Sintering machine head and tail water curtain liquid sealing device

A sintering machine and liquid sealing technology, which is applied to engine sealing, mechanical equipment, engine components, etc., can solve the problem of deformation of the trolley and the sealing cover, loss of sealing effect, increased gap between the bottom beam of the trolley and the sealing cover, etc. Problems, to achieve ideal sealing effect, ingenious design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings.

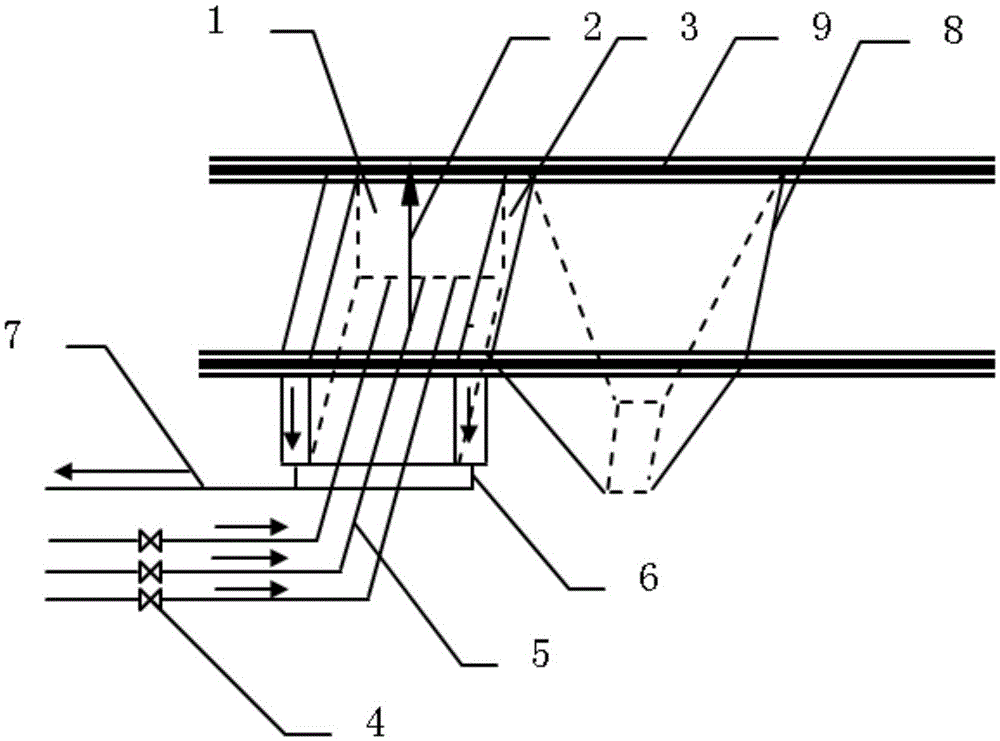

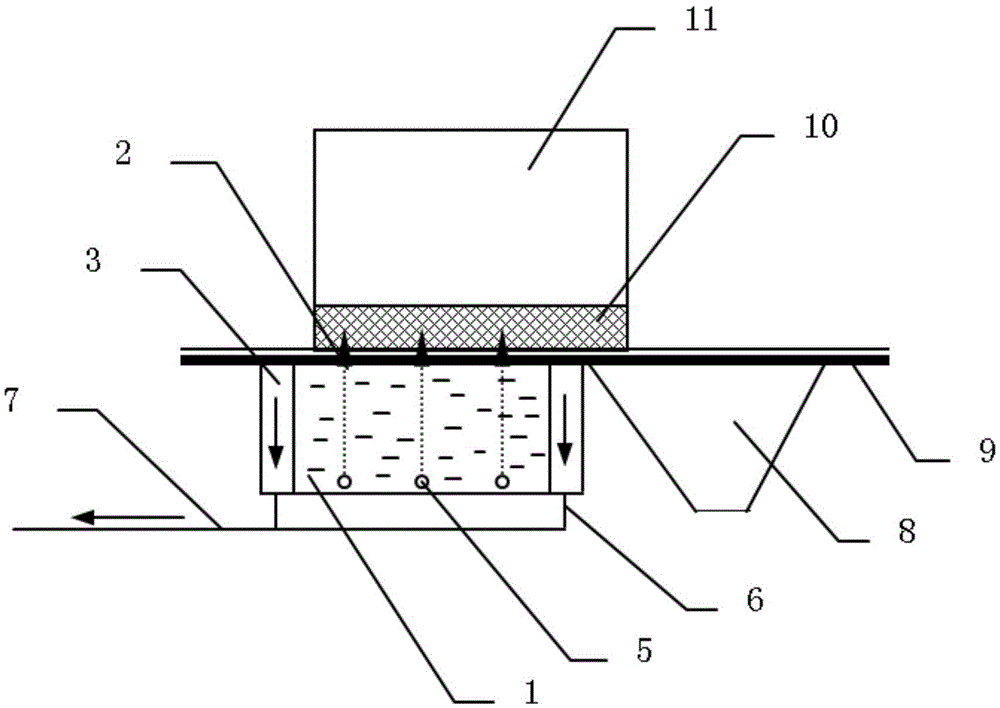

[0016] Such as figure 1 , figure 2 The shown sintering machine head and tail water curtain type liquid sealing device includes a trolley slide 9, a trolley 11 slidably arranged above the trolley slide 9, and a wind box 8 arranged below the trolley slide 9, and It also includes a sealed water tank 1 arranged beside the wind box 8 and below the trolley slide 9. The bottom of the sealed water tank 1 is provided with at least one water tank bottom water filling pipe 5, and the water tank bottom water filling pipe 5 is provided with at least A circular hole or notch that is vertically upward in one direction, the water addition pipe 5 at the bottom of the water tank sprays water to the bottom beam 10 of the trolley 11 to form a water curtain 2.

[0017] In the actual production of iron ore sintering, the air leakage generated by the ventilation system greatly reduces the production efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com