Shaft sleeve part drying machine

A technology for dryers and parts, applied in the field of shaft sleeve drying equipment, can solve the problems of difficult to meet the production requirements of shaft sleeves, low production efficiency, difficult process control, etc., to save manpower and material resources, reduce labor intensity, and achieve automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

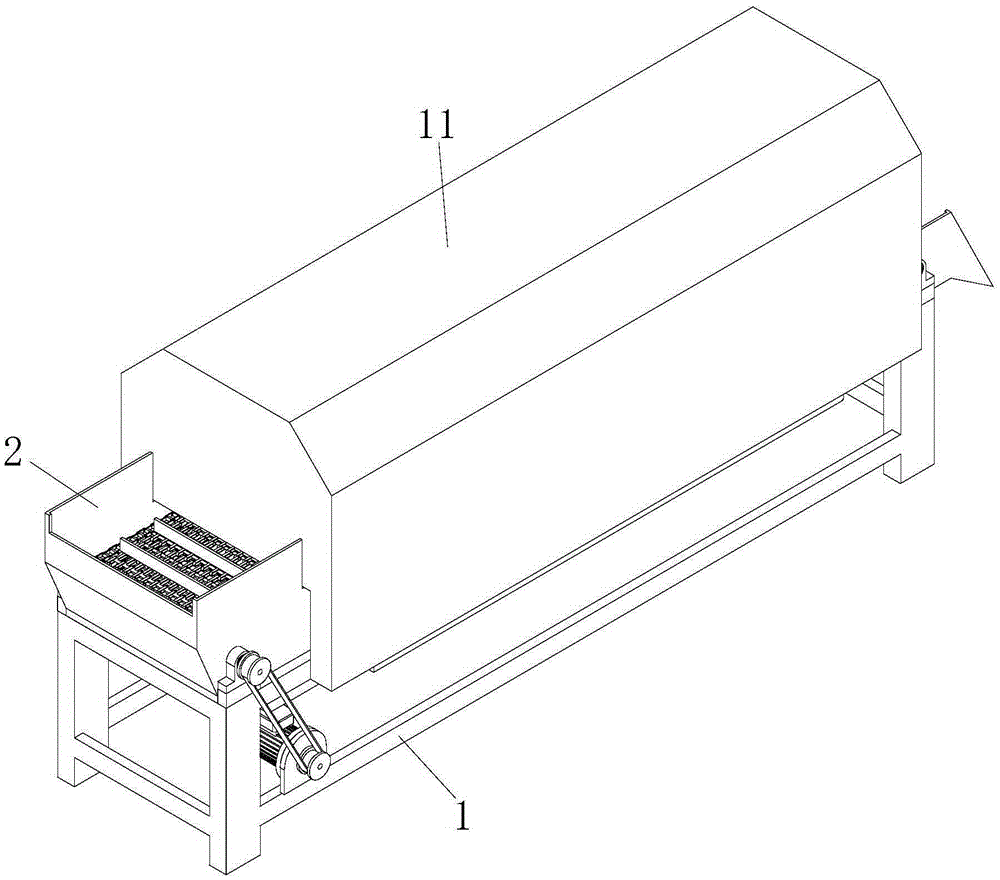

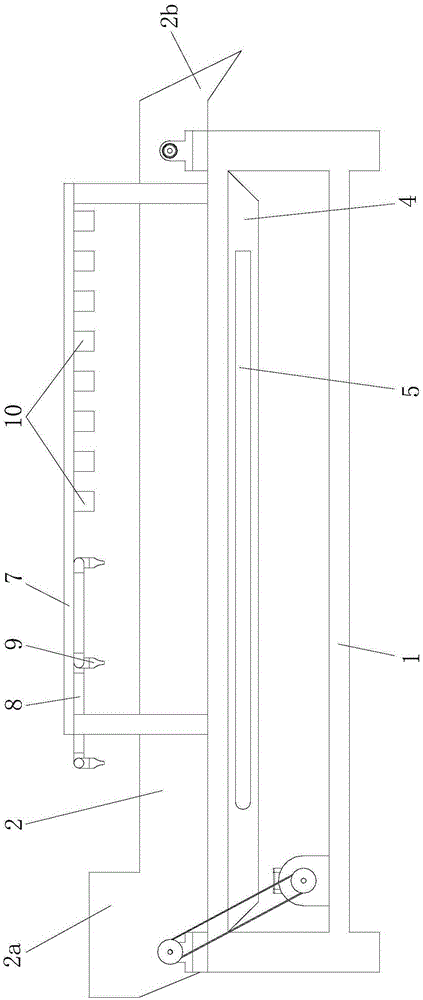

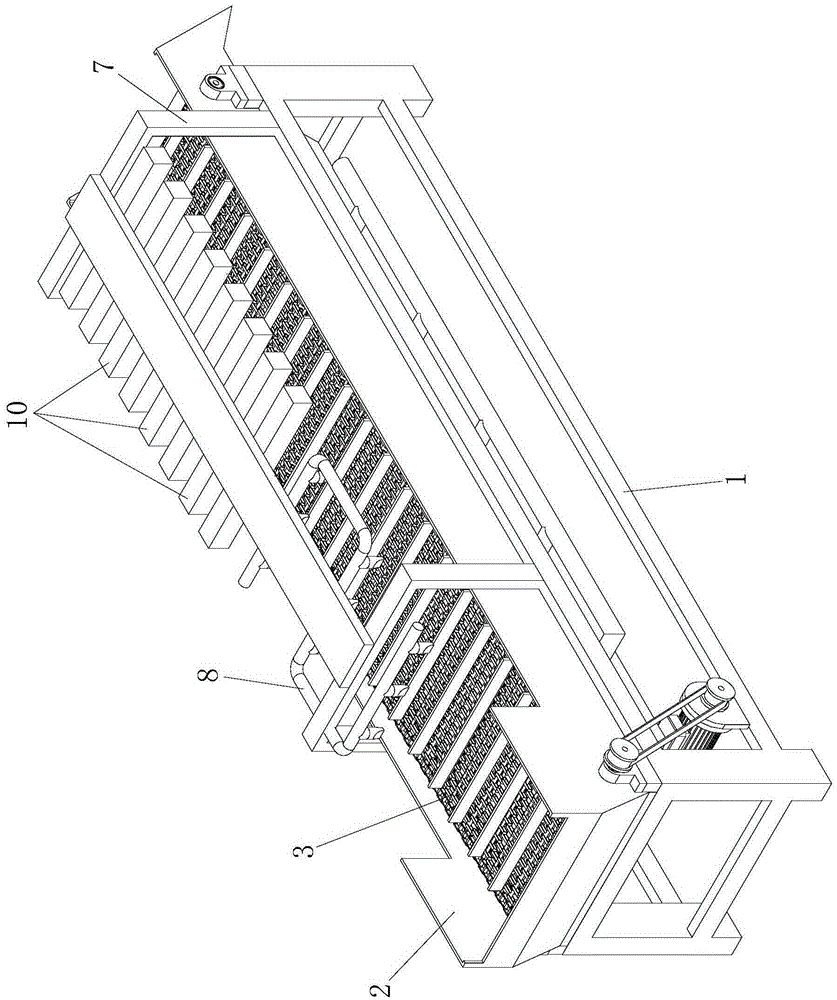

[0016] Such as Figure 1 to Figure 4 As shown, a shaft sleeve part dryer includes a frame 1, the upper end of the frame 1 is provided with a drying tank 2, a conveyor belt 3 is installed in the drying tank 2, and the lower end of the drying tank 2 is installed There is a sump 4, the left and right ends of the sump 4 are fixed with a trachea 5, the No. 1 air spray head 6 is evenly installed on the trachea 5, and a fixed frame 7 is arranged above the drying tank 2, so that The fixed mount 7 is installed on the upper end of the frame 1, the front portion of the fixed mount 7 is fixed with an S-shaped pipe 8, and the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com