Numerical control processing method for aluminum alloy high-precision flat bottom hanging hole

A processing method and high-precision technology, applied in the field of mechanical processing, can solve the problems of large cutting force, poor processing accuracy, and inability to fully meet the accuracy requirements of flat-bottomed hanging holes, etc., to improve processing quality and efficiency, and simplify processing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

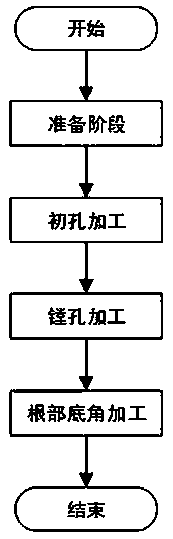

[0039] The present invention is realized through the following technical solutions, as Figure 1-Figure 4 As shown, a numerical control machining method for high-precision flat-bottomed hanging holes in aluminum alloys specifically includes the following steps:

[0040] Step S1: parts clamping;

[0041] Step S2: initial hole processing; specifically includes the following steps:

[0042] Step S21: Determine the diameter of the initial machining hole as φ F , the diameter of the final hole is φ, and the diameters of the final hole and the initial hole satisfy: φ-φ F ≥1mm and the initial hole is coaxial with the final hole;

[0043] Step S22: Select the milling tool as the initial hole processing tool, and use the milling method to process the initial hole; the bottom tooth radius R of the milling tool and the hole bottom angle diameter φ R Consistent, the length-to-diameter ratio of the milling tool is less than 4:1;

[0044] Step S23: Machining; specifically refers to: us...

Embodiment 2

[0055] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 , image 3 As shown, further, in order to better realize the present invention, the step S3 specifically includes the following steps:

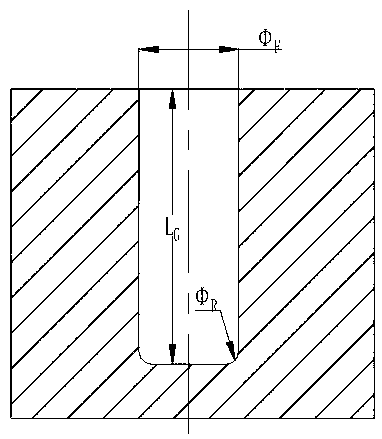

[0056] Step S31: Select a boring tool as a boring tool; specifically, when selecting a boring tool, the corresponding boring tool should be selected according to the characteristics of the boring hole, and the minimum boring diameter of the boring tool is D 1 , the maximum boring diameter of the boring tool is D 2 , satisfying D 1 ≤φ F ≤φ≤D 2 ;

[0057] Step S32: Determining the depth L of the boring T ; L T = L H -φ R -0.5; so as to effectively avoid milling to the fillet at the bottom of the hole during processing.

[0058] Further, in order to better realize the present invention, the step S3 also includes a step S33: after the boring tool, the retraction speed is consistent with the processing speed, so as to avoid scratching the ...

Embodiment 3

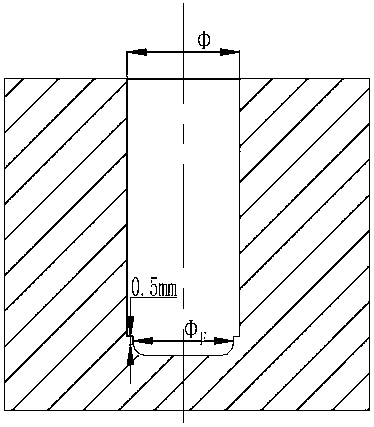

[0061] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 , Figure 4As shown, further, in order to better realize the present invention, the step S4 includes the following steps:

[0062] Step S41: Determine the base angle R of the machining tool according to the fillet angle at the bottom of the hole, satisfying R=φ R ;

[0063] Step S42: The bottom angle of the root is processed by the three-coordinate sequential milling method of circular arc advance and retreat; during processing, the axial and radial directions are not layered during processing, and the processing is completed in one cut, leaving margins on the side and bottom.

[0064] Further, in order to better realize the present invention, the radius of the circular arc advancing and retreating knife is 5mm, and the angle with the horizontal direction is 3°.

[0065] It should be noted that, through the above improvements, margins are left on the side and bottom surfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com