One-step control method for automatic starting and closing of water conveying pump group

A technology of automatic start and control method, applied in pump control, machine/engine, liquid variable capacity machinery, etc. Simple and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

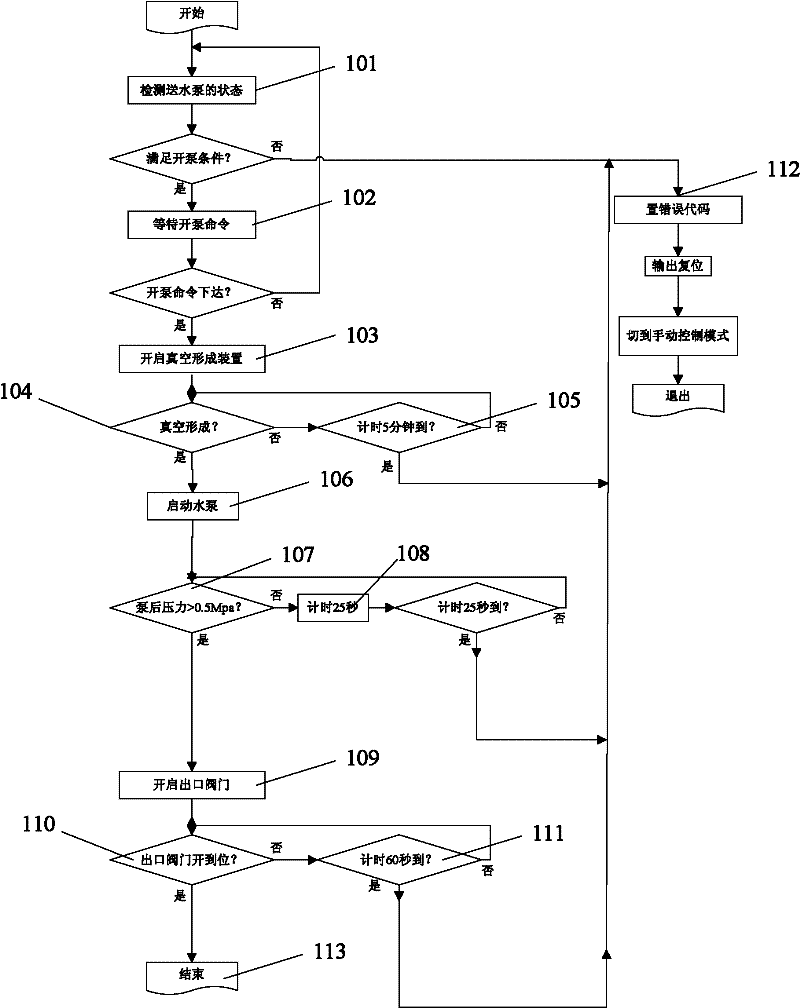

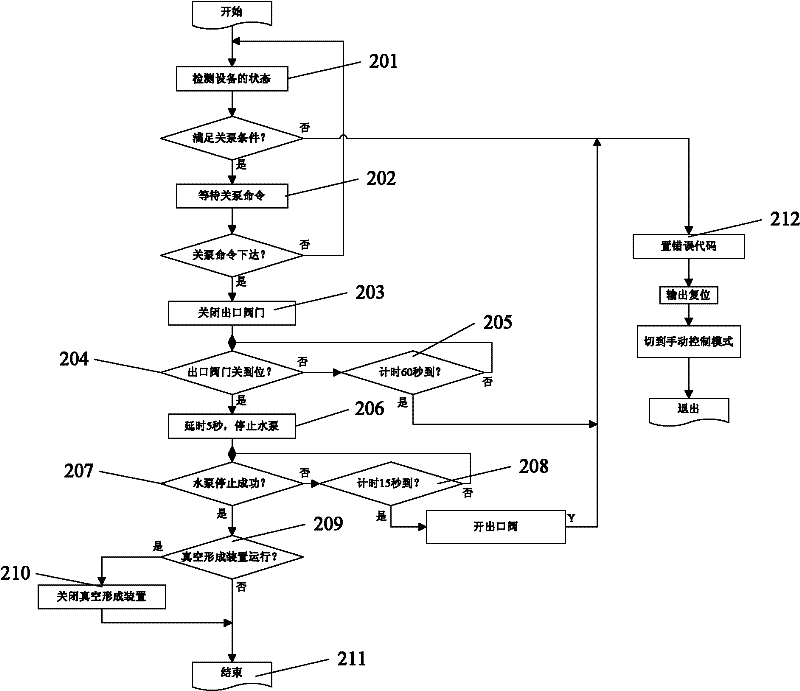

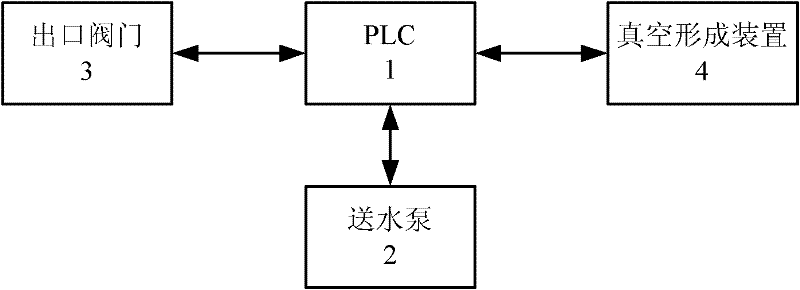

[0043] Such as figure 1 , image 3 As shown, a control method for automatically starting and shutting down a water delivery pump set includes the following steps:

[0044] 1. The sub-method for starting the water pump control;

[0045] 2. The sub-method for shutting down the water delivery pump.

[0046] Said step 1 water delivery pump startup control sub-method includes the following steps:

[0047] Step 101, PLC1 detects the status information of the water delivery pump 2, and judges whether the condition for turning on the pump is satisfied, if yes, execute step 102, if no, execute step 112;

[0048] Step 102, PLC1 waits for the command to turn on the pump, and judges in real time whether the command to turn on the pump is received, if yes, execute step 103, if not, return to step 101;

[0049] Step 103, PLC1 controls to open the vacuum forming device 4;

[0050] Step 104, judge whether the vacuum is formed, if yes, execute step 106, if no, execute step 105;

[0051] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com