Dry air-sealed end face groove profile rotating bilaterally

A dry gas sealing, bidirectional rotation technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of sharp corners being easily broken, friction, affecting the sealing effect, etc., to avoid sharp vertices and improve matching. , Improve the effect of sealing aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

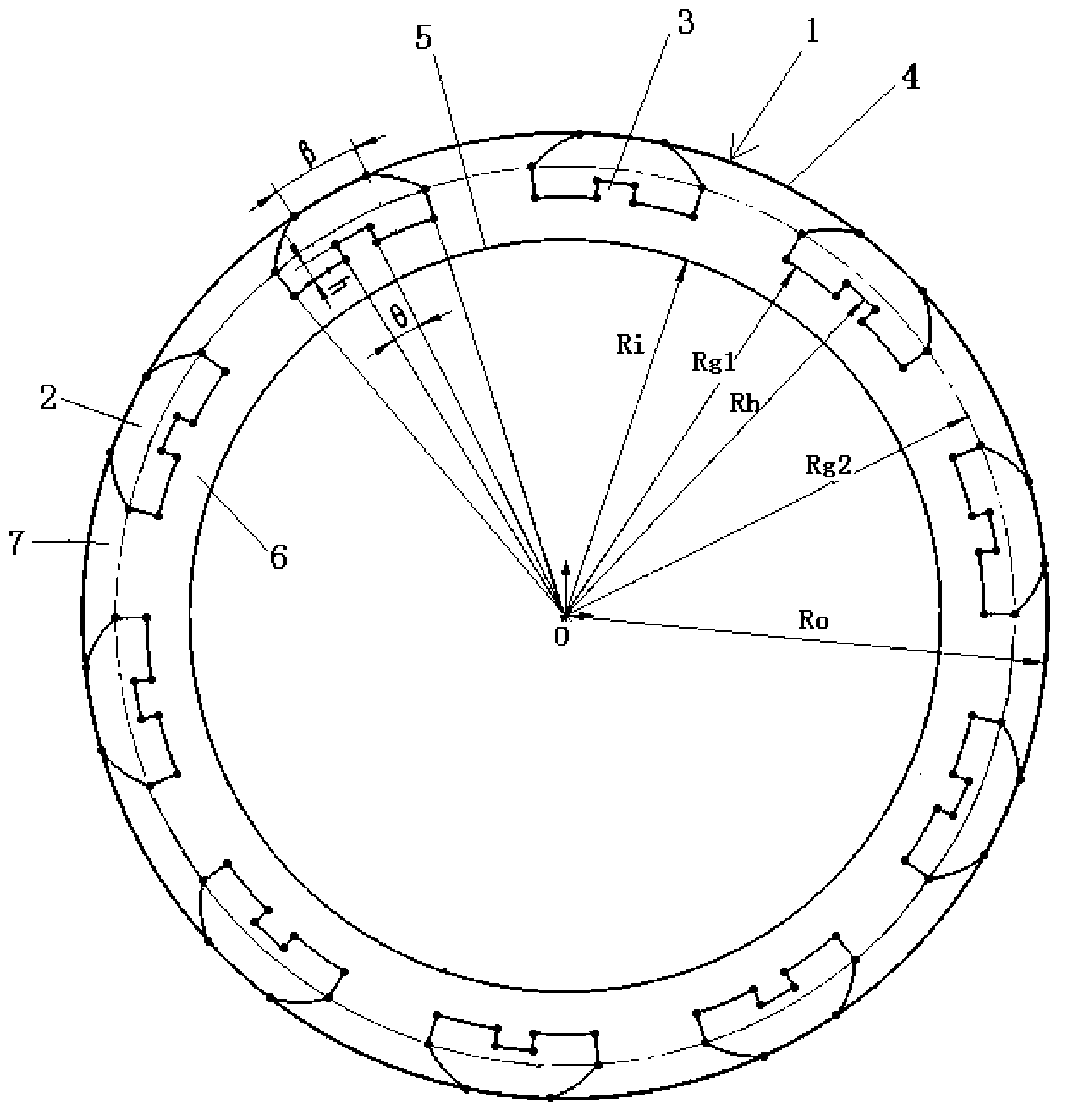

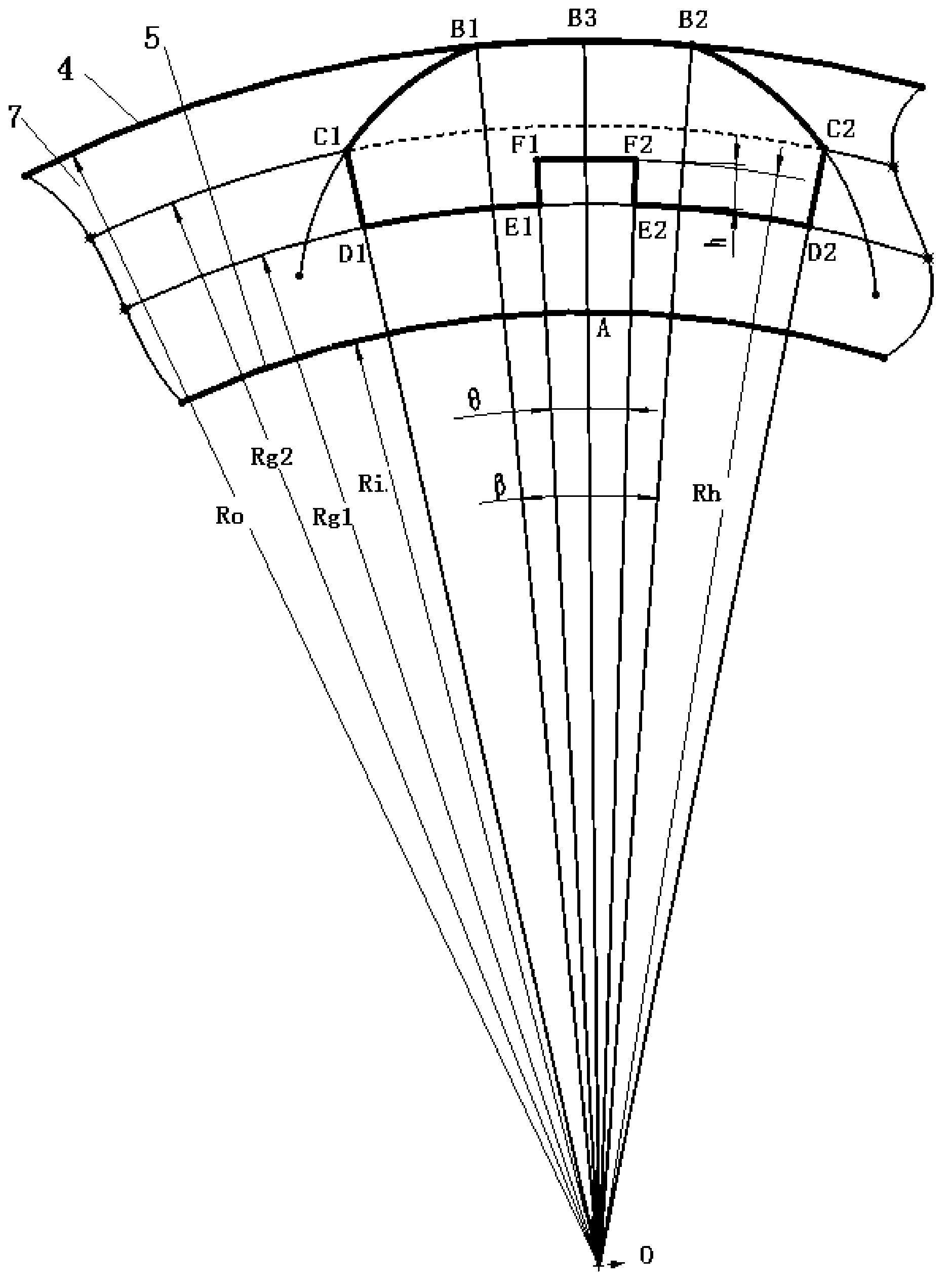

[0023] A two-way rotating dry gas seal end face groove type of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0024] The purpose of the present invention is to find a dry gas sealing groove with high opening force, low leakage, good aerodynamic performance and simple manufacturing process.

[0025] The terms involved in the present invention are as follows:

[0026] Static ring: a ring whose dry gas seal structure does not rotate with the shaft during normal operation;

[0027] Moving ring: the ring that the dry gas seal structure rotates with the shaft during normal operation;

[0028] Sealing end face: the moving ring and the static ring face in contact with the gas film;

[0029] Gas film: Between the dynamic ring and the static ring, a thin layer of gas formed by the gas pumped by the dynamic pressure groove separates the end faces of the dynamic and static rings, generally 2-5μm;

[0030] Dynam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com