Method utilizing active carbon to control MBR membrane pollution

A technology of activated carbon and membrane pollution, which is applied in the field of water treatment, can solve the problems of high energy consumption of aeration, and achieve the effects of good processing capacity, reduced space and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

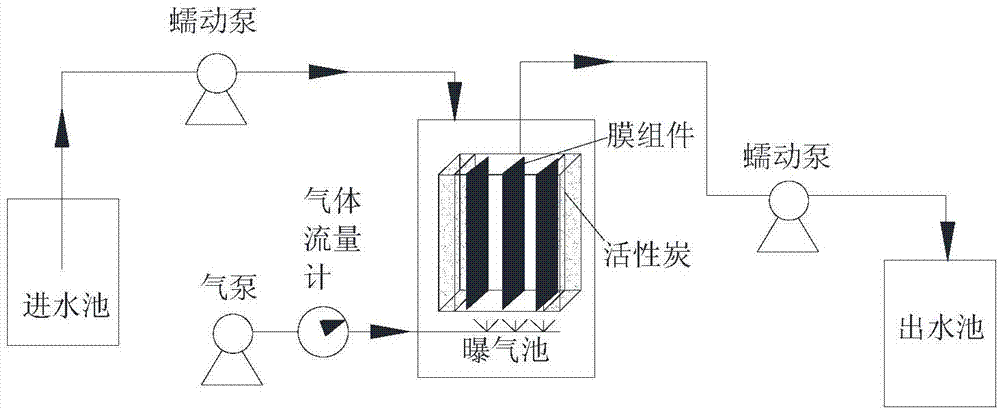

[0018] Example 1: Use 2 sets of the same 75L flat membrane submerged MBR reactor, the effective working volume is 62L, the filter membrane material is PES, the pore diameter is 0.04μm, and the membrane area is 0.5m 2 , a total of 6 pieces, continuous aeration 2L / min, inoculated activated sludge MLSS3000mg / L, influent COD 2900mg / L, effluent peristaltic pump speed controlled at 5rpm, one of which is as figure 1 , The surface of the filter membrane is fixed with a box-type filter screen for activated carbon layer (thickness 1cm, activated carbon average particle size 2.8mm). The 2 sets of MBR have been continuously operated for 40 days, and the COD removal rate is above 95%, and the MBR membrane flux without activated carbon is reduced to 1.44L / (m 2 h), while the flux of the MBR membrane with activated carbon layer is maintained at 10.5L / (m 2 h).

Embodiment 2

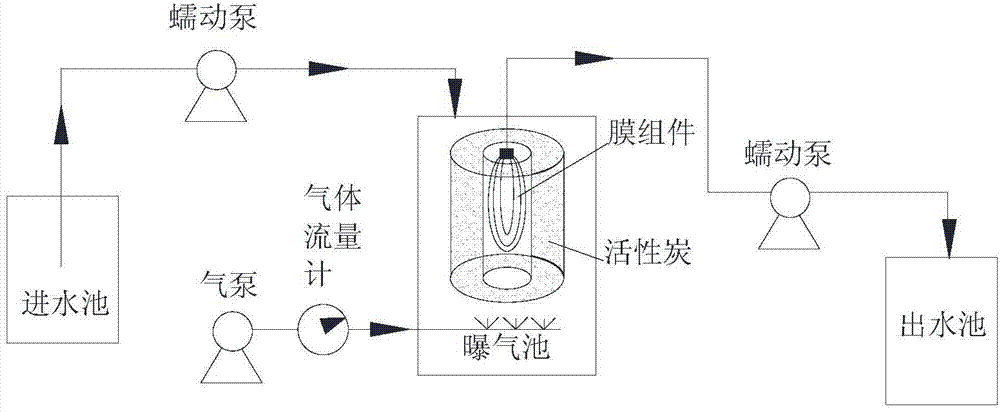

[0019] Example 2: Use 2 sets of the same 10L hollow fiber membrane submerged MBR reactor, the effective working volume is 6L, the filter membrane material is PVDF, the pore diameter is 0.1μm, and the total area of the membrane filament is 0.15m 2 , continuous aeration 2L / min, inoculated activated sludge MLSS3000mg / L, antibiotic sulfamethoxazole 10mg / L in the influent water, and the speed of the effluent peristaltic pump is controlled at 5rpm, one of which is as figure 2 , The surface of the filter membrane is fixed with a circular column type filter screen (thickness 2cm, activated carbon average particle size 5mm). Two sets of MBRs were operated continuously for 60 hours, the MBR sulfamethoxazole without activated carbon was not removed, and the membrane flux was reduced to 6.4L / (m 2 h), while the MBR sulfamethoxazole with activated carbon layer is not removed more than 90%, and the membrane flux remains at 16.8L / (m 2 h).

[0020] For plate-type membrane modules, activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com