A supercritical fluid complexation reaction device with online spectrum monitoring function

A technology of supercritical fluid and complexation reaction, which is applied in measuring devices, color/spectral characteristic measurement, material analysis through optical means, etc. It can solve problems such as uneven heating temperature, affecting spectral monitoring, and high temperature sensitivity. Achieve the effect of precise temperature control, high-quality spectral monitoring data, and easy design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

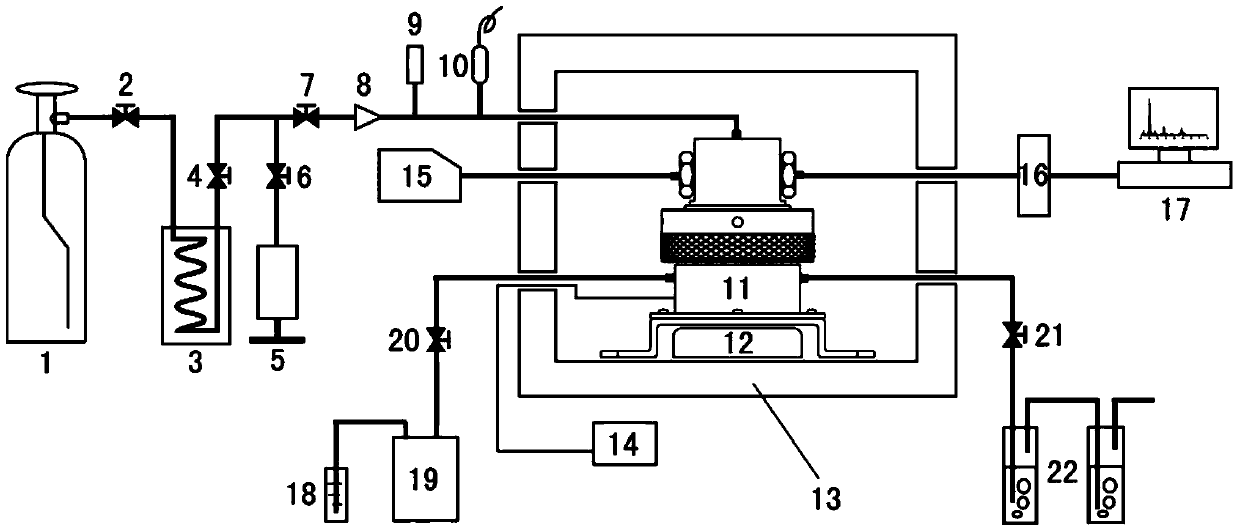

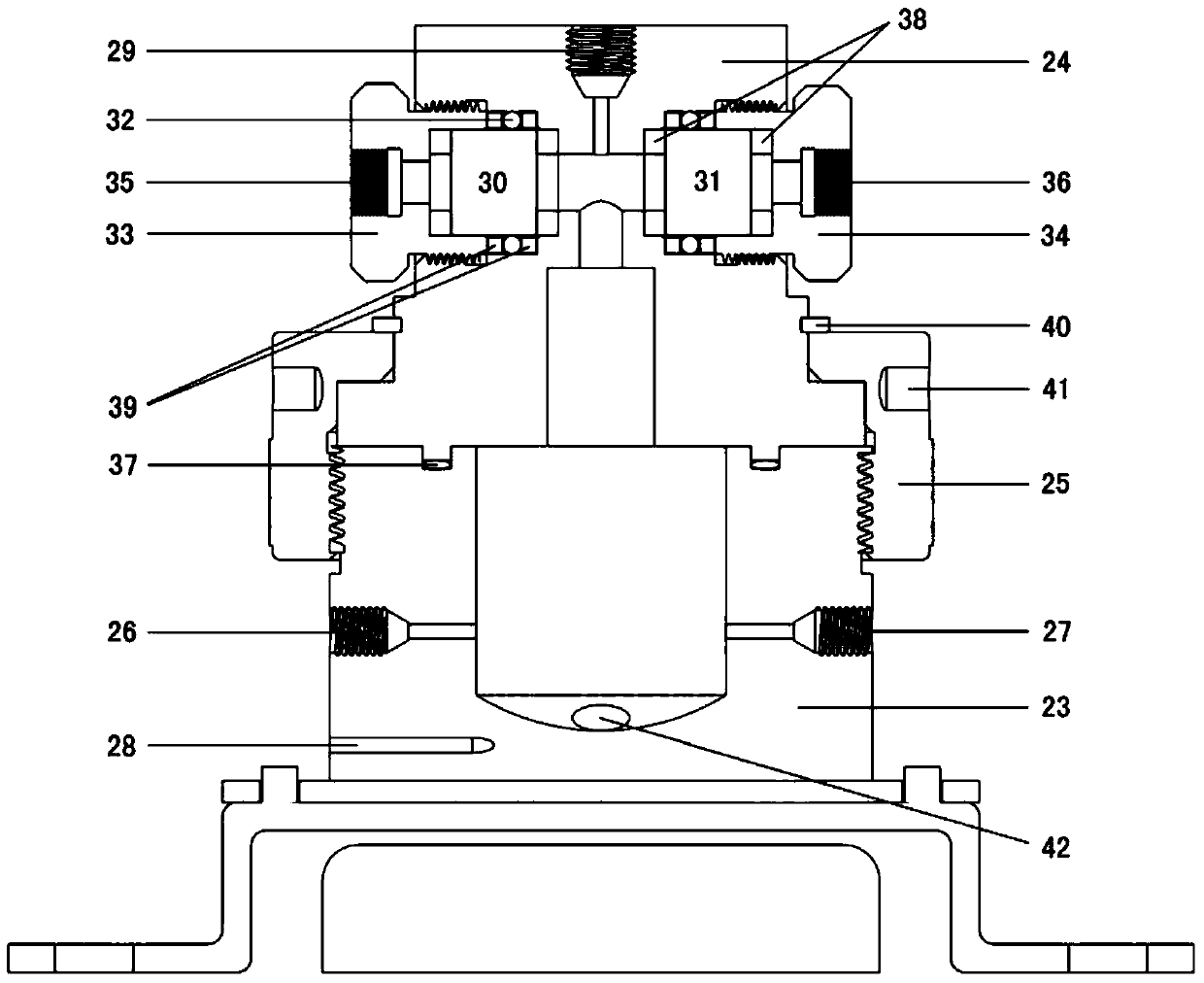

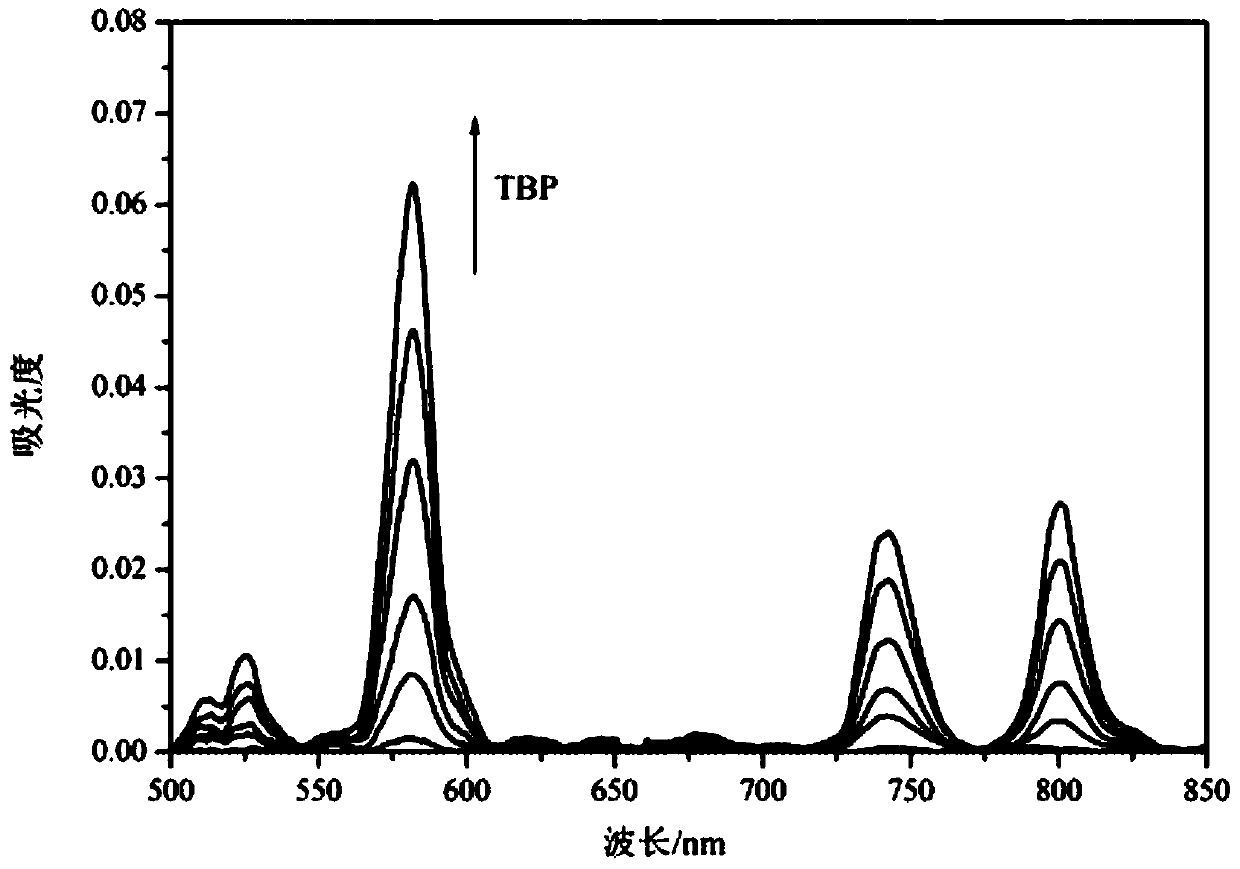

[0027] Adopt the supercritical fluid complexation reaction device of the present invention (the specific structure of the device is as attached Figure 1-2 shown) for supercritical CO 2 The complexation reaction of medium solid neodymium nitrate and tributyl phosphate (TBP) is monitored by online spectrum, and the main monitoring steps are as follows:

[0028] (1) Add solid neodymium nitrate and magnets to the reactor body, tighten the pressure cap of the lid of the kettle, so that the lid of the kettle is sealed with the body of the kettle; connect the rest of the device, and close all valves;

[0029] (2) Open the storage bottle valve, the refrigeration outlet valve, the intake valve, and the discharge valve in sequence, and use CO 2 Exhaust the air inside the reactor and related pipelines;

[0030] (3) Close the storage bottle valve, refrigeration outlet valve, intake valve, and discharge valve, open the thermostat to make the reaction kettle reach the required reaction t...

Embodiment 2

[0040] Adopt the supercritical fluid complexation reaction device of the present invention (the specific structure of the device is as attached Figure 1-2 shown) for supercritical CO 2 The complexation reaction between different solid lanthanide nitrate mixtures and a complexing agent is monitored by online spectroscopy, and the main monitoring steps are as follows:

[0041] (1) Add solid lanthanide nitrate mixture and magnet to the still body of the reactor, tighten the pressure cap of the still cover, so that the still cover is sealed with the still body; connect the rest of the device, and close all valves;

[0042] (2) Open the storage bottle valve, the refrigeration outlet valve, the intake valve, and the discharge valve in sequence, and use CO 2 Exhaust the air inside the reactor and related pipelines;

[0043] (3) Close the storage bottle valve, refrigeration outlet valve, intake valve, and discharge valve, open the thermostat to make the reaction kettle reach the re...

Embodiment 3

[0052] Adopt the supercritical fluid complexation reaction device of the present invention (the specific structure of the device is as attached Figure 1-2 shown) for supercritical CO 2 Online spectroscopic monitoring of the complexation reaction between solid lanthanide and actinide nitrate mixtures and a complexing agent, the main monitoring steps are as follows:

[0053] (1) Add solid lanthanide and actinide nitrate mixture and magnet to the still body of the reactor, tighten the pressure cap of the kettle cover, so that the kettle cover is sealed with the kettle body; connect the rest of the device, and close all valves;

[0054] (2) Open the storage bottle valve, the refrigeration outlet valve, the intake valve, and the discharge valve in sequence, and use CO 2 Exhaust the air inside the reactor and related pipelines;

[0055] (3) Close the storage bottle valve, refrigeration outlet valve, intake valve, and discharge valve, open the thermostat to make the reaction kettl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com