Multifunctional rotary type drying system and method for automated operation

A drying system and multi-functional technology, applied in the direction of drying, drying machine, non-progressive drying machine, etc., can solve the work and rest rules and the impact on physical health, the impact on the health of staff, and the violation of coal sample drying treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings. However, the following specific embodiments are only preferred examples of the present invention, and should not be construed as limiting the protection scope of the present invention.

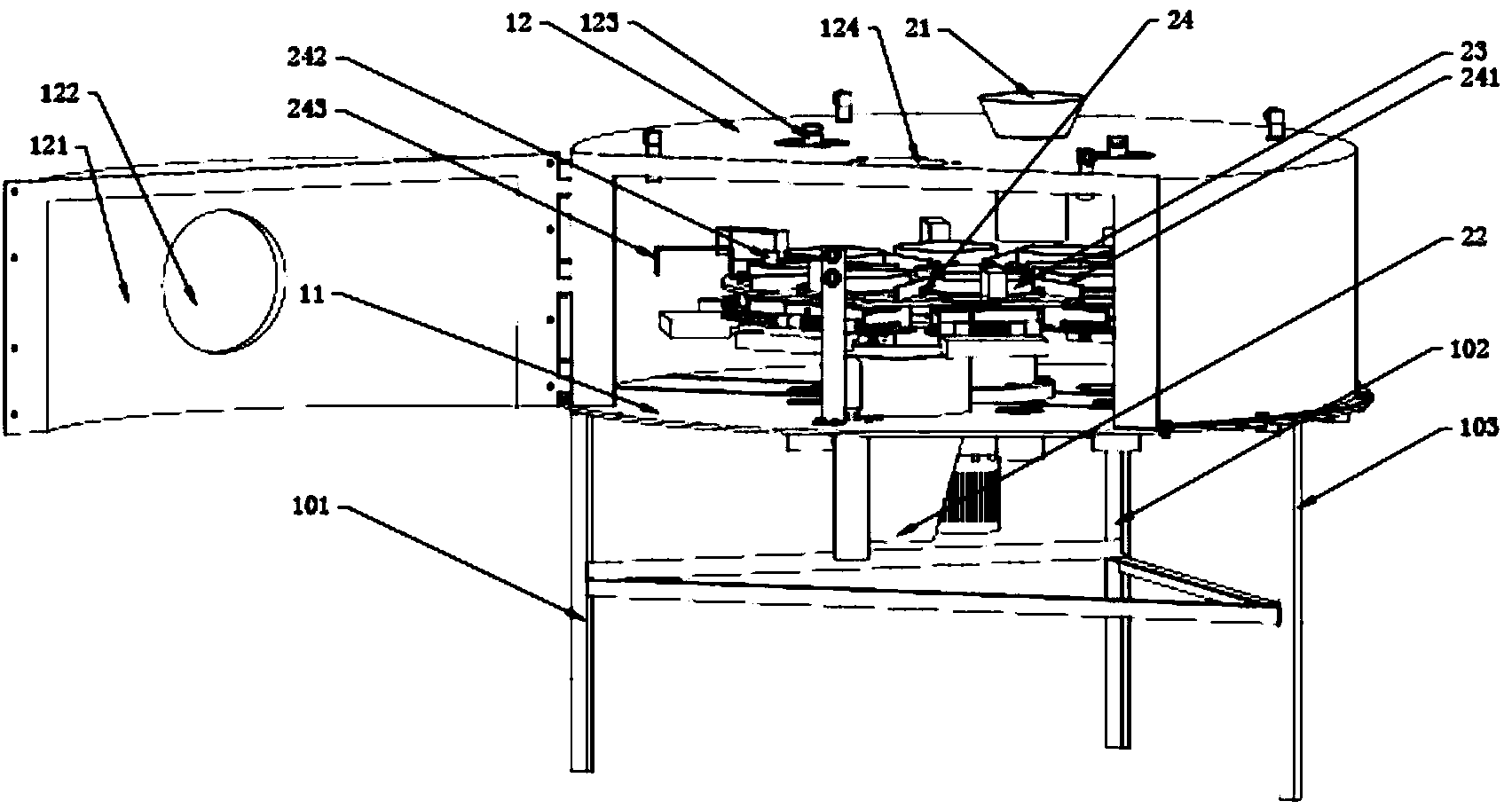

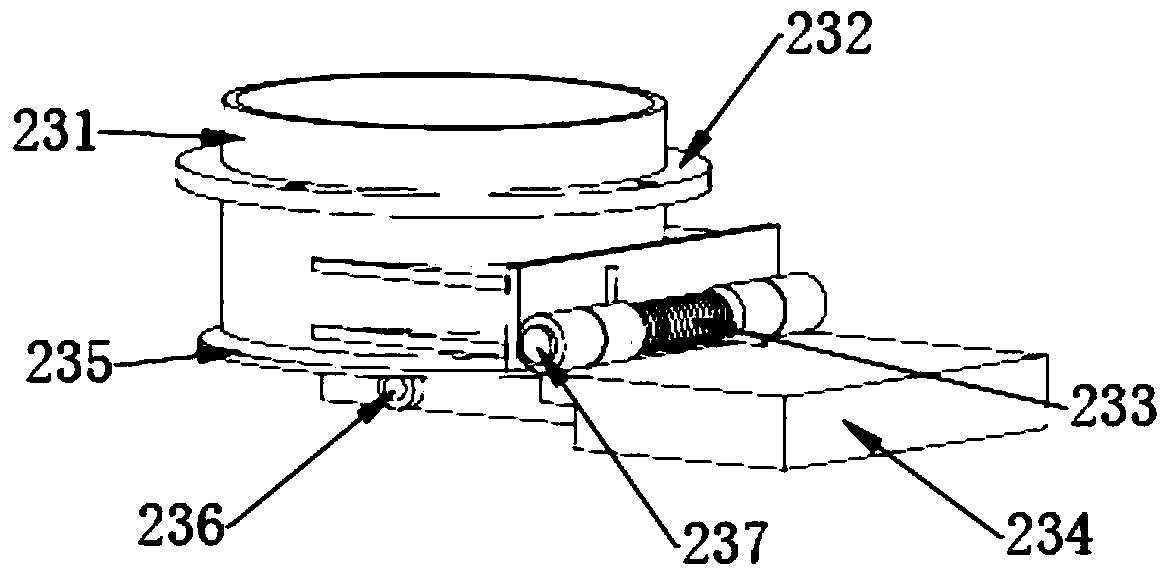

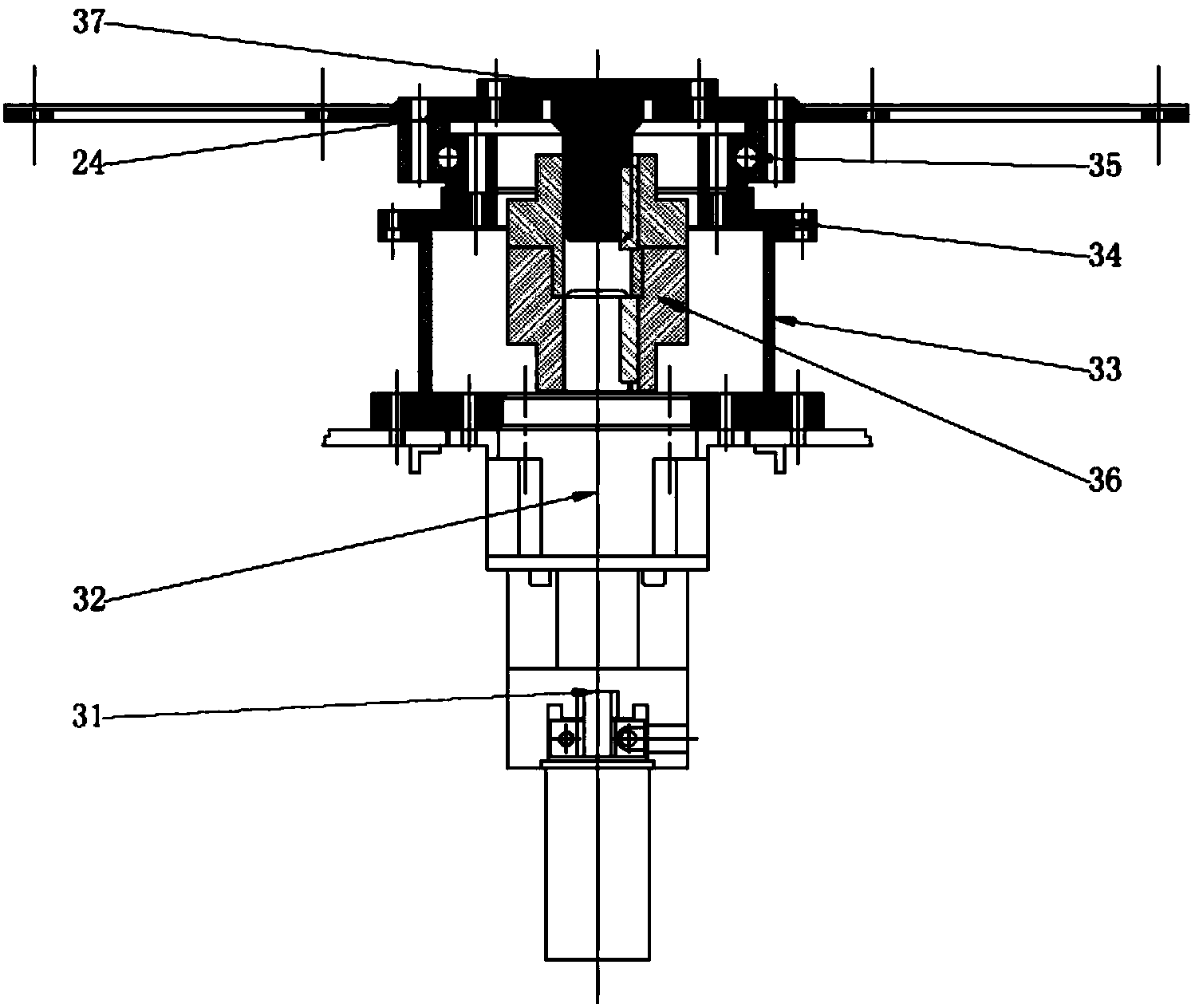

[0022] like figure 1 As shown, the multifunctional rotary drying device of the embodiment of the present invention includes a box body 1 , a material conveying unit 2 , a power unit 3 and a control device 4 .

[0023] The box body 1 is located outside the multifunctional rotary drying device, and is used to form a seal to maintain the temperature and humidity required for drying coal samples, and is used as a container or carrier to accommodate or carry the multifunctional rotary drying device. Dry other parts of the device.

[0024] The box can adopt various shapes suitable for heat preservatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com