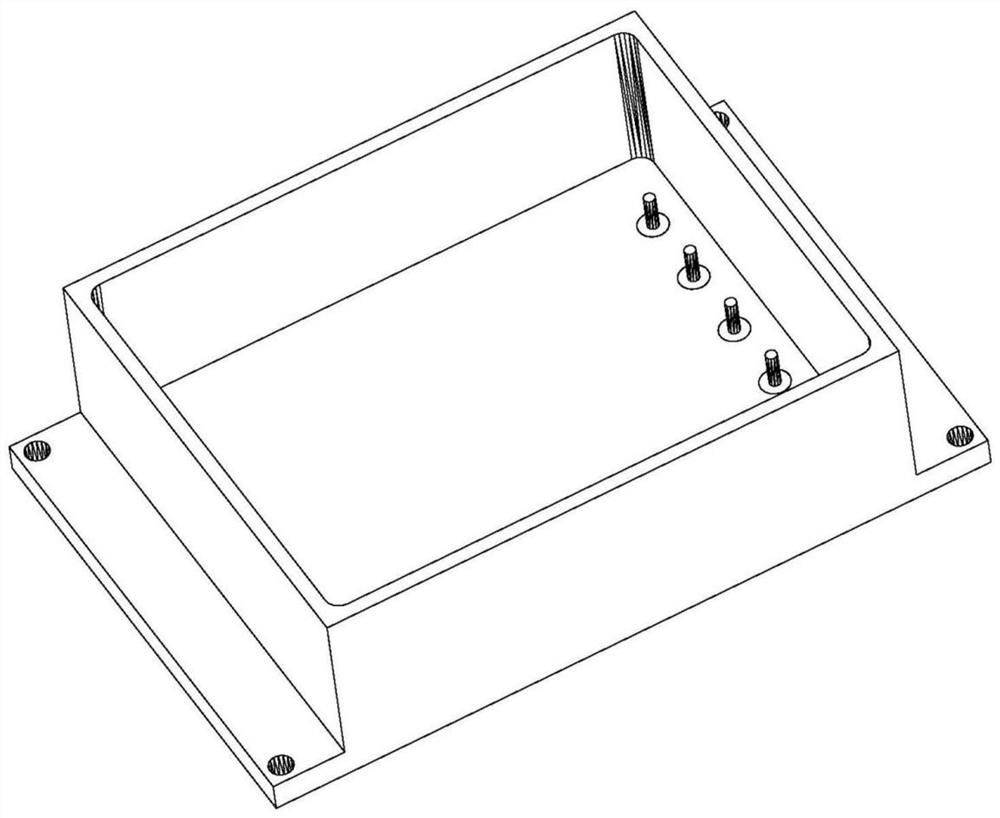

Intermittent seal failure analysis method for sealed circuit module in high temperature environment

ActiveCN110286313AAvoid Sealing DefectsAvoid going onlineDetection of fluid at leakage pointMaterial analysis using wave/particle radiationAir atmosphereNoble gas

The invention discloses an intermittent seal failure analysis method for a sealed circuit module in a high temperature environment. A circuit module and a rare gas are encapsulated into a cavity tool, a heating storage or power ageing experiment is performed on the encapsulated cavity tool, water vapor detection is performed on the circuit module after the experiment, whether the circuit module has high temperature intermittent seal failure is judged, qualitative analysis can be performed on a fact that whether the sealed circuit module has sealing failure and internal and external gas exchange is caused, location analysis is performed on an unqualified circuit module, a shell of the circuit module with the high temperature intermittent seal failure is cut into two parts, one part is subjected to heating storage in an air atmosphere, the other part is not treated, a pin and an insulator on the shell of the circuit module are taken out, a part, contacted with the insulator, on the shell of the circuit module is analyzed, a specific poorly-sealed failure part is found, so as to conveniently analyze a specific reason of the failure part, and a result is fed back to a manufacturer.

Owner:XIAN MICROELECTRONICS TECH INST

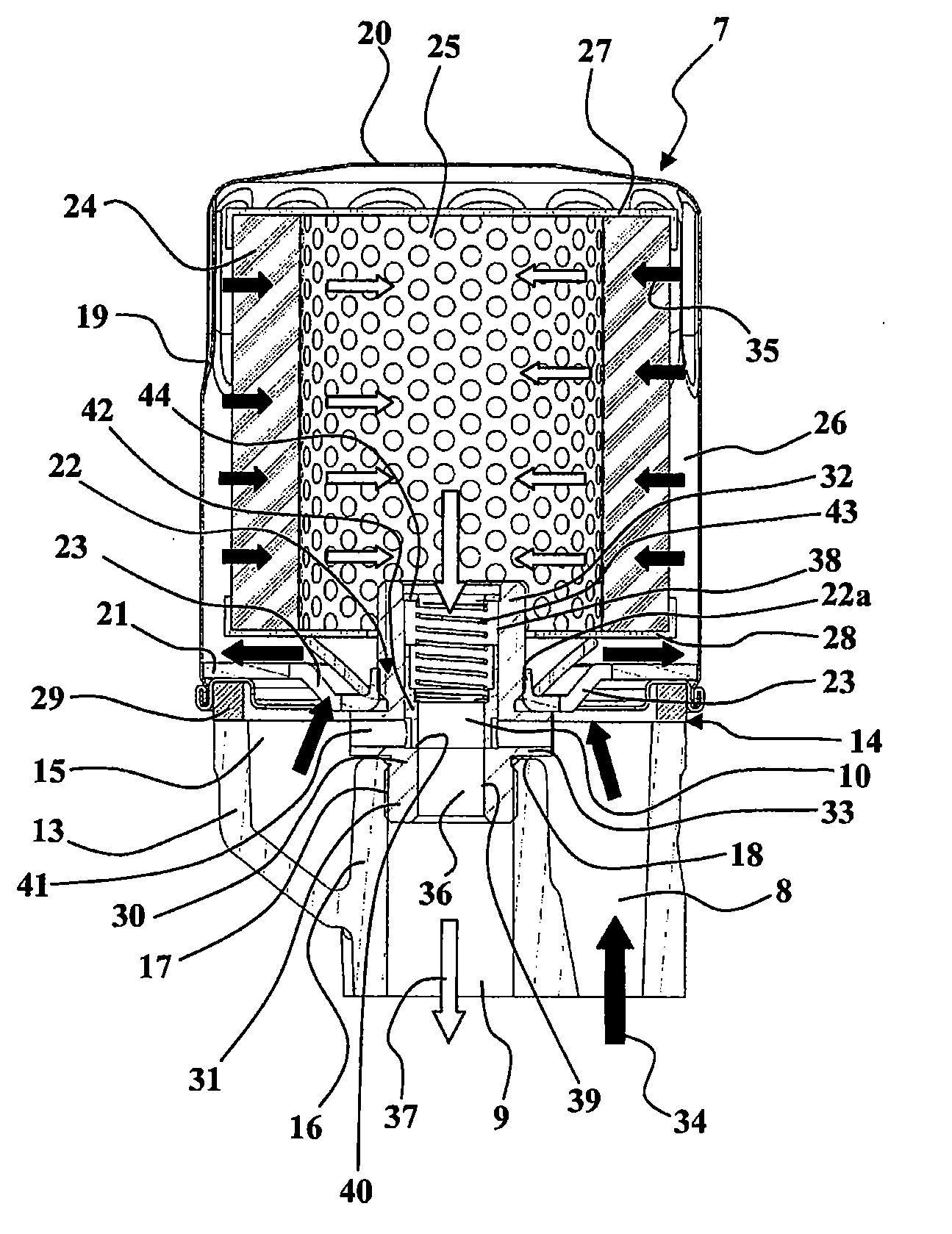

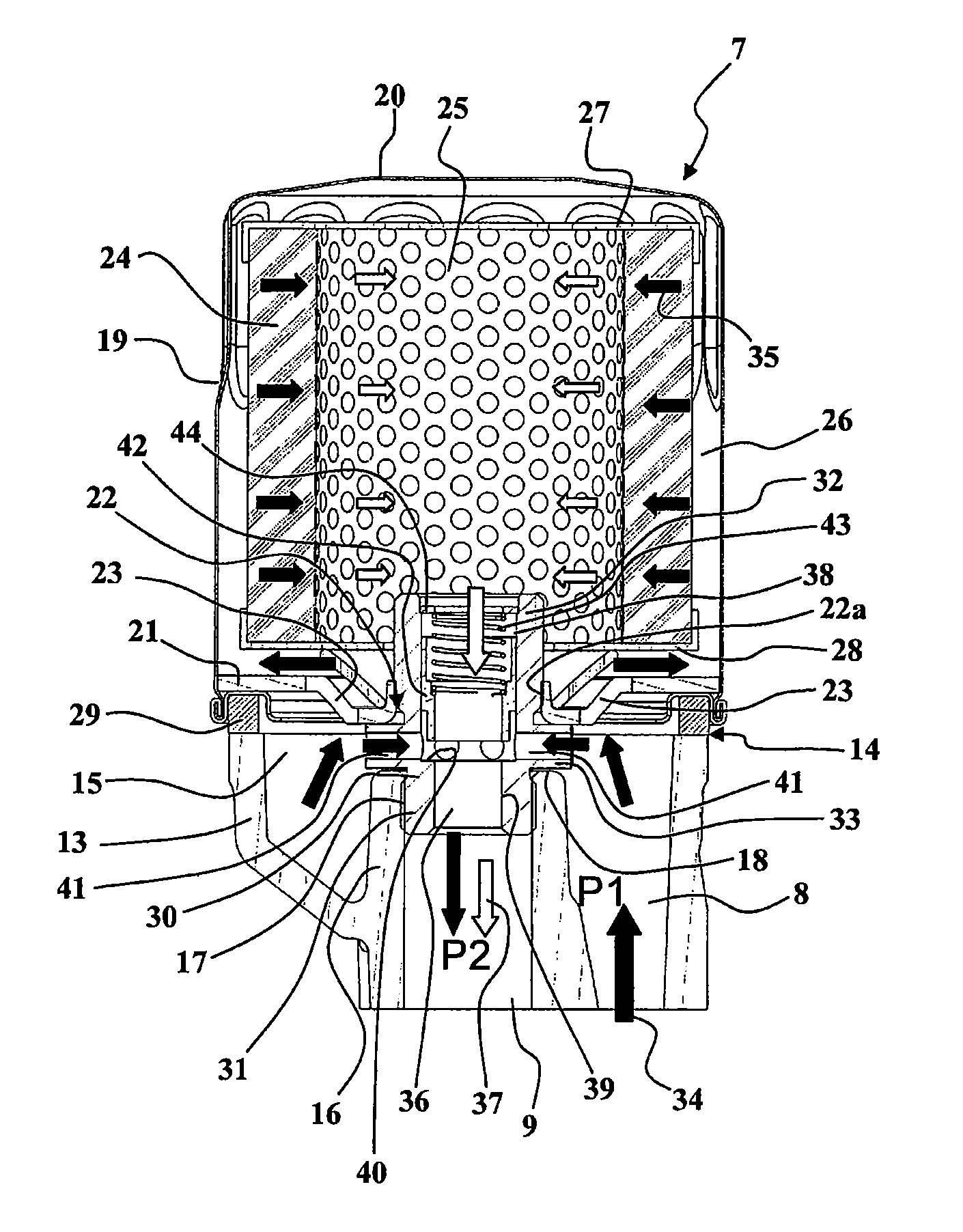

Oil bypass device, and engine fitted with such a device

ActiveUS7883621B2Improve reliabilityAvoid risk of failureHollow article cleaningPipe heating/coolingPressure riseEngineering

According to the invention, the filter is fixed to the engine block by screwing it to an attached connecting sleeve. The connecting sleeve contains a bypass valve, in the form of a tubular piston sliding in a through-passage and pushed against an intermediate shoulder by a spring. By sliding, the piston opens or closes a radial passage establishing direct communication between the inlet passage and the through-passage of the device. If the filter element of the filter is clogged, the pressure rise in the inlet passage causes the piston to move and the radial passage to open to reduce the pressure rise and ensure a satisfactory flow of oil. This reduces pressure rises upstream of the filter and ensures sufficient lubrication of the engine even in the case of clogging of the filter.

Owner:BONTAZ CENT

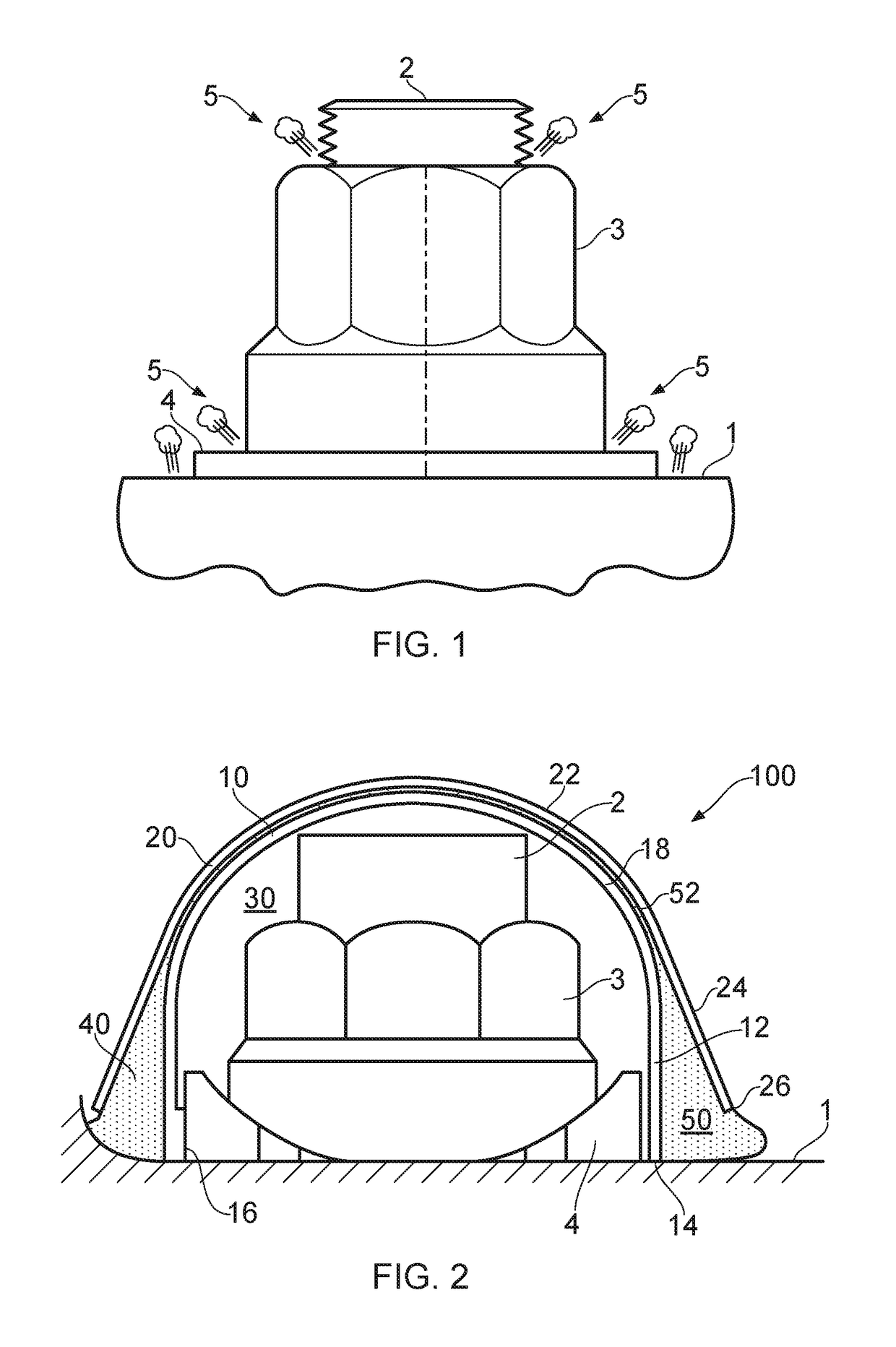

Method of installing a spark containment cap

InactiveUS10215216B2Avoid Sealing DefectsReduce the time required for installationAircraft lighting protectorsNutsEngineeringFastener

Owner:AIRBUS OPERATIONS LTD

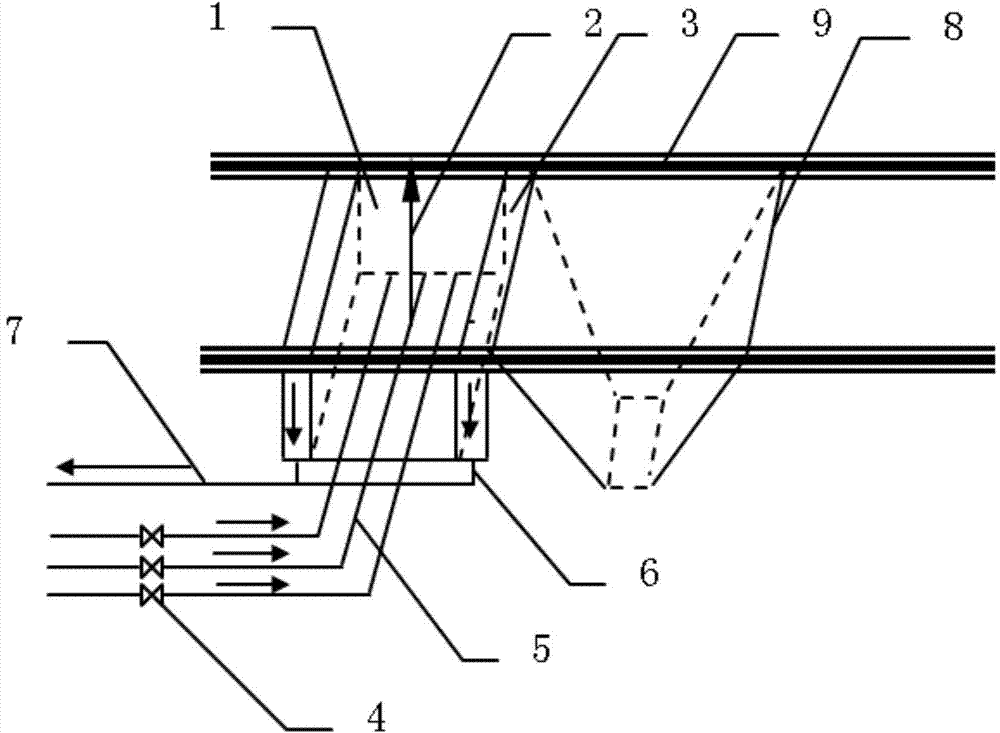

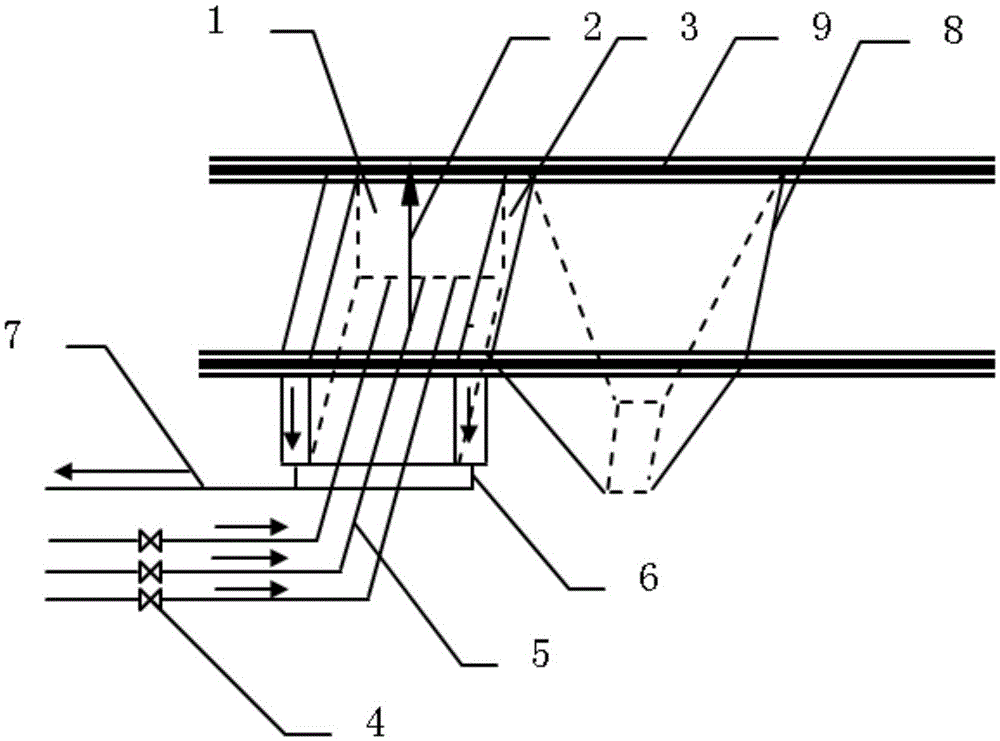

Water curtain type liquid sealing device for head and tail of sinter machine

The invention relates to the field of flexible liquid sealing devices for the heads and the tails of sinter machines, in particular to a water curtain type liquid sealing device for the head and the tail of a sinter machine, and aims to form a water curtain through spraying to effectively realize sealing of a sintering system. The device comprises a trolley slideway, a trolley, a bellows and a sealing water tank, wherein the trolley is slidably arranged above the trolley slideway, and the bellows is arranged under the trolley slideway; the sealing water tank is arranged beside the bellows and positioned under the trolley slideway; at least one water tank bottom water supply pipe with an upward opening is arranged at the bottom of the sealing water tank; the water tank bottom water supply pipe jets water flow to a trolley bottom beam of the trolley to form water seal. As the water seal is adopted, the water curtain type liquid sealing device is ideal in sealing effect, fundamentally avoids the sealing defects, caused by factors, such as deformation, of the traditional solid sealing baffle plate, is especially suitable for sinter machines with high sealing requirements, and has an important realistic meaning on productivity increasing and energy saving.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Sealing joint for gas insulation switch cabinet

InactiveCN111106563AAvoid Sealing DefectsImproves sealing reliabilitySwitchgear arrangementsEpoxyDisplay device

The invention discloses a sealing joint for a gas insulation switch cabinet. The sealing joint comprises an epoxy resin sealing body. The epoxy resin sealing body is integrally fixed at an opening ofthe gas insulation switch cabinet. A metal insert penetrates through the epoxy resin sealing body. A first internal thread groove is formed in one end, close to the opening of the gas insulation switch cabinet, of the metal insert, and a second internal thread groove is formed in the other end of the metal insert. The first internal thread groove is connected with a secondary control loop of the gas insulation switch cabinet. The secondary control loop is connected with a display device. The second internal thread groove is connected with a high-voltage current transformer in the gas insulation switch cabinet. According to the invention, the sealing joint can replace an aviation plug; through a mature and reliable epoxy resin pouring technology, the sealing defect of the joint body is avoided; threads are arranged at the two ends of the insert; a secondary signal line of the high-voltage current transformer does not need to be welded with a contact pin hole of an aviation socket manually; sealing damage caused by welding is avoided; and the sealing reliability of switch equipment is greatly improved.

Owner:SHANGHAI PINGGAO TIANLING SWITCHGEAR CO LTD +2

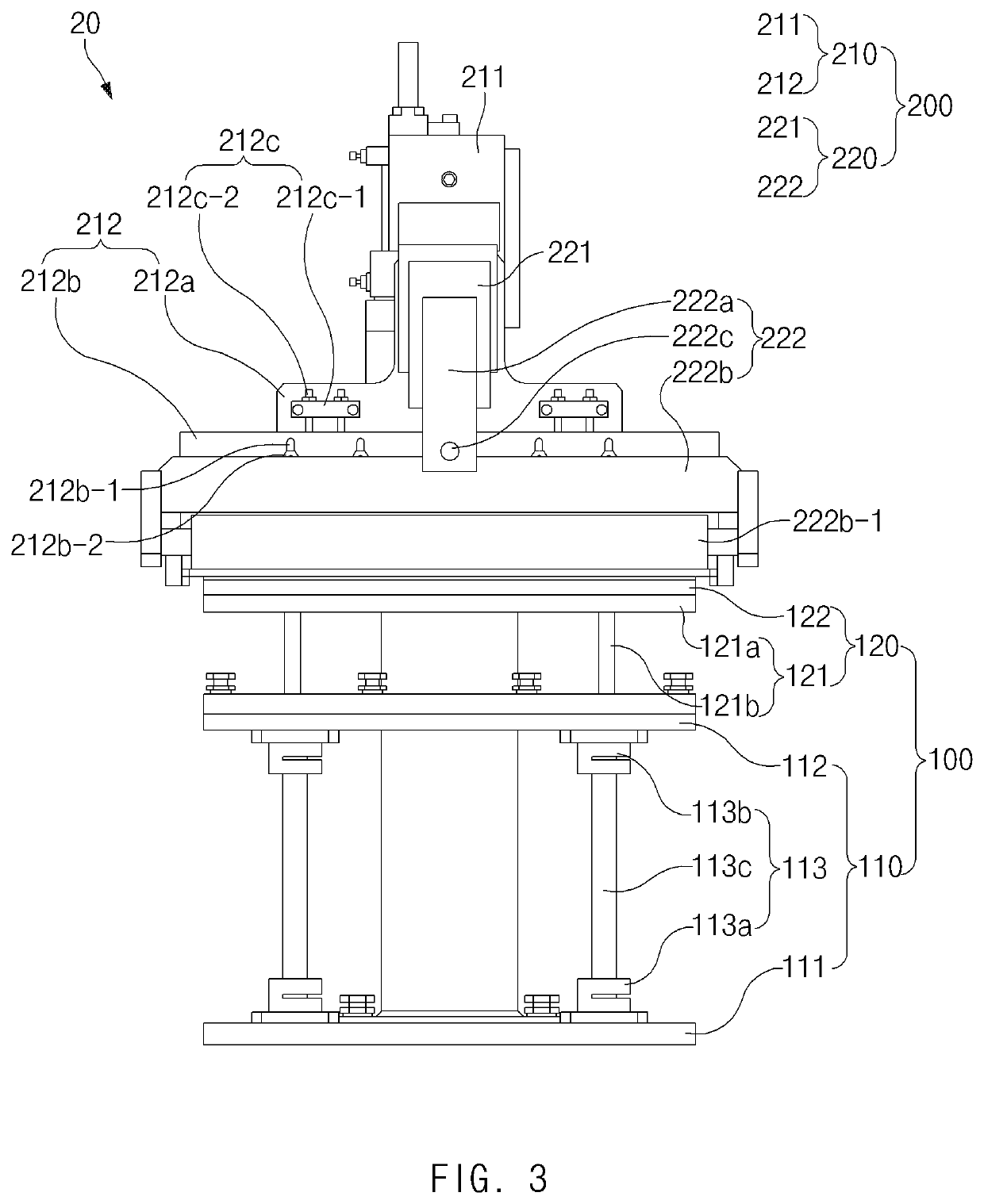

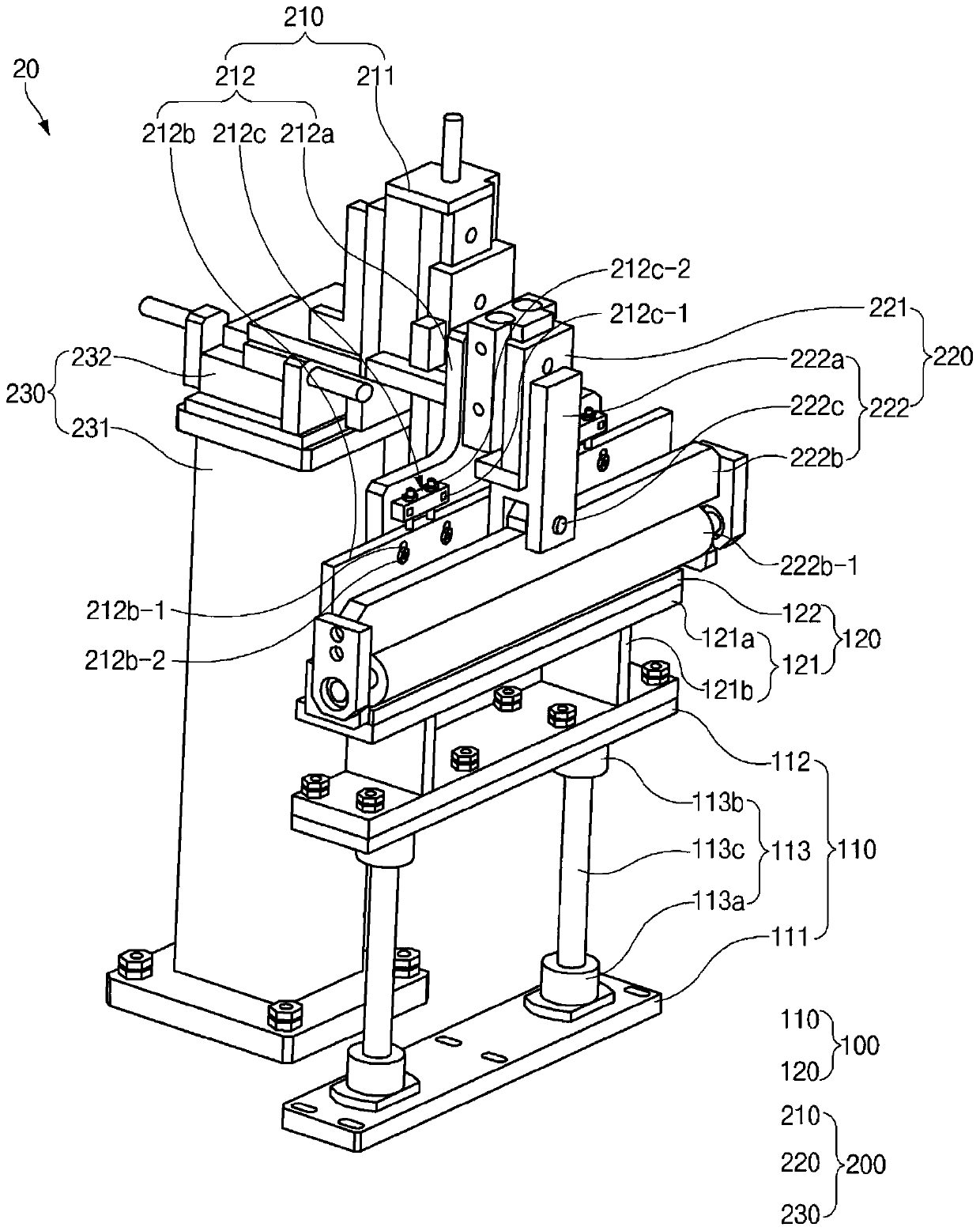

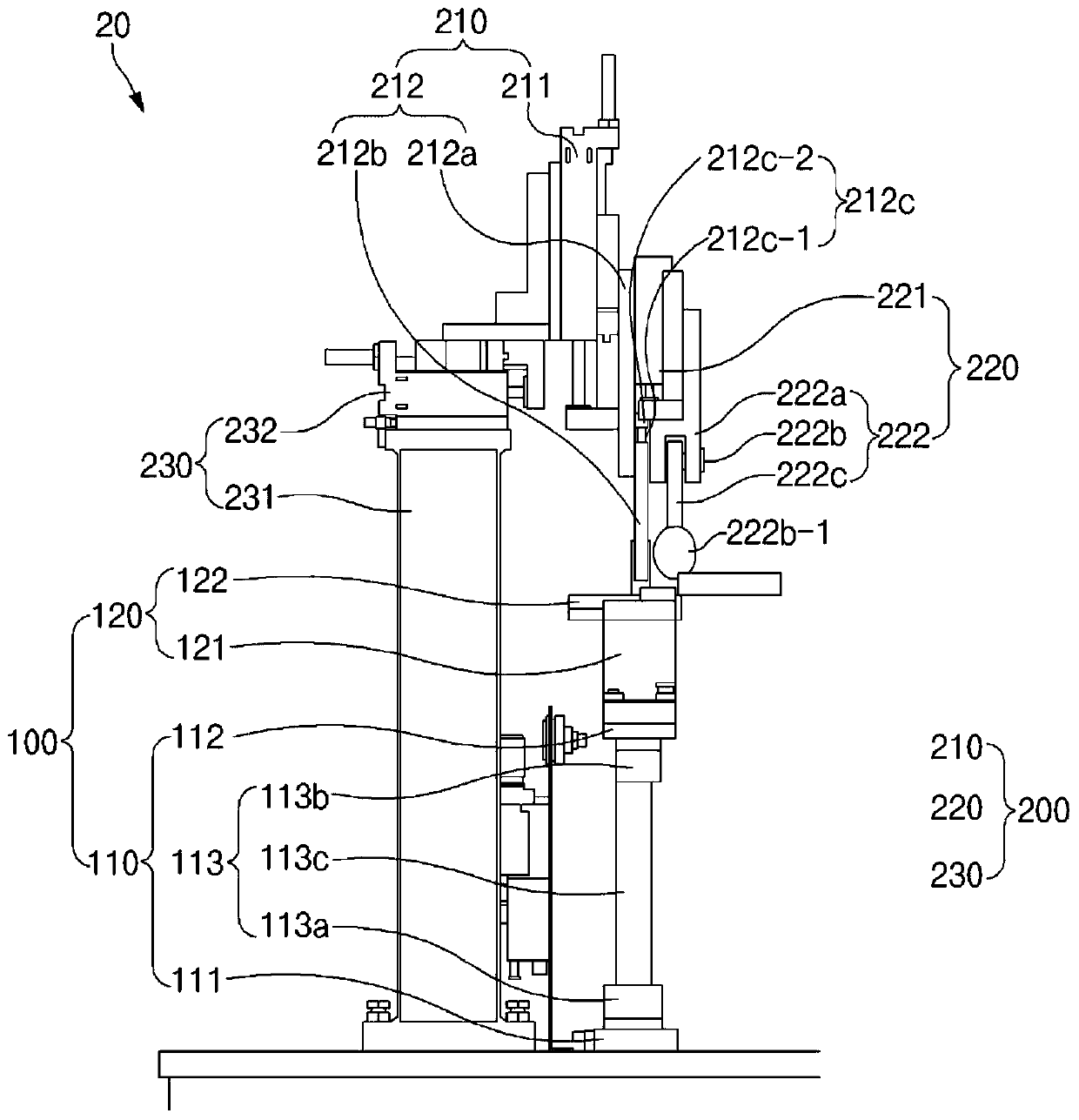

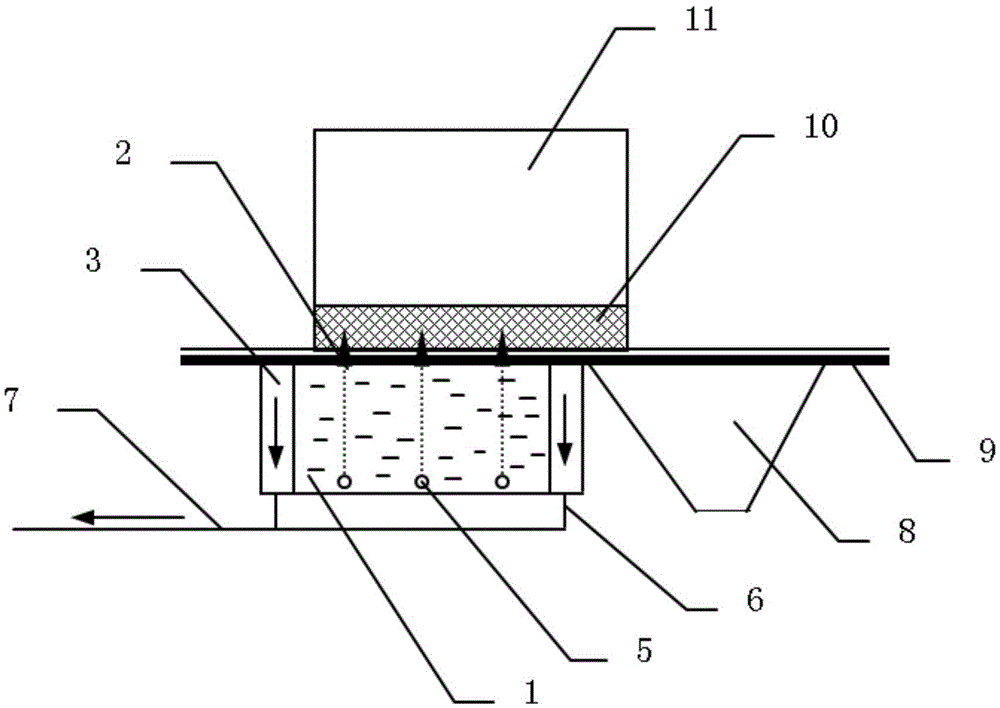

Electrolyte Removing Device, Apparatus and Method for Manufacturing Secondary Battery Comprising the Same, and Secondary Battery

ActiveUS20210036302A1Avoid Sealing DefectsRemove completelyAssembling battery machinesFinal product manufactureElectrolyteChemical engineering

The present invention relates to an electrolyte removing device. The electrolyte removing device comprises: a jig assembly configured to receive in a seated position a pouch comprising an accommodation part in which an electrode assembly is accommodated, a gas pocket part, and a connection part connecting the accommodation part to the gas pocket part; and an electrolyte removing assembly configured to push an electrolyte remaining on the connection part to the gas pocket part to remove the electrolyte from the connection part.

Owner:LG ENERGY SOLUTION LTD

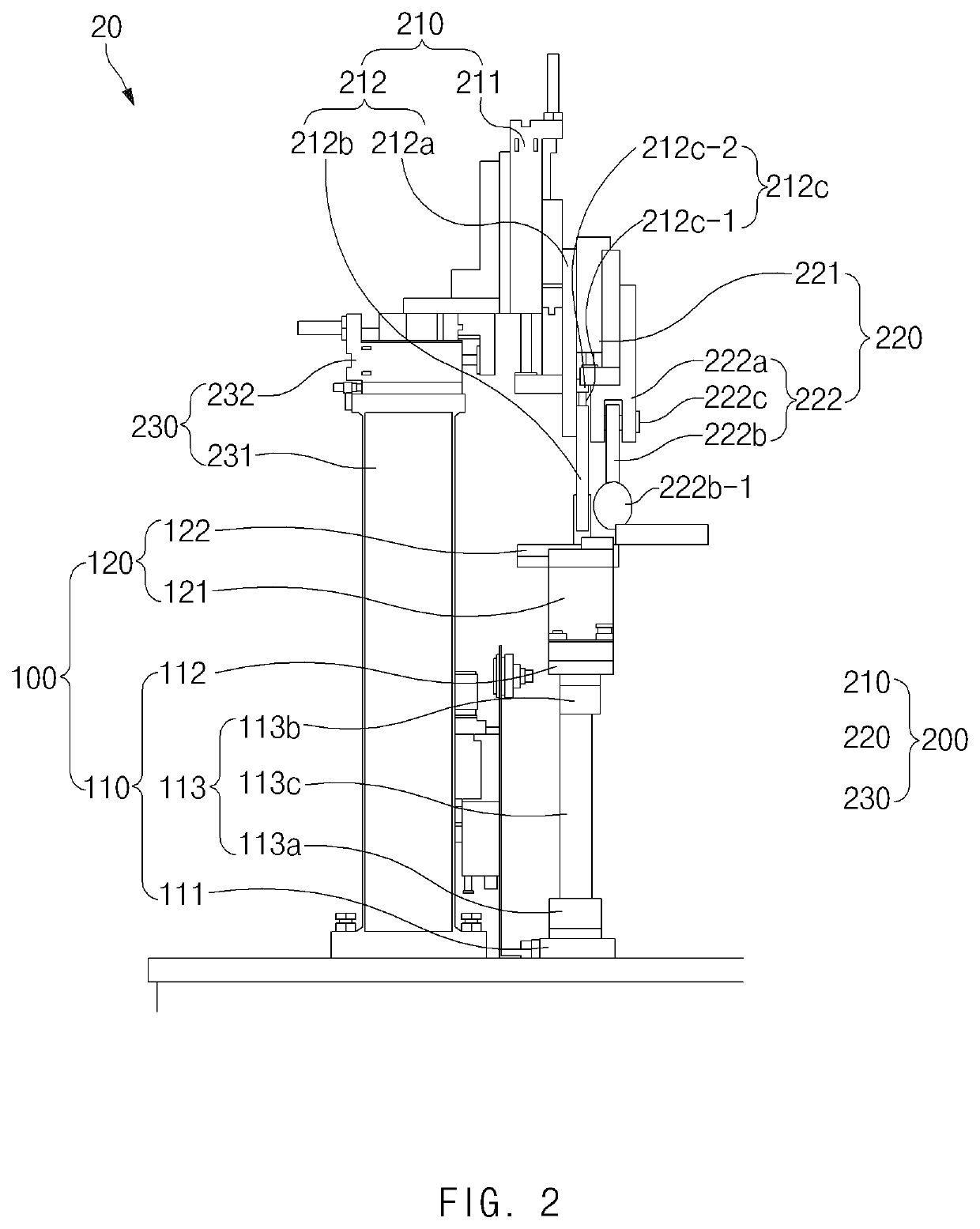

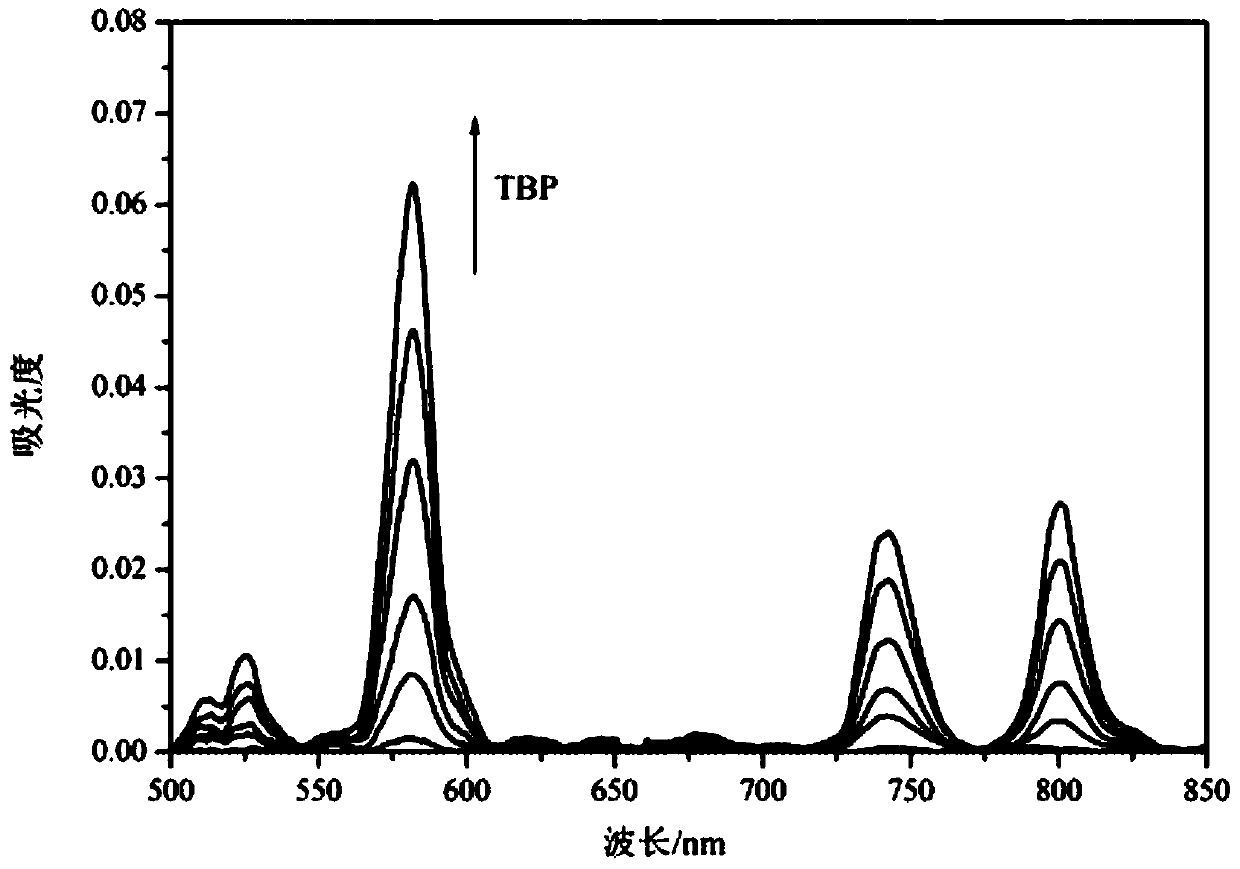

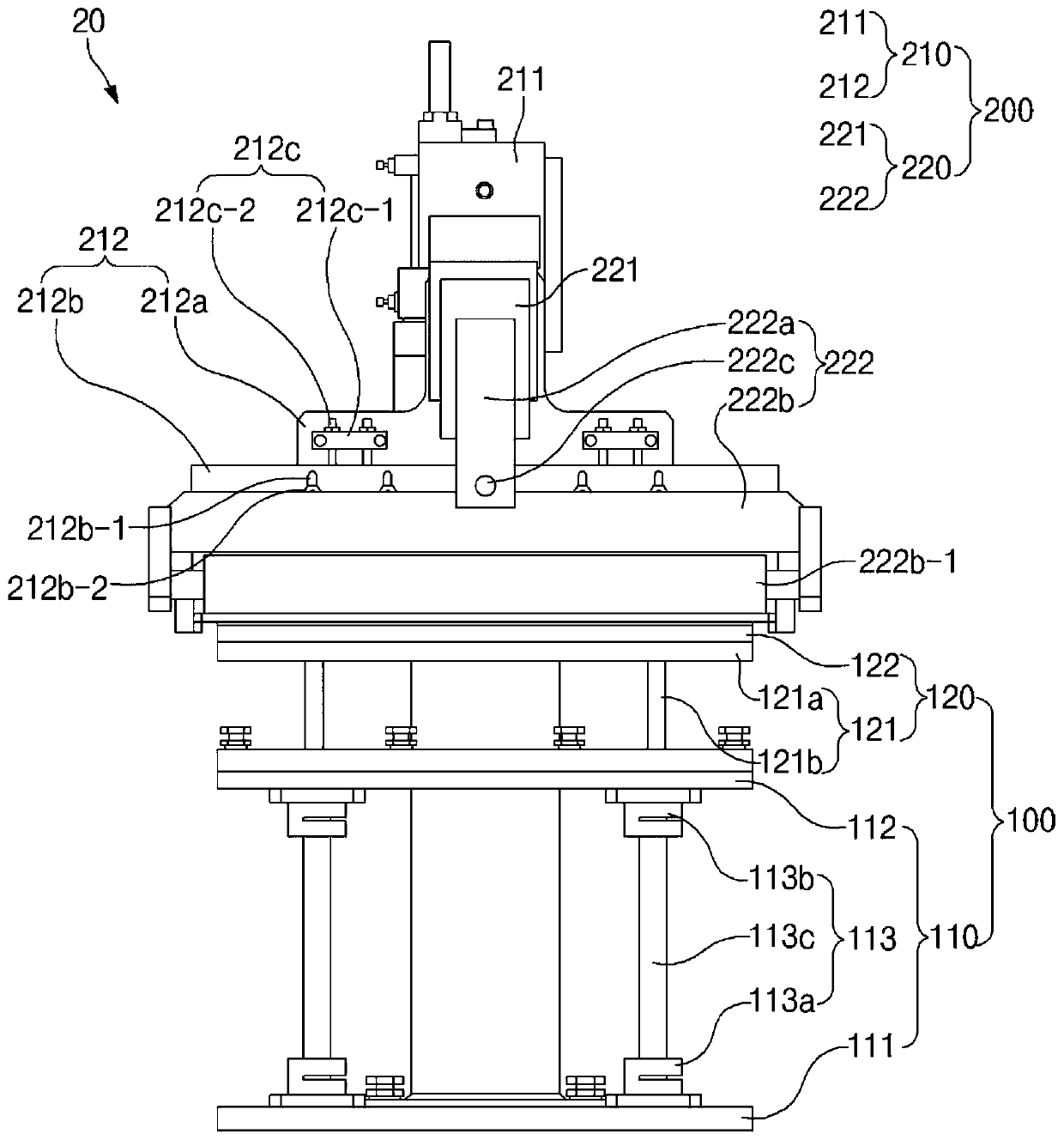

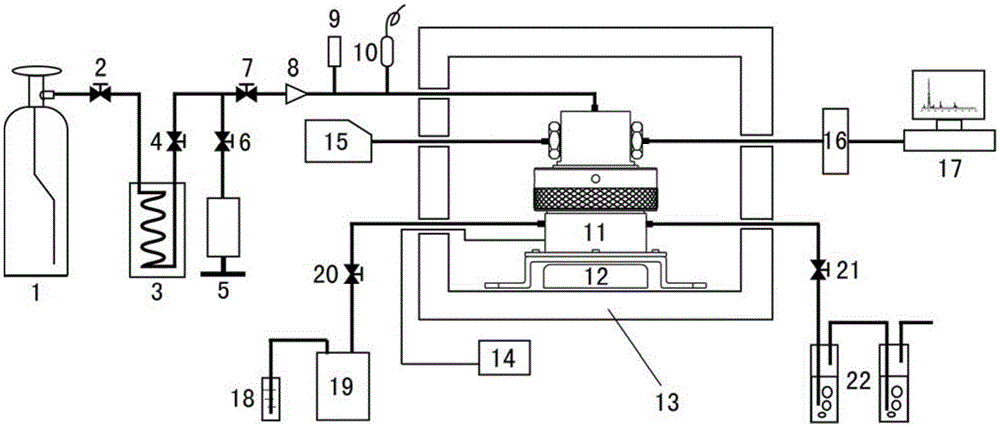

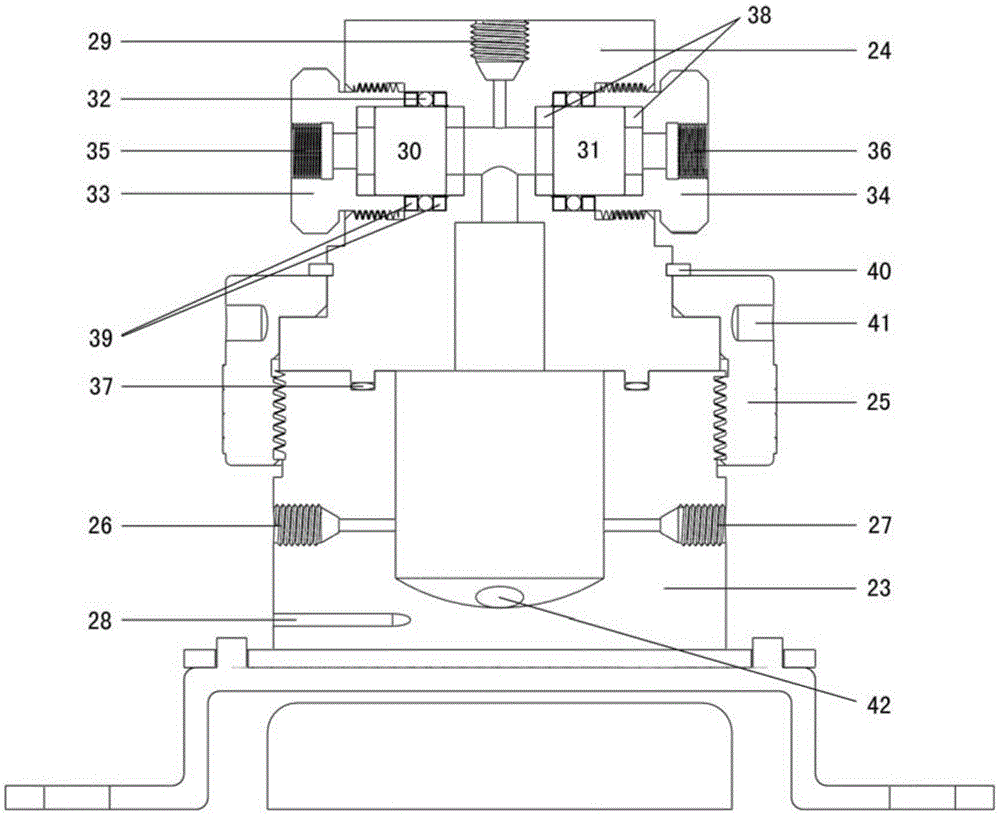

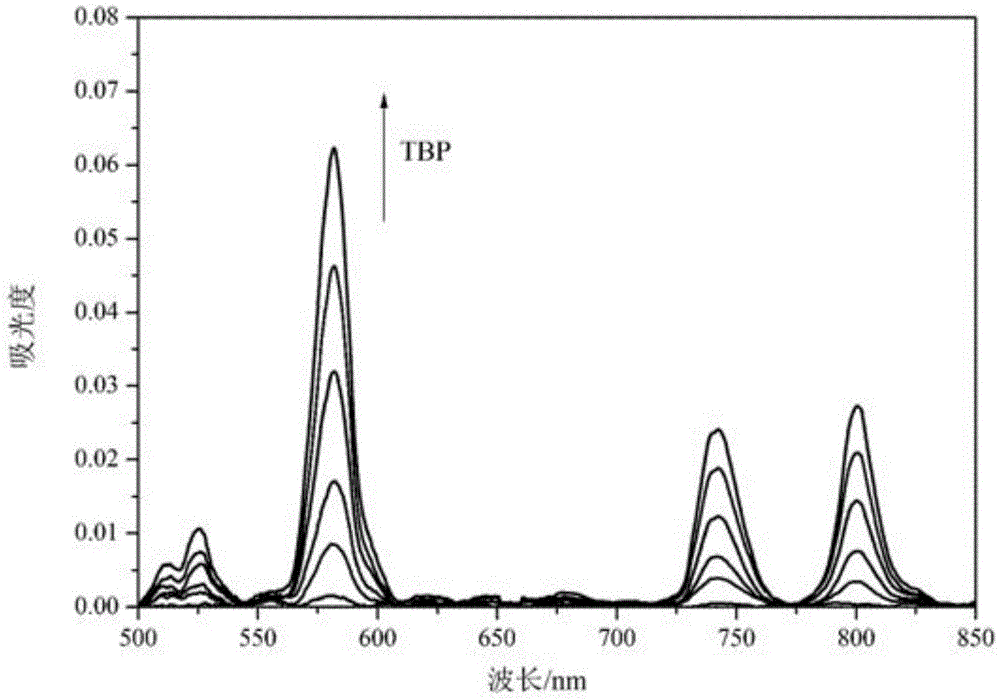

A supercritical fluid complexation reaction device with online spectrum monitoring function

ActiveCN105641968BRealize large-scaleAvoid Sealing DefectsSolvent extractionColor/spectral properties measurementsCo2 storageLanthanide

The invention belongs to the research field of separation of actinide series elements and lanthanide series elements by a supercritical fluid. In order to overcome the disadvantages of an existing supercritical fluid complex reaction device, the invention provides a supercritical fluid complex reaction device with an online spectrum monitoring function. The device comprises a CO2 storage bottle, a refrigerator, a gas pump, a reaction kettle, a magnetic stirrer, a constant-temperature box, a temperature sensor, a light source, a spectrograph, a data processing system, a reagent bottle, a metering pump and a receiving bottle; and the reaction kettle comprises a kettle body, a kettle cover and a kettle pressing cap. The supercritical fluid complex reaction device provided by the invention has the advantages of rapid supercritical complex reaction speed, capability of rapidly acquiring high-quality spectrum monitoring data, convenience for accurately adding materials and accurately controlling temperatures, high reliability and the like; and application researches of the extraction and separation of the actinide series elements and lanthanide series elements by supercritical CO2.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method and device for manufacturing bag with clamping device

ActiveUS7695419B2Inhibit transferAvoid Sealing DefectsEnvelopes/bags making machineryMechanical working/deformationEngineeringMechanical engineering

A tape with a zipper member and a bag film are continuously moved by rotation of a rotary drum while being overlaid with each other such that the tape travels in a tape introducing groove for a tape with a zipper member, the groove formed along a circumferential direction of the rotary drum. The tape with the zipper member is continuously welded to the bag film on a circumferential surface of the rotary drum by a seal bar that has a welding surface in a curved shape corresponding to a circumferential surface shape of the rotary drum. A heat-insulation portion is provided on at least one of the tape body of the tape and the rotary drum so that heat applied from the seal bar to the tape with the zipper member is prevented from transferring to the rotary drum.

Owner:IDEMITSU UNITECH CO LTD

A Method for Intermittent Seal Failure Analysis of Sealed Circuit Modules in High Temperature Environment

ActiveCN110286313BAvoid Sealing DefectsAvoid going onlineDetection of fluid at leakage pointMaterial analysis using wave/particle radiationAir atmosphereThermodynamics

Owner:XIAN MICROELECTRONICS TECH INST

Circular-flat integrated cable for electric submersible pump

ActiveCN102456431BExtend your lifeAvoid Sealing DefectsInsulated cablesConnections effected by permanent deformationElectrical conductorVulcanization

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Electrolyte removal device, apparatus and method for manufacturing secondary battery comprising same, and secondary battery

ActiveCN110603665AAvoid Sealing DefectsRemove completelyAssembling battery machinesFinal product manufactureEngineeringBattery cell

Owner:LG ENERGY SOLUTION LTD

Supercritical fluid complex reaction device with online spectrum monitoring function

ActiveCN105641968ARealize large-scaleAvoid Sealing DefectsSolvent extractionColor/spectral properties measurementsCo2 storageSpectrograph

The invention belongs to the research field of separation of actinide series elements and lanthanide series elements by a supercritical fluid. In order to overcome the disadvantages of an existing supercritical fluid complex reaction device, the invention provides a supercritical fluid complex reaction device with an online spectrum monitoring function. The device comprises a CO2 storage bottle, a refrigerator, a gas pump, a reaction kettle, a magnetic stirrer, a constant-temperature box, a temperature sensor, a light source, a spectrograph, a data processing system, a reagent bottle, a metering pump and a receiving bottle; and the reaction kettle comprises a kettle body, a kettle cover and a kettle pressing cap. The supercritical fluid complex reaction device provided by the invention has the advantages of rapid supercritical complex reaction speed, capability of rapidly acquiring high-quality spectrum monitoring data, convenience for accurately adding materials and accurately controlling temperatures, high reliability and the like; and application researches of the extraction and separation of the actinide series elements and lanthanide series elements by supercritical CO2.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

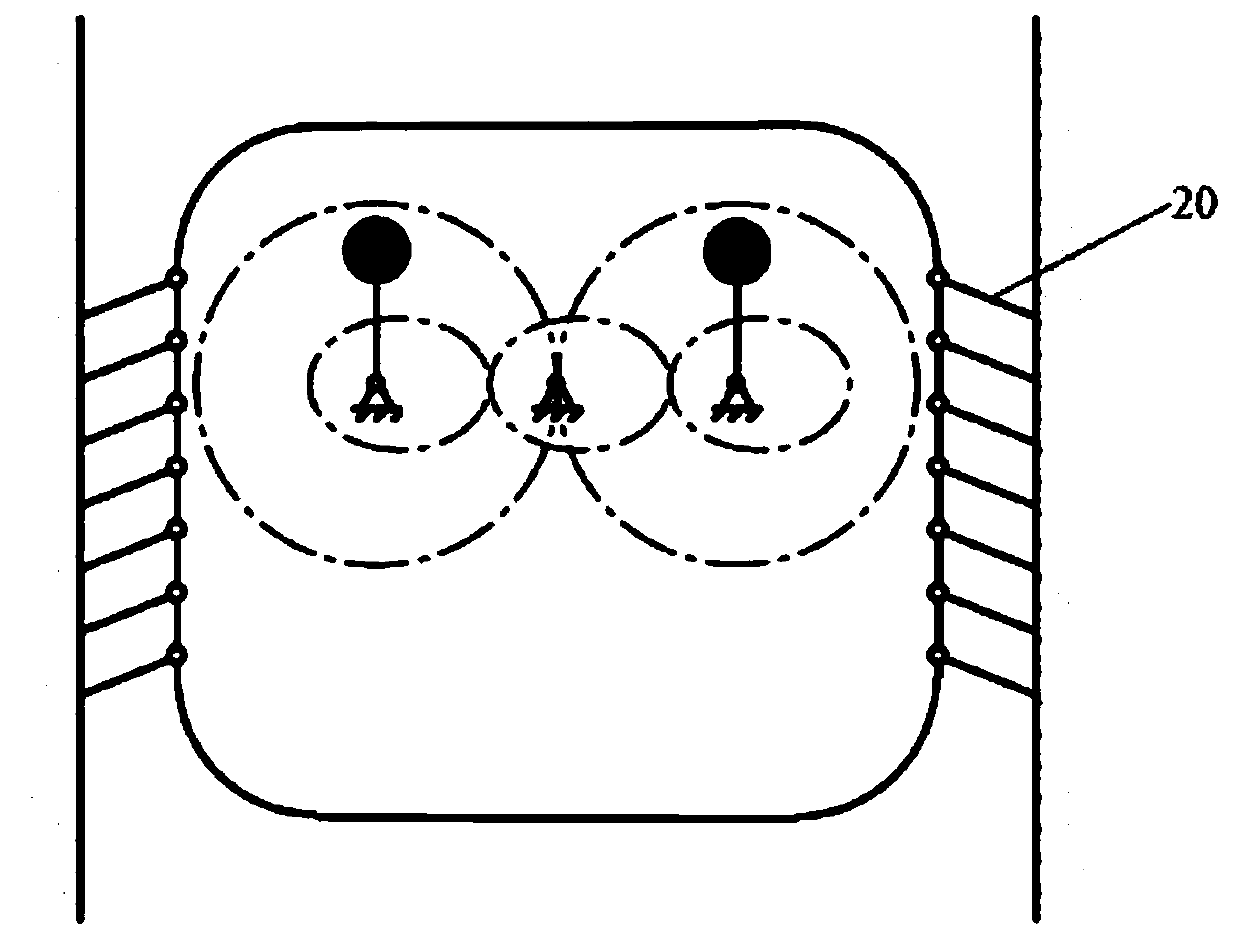

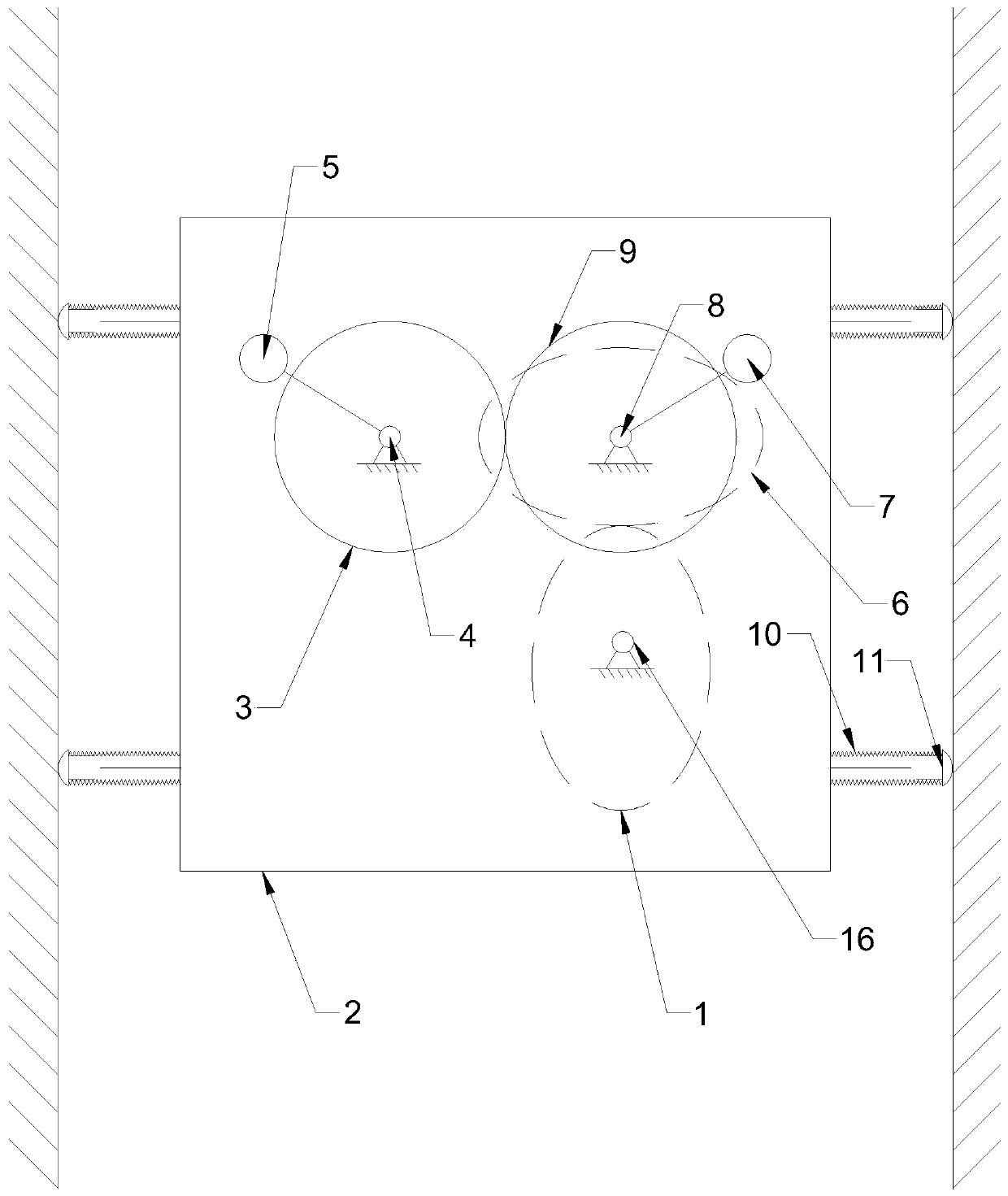

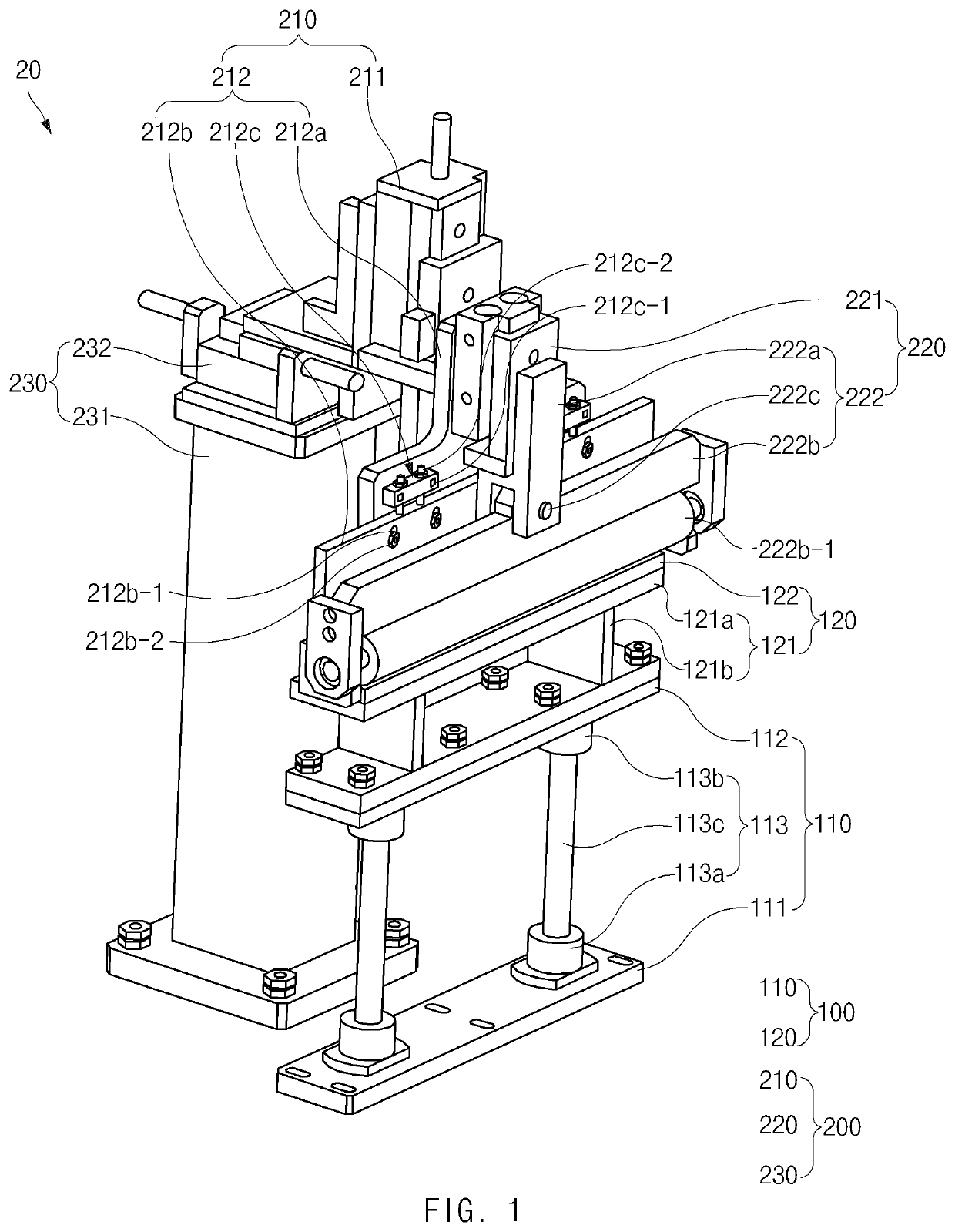

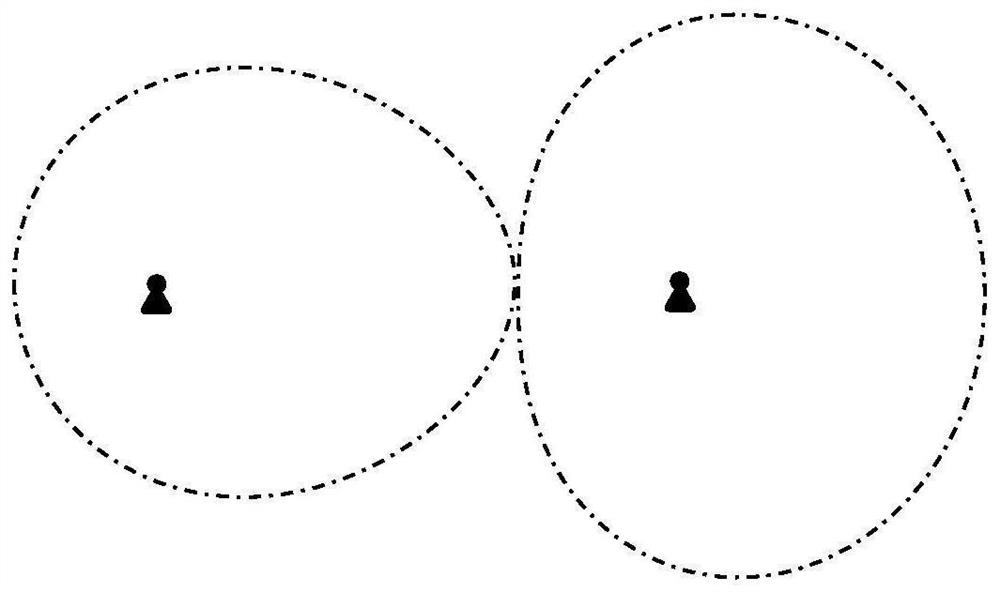

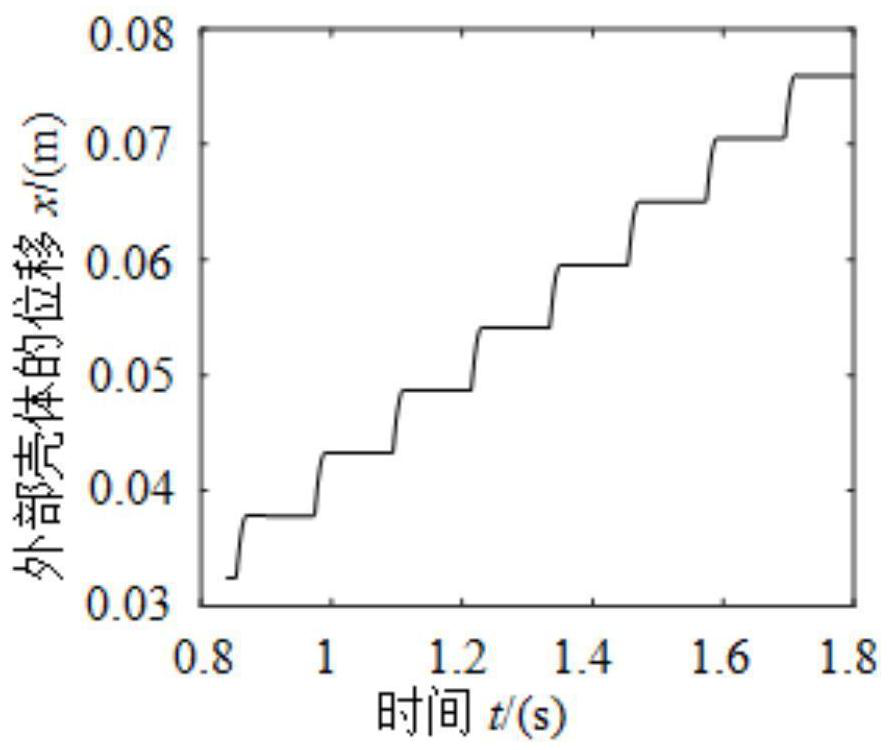

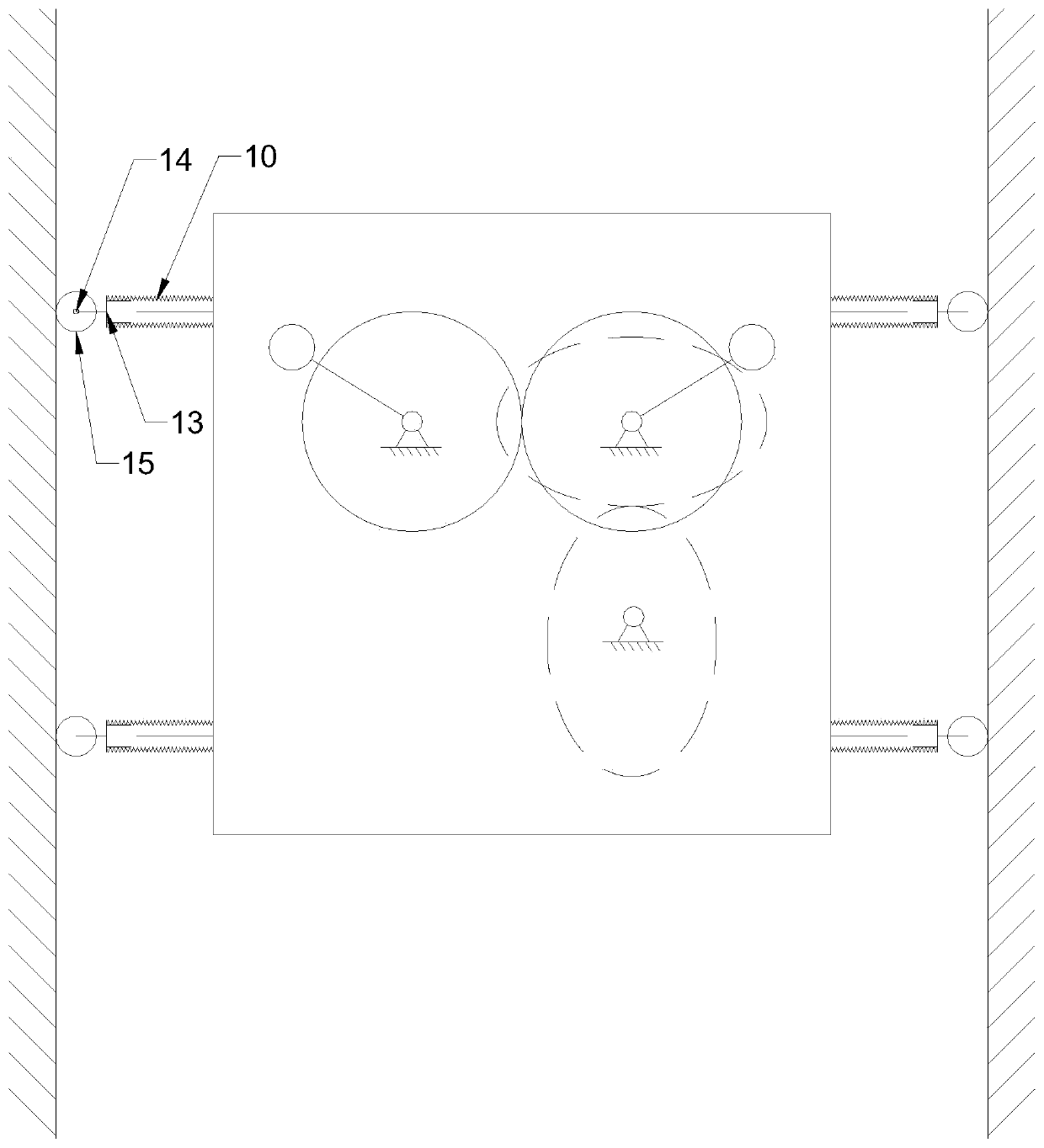

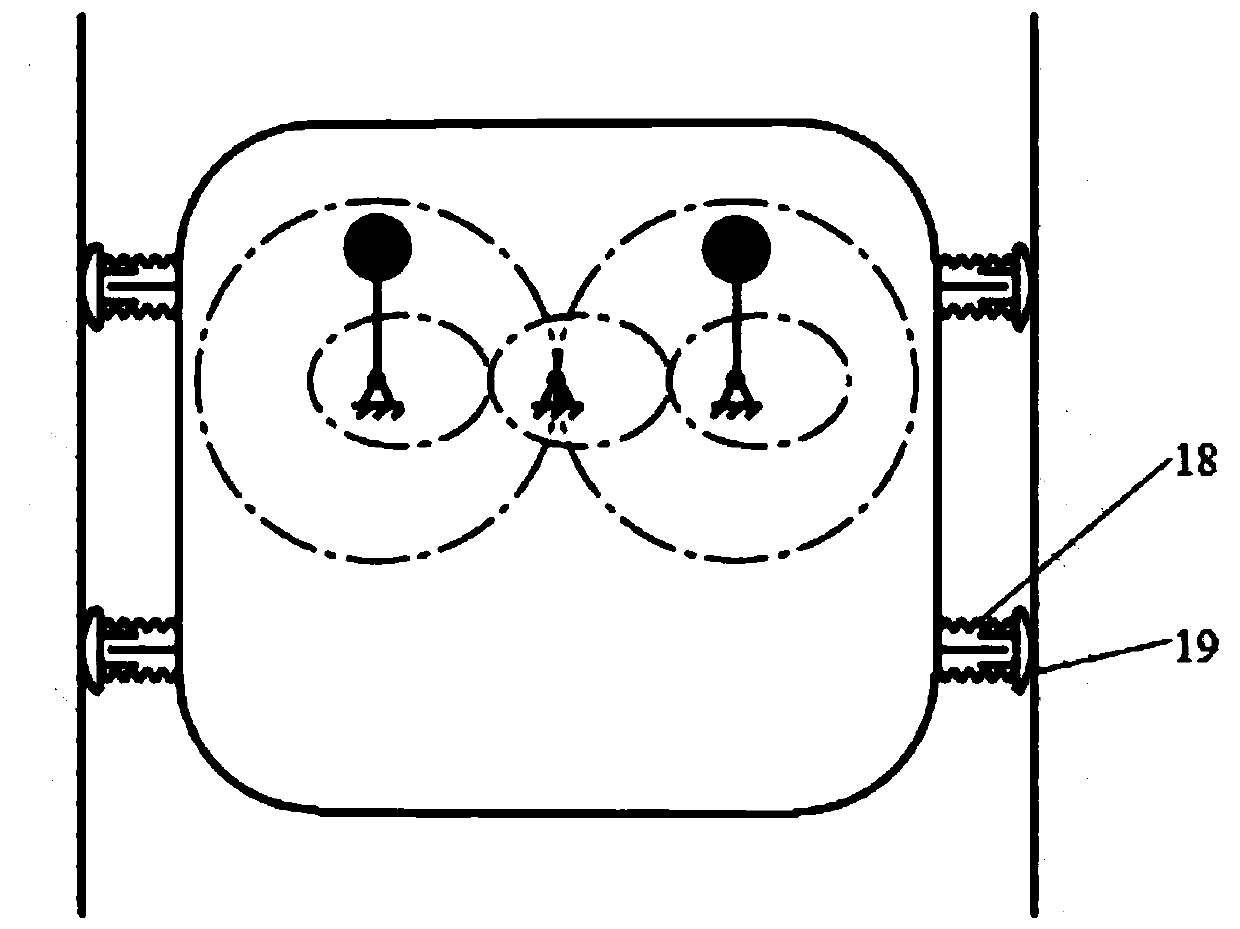

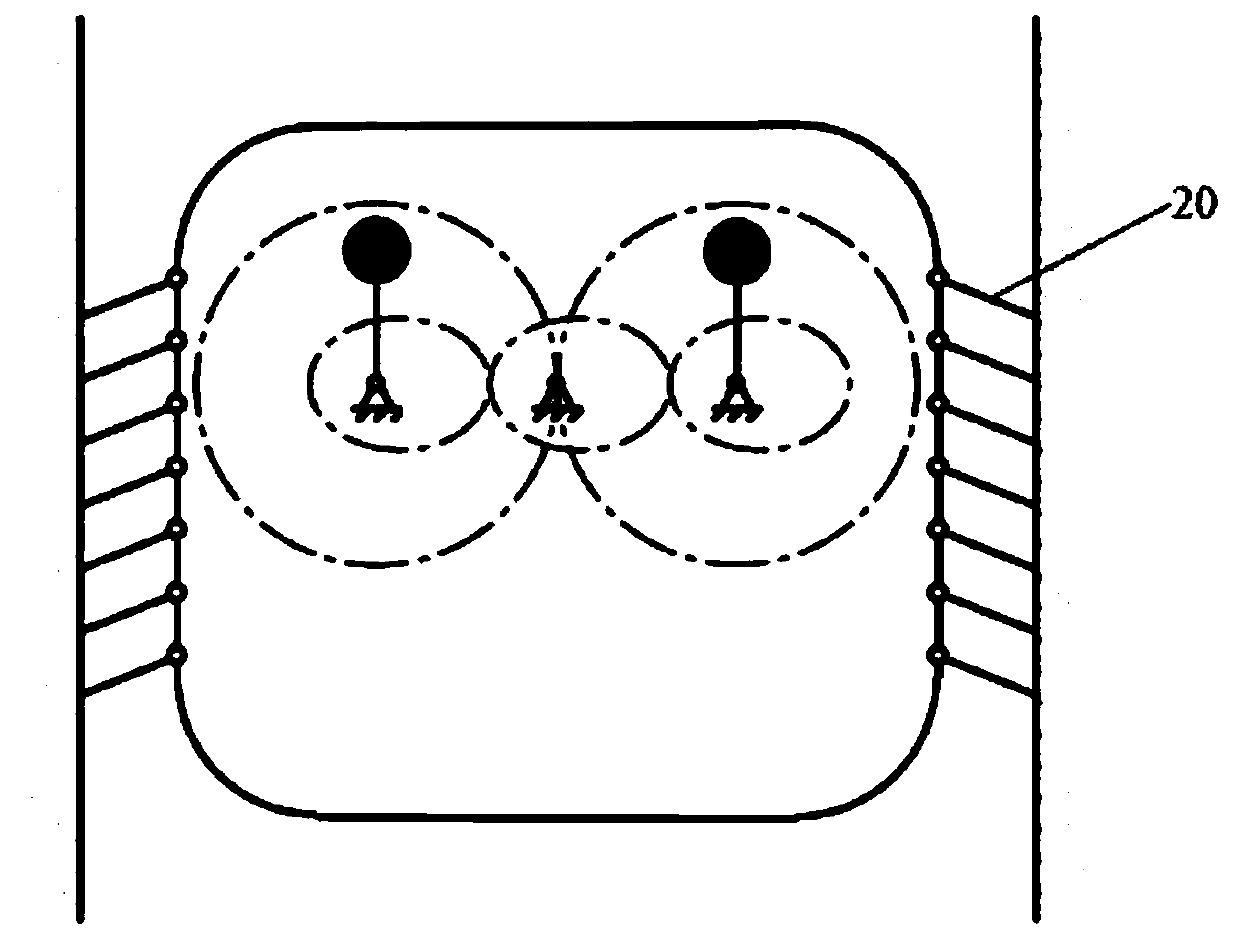

Double-mass impact type pipeline robot driven by non-circular gears and motion modeling method

ActiveCN113503423AAvoid Sealing DefectsSize advantageDesign optimisation/simulationPigs/molesGear wheelControl engineering

The invention provides a double-mass impact type pipeline robot driven by non-circular gears and a motion modeling method. The pipeline robot comprises a motor, a pair of non-circular gears, a pair of synchronous circular gears, two eccentric blocks and an outer shell, wherein an output shaft of the motor is fixedly connected with the driving non-circular gear; the driven non-circular gear is connected with one of the synchronous circular gears; the two synchronous circular gears are connected with the eccentric blocks respectively; the two eccentric blocks are the same in shape and keep rotating in a centering mode; and the outer shell keeps in elastic contact with the inner wall of the pipeline. A power system of the double-mass impact type pipeline robot is completely sealed, no external driving part is needed, the size, sealing performance, corrosion resistance and other performance of the double-mass impact type pipeline robot have more advantages, and the double-mass impact type pipeline robot not only has the capacity of walking in a common pipeline environment but also has the capacity of high-efficiency operation in a special pipeline system for conveying corrosive and inflammable media or small in diameter.

Owner:YANSHAN UNIV

Rainproof threshold structure of railway vehicle control cabin and railway vehicle

ActiveCN114655259AInvulnerableSimple structureDoor arrangementRailway transportStructural engineeringControl room

The invention discloses a rainproof doorsill structure of a control cabin of a railway vehicle and the railway vehicle, the rainproof doorsill structure comprises a rain eave, one end of the rain eave is connected to the outer side of a control cabin door of the railway vehicle, and the other end of the rain eave inclines downwards and extends towards the outer side of a lower doorframe of the control cabin door of the railway vehicle; a cavity is defined by the doorsill on the inner side of the lower door frame, the doorsill comprises a flow guide part, the flow guide part is arranged at the end, close to the lower door frame, of the doorsill and inclines downwards, a plurality of notches are formed in the end, close to the lower door frame, of the flow guide part, and drainage holes are formed in the bottom of the lower door frame; according to the rainproof doorsill structure, the structure of a rubber barrier strip is omitted, the rain eave is directly connected to the outer side of the control room door, the structure is simplified, meanwhile, the sealing defect caused by deformation or aging due to rubber riveting is avoided, the doorsill with the flow guide part is adopted to guide rainwater entering the inner side of the lower doorframe, and the rainproof effect is good. And the gaps and the drainage holes are formed, so that the guided rainwater can be completely drained, and the interior of the railway vehicle is protected against rainwater invasion.

Owner:CRRC TAIYUAN CO LTD

a pipeline robot

The invention relates to a pipeline robot and belongs to the technical field of robots. The pipeline robot comprises an inertial excitation mechanism which comprises a rotary power source, a non-circular gear transmission mechanism and at least two same eccentric mechanisms, and all eccentric mechanisms are uniformly distributed circumferentially on a plane; each eccentric mechanism comprises an eccentric mass block which rotates around a rotating shaft; the rotary power source drives the eccentric mass block to rotate around the rotating shaft through the non-circular gear transmission mechanism; the rotating speeds of the eccentric mass blocks are consistent and the component forces of a resultant force of eccentric forces generated by all the eccentric mass blocks are zero. The pipelinerobot moves by means of joint action of an inner inertial force and an environmental friction force. By adopting the driving mode, the defect that a driving device and an executing device in a conventional driving mode must be sealed is overcome fundamentally, so that the pipeline robot is suitable for extremely severe pipeline operating environments such as narrow, corrosive, inflammable and high-temperature environments, and has a huge potential in the aspect of miniaturization.

Owner:大庆市大广测绘服务有限公司

A Two-way Moving Inertial Pipeline Robot

The invention provides a bidirectional moving inertia pipeline robot. At present, due to the structure, most pipeline robots can not work bidirectionally in high pressure, flammable and explosive, corrosive and other severe environments. The bidirectional moving inertia pipeline robot mainly comprises a shell and an inertia excitation mechanism. The inertia excitation mechanism comprises a rotation power source, three non-circular gear connected in series and two identical eccentric mechanisms, and the inertia excitation mechanism is arranged inside the robot shell. The two eccentric mechanisms are transmitted through a pair of synchronous cylindrical gears, revolving shafts of the two non-circular gears are connected with revolving shafts of the synchronous cylindrical gears respectivelythrough two overrun clutches, and the work directions of the two overrun clutches are opposite. The inertia pipeline robot moves through the mutual action of interior inertia and environment frictionforce, the defect that movable sealing must be arranged between a traditional power source and main driving feet can be overcome fundamentally by means of the driving mode, and the bidirectional moving inertia pipeline robot is suitable for small, high pressure, corrosive, flammable, high temperature and other extreme severe pipeline work environments.

Owner:上海乔智科技有限公司

Sintering machine head and tail water curtain liquid sealing device

ActiveCN104501600BAvoid Sealing DefectsIdeal gas sealing effectEngine sealsFurnace typesWater flowWater pipe

The invention relates to the field of flexible liquid sealing devices for the heads and the tails of sinter machines, in particular to a water curtain type liquid sealing device for the head and the tail of a sinter machine, and aims to form a water curtain through spraying to effectively realize sealing of a sintering system. The device comprises a trolley slideway, a trolley, a bellows and a sealing water tank, wherein the trolley is slidably arranged above the trolley slideway, and the bellows is arranged under the trolley slideway; the sealing water tank is arranged beside the bellows and positioned under the trolley slideway; at least one water tank bottom water supply pipe with an upward opening is arranged at the bottom of the sealing water tank; the water tank bottom water supply pipe jets water flow to a trolley bottom beam of the trolley to form water seal. As the water seal is adopted, the water curtain type liquid sealing device is ideal in sealing effect, fundamentally avoids the sealing defects, caused by factors, such as deformation, of the traditional solid sealing baffle plate, is especially suitable for sinter machines with high sealing requirements, and has an important realistic meaning on productivity increasing and energy saving.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

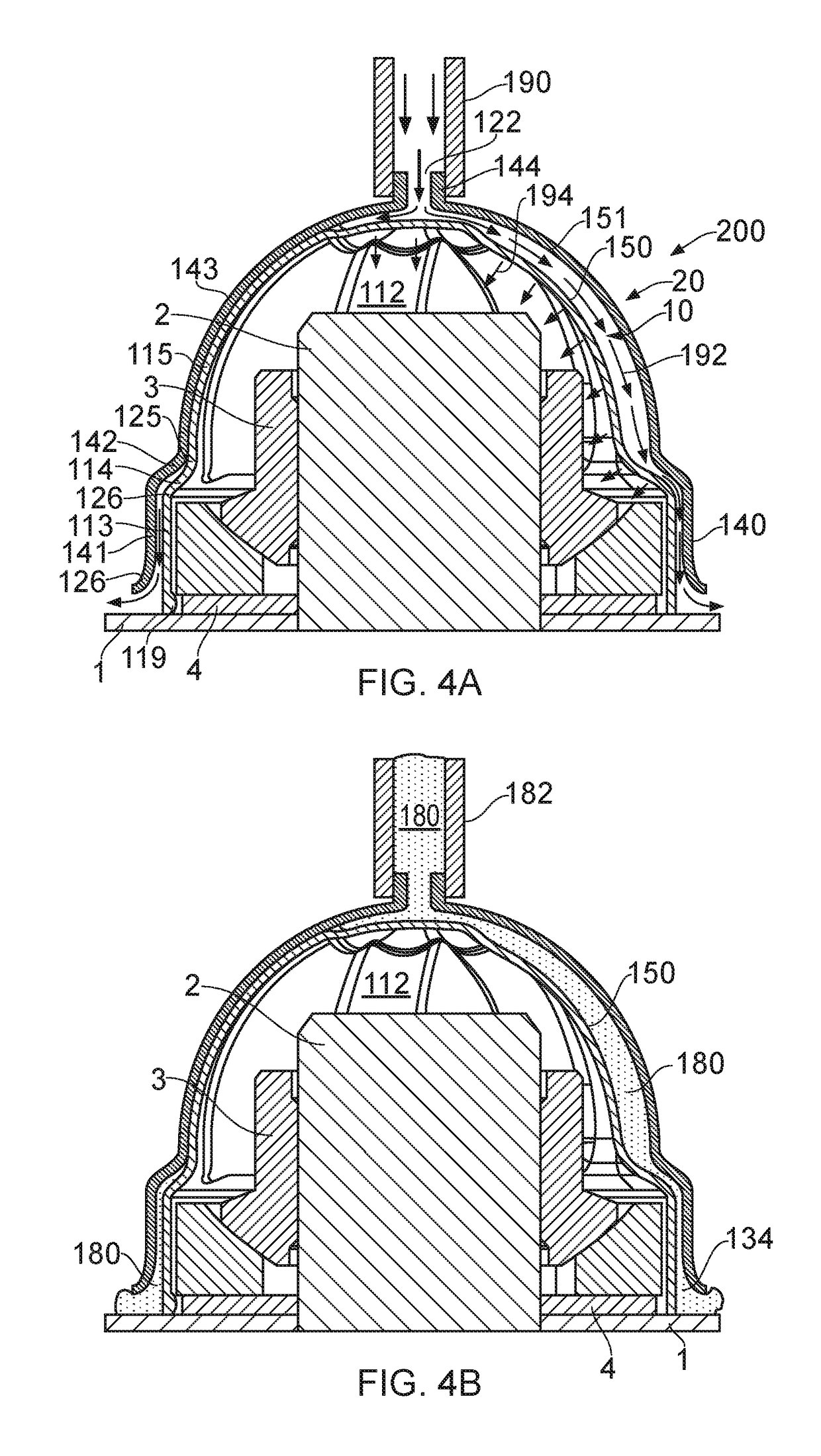

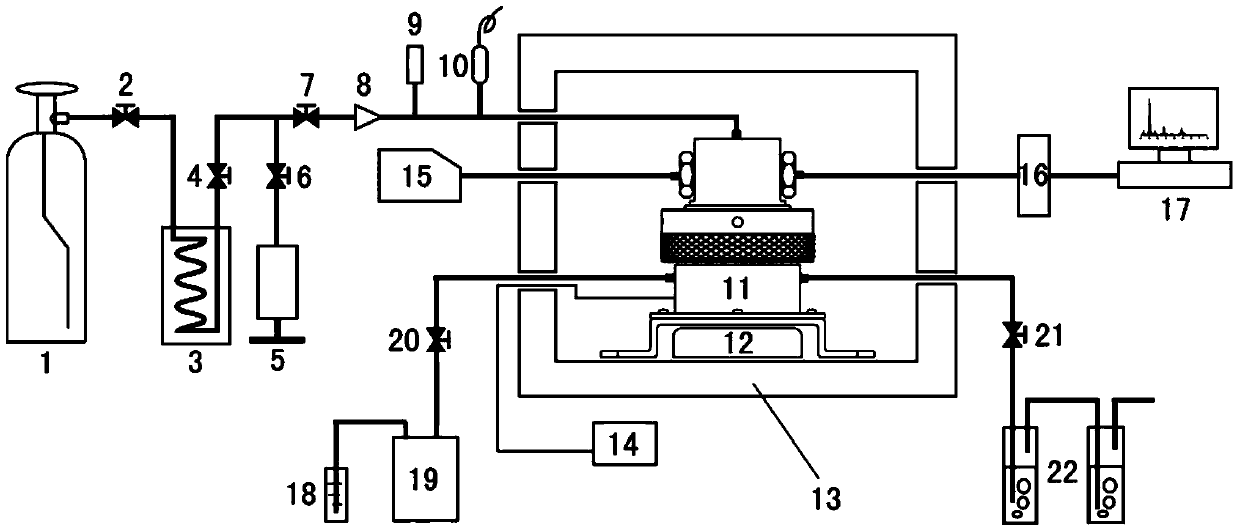

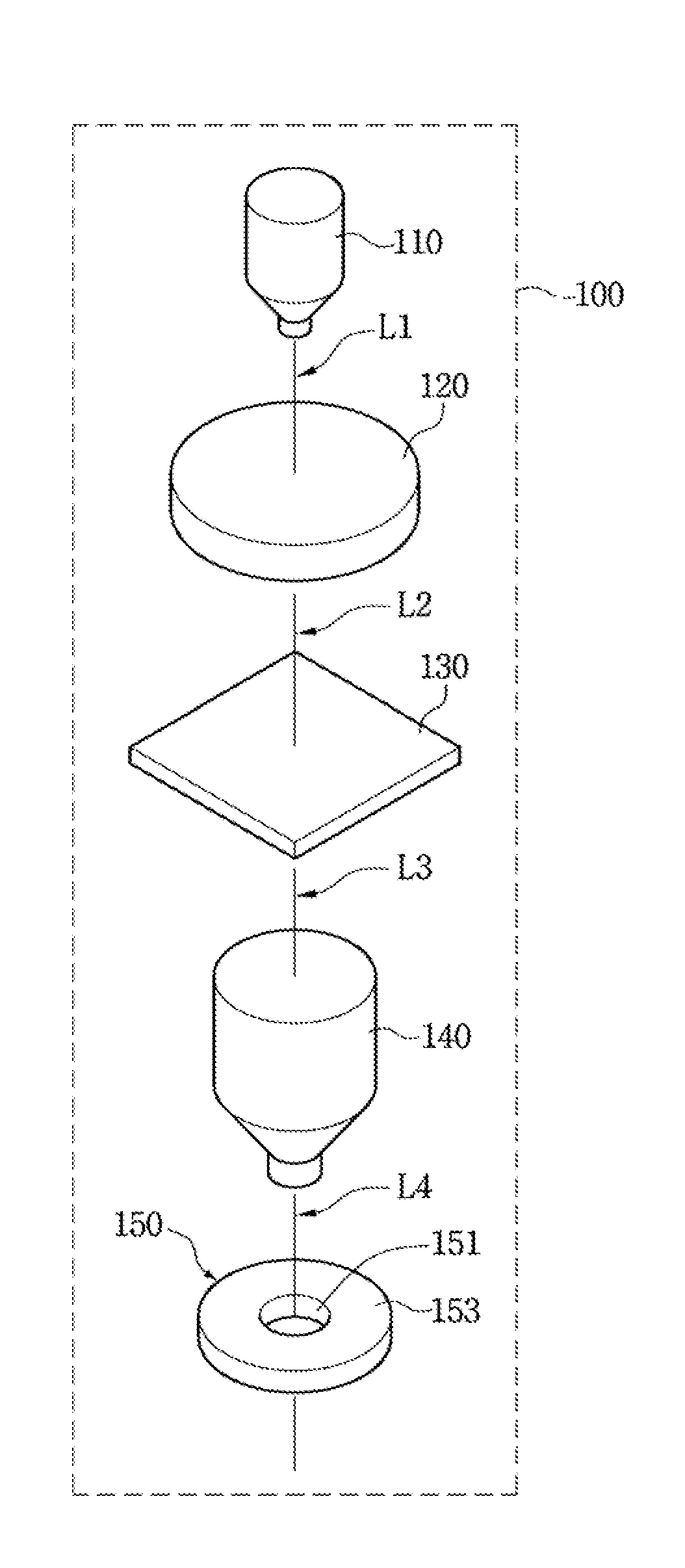

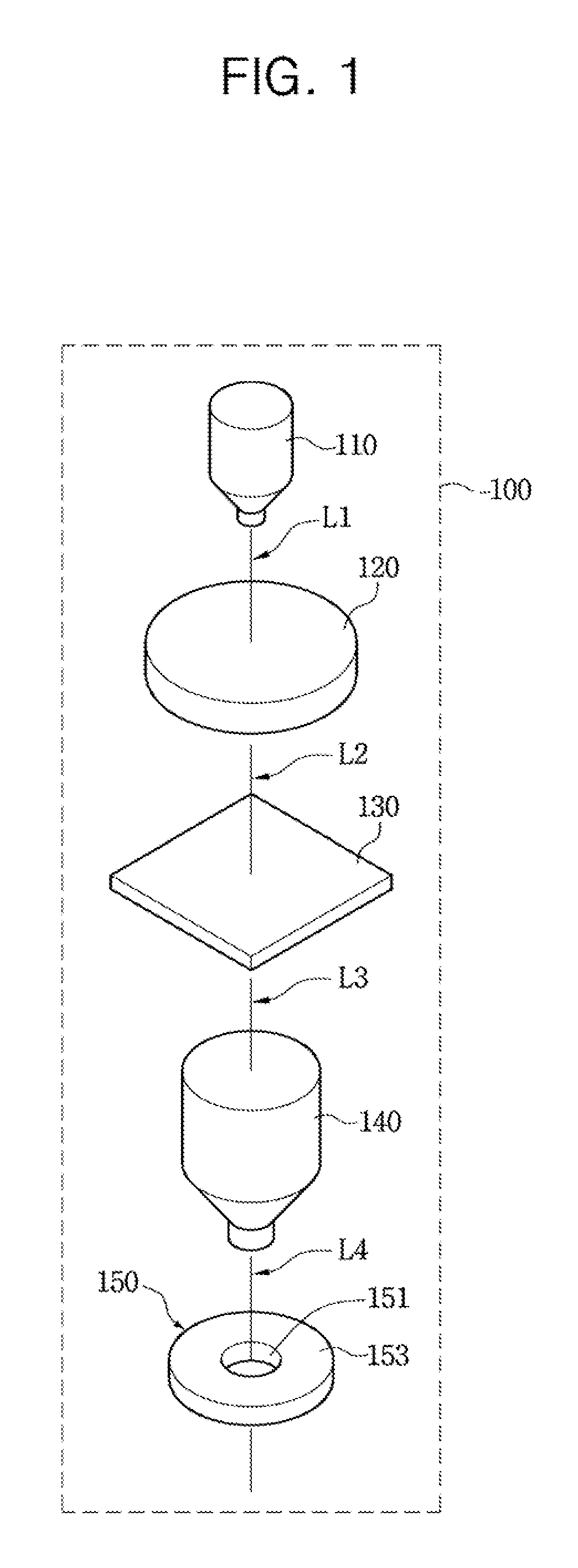

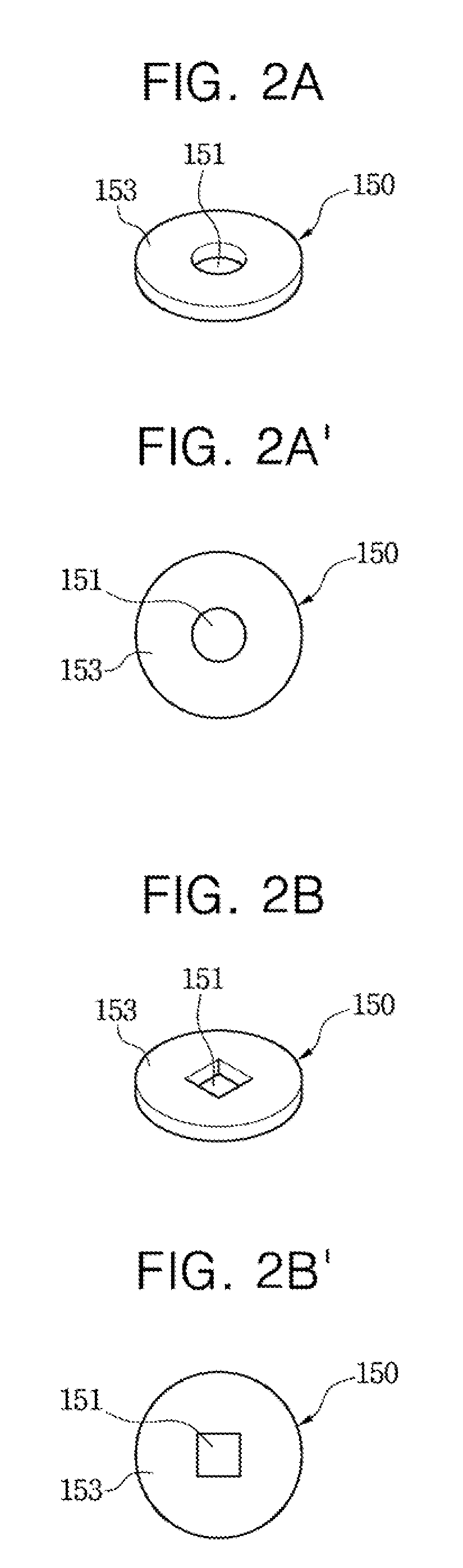

Light radiating device and method of fabricating organic light emitting diode display device using the same

ActiveUS8848749B2Low production costAvoid Sealing DefectsElectroluminescent light sourcesSolid-state devicesFritDisplay device

A light radiating device capable of reducing production costs and preventing sealing defects for a display device, and a method of fabricating an organic light emitting diode (OLED) display device using the same are provided. The light radiating device includes a light source to generate light and a light modifier, including a transmissive region and a non-transmissive region, that define an exposure region on a substrate. The method includes applying a frit to at least one of a first substrate having a pixel region and a second substrate, plasticizing the frit, and aligning the first substrate, the second substrate, and a light radiating device to define an exposure region on the at least one of the first substrate and the second substrate, and radiating the light to the frit to couple the first substrate and the second substrate.

Owner:SAMSUNG DISPLAY CO LTD

Fingertip sealing device with core hollow fingertip sheet

ActiveCN108223798BImprove the high temperature performance of the sealReduce leakageEngine sealsAviationAero engine

The invention belongs to the field of aircraft engine design, and relates to a gas sealing device for an engine main flow path and a secondary flow path. The finger seal device is composed of a frontbaffle (1), a rear baffle (2) and the core hollowed-out finger piece (3). A gap is formed in the core hollowed-out finger piece (3) from the inner diameter, a finger body (7) and a seal shoe (8) are arranged in the gap, and the core of the finger body (7) and the core of the seal shoe (8) are hollowed out. Frictional wear between the seal shoe and a rotator is reduced, the high temperature resistance performance of finger seal is improved, and besides, the optimal performance of conventional finger seal is basically maintained.

Owner:AECC SICHUAN GAS TURBINE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com