Six-arm roller centering device

A roller and six-arm technology, applied in the field of six-arm roller centering device, can solve the problems of high maintenance cost, poor centering effect of spring sheets, large eccentric moment, etc., and achieve the effect of strong bearing capacity, small additional load and small eccentric moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

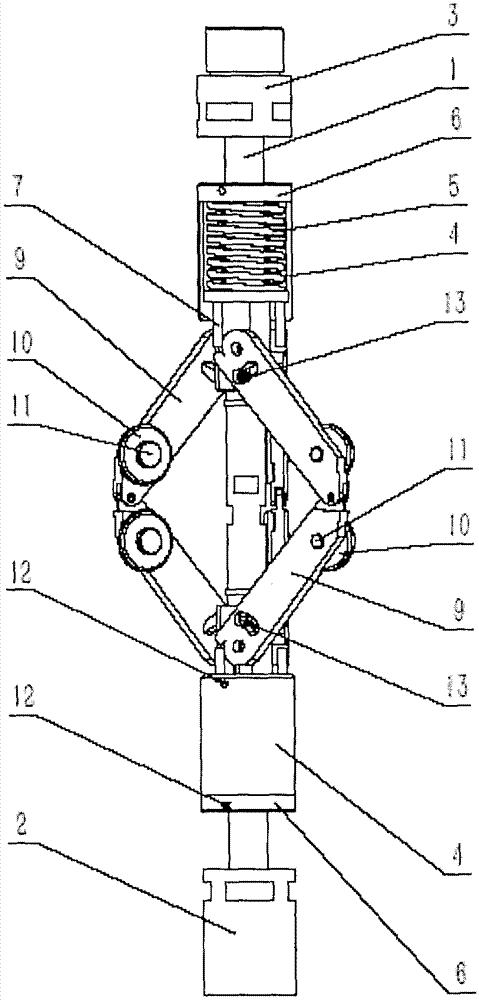

[0010] Example 1 as figure 1 As shown, the six-arm roller centering device includes a central shaft 1, and the two ends of the central shaft 1 are connected with the left connecting seat 2 and the right connecting seat 3 through threads, and the left connecting seat 2 and the right connecting seat 3 have internal and external threads respectively, for Connect other devices of the pipeline robot, the inner side of the connecting seat is symmetrically arranged with the arm seat 4, the arm seat 4 has a built-in rectangular spring 5, the two ends of the rectangular spring 5 are the end cover 6 and the push rod seat 7, and the side of the push rod seat 7 presses the sleeve 8 , the sleeve 8 is set on the central shaft 1, and passes through the arm seat 4. The support arm 9 is hinged on the sleeve 7. The end of the support arm 9 connected to the sleeve 8 has a waist-shaped hole, and the waist-shaped hole is fixed on the sleeve. The fixed pin 13 on 8 limits the rotation range of the s...

Embodiment 2

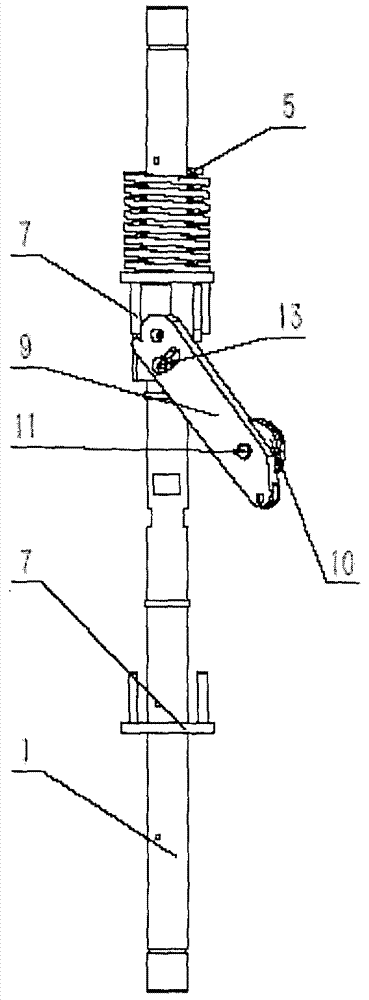

[0011] Example 2 as figure 2 As shown, the push rod on the push rod base 7 pushes the support arm 9 and rotates around the hinge of the sleeve 8. The three form a lever mechanism, and the hinge of the support arm 9 and the sleeve 8 is the lever fulcrum. A small amount of displacement of the push rod seat 7 is amplified by the lever mechanism, resulting in a large radial displacement of the support arm 9. Since the displacement of the push rod seat 7 is small during the operation, the return force of the rectangular spring 5 changes very little, and the centering force of the centering device Almost constant, so this six-arm roller centering device can accommodate a wide range of pipe diameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com