Golf washing and drying system

A drying system and golf ball technology, applied to ball games, sports accessories, etc., can solve the problems of time-consuming and laborious, golf balls cannot be used directly, and achieve the effect of reducing manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

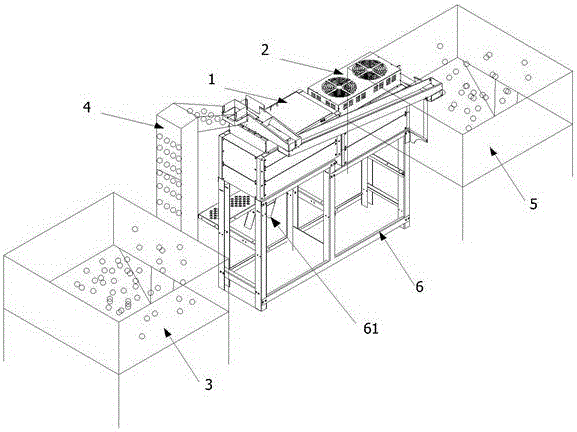

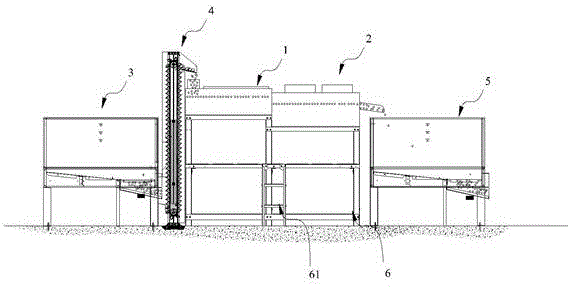

[0030] refer to Figure 1 to Figure 9 As shown, the present invention provides a golf ball washing and drying system, comprising:

[0031] A goal groove 3, the bottom of which is funnel-shaped;

[0032] A vertical conveyor 4, its ball entry port is positioned at the bottom end of ball entry groove 3;

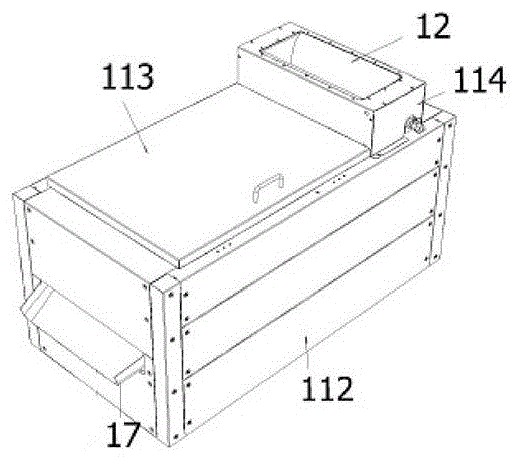

[0033] A ball washing machine 1, its ball inlet 12 is located directly below the outlet at the top of the vertical conveyor 4;

[0034] A dryer 2, the ball inlet of which is connected to the ball outlet of the ball washing machine 1;

[0035] A ball outlet groove 5 is placed directly below the dryer 2 ball outlets.

[0036] In the present invention, see the applicant’s previous application CN201620895349.0 for the vertical transmission device out of the ball entrance. The vertical conveyor 4 is used to transport the collected golf balls to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com