Rainproof threshold structure of railway vehicle control cabin and railway vehicle

A railway vehicle and control room technology, which is applied in the rainproof threshold structure and the field of railway vehicles, to achieve the effects of avoiding corrosion of weld seams, reducing repairs and maintenance, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

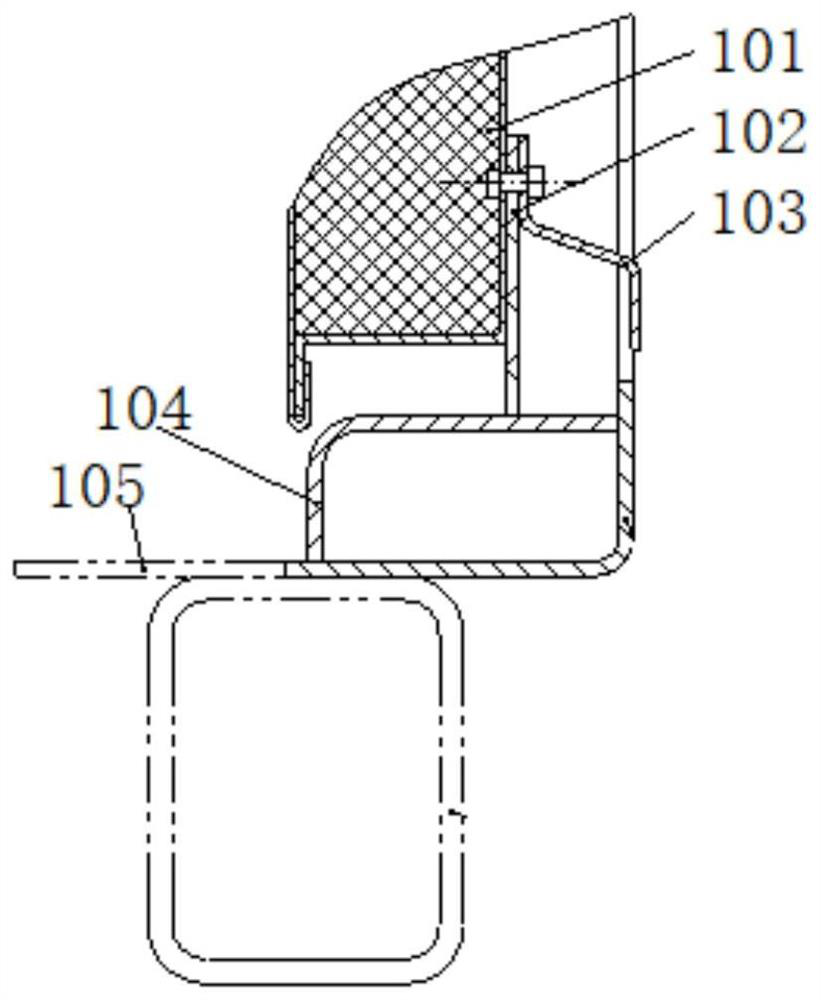

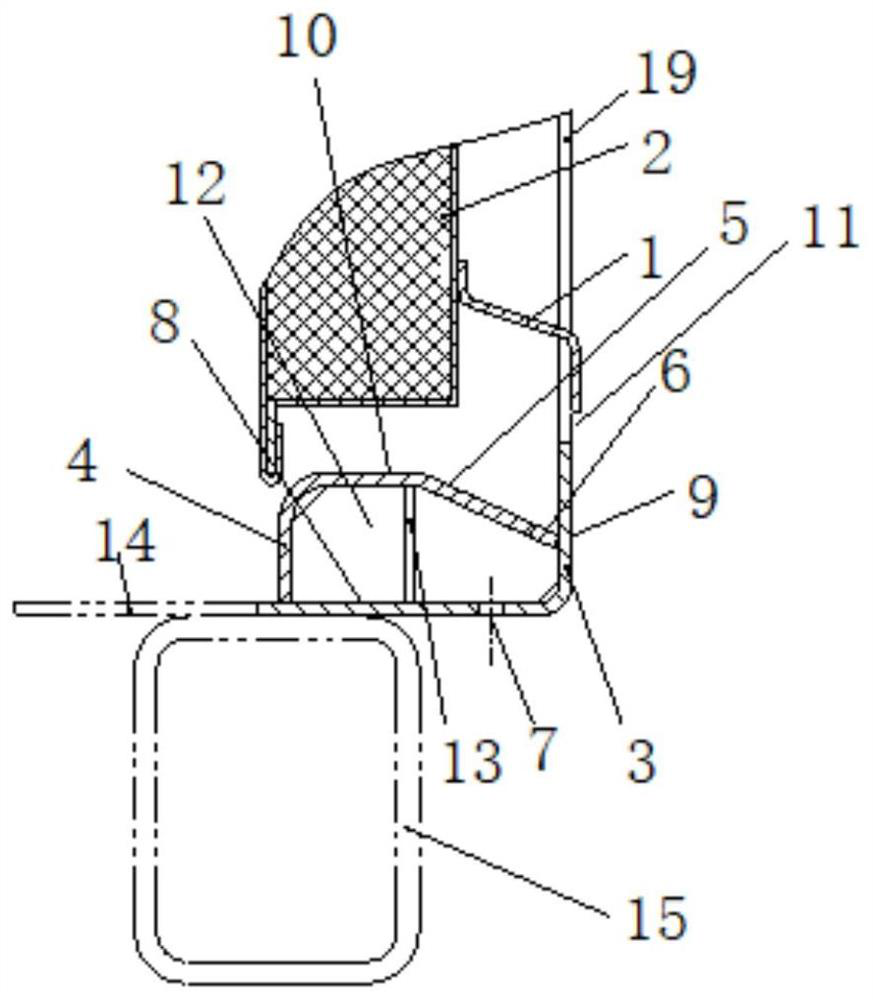

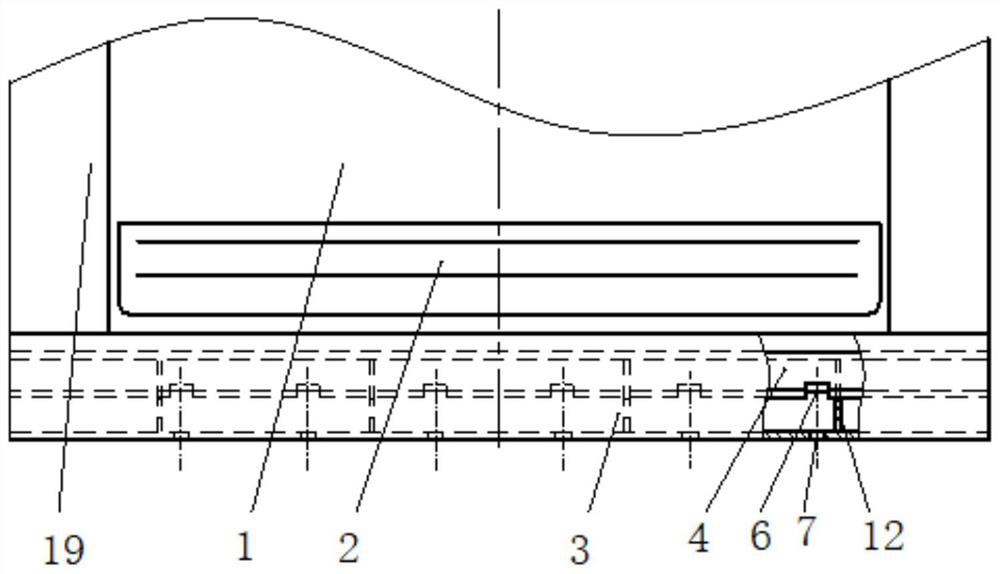

[0039] like Figure 2 to Figure 8 As shown, the present invention provides a rain-proof door sill structure of a railway vehicle operating room and a railway vehicle, the structure comprising:

[0040] Rain eaves 1, one end of the rain eaves 1 is connected to the outside of the control room door 2 of the railway vehicle, and the other end of the rain eaves 1 is inclined downward and extends to the outside of the lower door frame 3 of the control room door 2 of the railway vehicle;

[0041] The door sill 4, the door sill 4 encloses a cavity on the inner side of the lower door frame 3, the door sill 4 includes a guide part 5, the guide part 5 is arranged at one end of the door sill 4 close to the lower door frame 3 and slopes downward, and the guide part 5 is close to the lower door frame 3 One end of the door is provided with a plurality of notches 6, and the bottom of the lower door frame 3 is provided with a drainage hole 7.

[0042] Specifically, the structure of the rain-p...

Embodiment 2

[0059] like Figure 9 and Figure 10 As shown, the difference between this embodiment and the first embodiment is:

[0060] In this embodiment, one end of the lower door frame 3 close to the interior of the railway vehicle is connected to the floor 14 of the railway vehicle, the lower side beam 15 of the railway vehicle is located below the lower door frame 3, and the drainage hole 7 is located on the inner side of the lower side beam 15; A first through hole 16 and a second through hole 17 are respectively opened on the top surface and the bottom surface of the beam along the vertical direction, and the first through hole 16 communicates with the drainage hole 7 .

[0061] Specifically, when the vertical part 9 of the lower door frame 3 of the operating room is aligned with or close to the outer side of the lower side beam, the lower measuring beam affects the drainage function of the drainage hole 7 . A corresponding number of first through holes 16 and second through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com