Patents

Literature

35results about How to "Reduce stress concentration points" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

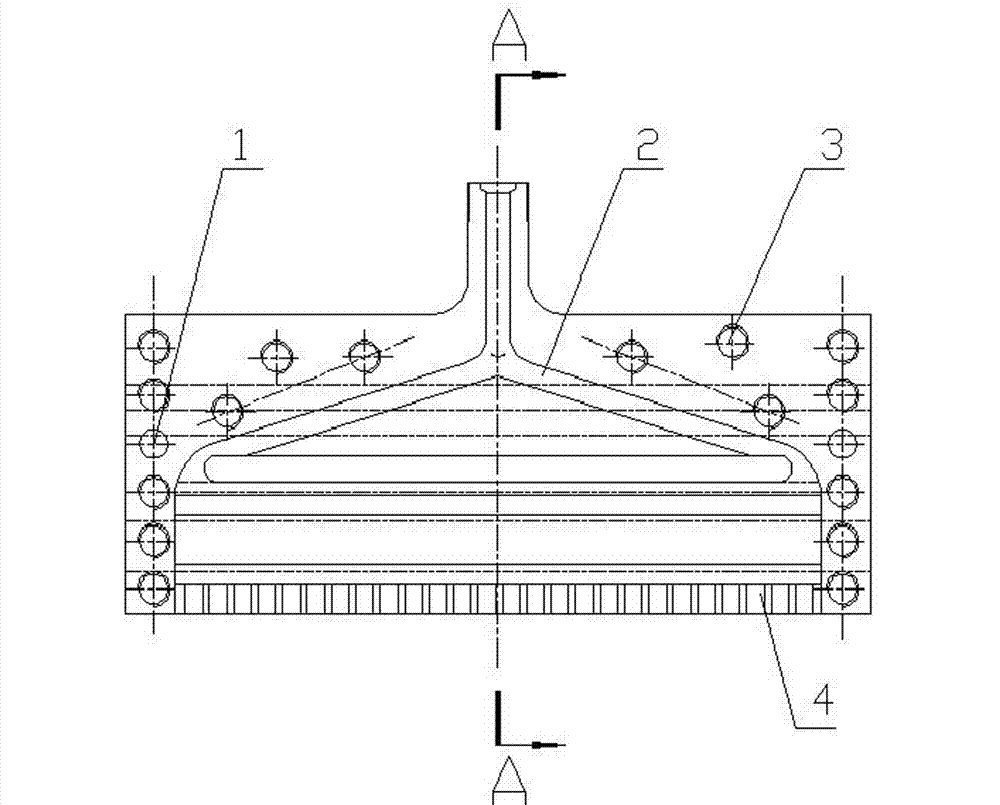

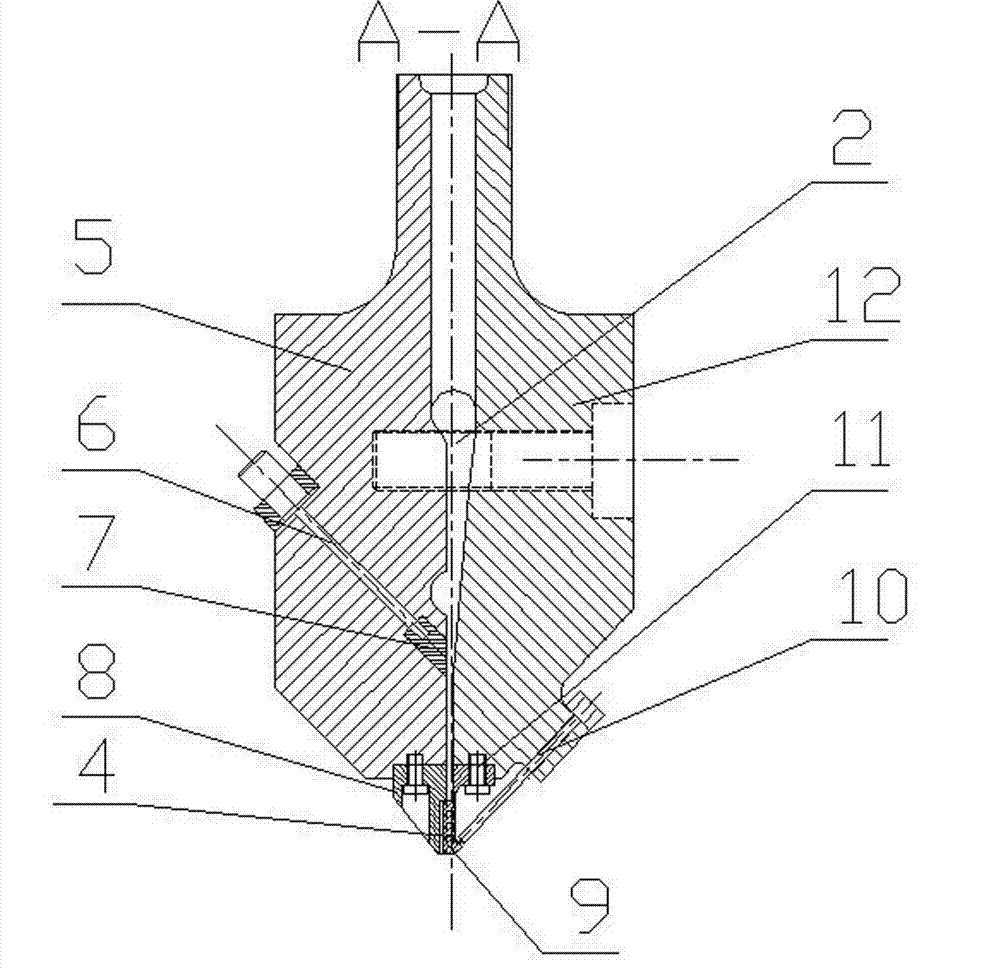

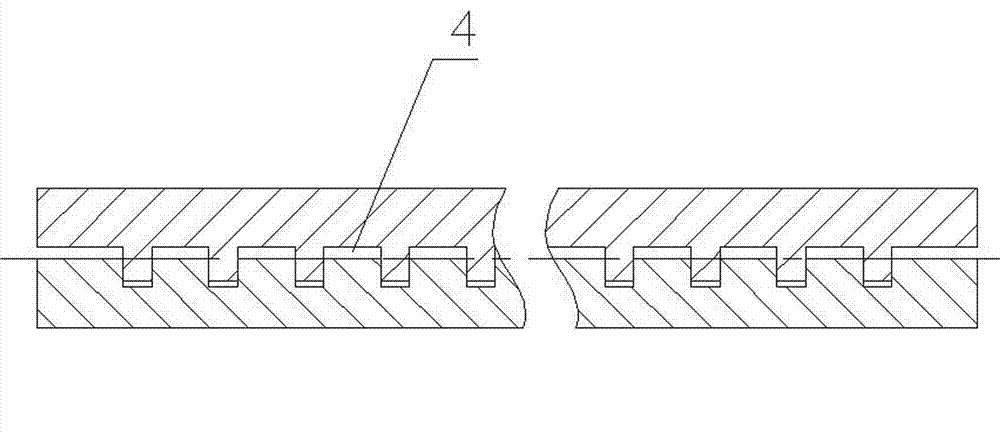

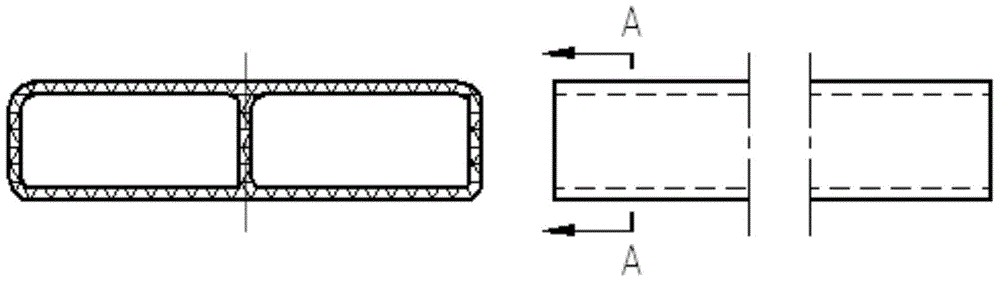

Flat membrane handpiece for producing PET tape yarn

ActiveCN103290489AAvoid damageReduce the chance of stress concentration pointsSpinnerette packsYarnHigh polymer

Owner:ZHENGZHOU UNIV

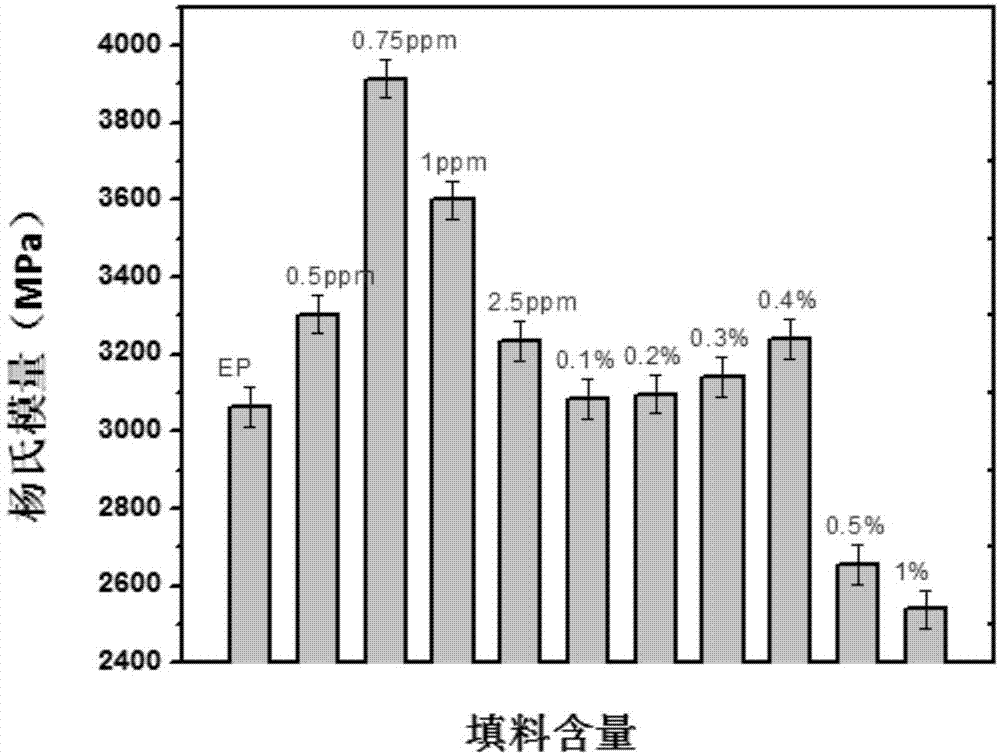

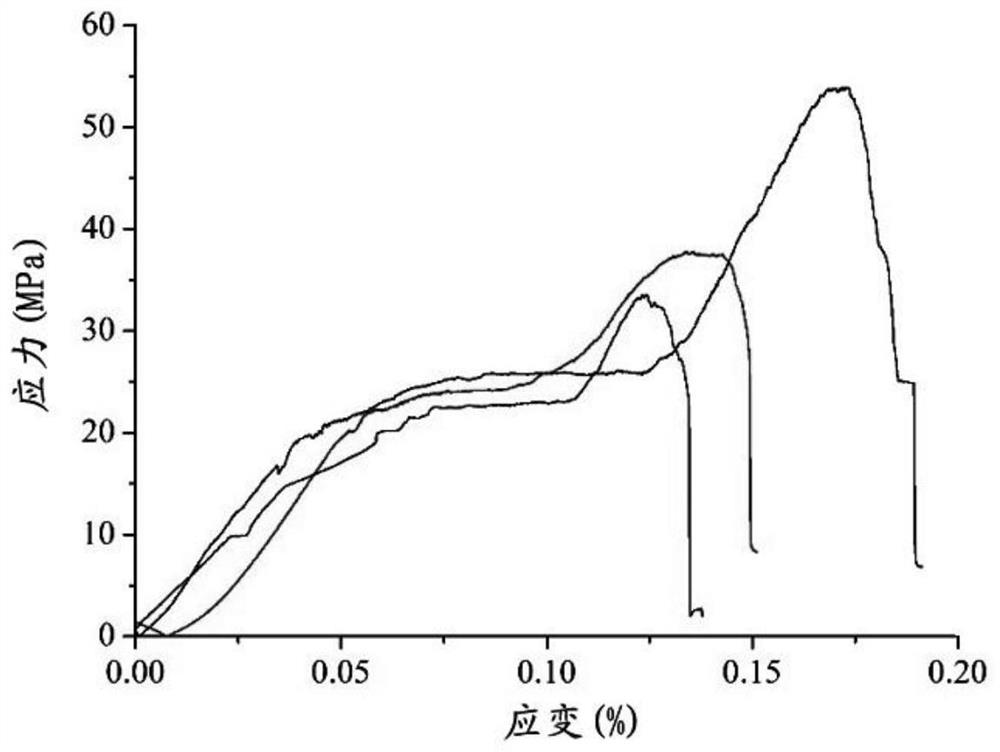

Polymeric composite material and preparation method thereof

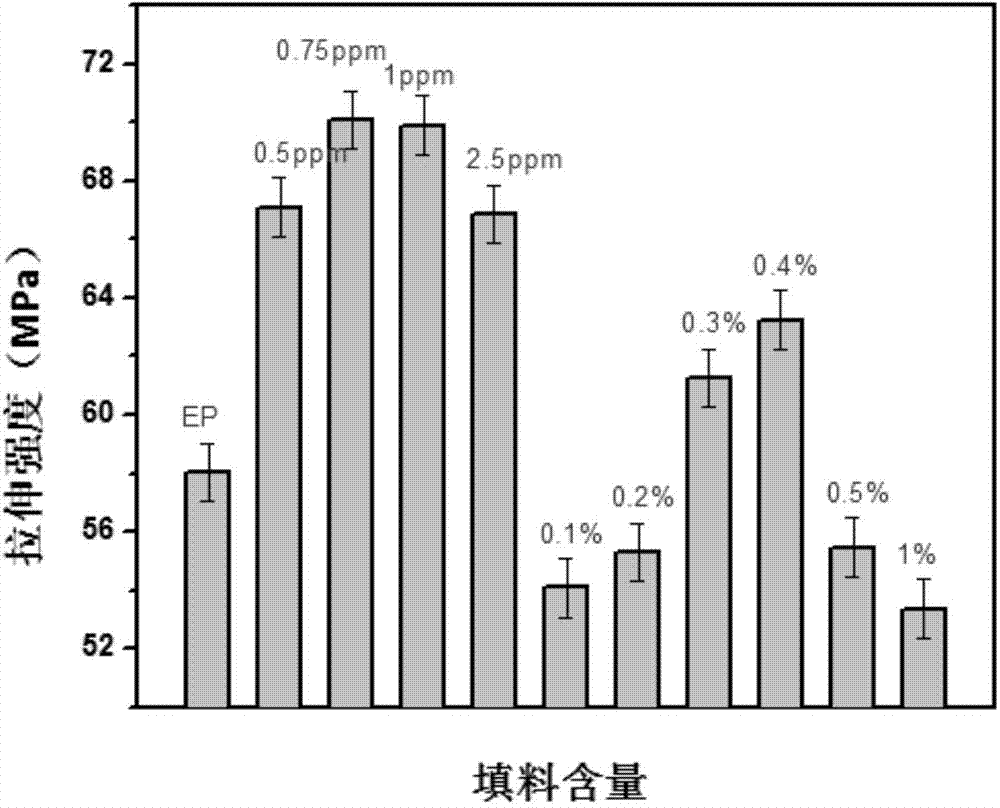

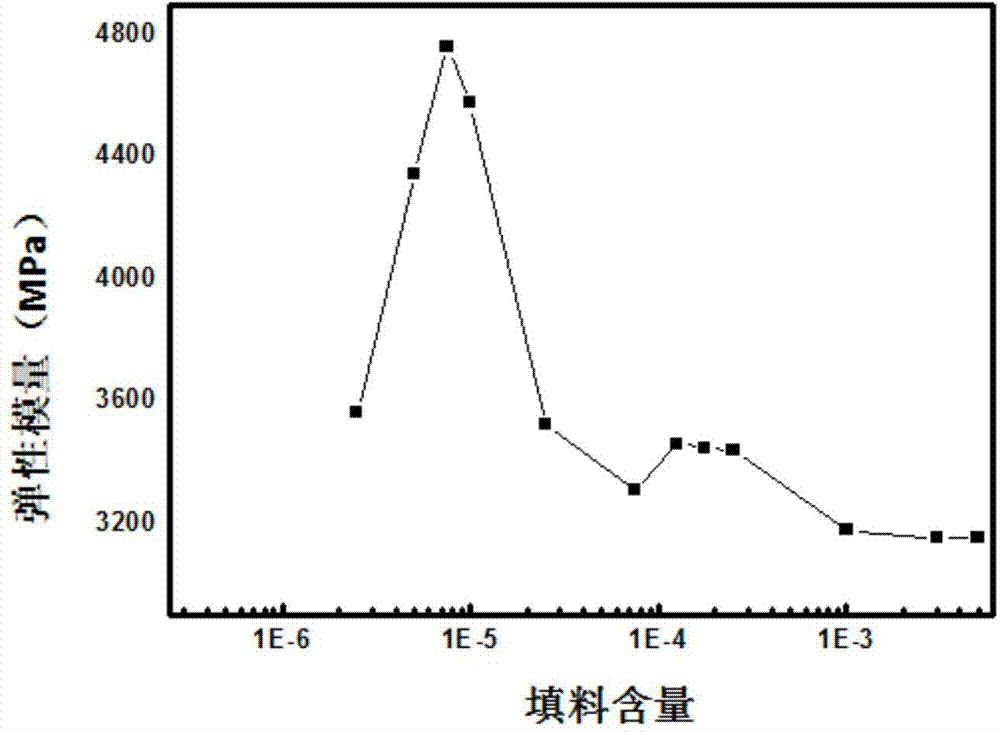

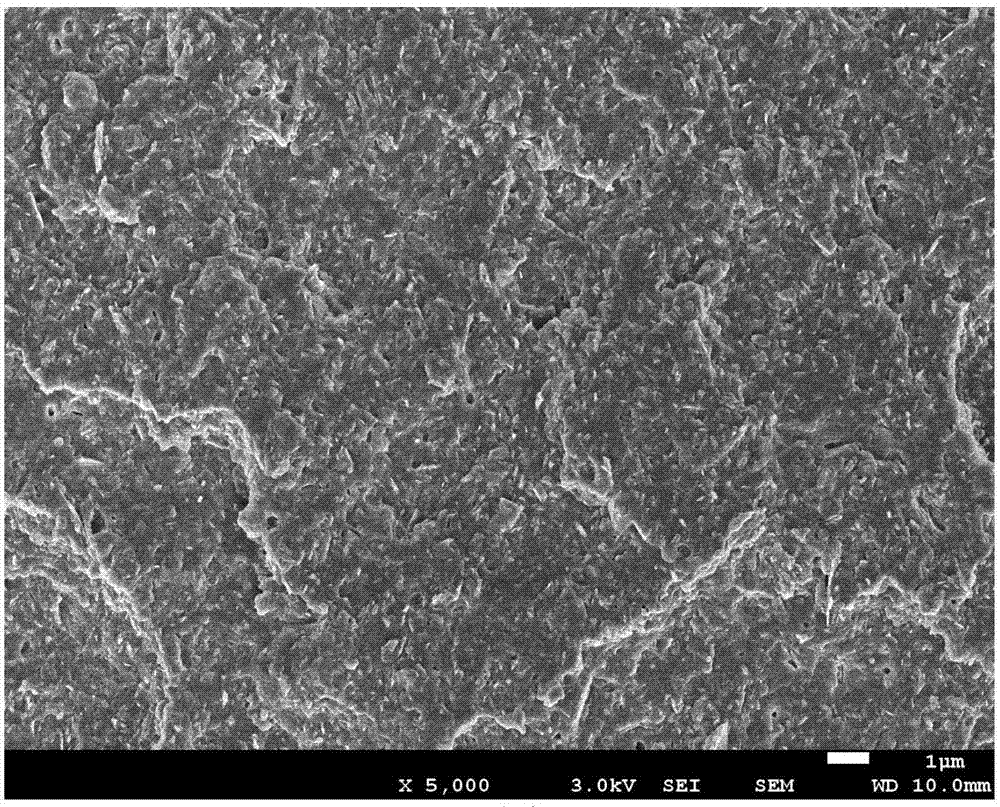

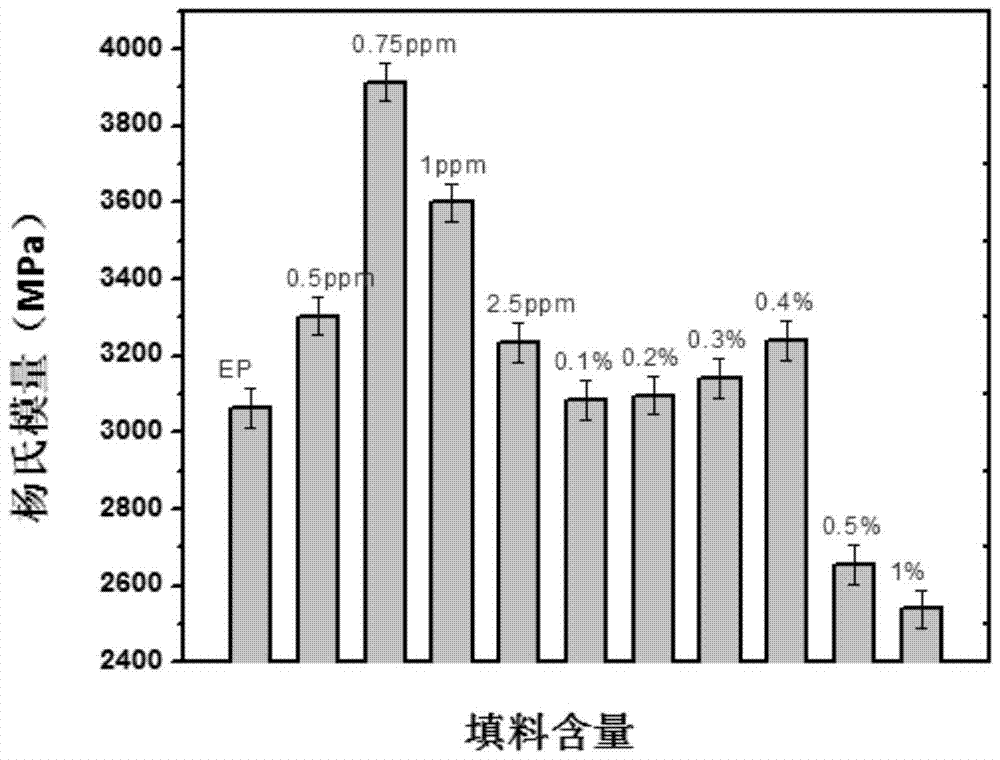

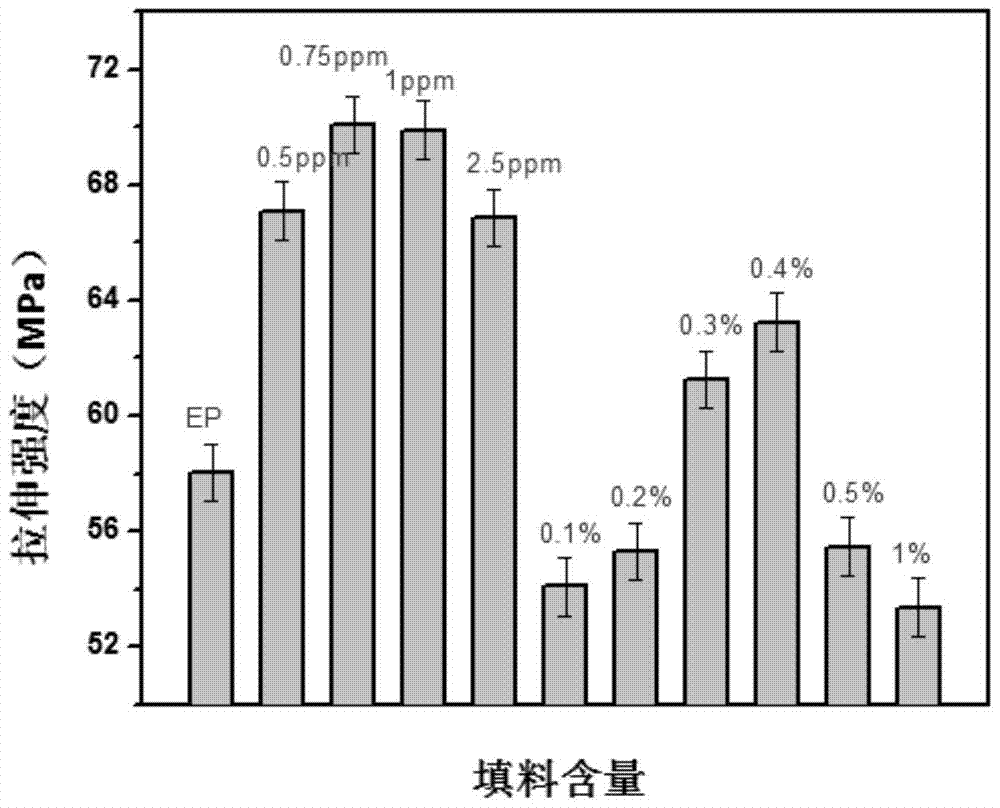

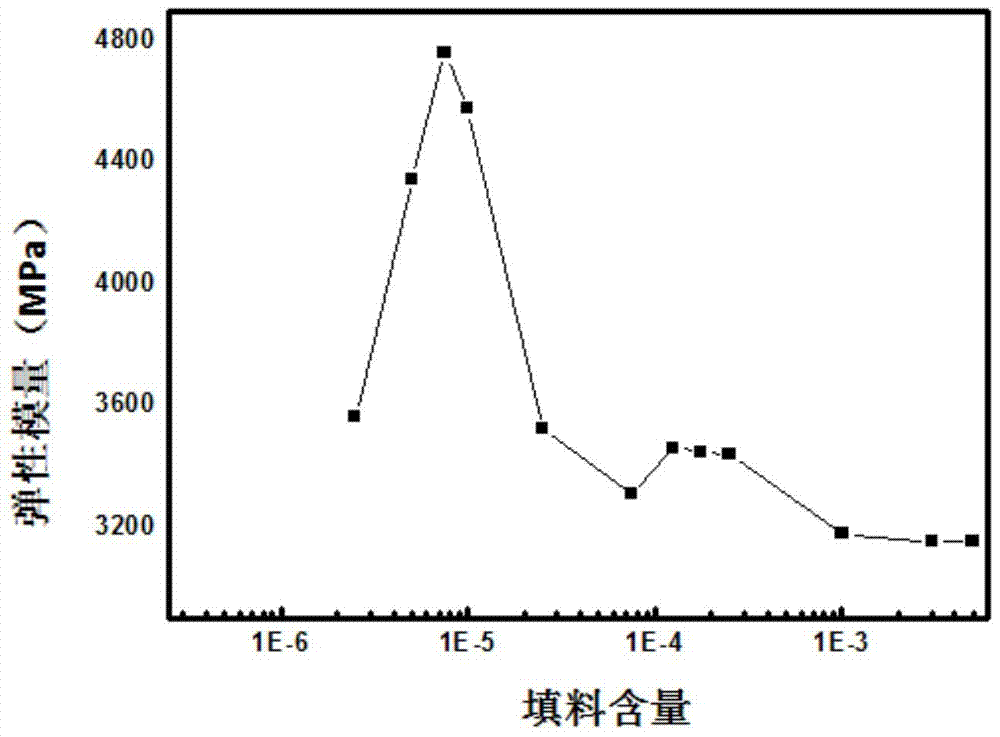

The invention provides a polymeric composite material and a preparation method thereof. In the polymeric composite material, the mass concentration of a filler in a polymeric matrix is 0.1-20ppm, wherein the filler is at least one of graphene, silicon dioxide, carbon nanotube, carbon black, aluminum oxide, zinc oxide, calcium carbonate, titanium dioxide, talcum powder and montmorillonite; and the polymeric matrix is at least one of epoxy resin and unsaturated resin. The preparation method comprises the following steps: uniformly premixing the filler and a proper amount of polymeric matrix to form a master batch, wherein when the polymeric matrix contains epoxy resin, a polymeric medium needs to be added to reduce the viscosity of the polymeric matrix; and taking a proper amount of master batch, diluting the master batch into the polymeric matrix according to the mass concentration ratio of the filler in the polymeric matrix, and uniformly mixing to obtain the polymeric composite material. The polymeric composite material provided by the invention is favorable in monodispersity and high in mechanical property; and the preparation method is simple, easy to operate and easy to realize industrial large-batch production operation.

Owner:厦门祥福兴科技股份有限公司

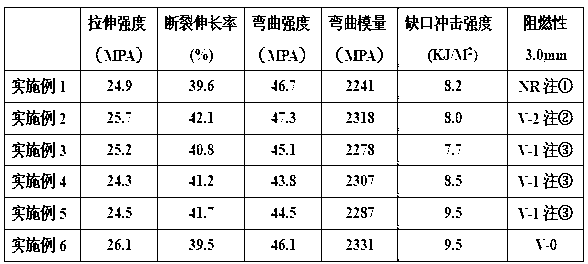

High impact-resistance anti-smoldering polystyrene resin composite and preparation method thereof

ActiveCN101864137AImprove flame retardant performanceNo smoldering phenomenonPolymer sciencePolymer chemistry

The invention relates to the field of the modified polystyrene, and provides a high impact-resistance anti-smoldering polystyrene resin composite and a preparation method thereof. The composite comprises the following components: 70 to 85 parts of polystyrene, 8 to 15 parts of fire retardant, 3 to 4.5 parts of auxiliary fire retardant, 0.2 to 1.5 parts of stabilizer, 0.2 to 1.0 part of lubricant,0 to 0.5 part of dispersion oil and 0.2 percent of other assist agents. The high impact-resistance anti-smoldering polystyrene resin composite is prepared by selecting the high impact-resistance polystyrene, fire retardant and other assist agents and by improving the compatibility of the fire retardant and the basal material high impact-resistance polystyrene (HIPS). The composite has high fire retardance, no smoldering and good impact resistance, and is particularly suitable for producing the products requiring high retardance such as electronic elements, parts, shell materials of electronicdevice, and the like.

Owner:SUZHOU SILVER AGE TECH CO LTD

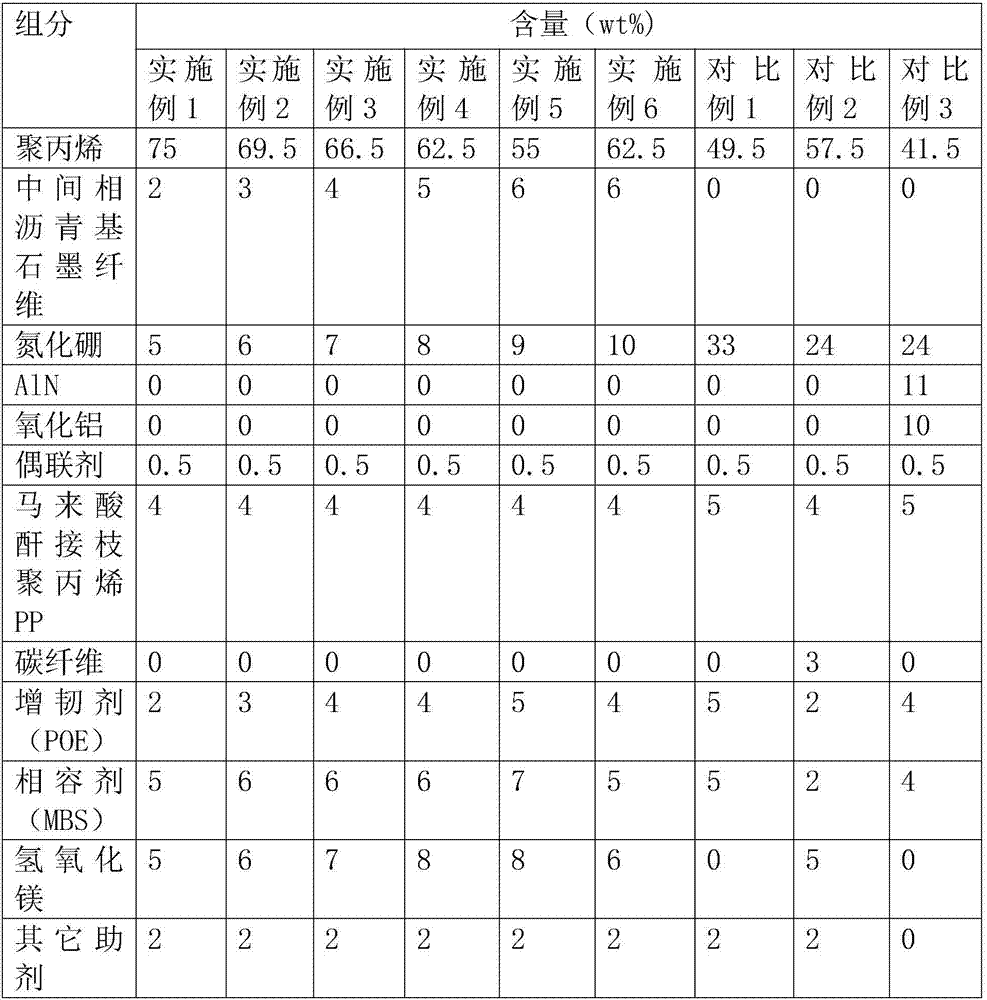

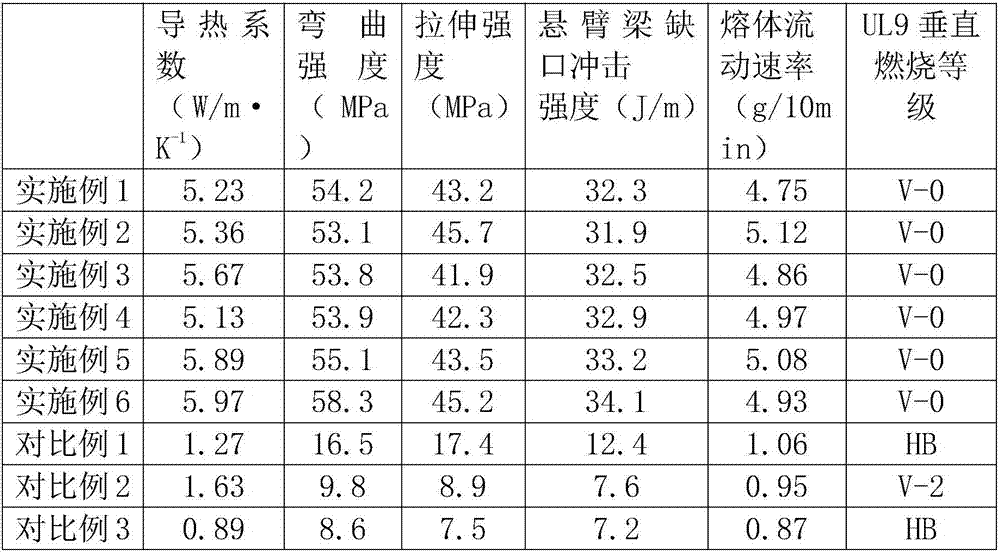

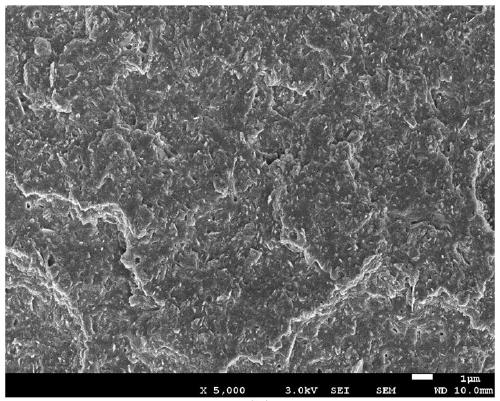

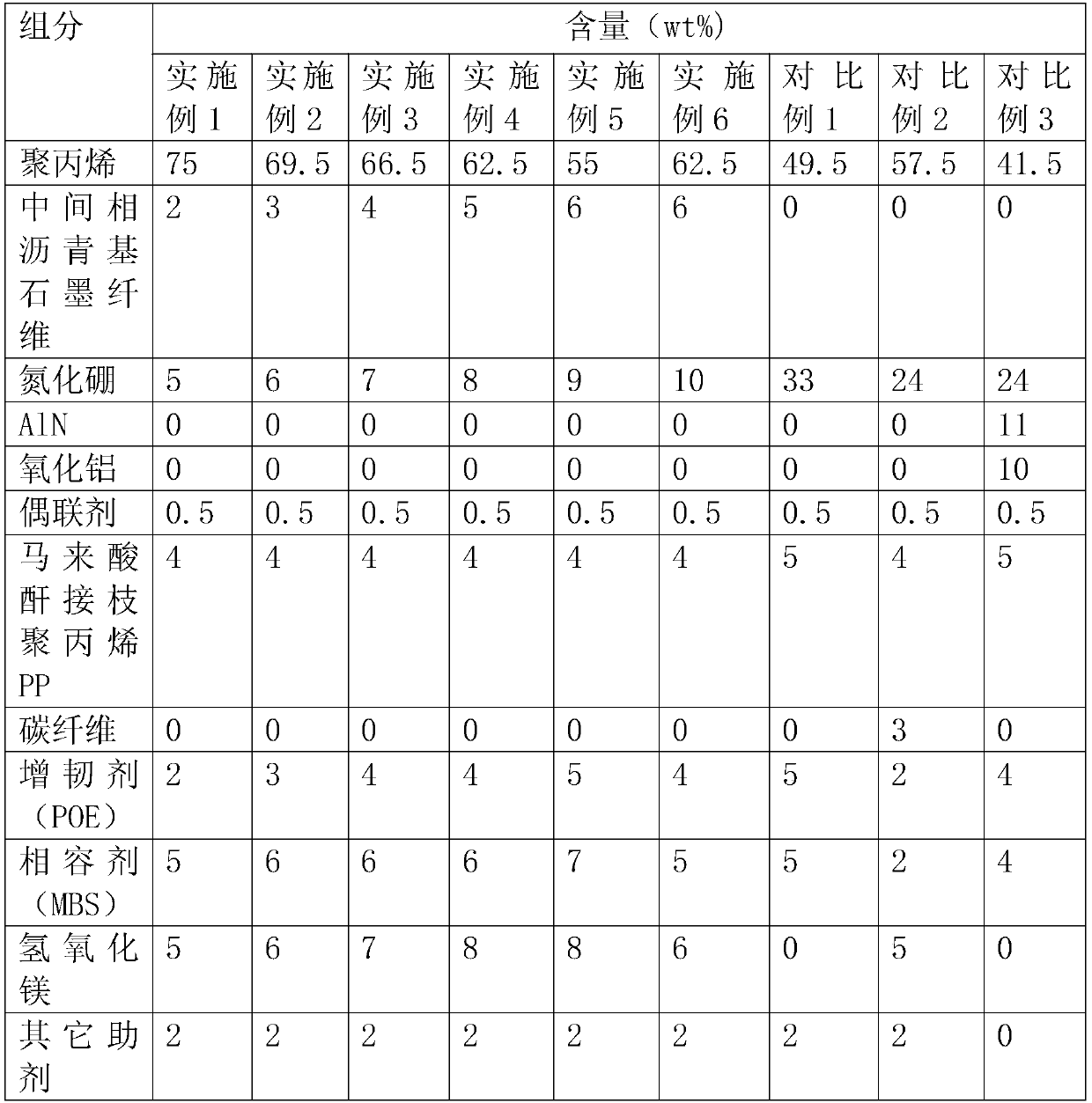

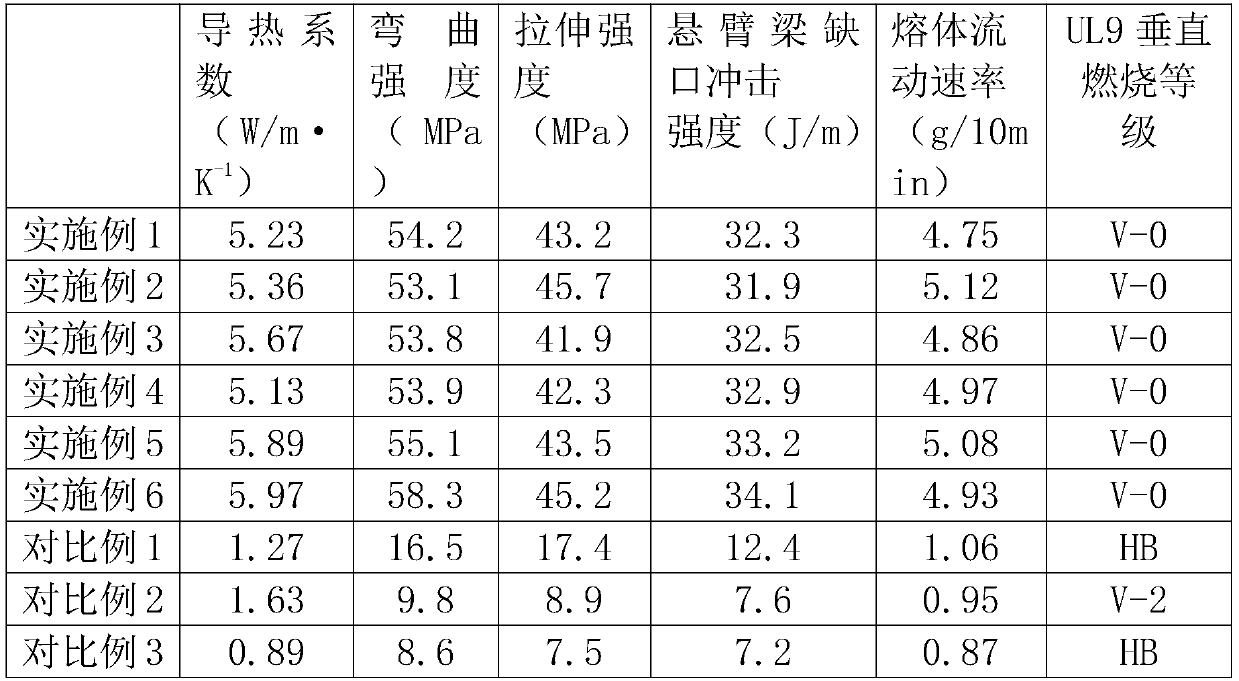

Mesophase pitch-based graphite fiber/polypropylene composite material and preparation method thereof

ActiveCN107090129ACompatibleImprove thermal conductivityHeat-exchange elementsHeat conductingBoron nitride

The invention discloses a mesophase pitch-based graphite fiber / polypropylene composite material and a preparation method thereof. The mesophase pitch-based graphite fiber / polypropylene composite material is prepared from the following components in parts by weight: 55-75 parts of polypropylene, 2-6 parts of mesophase pitch-based graphite fiber, 5-10 parts of boron nitride, 0.5 part of a coupling agent, 4 parts of maleic anhydride-grafted polypropylene, 5-7 parts of a compatilizer, 5-8 parts of nano-magnesium hydroxide, 2-6 parts of a flexibilizer and 2 parts of other assistants. Polypropylene is modified through selecting the mesophase pitch-based graphite fiber and compounded with the related flexibilizer, coupling agent, compatilizer, fire retardant and lubricant, and the mesophase pitch-based graphite fiber / polypropylene composite material is prepared through a blending mode, so that the heat-conducting property and the flame retardant property are very excellent, a heat-conducting filler and matrix resin are good in compatibility and good in mechanical properties, and furthermore, the machining process is relatively simple.

Owner:QINGDAO UNIV OF SCI & TECH

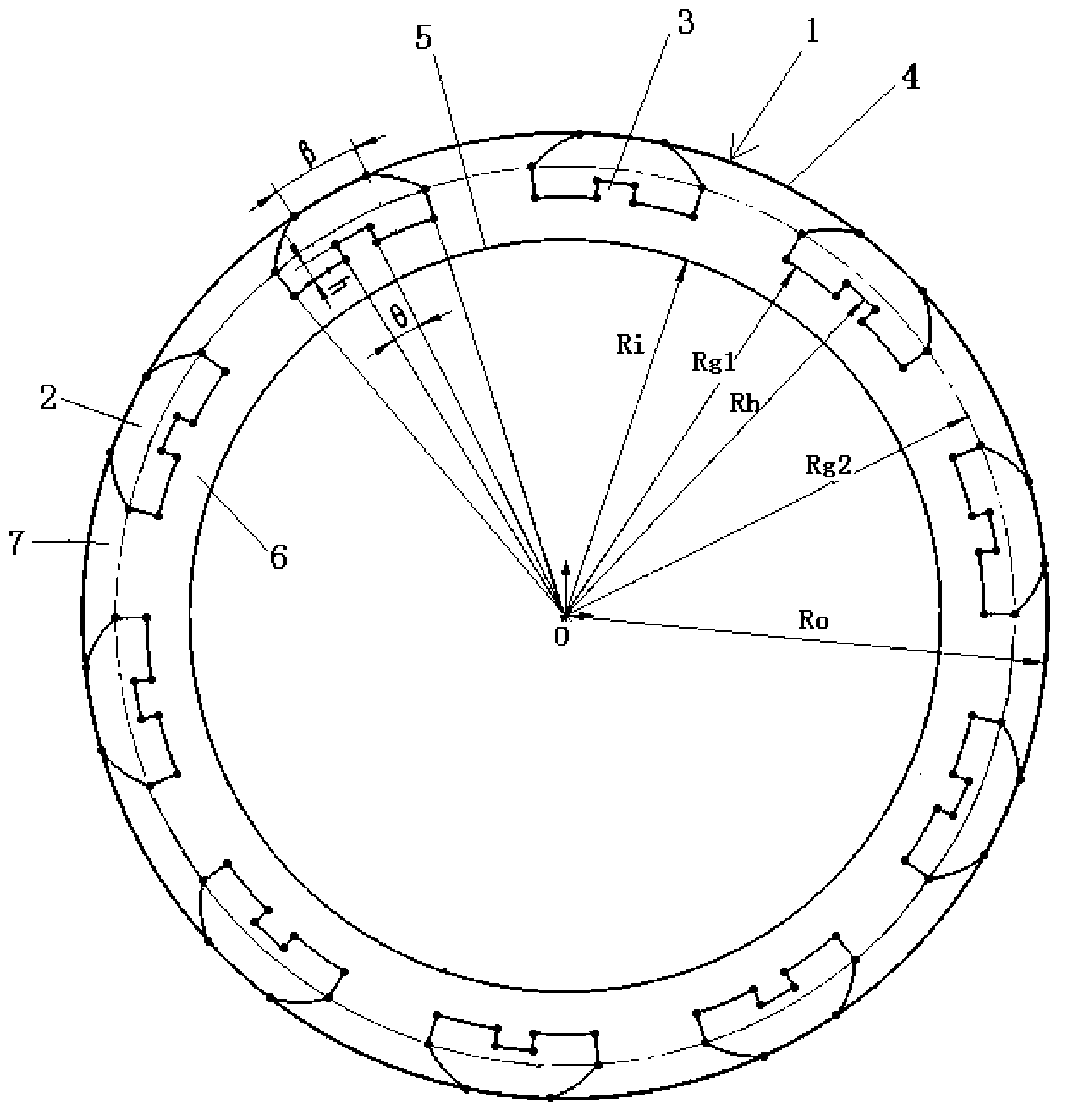

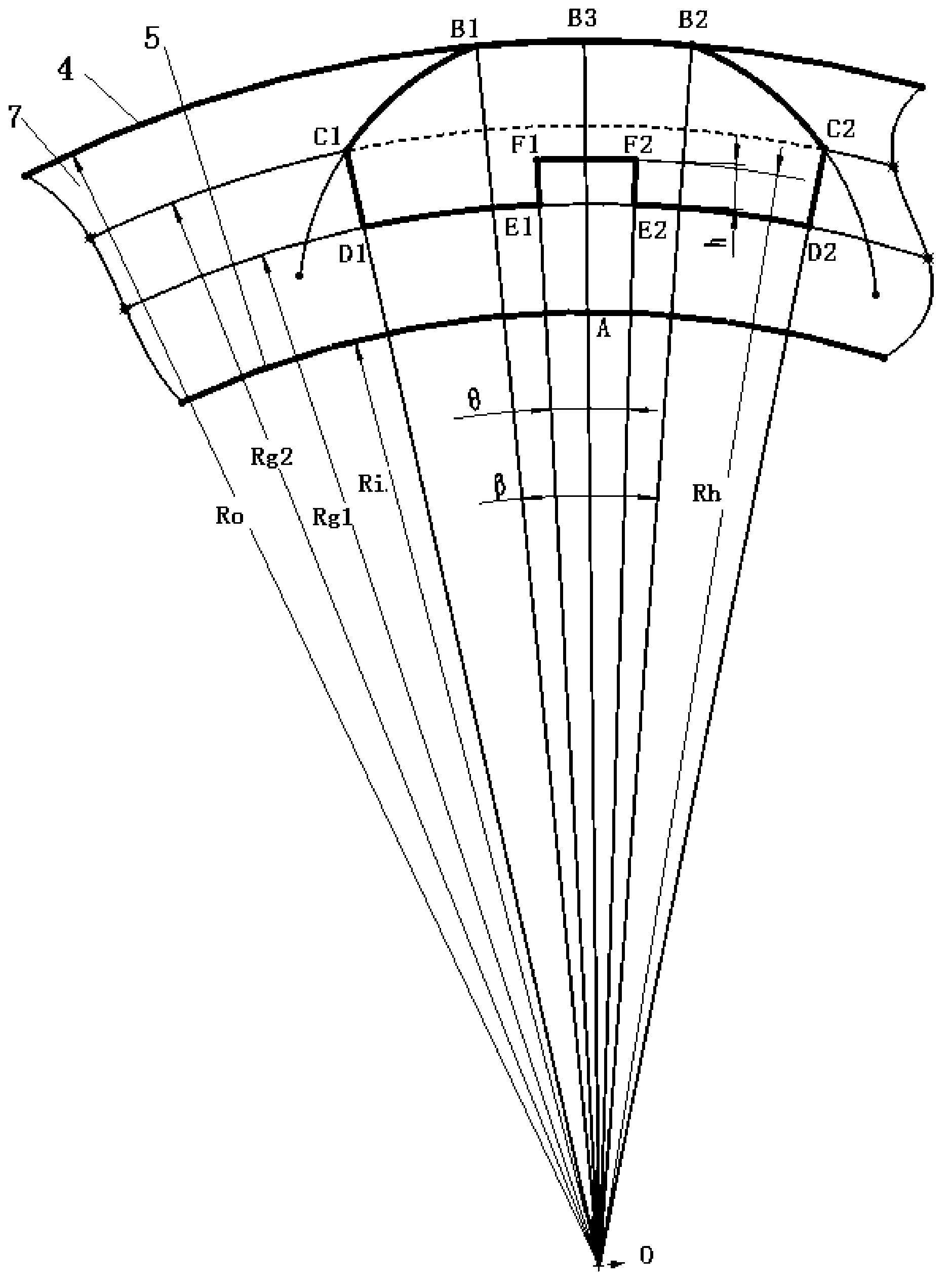

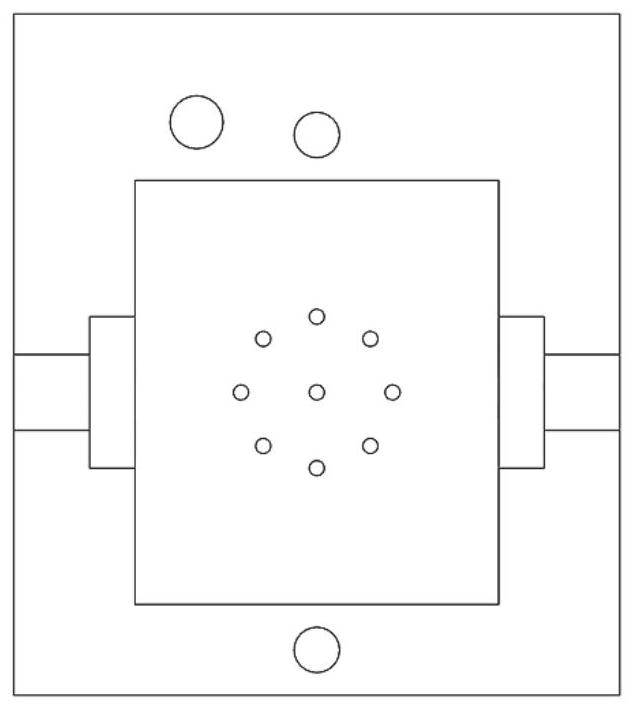

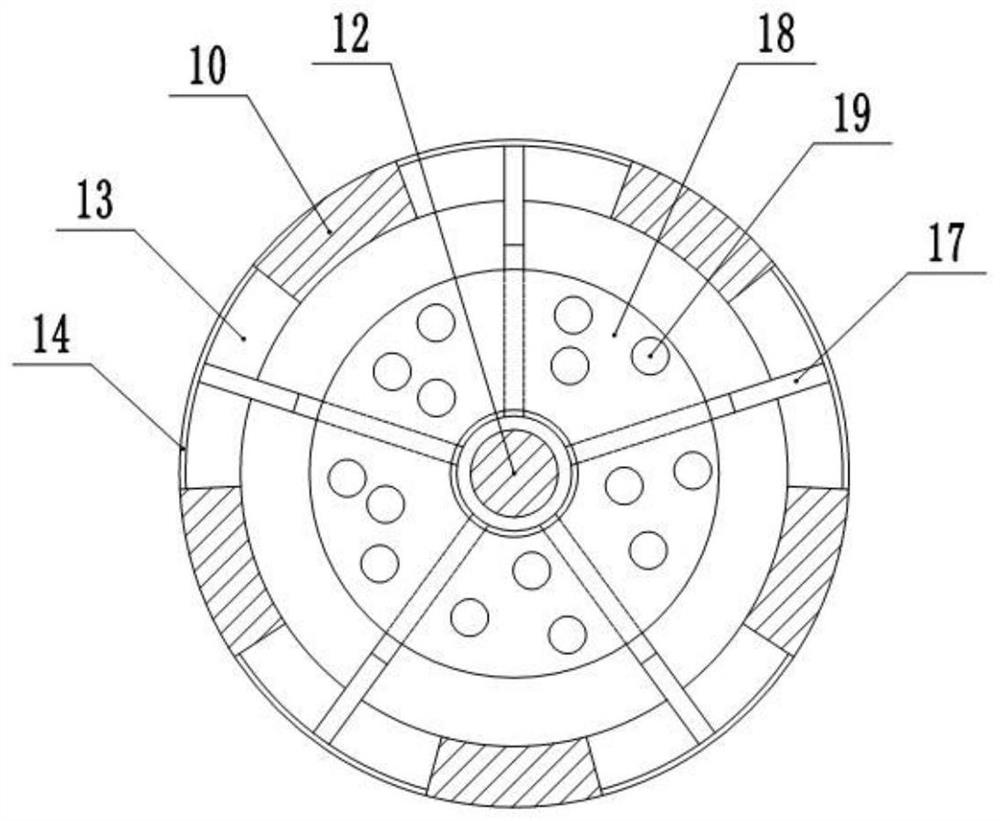

Dry air-sealed end face groove profile rotating bilaterally

InactiveCN103216626ASimplify processing difficultyAchieve serializationEngine sealsDry gas sealEngineering

The invention discloses a dry air-sealed end face groove profile rotating bilaterally. The dry air-sealed end face groove profile is provided with a movable ring end face, wherein 8-12 dynamic pressure grooves are uniformly distributed on the dynamic ring end face along a circumferential direction; each dynamic pressure groove is concave; the depth of each dynamic pressure groove is 5-15 mum; and each dynamic pressure groove has a concave structure constructed by an inlet arc line which is formed on the outer circumference of a dynamic ring, a left outer-side arc edge and a right outer-side arc edge which are connected to the two ends of the inlet arc line symmetrically, a left outer side straight edge and a right outer side straight edge which are correspondingly connected to the other ends of the left outer side arc edge and the right outer side arc edge respectively and of which the extension lines are vertical to the inner circumference of the dynamic ring, a left groove root and a right groove root which are correspondingly connected to the other ends of the left outer side straight edge and the right outer side straight edge respectively and are parallel to the outer circumference of the dynamic ring and the inner circumference of the dynamic ring, and a middle isolating block of which the periphery is connected with the other ends of the left groove root and the right groove root. Due to the adoption of the dry air-sealed end face groove profile, the sealing pneumatic performance can be improved, the groove profile processing difficulty is lowered, the matching property of a sealed groove profile and the practical requirement is improved, and the higher requirement of modern industry on sealing is met.

Owner:TIANJIN UNIV

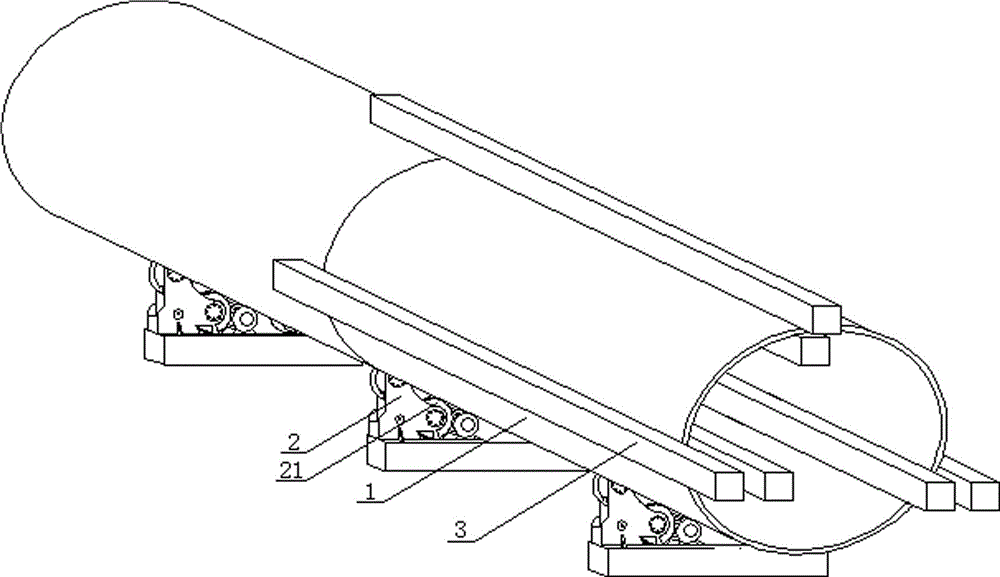

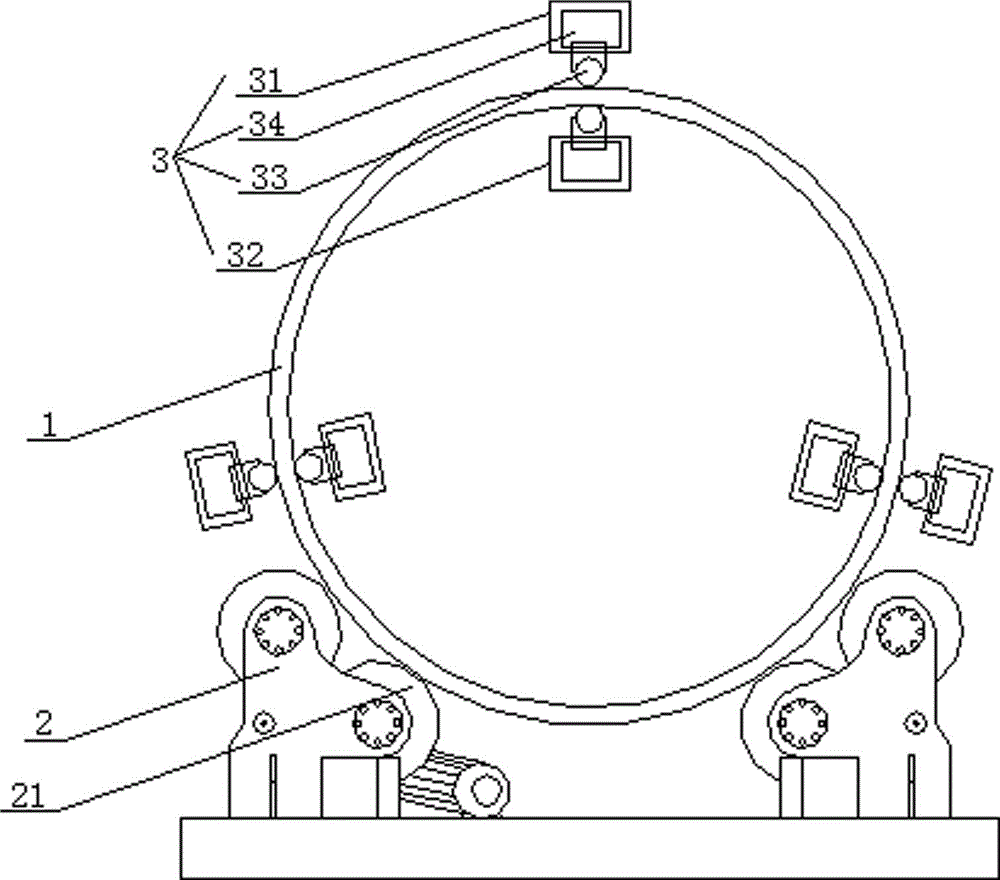

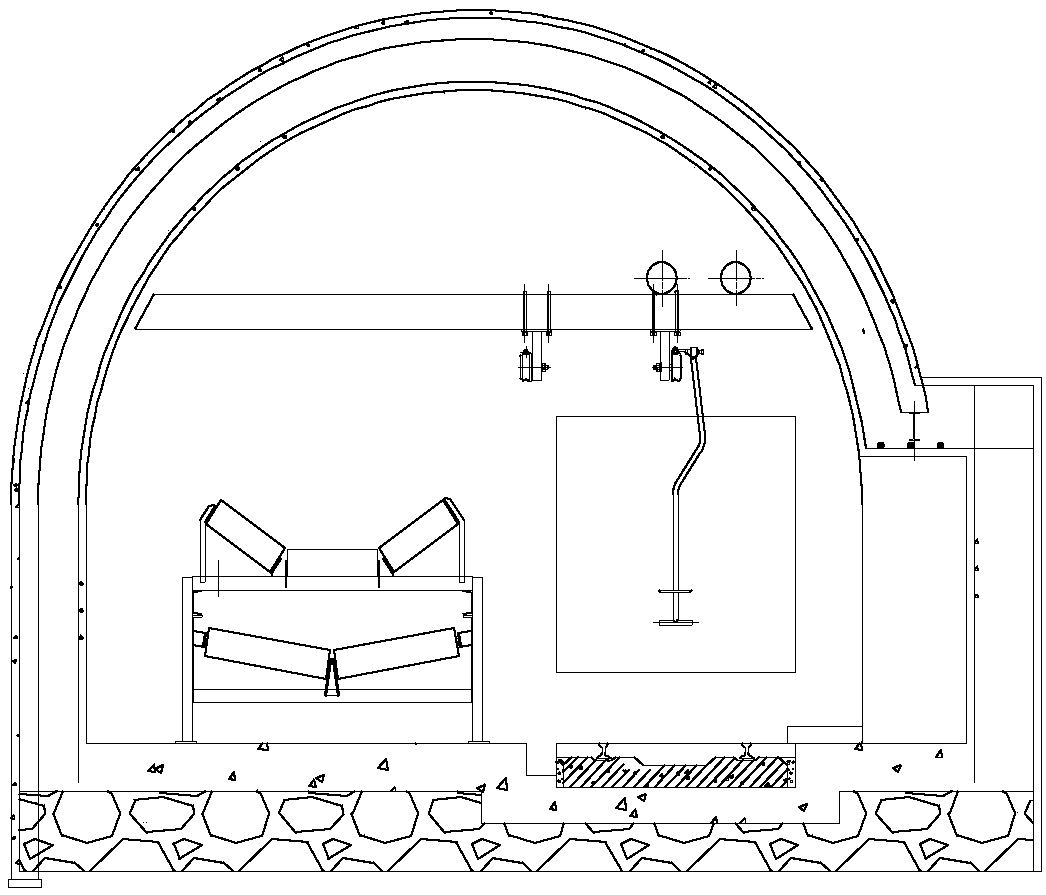

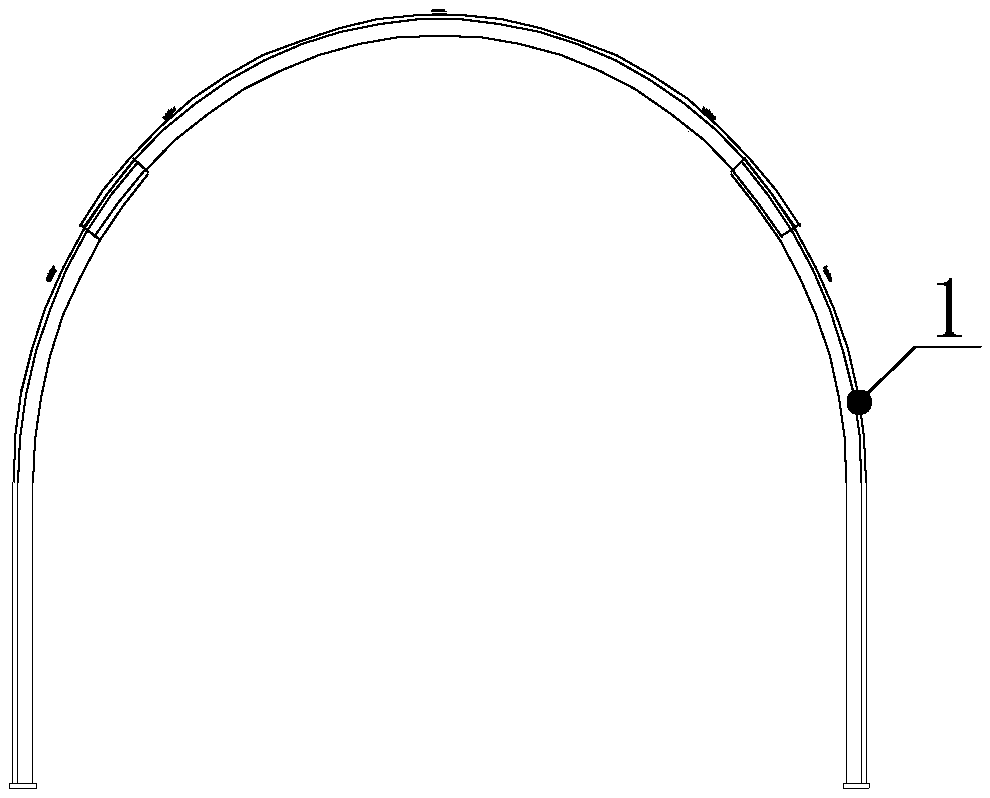

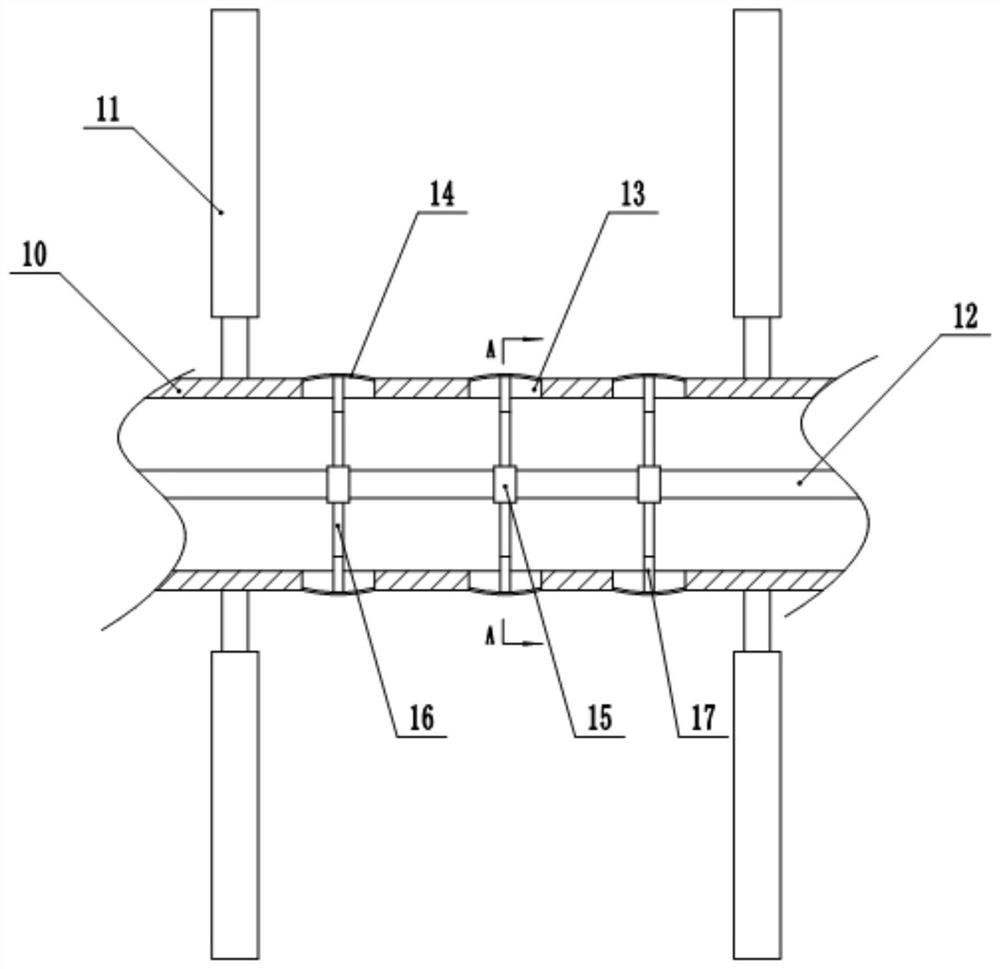

Assembly process of tower sections for large-diameter wind-power tower tube

InactiveCN105904111AGuaranteed continuityReduce stress concentration pointsWelding/cutting auxillary devicesAuxillary welding devicesStress concentrationElectricity

The invention discloses assembly process of tower sections for a large-diameter wind-power tower tube. The two tower sections are placed on corresponding groups of roller racks. Two groups of support rollers are arranged on each group of roller racks with one roller being as a main driving roller. Three groups of alligator-type assembly machines having rollers are positioned according to different positions in the tower sections by pushing the three groups in the tower sections. Main driving rollers of the groups of roller racks drive the two tower sections to rotate at the same time. During rotation of the tower sections, CO2 gas is utilized for shielded welding, positioning and welding in the position within the range of 200-300 mm of liftable roller centers of the three groups of alligator-type assembly machines having rollers. Positioning and welding are carried out in three positions at the same time. The assembly process of the tower sections for the large-diameter wind-power tower tube has following beneficial effects: continuous adjustments are made to overall alignment tolerance of whole sections of circular arcs in order to reduce stress concentration points at butt joints; stress can be uniformly distributed and quality risk is reduced; assembly efficiency is greatly improved; and accuracy quality is ensured.

Owner:FUJIAN FUCHUAN YIFAN NEW ENERGY EQUIP MFG CO LTD

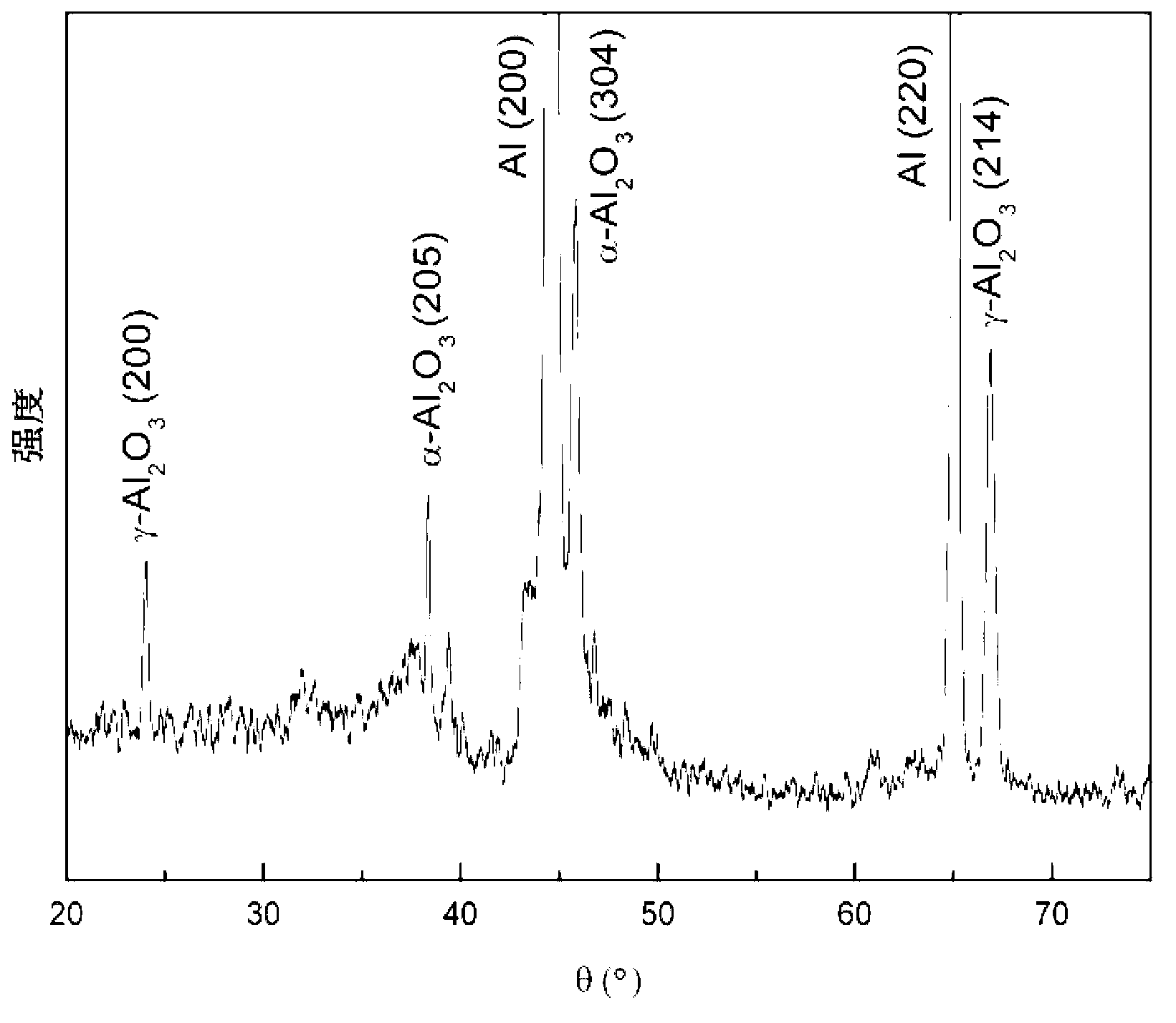

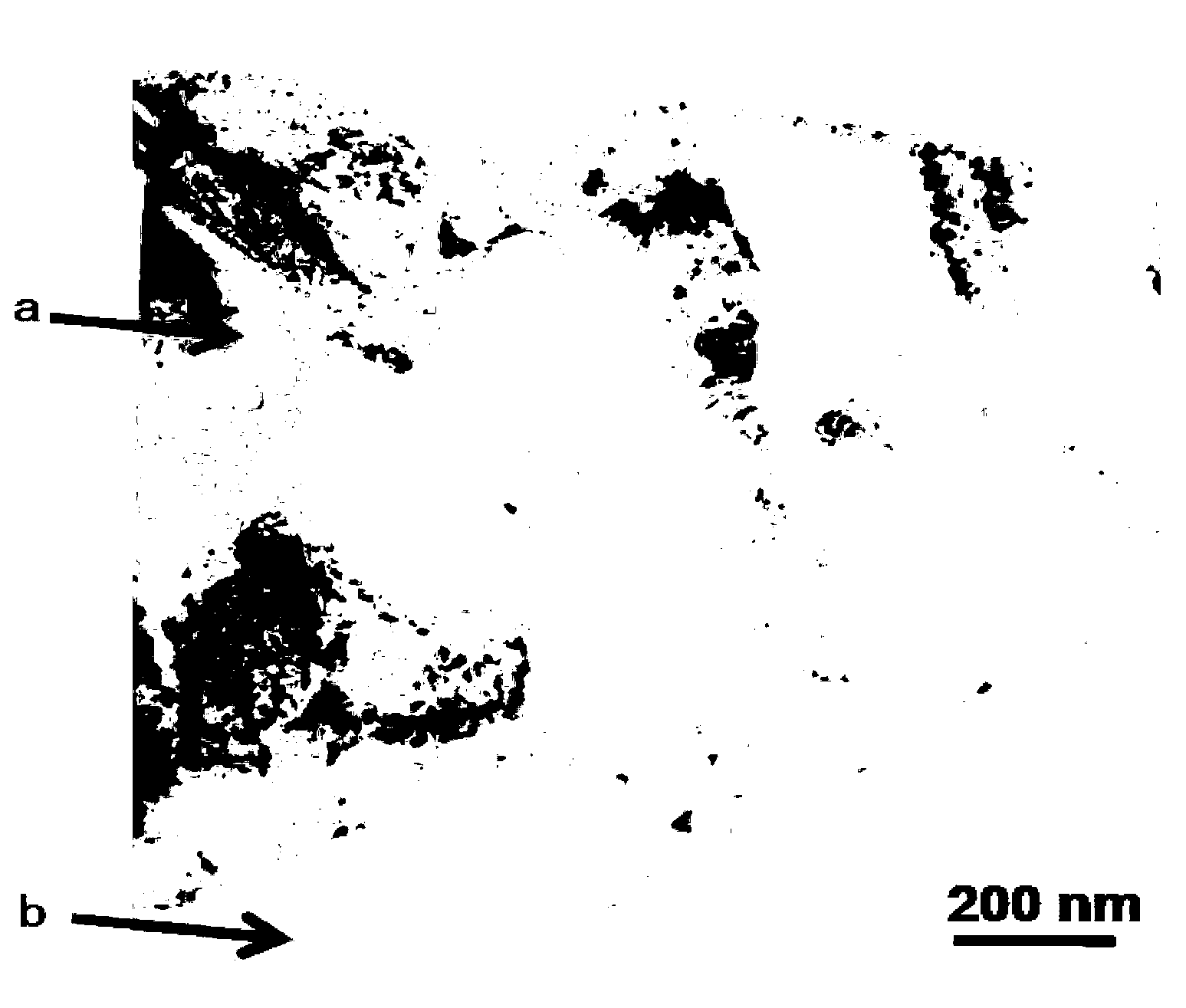

Preparation method of tough alumina ceramic membrane

The invention relates to a preparation method of a tough alumina ceramic membrane, and solves the problems that the alumina ceramic membrane prepared according to the conventional method is low in toughness, small in processing area and complex in process and has a strain value of lower than 1%. The preparation method comprises the following steps: 1, preparing weak alkaline electrolyte with alkalinity regulator and spark control agent; 2, putting aluminium alloy into a tank body with electrolyte, wherein an anode is made of aluminium alloy, and an anticathode is made of stainless steel or graphite; 3, oxidizing the aluminium alloy for 1-12 minutes with a liquid phase plasma oxidizing power supply under the condition that the current density of 0.02-0.14A / cm<2>; and 4, rinsing and drying the aluminium alloy processed in the step 3 to obtain the tough alumina ceramic membrane. The preparation method of the tough alumina ceramic membrane is applied to the field of chemical industry.

Owner:HARBIN INST OF TECH

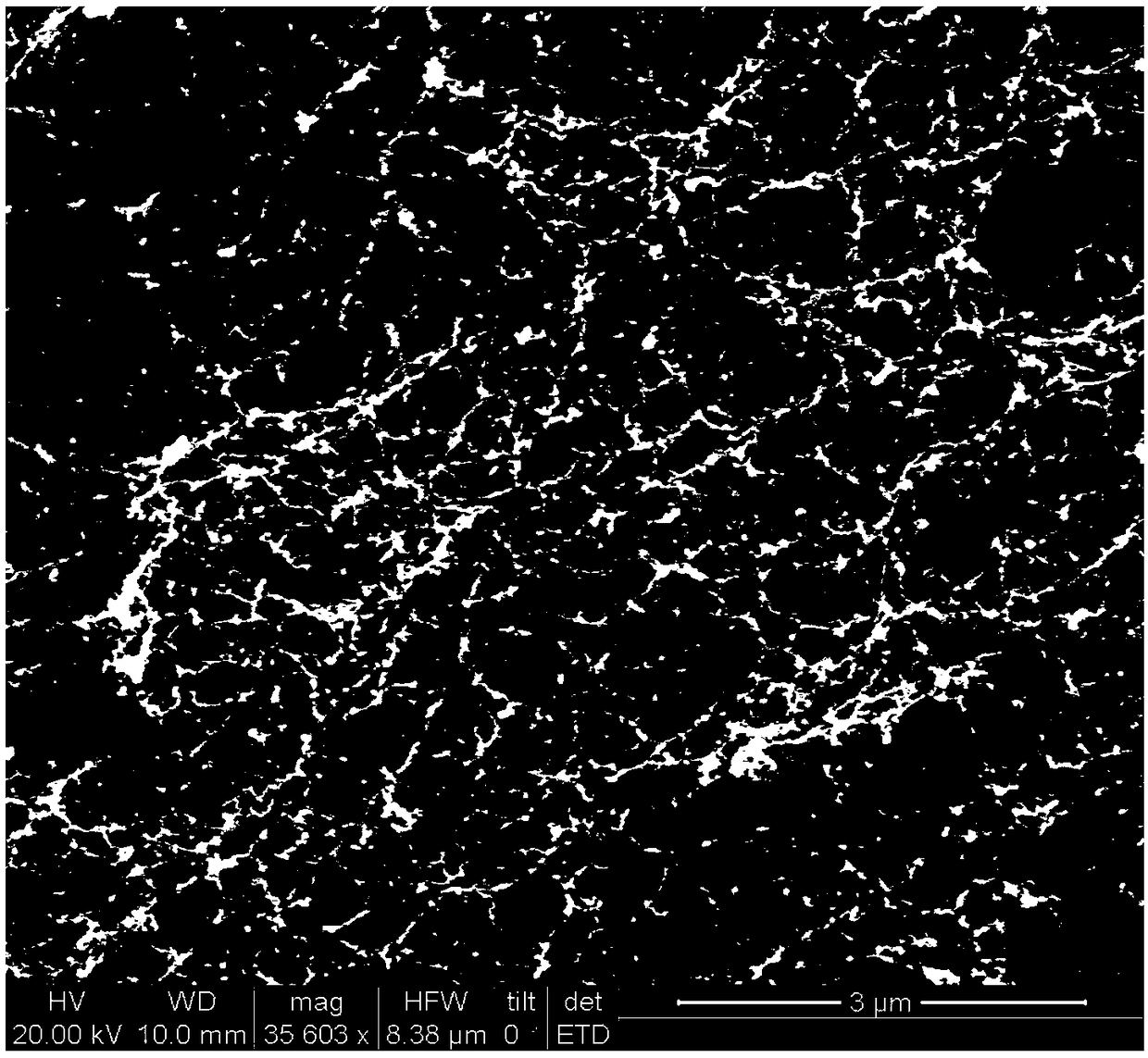

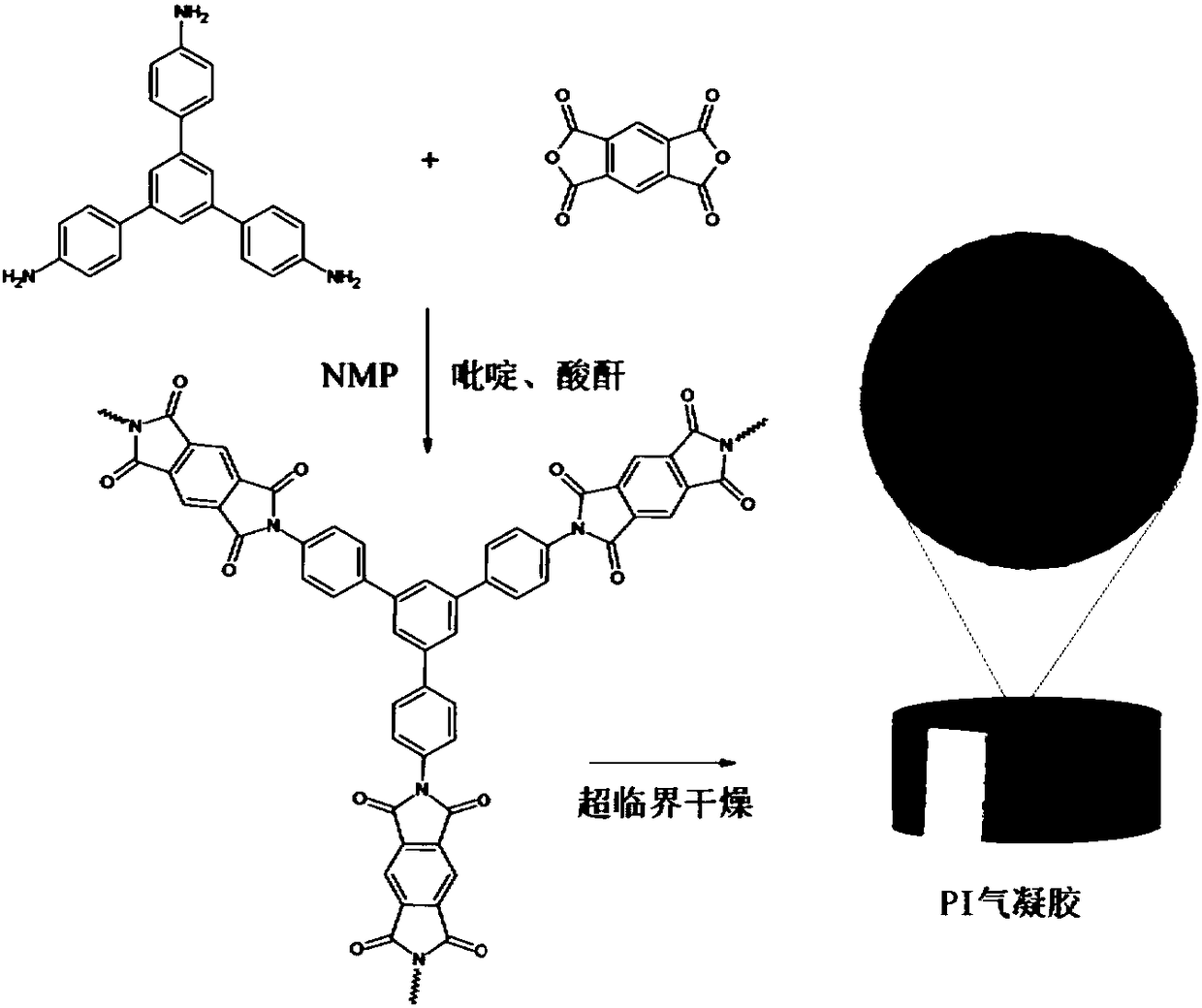

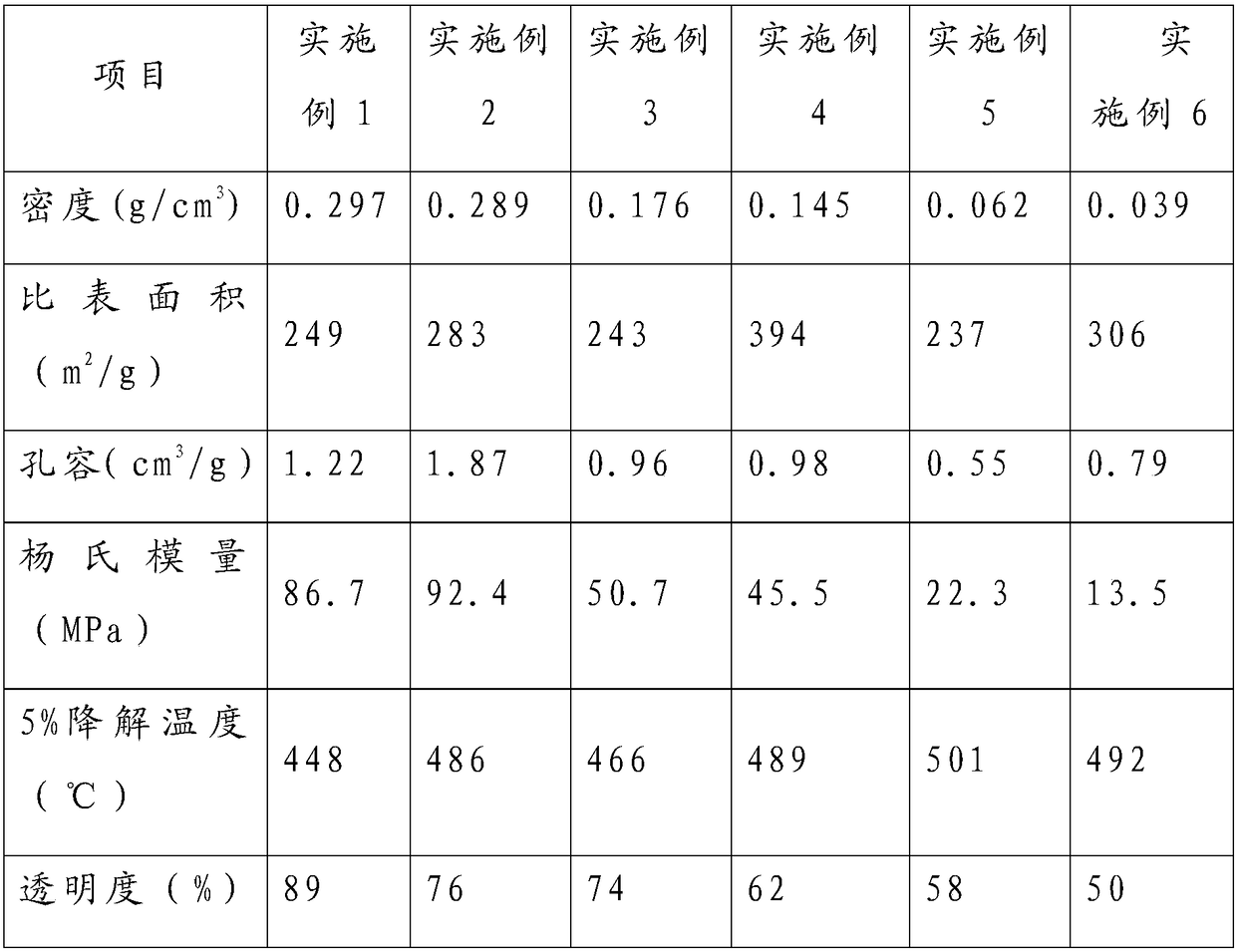

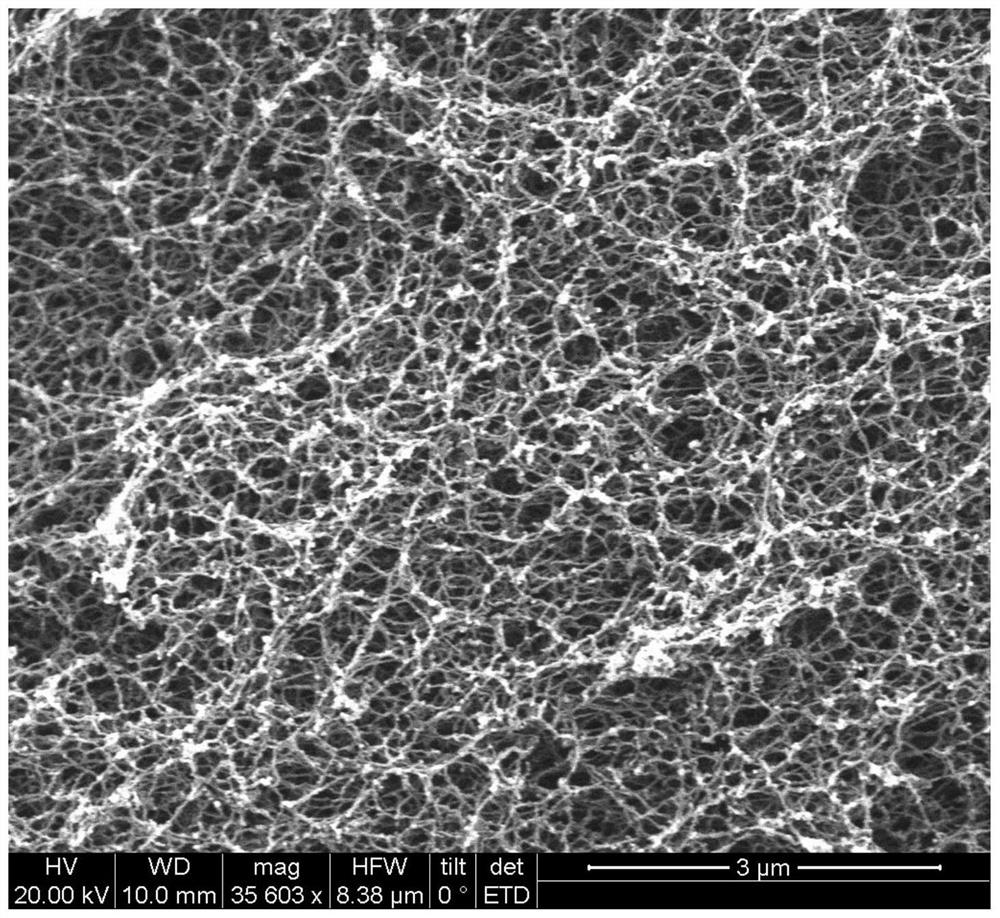

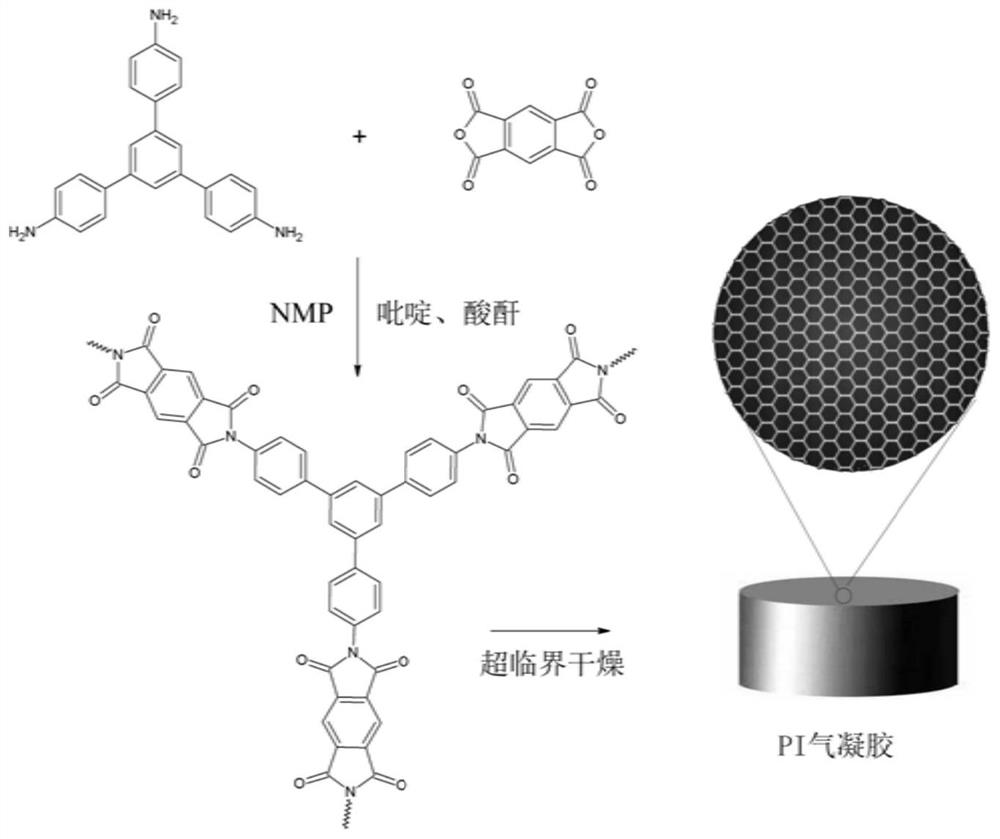

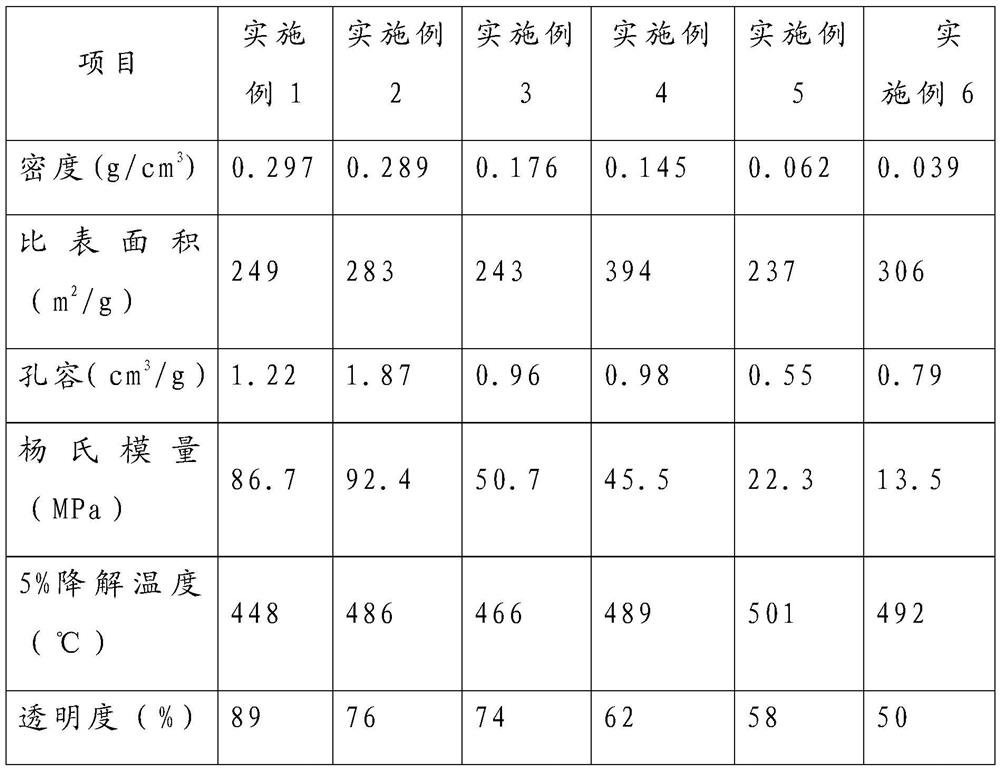

Transparent and high-strength polyimide aerogel and preparation method thereof

The invention provides transparent and high-strength polyimide aerogel and a preparation method thereof, which belongs to the technical field of nano porous materials and heat insulation and heat preservation. The preparation method comprises the following steps: dissolving aromatic triamine monomers and dianhydride monomers in a solvent to be reacted until a reaction system is completely transparent; adding a dewatering agent into the transparent system, stirring, defoaming, then standing, and forming gel; and performing the solvent replacement for the gel, and drying the gel, thus obtainingthe polyimide aerogel. The polyimide aerogel obtained by the invention has the characteristics of low density (the density is 0.08 g / cm<3> to 0.3 g / cm<3>), high specific surface area (the specific surface area is greater than 200 m<2> / g), high strength (the compression Young modulus is greater than 10MPa), low heat conductivity, high heat stability (the thermal degradation temperature is greater than 400 DEG C) and high transparency (the transmittance is greater than 50 percent), and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

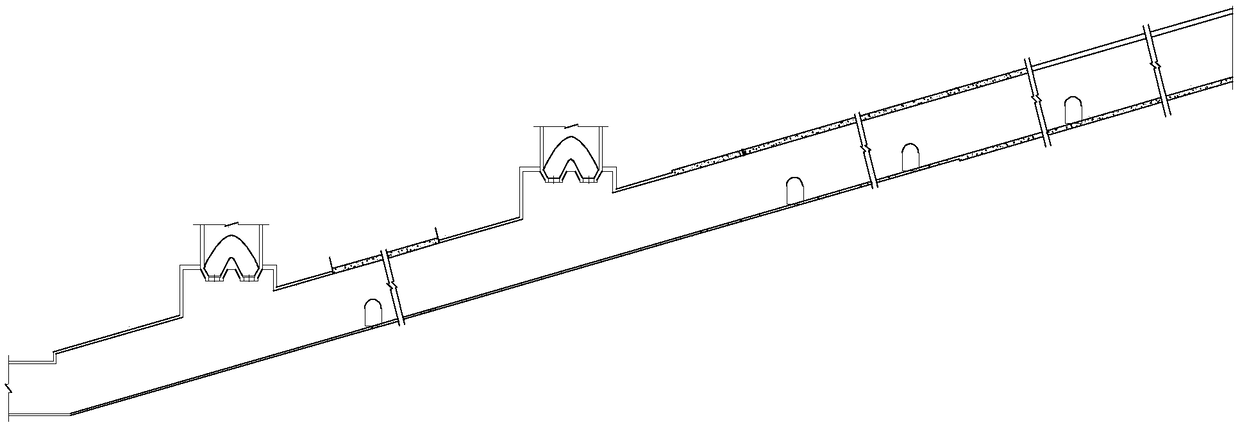

Inclined well wall support construction method and inclined well wall support system

InactiveCN108915735ARelieve pressureGood for supportUnderground chambersMaterial fill-upStress concentrationSupporting system

The invention provides an inclined well wall support construction method. The method comprises the steps that a steel support is firstly erected, crushed gangue is filled, a gangue layer is formed, asprayed concrete layer is formed by spraying concrete on the gangue layer, and a gap is filled. A set of inclined well wall support system is constructed by the inclined well wall support constructionmethod, the inclined well wall support system is based on a U-shaped steel shed support, a reinforcing bar mesh back plate is arranged on the steel support, the gangue is filled between the reinforcing mesh back plate and an inclined well wall, and a grout is filled in the gap between the gangue by grouting. The method adopts a wall back filler to uniformly transfer the external load from surrounding rocks to the steel support, so that the steel support receives a uniform load along the periphery, which is beneficial to exerting the supporting force of the steel support. The method reduces the rigidity of the filler, is very advantageous for reducing the surrounding rock pressure, adopts a method that the crushed gangue fills the rear space of the support to ensure the uniform bearing ofthe steel support, and reduces stress concentration points.

Owner:ANHUI UNIV OF SCI & TECH

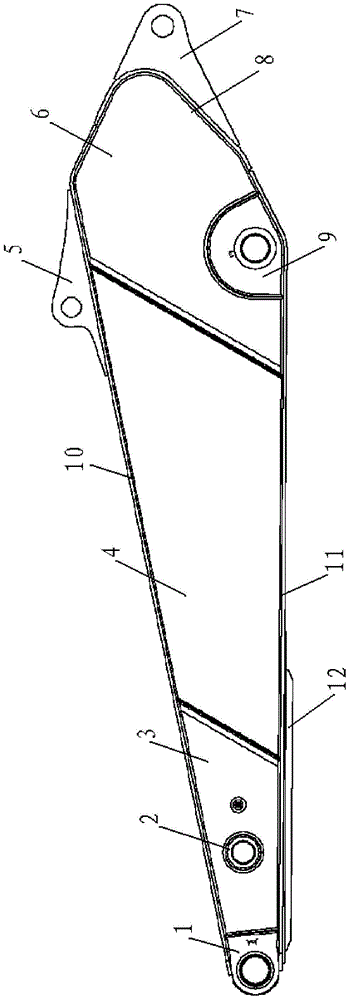

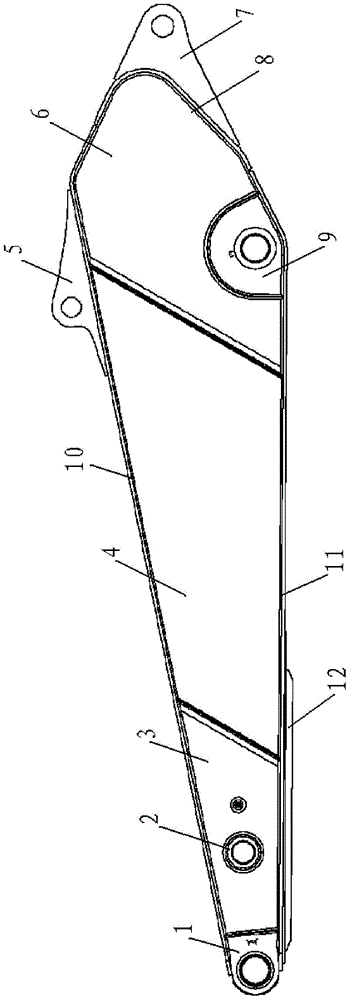

Lug plate structure with equal and colinear stress, and engineering machine

The invention discloses a lug plate structure with equal and colinear stress, and an engineering machine, belonging to the field of machine manufacturing. The lug plate structure comprises a box structure and a lug plate assembly, wherein the box structure comprises a top plate 10 with a bent end, and a bent rear bent plate 8, the bent end of the top plate 10 is connected with the rear bent plate 8, the lug plate assembly comprises two upper lug plates 5 arranged on the top plate 10 of the box structure, one end of each upper lug plate 5 is connected with the top plate 10 and is adjacent to the bent end of the top plate 10, and the tangential direction of the other end of each upper lug plate 5 is the same as that of the bent end of the top plate 10. According to the technical scheme, the lug plate structure with a colinear design is adopted, and the tangential direction of each lug plate is the same as that of the top plate, so the overall stress is homogenized, the stress on the bent plate and a butt welding seam is reduced, and the service life is prolonged.

Owner:SHANGHAI SANY HEAVY IND

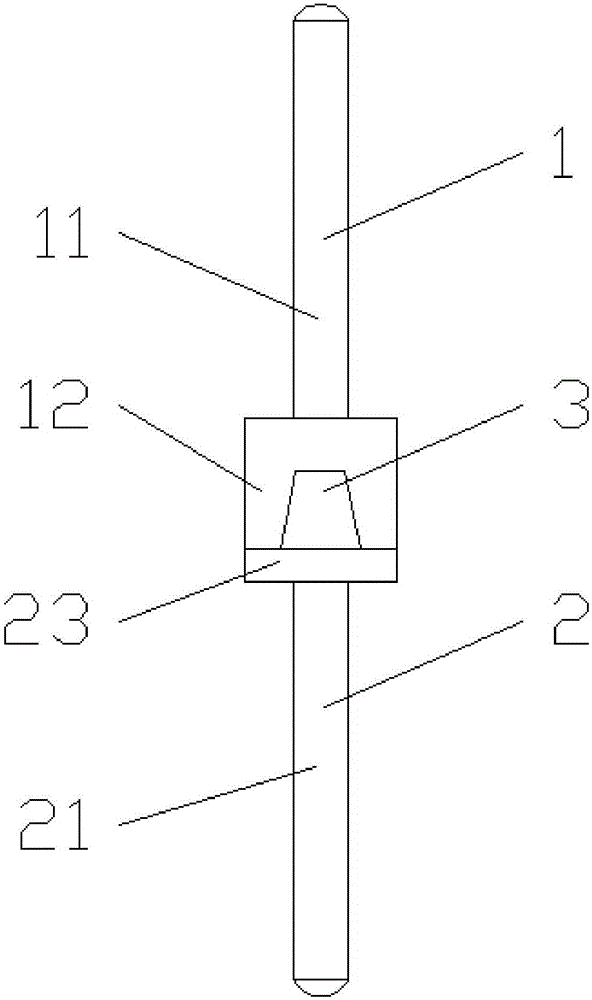

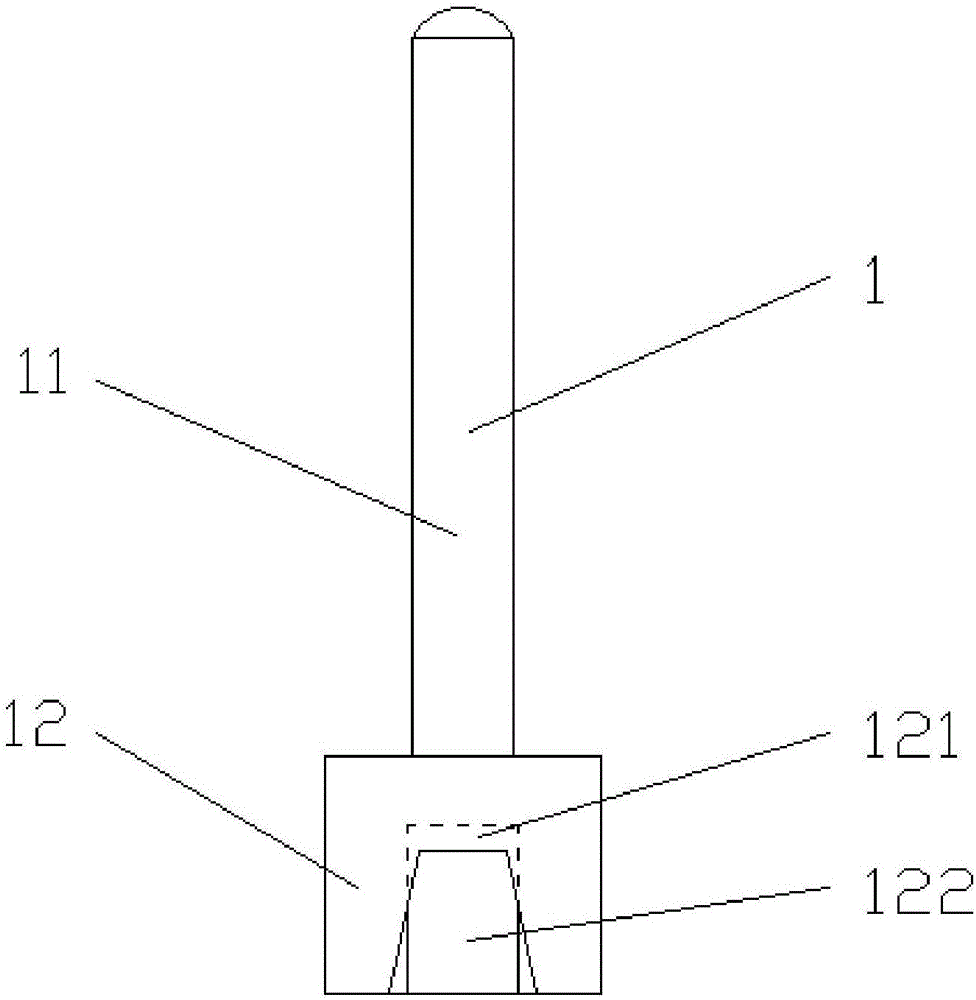

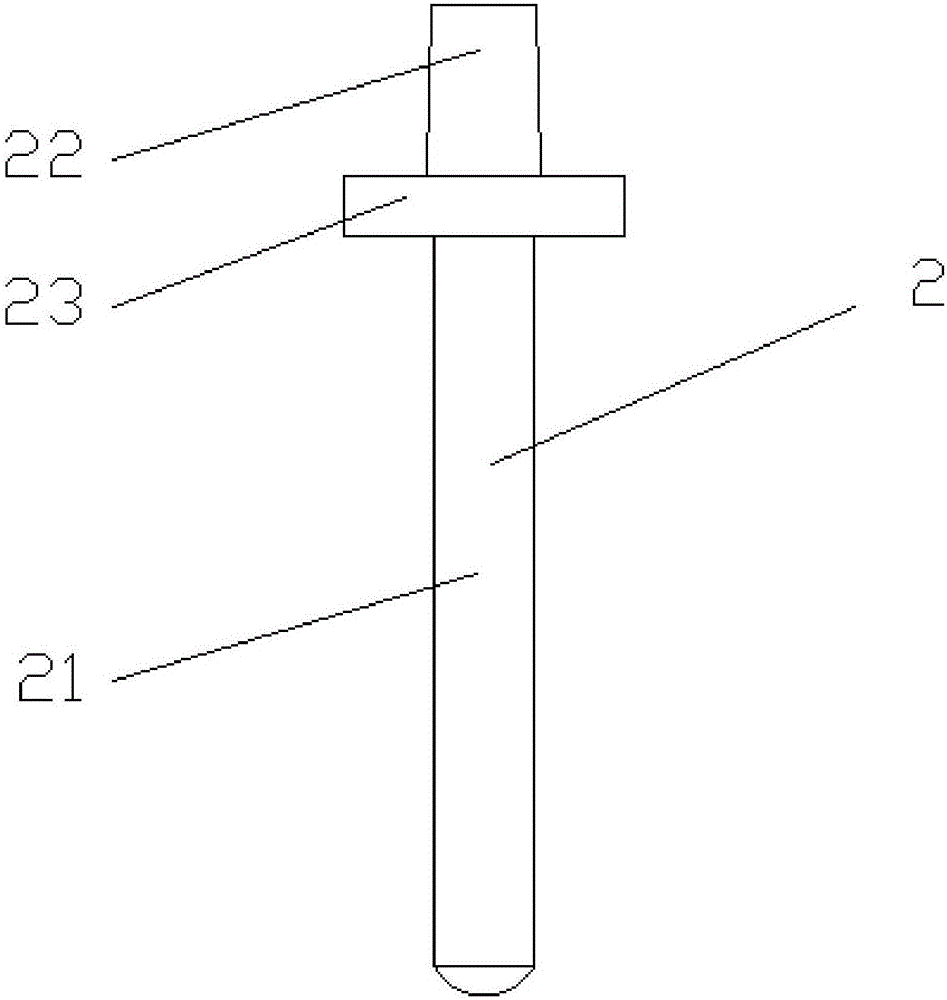

Sleeve type osteotomy segment diaphysis prosthesis

The invention discloses a sleeve type osteotomy segment diaphysis prosthesis, and belongs to the field of medical equipment. The sleeve type osteotomy segment diaohysis prosthesis comprises a first prosthesis, a second prosthesis and a patch. The first prosthesis comprises an intramedullary stalk a and a connecting block. The lower end of the intramedullary stalk a is fixedly connected with the upper end of the connecting block, the lower end of the connecting block is provided with a blind hole, and the diameter of the connecting block is greater than the diameter of the intramedullary stalk a. The second prosthesis comprises an intramedullary stalk b and a plug matched with the blind hole, the upper end of the intramedullary stalk b is fixedly connected with the lower end of the plug, the side wall of the connecting block is provided with a gap matched with the patch, the gap is communicated with the lower end of the connecting block and the blind hole, the patch is a trapezoid, and the area of the back face of the trapezoid is greater than the area of the front face. By the adoption of the connecting block, no thread fixation is needed, and the service life is prolonged; the design of the gap and the patch can reduce a pull-apart distance between two diaphysis, the difficulty of operation is reduced, and at the same time, the fixation strength is increased.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

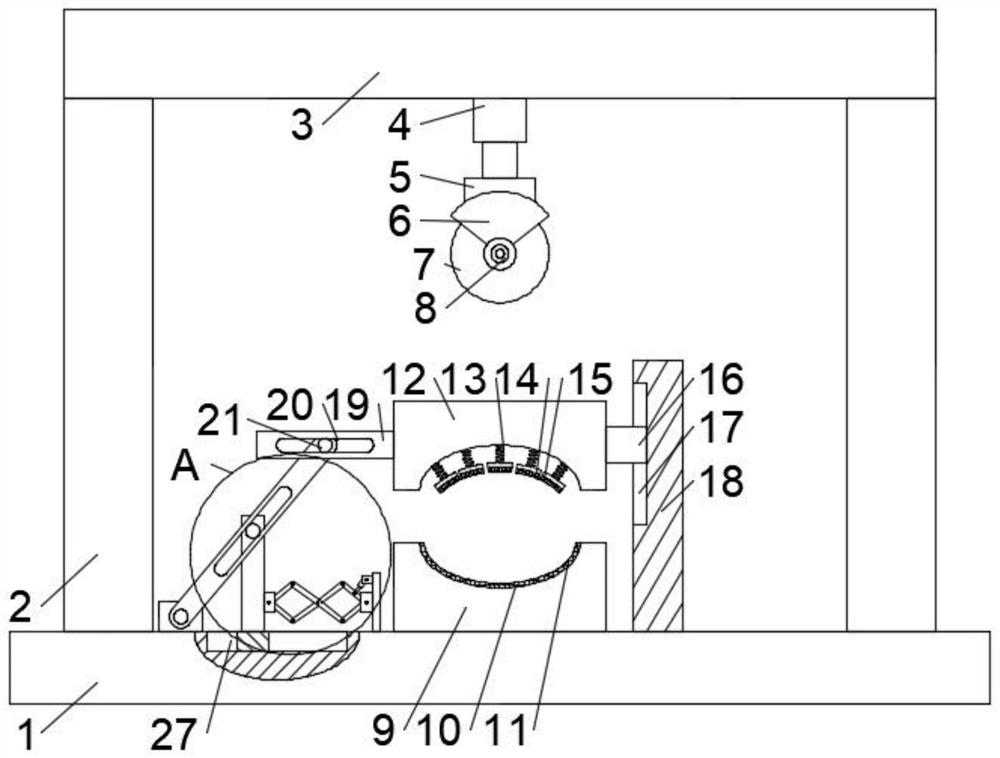

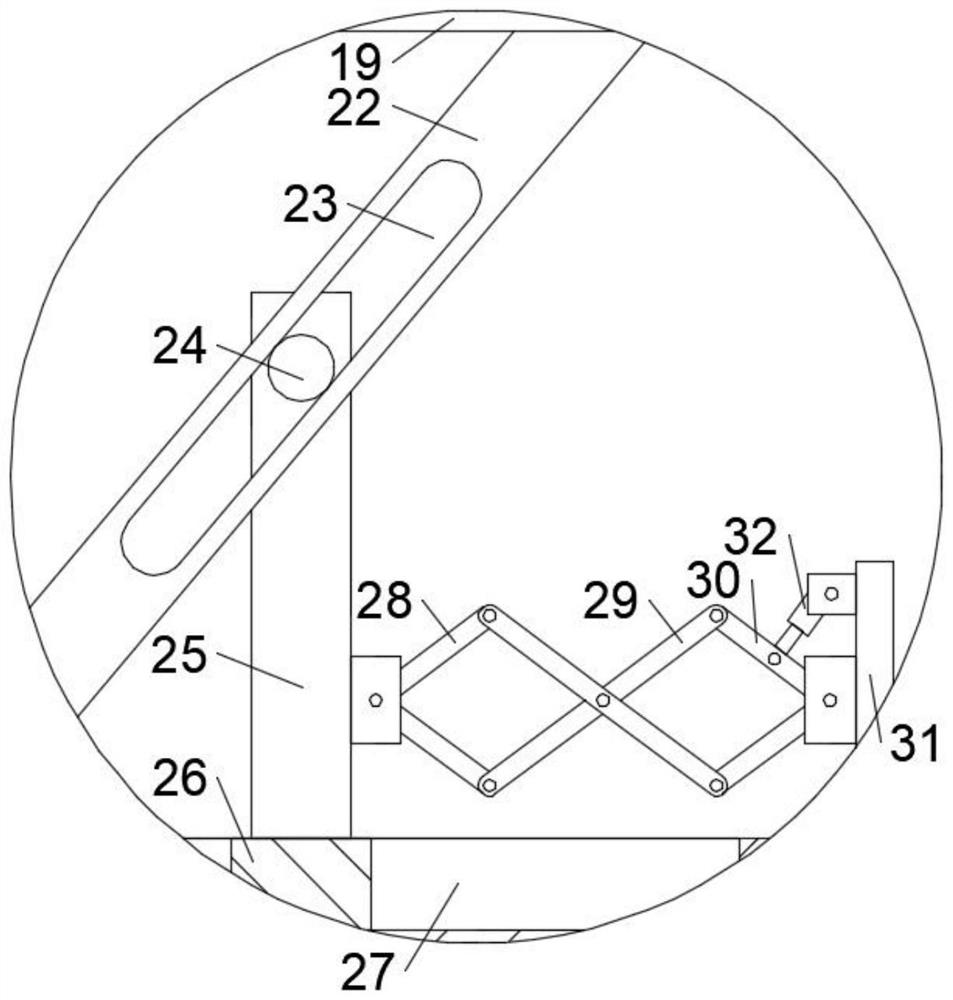

Processing device for shearing welded steel pipe

InactiveCN112548198AImprove clamping effectReduce shockTube shearing machinesShearing machine accessoriesSteel tubeManufacturing engineering

The invention relates to the technical field of steel pipe processing equipment, in particular to a processing device for shearing welded steel pipes. The processing device comprises a base, upright posts are symmetrically and fixedly connected to the surface of the base, a cross beam is fixedly connected to the end parts of the upright posts, and an air cylinder is fixedly connected to the bottomsurface of the cross beam and is connected with a connecting piece; and the connecting piece is fixedly connected with a protective cover, and the protective cover is rotatably connected with a knifeflywheel. The processing device solves the problems that according to an existing shearing machining device for welded steel pipes, the clamping effect is not ideal, a clamp is prone to breakage, theproduction efficiency of companies is seriously affected, and the production cost is greatly improved, and the processing device is reasonable in structural design, and convenient to use, improves the clamping effect, reduces impact on the clamp, eliminates stress concentration points of the device, avoids clamp breakage, improves the working efficiency, reduces the production cost and improves the economic benefits of enterprises when used for shearing the welded steel pipes.

Owner:东台嘉琳铧不锈钢有限公司

Die-pressing cap making machine and cap making die thereof

PendingCN112339197ARealize mutual heat exchange functionUniform water flowDomestic articlesCooling effectProcess engineering

The invention provides a die-pressing cap making machine and a cap making die thereof. The cap making die comprises an upper die and a lower die, the upper die is provided with a first water conveyingassembly and a second water conveying assembly at the axis of a cylindrical pipe sleeve, the first water conveying assembly comprises a spiral water conveying core and an upper die waterproof sleevearranged on the outer side of the spiral water conveying core in a sleeving mode, the spiral water conveying core is connected with an inner sleeve to form a first liquid inlet flow channel, the upperdie waterproof sleeve is communicated with an outer sleeve to form a first liquid return flow channel, the second water conveying assembly comprises a threaded core arranged outside the upper die waterproof sleeve in a sleeving mode, and a serpentine coiled core cooling flow channel is formed in the lower end in the wall body of a threaded core column core. The service life of parts in the die isprolonged, the speed is increased, the cooling effect are improved, and then the production efficiency is improved. The die-pressing cap making machine adopts the cap making die, so that the failurerate caused by the cap making die in the machine operation production process is effectively reduced, and meanwhile, the bottle cap production efficiency and quality of the whole die-pressing cap making machine are improved.

Owner:GUANGZHOU JEEPINE INTELLIGENT COMPRESSION MOLDING MACHINE CO LTD

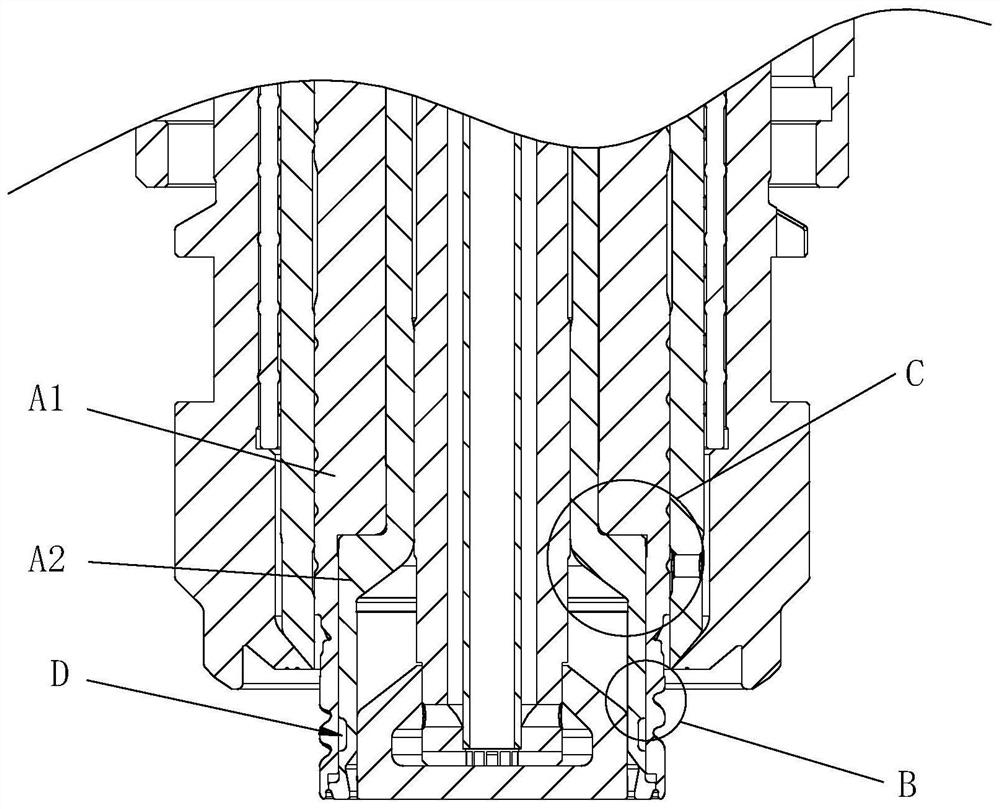

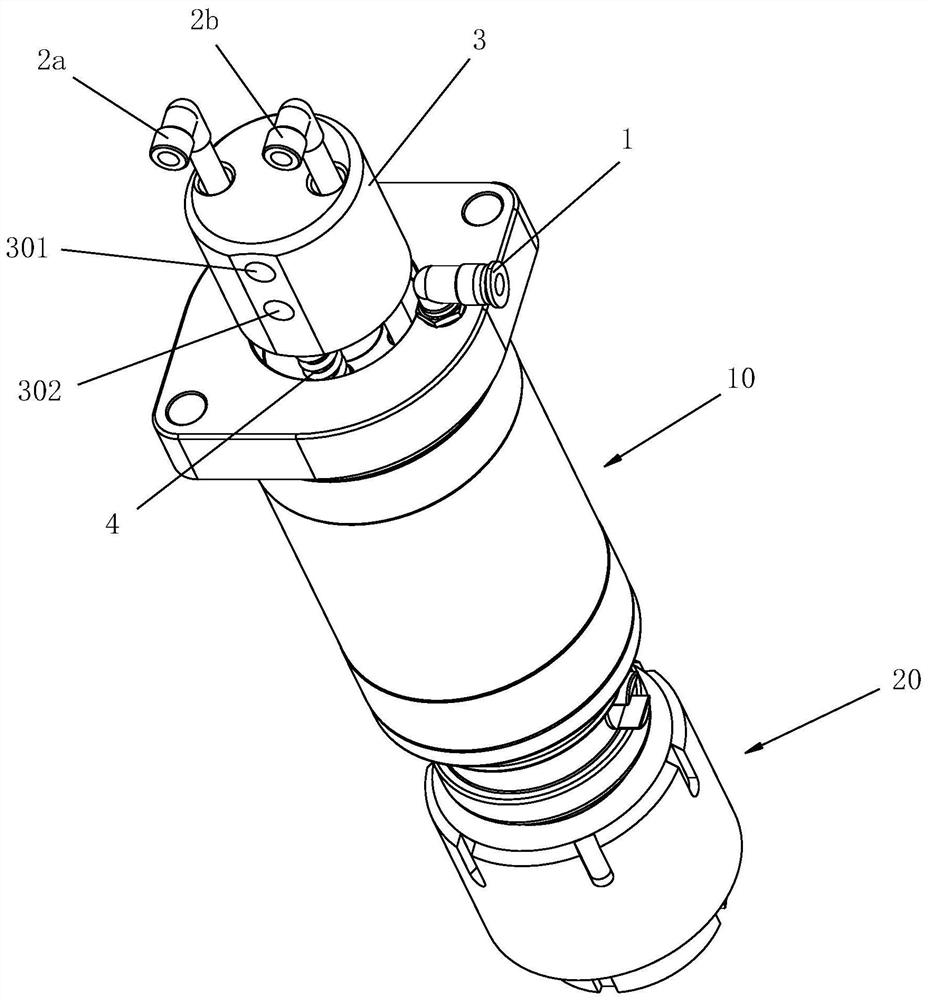

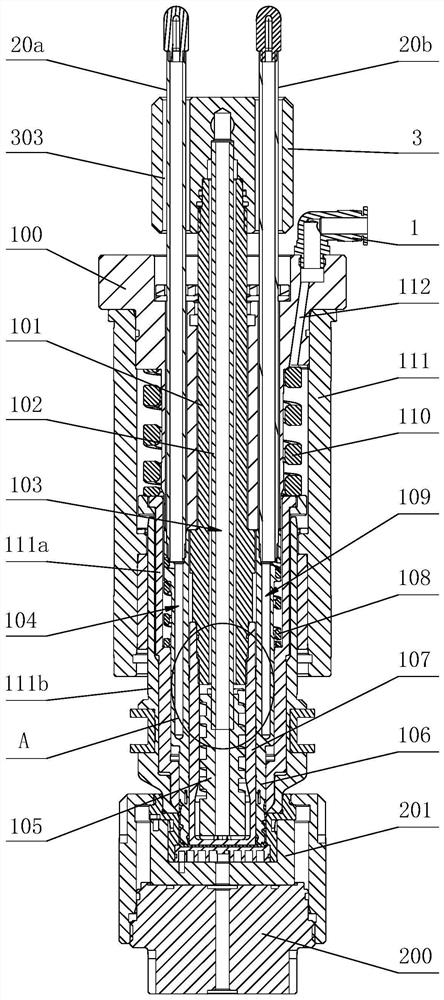

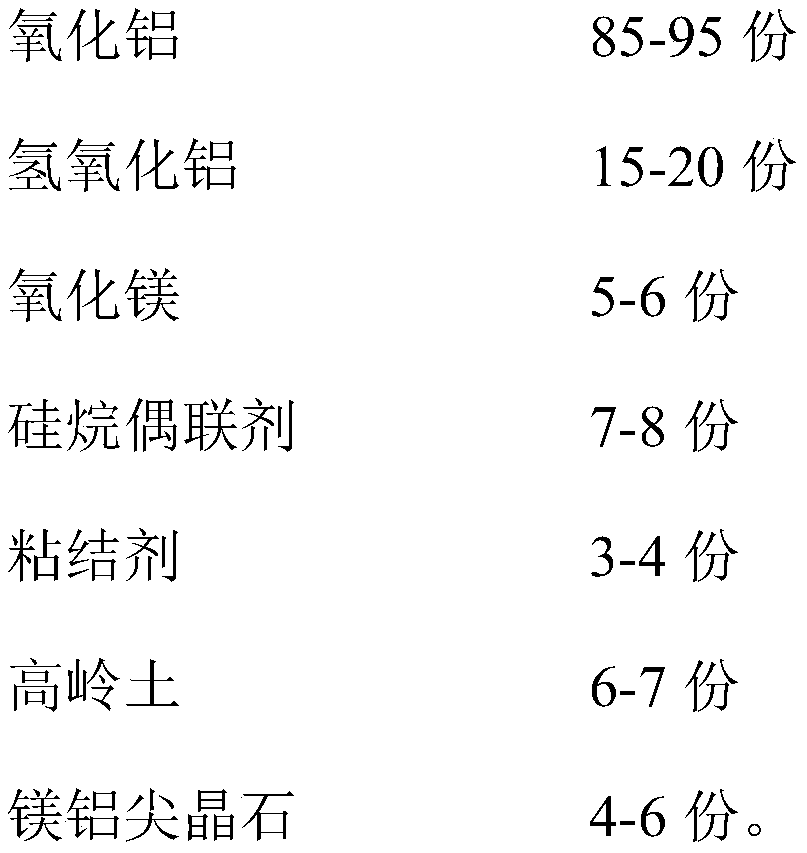

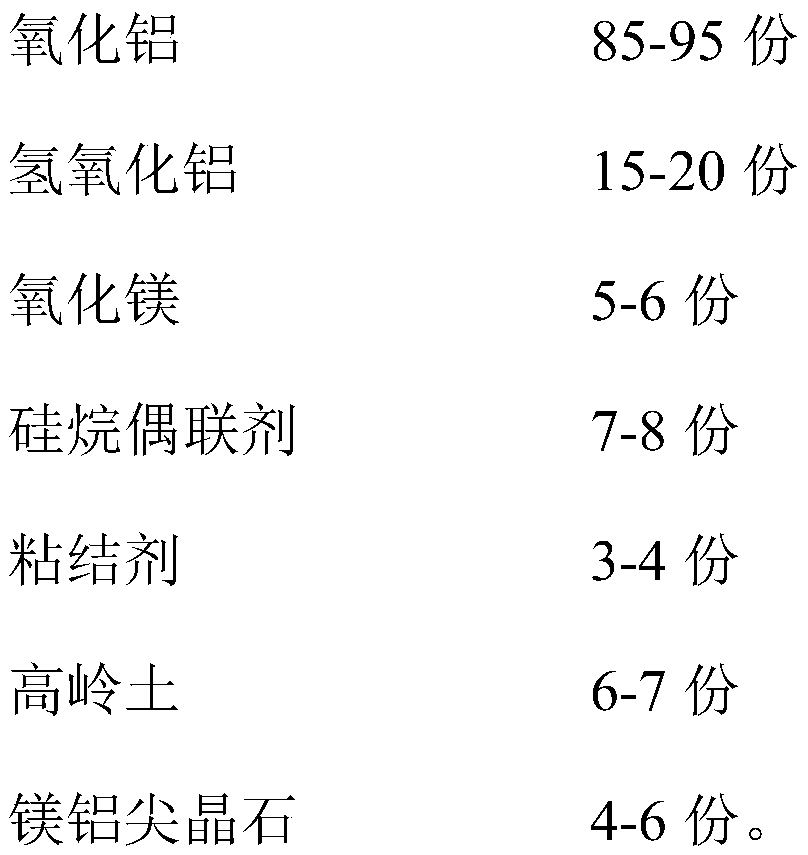

A kind of alumina ceramic and preparation method thereof

The invention discloses alumina ceramic and a preparation method thereof; in one aspect of the alumina ceramic, the surface of inorganic powder is coated with a binder through silane coupling agent, mobility and uniformity of the inorganic powder are enhanced, and the binder may break down and disperse from inside with the formation of zero or few holes and cracks during degumming; in second aspect, aluminum hydroxide, silane coupling agent and binder may break down and produce alumina and silica to fill possibly produced holes and cracks, and product compactness is enhanced; in third aspect, binding force between alumina and magnesia may increase under the induction of magnesium aluminate spinel; under the joint action of the three aspects, the alumina ceramic has increased hardness and strength. The growth of alumina grains is jointly inhibited under the cooperation of the magnesium aluminate spinel and magnesia at the premise of improving the hardness and strength of the alumina ceramic, inter-grain gaps are eliminated, the defects are lessened, stress concentration points are decreased, and the ductility of the alumina ceramic is improved.

Owner:JINGDEZHEN CERAMIC UNIV

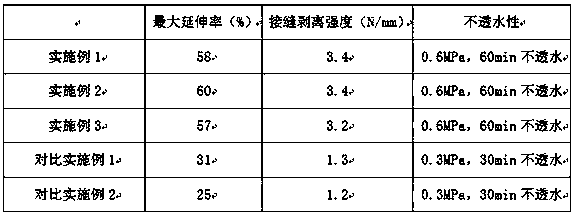

Waterproof coil material with high elongation, and preparation method thereof

The invention discloses a waterproof coil material with high elongation, and a preparation method thereof. According to the present invention, the prepared waterproof coil material has high elongationand high seam peeling strength, can be used in construction environments with high requirements, and further has high water impermeability and significant water resistance; by modifying nanometer magnesium oxide and nanometer titanium dioxide with peach gum powder and Shellac, the compatibility of the nanometer inorganic filler and the substrate is enhanced, the uniform dispersion is easily achieved, the stress concentration points are reduced, and the elongation and the seam peeling strength of the target material are improved; and by re-modifying the nanometer inorganic filler with the titanate coupling agent and the polyurethane emulsion, the dispersibility and the compatibility of the filler are further enhanced while the water resistance of the inorganic filler is enhanced so as to improve the waterproof performance of the target material.

Owner:马鞍山市永固防水科技有限公司

High-strength and high-whiteness ceramic product and processing technology thereof

ActiveCN114477951AGood dispersionImprove bindingGlass shaping apparatusCeramic materials productionKaolin clayUltimate tensile strength

The invention relates to a high-strength and high-whiteness ceramic product and a processing technology thereof. The high-strength and high-whiteness ceramic product comprises the following components in parts by weight: 20-30 parts of tempered glass, 30-40 parts of a nano precursor, 5-8 parts of quartz, 6-8 parts of magnesium oxide, 10-12 parts of a binder, 10-15 parts of bentonite and 18-20 parts of kaolin. The processing technology of the high-strength and high-whiteness ceramic product comprises the following steps: S1, stirring and mixing tempered glass, quartz, magnesium oxide, bentonite and kaolin, carrying out ball milling, and sieving with a 200-mesh sieve to obtain a mixture; s2, adding a binder and a nano precursor into the mixture obtained in the step S1, and continuously stirring to obtain a forming material; and S3, carrying out molding, degumming and sintering on the molded material obtained in the step S2 to obtain the high-strength and high-whiteness ceramic product. The prepared high-strength and high-whiteness ceramic product is high in whiteness, excellent in strength and good in mechanical property.

Owner:福建省德化新艺美陶瓷有限公司

A kind of transparent, high strength polyimide airgel and preparation method thereof

The invention provides transparent and high-strength polyimide aerogel and a preparation method thereof, which belongs to the technical field of nano porous materials and heat insulation and heat preservation. The preparation method comprises the following steps: dissolving aromatic triamine monomers and dianhydride monomers in a solvent to be reacted until a reaction system is completely transparent; adding a dewatering agent into the transparent system, stirring, defoaming, then standing, and forming gel; and performing the solvent replacement for the gel, and drying the gel, thus obtainingthe polyimide aerogel. The polyimide aerogel obtained by the invention has the characteristics of low density (the density is 0.08 g / cm<3> to 0.3 g / cm<3>), high specific surface area (the specific surface area is greater than 200 m<2> / g), high strength (the compression Young modulus is greater than 10MPa), low heat conductivity, high heat stability (the thermal degradation temperature is greater than 400 DEG C) and high transparency (the transmittance is greater than 50 percent), and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

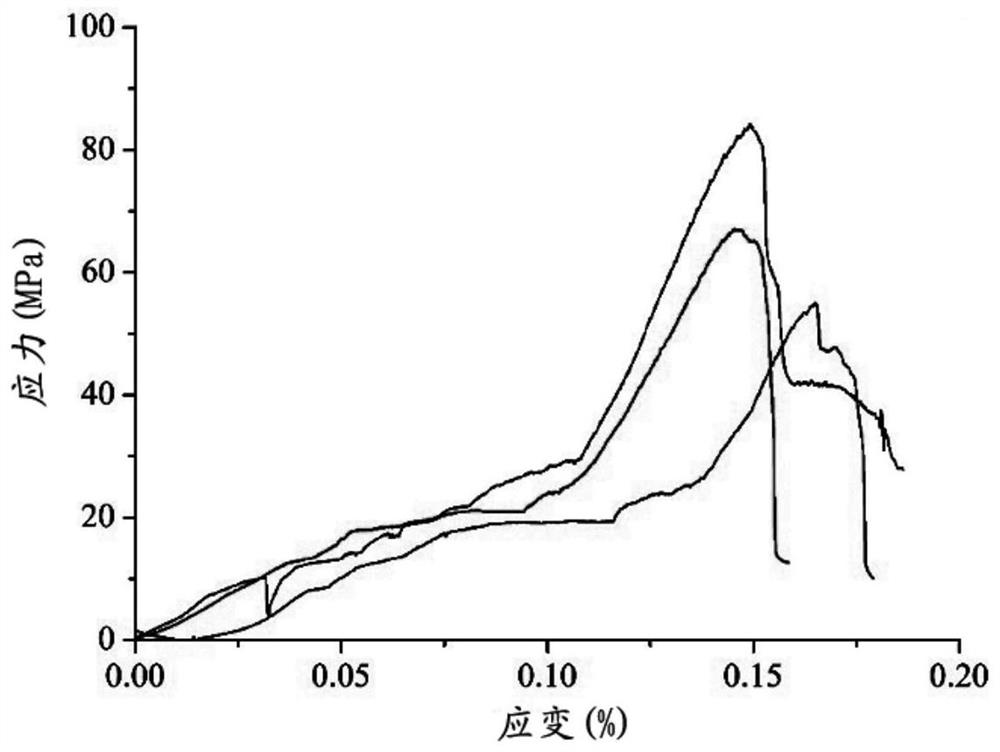

A kind of polymer structure composite material and preparation method thereof

The invention provides a polymer structure composite material and a preparation method thereof: the mass concentration of the filler in the polymer structure composite material in the polymer matrix is 0.1-20 ppm; the filler is graphene, silicon dioxide, carbon nanometer At least one of tubes, carbon black, aluminum oxide, zinc oxide, calcium carbonate, titanium dioxide, talc, and montmorillonite, and the polymer matrix is at least one of epoxy resins and unsaturated resins; the preparation method is as follows : First mix the filler with an appropriate amount of polymer matrix to form a master batch. When there is epoxy resin in the polymer matrix, a polymer medium needs to be added to reduce the viscosity of the polymer matrix; take an appropriate amount of masterbatch, press The mass concentration ratio of the filler in the polymer matrix The masterbatch is diluted into the polymer matrix and mixed evenly to obtain the polymer structure composite material. The polymer structure composite material of the invention has good monodispersity and high mechanical properties; the preparation method is simple and easy to operate, and is easy to be used for industrialized mass production.

Owner:厦门祥福兴科技股份有限公司

A Modified Zirconium Silicate Whisker Reinforced Alumina Ceramics

ActiveCN108752029BImprove densification performanceImprove wear resistanceSilicic acidPhysical chemistry

The invention discloses a modified zirconium silicate whisker-reinforced alumina ceramic, which relates to the technical field of new materials. The modified zirconium silicate whisker-reinforced alumina ceramic contains 6.40-6.46% of modified silicic acid by mass Zirconium whiskers and 3.20‑3.23% thiolated nanohybrid materials. The ceramic material prepared by the modified zirconium silicate whisker reinforced alumina ceramic not only has good bending strength, but also has good hardness.

Owner:淄博奥克非金属新材料科技有限公司

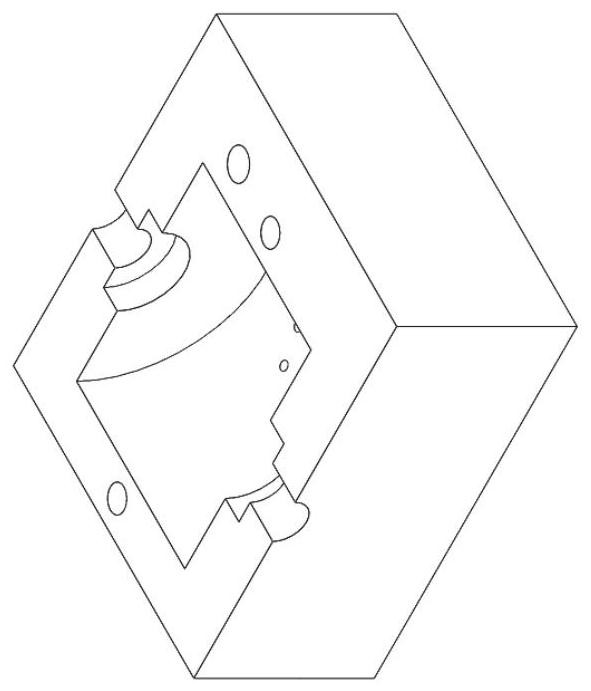

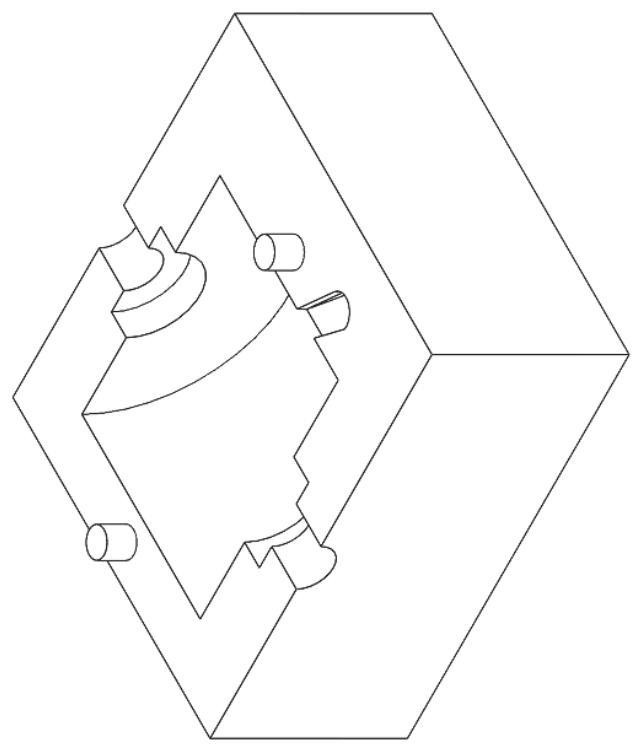

A core structure for sand casting, a manufacturing method, and a mold comprising the core

ActiveCN113458339BHigh strengthSmall amount of deformationAdditive manufacturing apparatusFoundry mouldsSand castingMechanical engineering

The invention discloses a core structure for sand casting, a manufacturing method and a mold including the core, which comprises a core body, the interior of the core body is hollow, and a support structure is arranged inside the core body. The structure is an array structure, and the array is formed by connecting a plurality of unit cells together. The sand volume and weight of the hollow core are smaller than those of the solid core. Under the same external structure and size, the experiment found that the weight of the hollow core is 3Kg lighter than that of the solid core, and the amount of sand used is about 83% of the previous one. The heat dissipation of the hollow sand mold is better than that of the solid core. Under the same casting conditions, the experiment found that the heating rate of the solid core is significantly higher than that of the hollow core supported by the unit body. Under the condition of the same solidification shrinkage force, the deformation of the hollow core supported by the proposed unit body is smaller than that of the hollow core of the same size truss structure.

Owner:SHANDONG UNIV

An ear plate structure with equal and collinear stress and construction machinery

InactiveCN103953084BSimple designEasy to implementMechanical machines/dredgersButt weldingEngineering

The invention discloses a lug plate structure with equal and colinear stress, and an engineering machine, belonging to the field of machine manufacturing. The lug plate structure comprises a box structure and a lug plate assembly, wherein the box structure comprises a top plate 10 with a bent end, and a bent rear bent plate 8, the bent end of the top plate 10 is connected with the rear bent plate 8, the lug plate assembly comprises two upper lug plates 5 arranged on the top plate 10 of the box structure, one end of each upper lug plate 5 is connected with the top plate 10 and is adjacent to the bent end of the top plate 10, and the tangential direction of the other end of each upper lug plate 5 is the same as that of the bent end of the top plate 10. According to the technical scheme, the lug plate structure with a colinear design is adopted, and the tangential direction of each lug plate is the same as that of the top plate, so the overall stress is homogenized, the stress on the bent plate and a butt welding seam is reduced, and the service life is prolonged.

Owner:SHANGHAI SANY HEAVY IND

Ptfe composite material and its preparation method

InactiveCN106867160BImprove mechanical propertiesImprove radial stiffnessFiberUltimate tensile strength

The invention relates to a PTFE composite material, and a preparation method thereof. The PTFE composite material is prepared from, by mass, 2 to 30% of continuous fiber, 30 to 98% of PTFE powder, and 0 to 50% of a filling material powder. According to the preparation method, the PTFE composite material is obtained via modification of polytetrafluoroethylene with a certain ratio of continuous fiber and the filling material powder, the continuous fiber is taken as a skeleton, internal stress concentration points are reduced, when the PTFE composite material is loaded with external load, the load is transferred onto the continuous fiber, the continuous fiber is used for load-bearing, the mechanical properties of the PTFE composite material are improved effectively, and the tensile strength is capable of reaching 272.4MPa. The PTFE composite material with a large size thin wall cylindrical body shape is provided with excellent mechanical properties, and annular reinforcing ribs are arranged on the cylindrical PTFE composite material so as to improve the radial stiffness of the PTFE composite material further.

Owner:NAT UNIV OF DEFENSE TECH

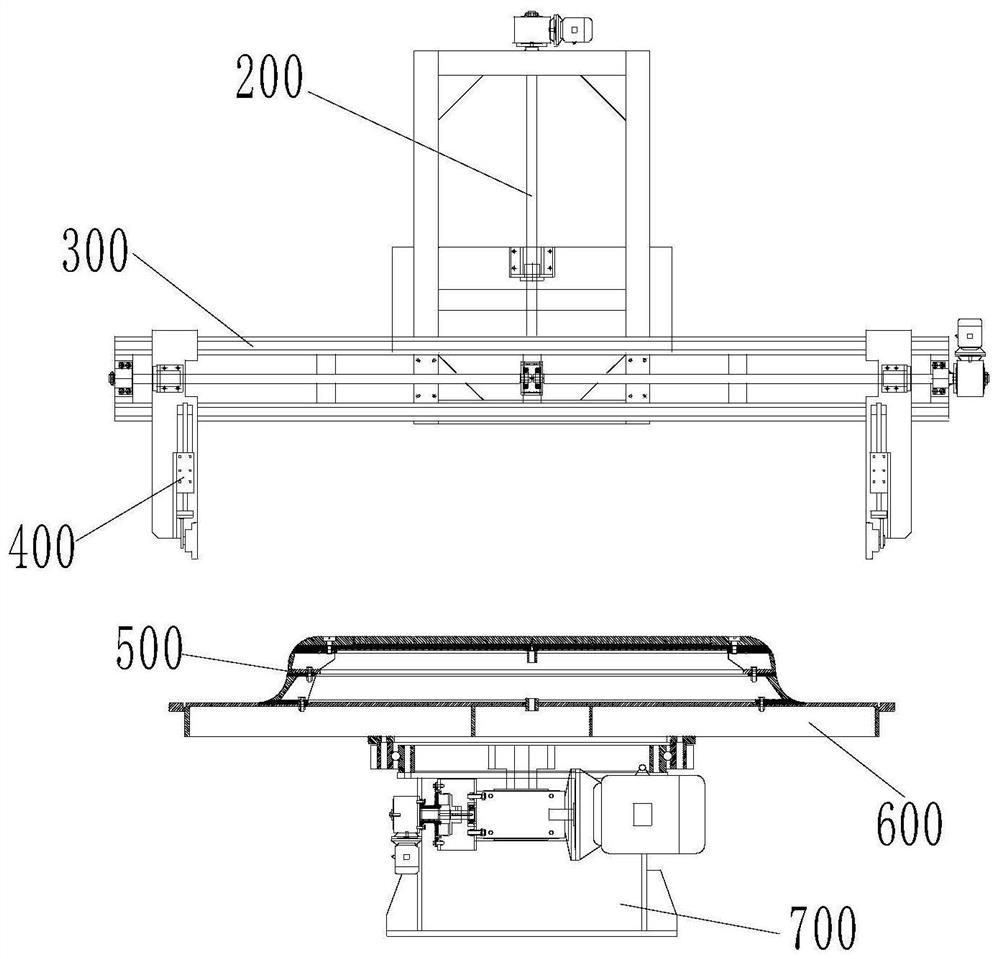

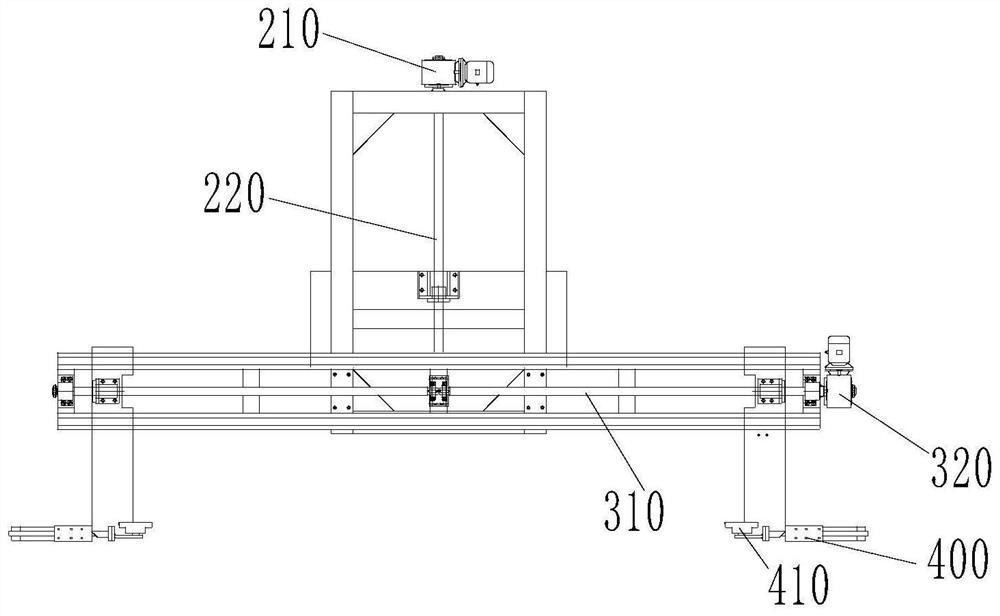

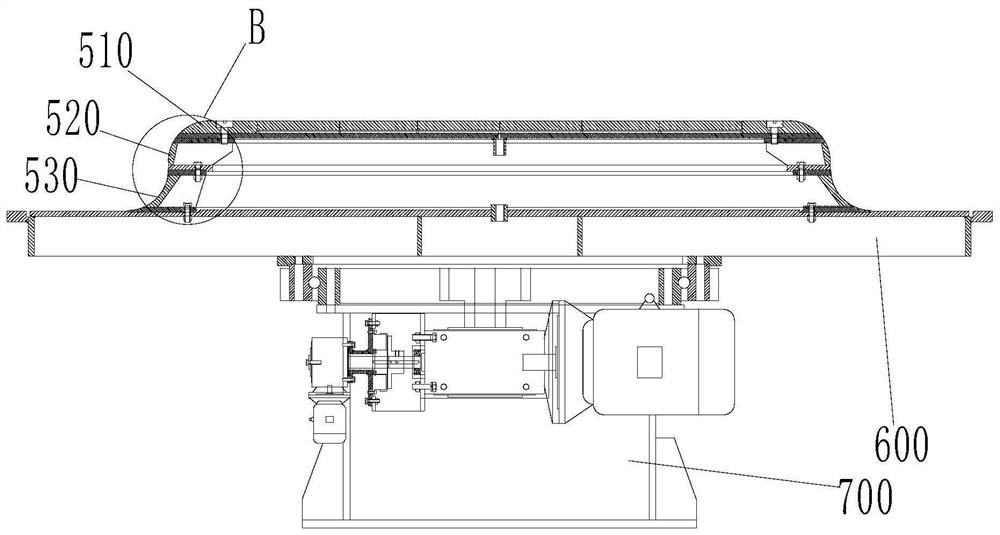

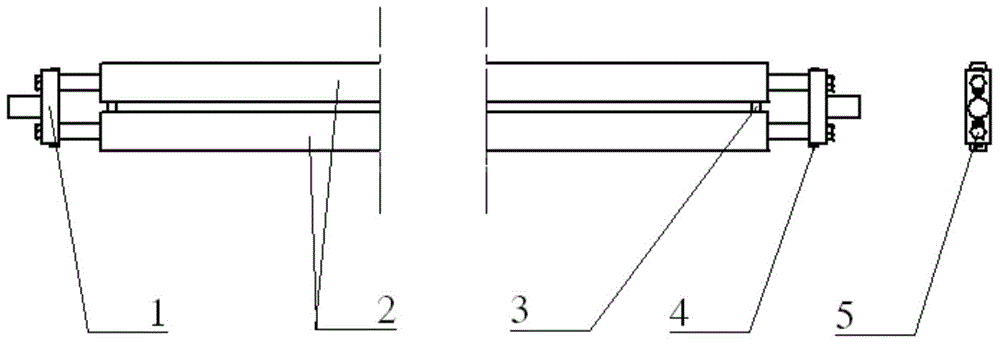

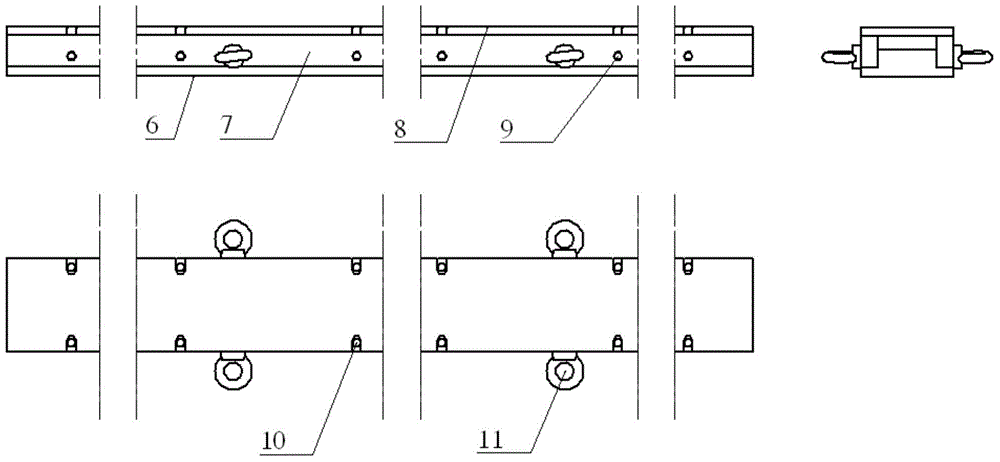

Self-adaptive base blank forming machine and method

PendingCN112123809AReduce stress concentration pointsNo starting point for damageMolding machineLap joint

The invention relates to the technical field of rubber product forming, in particular to a self-adaptive base blank forming machine and method. The self-adaptive base blank forming machine comprises amachine base, a die and a rack, wherein the machine base comprises a base body and a rotatable platform mounted on the base body, and the die is mounted on the rotatable platform, so that the die canrotate along with the rotatable platform; the rack comprises pressing rollers, and the pressing rollers are used for acting on a material layer laid on the die. The self-adaptive base blank forming machine and method are provided in order to solve the problem that a stress concentration point can be formed at a lap joint between two cord fabric layers in an arc-shaped area of a self-adaptive rubber base due to adoption of an existing self-adaptive rubber base forming process.

Owner:GUIZHOU TIRE

Pavement rubber asphalt joint glue and preparation method

ActiveCN112409981BReduce crosslink densityWeakened oil-absorbing swelling capacityNon-macromolecular adhesive additivesPlastic recyclingElastomerPolymer science

The invention relates to the technical field of rubber asphalt, and specifically discloses a road surface rubber asphalt joint glue and a preparation method, including 100 parts of asphalt, 25-40 parts of rubber composition, 1-3 parts of elastomeric polymer, 27-39 parts of softening oil, 1 to 4 parts of interface compatibilizer and 3 to 7 parts of rubber vulcanizing agent; the rubber composition includes 100 parts of rubber powder, 2 to 6 parts of rubber activator and 15 to 30 parts of rubber softener; the rubber powder, rubber activator After high-temperature kneading with softening agent and rubber softener, knead with softening oil, elastomer polymer, and rubber vulcanizing agent to obtain mixture A. After the asphalt is heated up, add mixture A and interfacial compatibilizer for stirring, and obtain rubber asphalt after cooling Joint potting glue, the high temperature and low temperature performance, cohesion and aging resistance of the joint potting glue obtained by this process have been greatly improved.

Owner:包头交通投资集团物资有限责任公司

A method for forming a rectangular reinforced pipe fitting made of carbon fiber composite material

Owner:BEIJING SATELLITE MFG FACTORY

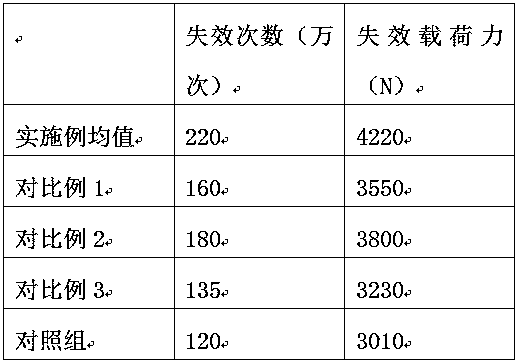

Fatigue resistant rubber additive

The invention discloses a fatigue resistant rubber additive and relates to the technical field of rubber materials. The fatigue resistant rubber additive is obtained with a mixture of polycyclic aminemodified nano-crystalline cellulose and graphene, wherein the nano-crystalline cellulose and the graphene are mixed according to the mass ratio of 10 to (1.3-1.5). The fatigue resistant rubber additive provided by the invention is applied to the rubber materials to be capable of remarkably improving the fatigue resistance of the rubber materials.

Owner:合肥旭亚新材料科技有限公司

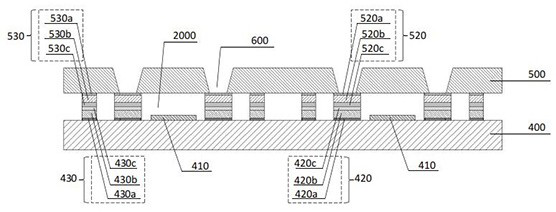

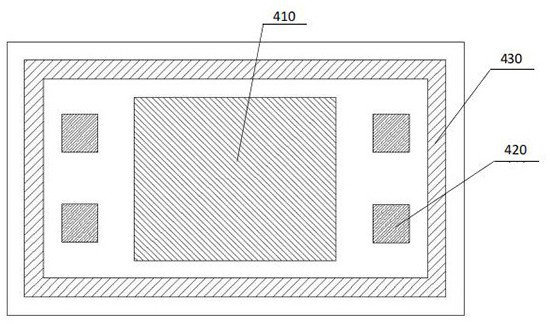

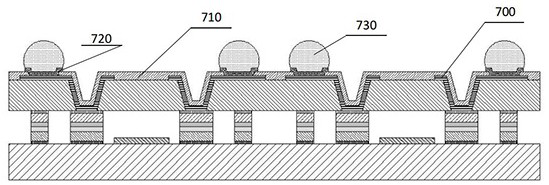

A filter chip wafer-level packaging structure and packaging process

ActiveCN114157260BReduce process linksReduce thicknessImpedence networksSemiconductor/solid-state device detailsWaferMaterials science

The invention provides a filter chip wafer-level packaging structure and packaging technology. The filter chip wafer-level packaging structure includes a filter chip wafer and a silicon lid wafer; both the filter chip wafer and the silicon lid wafer are provided with a multi-layer metal superimposed metal bonding layer; the The filter chip wafer and the silicon cap wafer are bonded and connected through the multi-layer metal stacked metal bonding layer to form a filter cavity. Wherein, the thickness of the filter cavity is not less than 2 μm. The encapsulation structure and encapsulation process can effectively reduce the process cost and improve the mechanical strength of the silicon cap wafer.

Owner:深圳新声半导体有限公司

A kind of mesophase pitch-based graphite fiber/polypropylene composite material and preparation method thereof

ActiveCN107090129BCompatibleImprove thermal conductivityHeat-exchange elementsPolypropylene compositesBoron nitride

The invention discloses a mesophase pitch-based graphite fiber / polypropylene composite material and a preparation method thereof. The mesophase pitch-based graphite fiber / polypropylene composite material is prepared from the following components in parts by weight: 55-75 parts of polypropylene, 2-6 parts of mesophase pitch-based graphite fiber, 5-10 parts of boron nitride, 0.5 part of a coupling agent, 4 parts of maleic anhydride-grafted polypropylene, 5-7 parts of a compatilizer, 5-8 parts of nano-magnesium hydroxide, 2-6 parts of a flexibilizer and 2 parts of other assistants. Polypropylene is modified through selecting the mesophase pitch-based graphite fiber and compounded with the related flexibilizer, coupling agent, compatilizer, fire retardant and lubricant, and the mesophase pitch-based graphite fiber / polypropylene composite material is prepared through a blending mode, so that the heat-conducting property and the flame retardant property are very excellent, a heat-conducting filler and matrix resin are good in compatibility and good in mechanical properties, and furthermore, the machining process is relatively simple.

Owner:QINGDAO UNIV OF SCI & TECH

High impact-resistance anti-smoldering polystyrene resin composite and preparation method thereof

ActiveCN101864137BImprove flame retardant performanceNo smoldering phenomenonPolymer sciencePolymer chemistry

The invention relates to the field of the modified polystyrene, and provides a high impact-resistance anti-smoldering polystyrene resin composite and a preparation method thereof. The composite comprises the following components: 70 to 85 parts of polystyrene, 8 to 15 parts of fire retardant, 3 to 4.5 parts of auxiliary fire retardant, 0.2 to 1.5 parts of stabilizer, 0.2 to 1.0 part of lubricant,0 to 0.5 part of dispersion oil and 0.2 percent of other assist agents. The high impact-resistance anti-smoldering polystyrene resin composite is prepared by selecting the high impact-resistance polystyrene, fire retardant and other assist agents and by improving the compatibility of the fire retardant and the basal material high impact-resistance polystyrene (HIPS). The composite has high fire retardance, no smoldering and good impact resistance, and is particularly suitable for producing the products requiring high retardance such as electronic elements, parts, shell materials of electronicdevice, and the like.

Owner:SUZHOU SILVER AGE TECH CO LTD

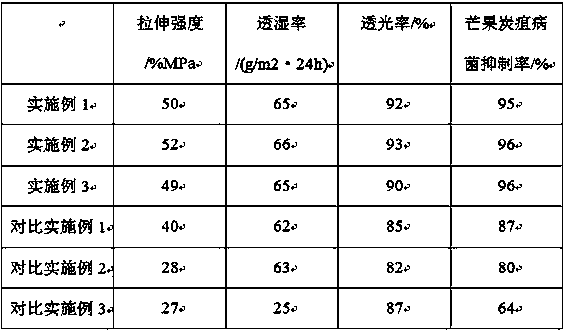

Fresh-keeping film containing aerogel and preparation method thereof

InactiveCN109111668AHigh tensile strengthImprove mechanical propertiesStress concentrationDispersity

The invention discloses a fresh-keeping film containing aerogel and a preparation method thereof. The prepared fresh-keeping film has relatively high tensile strength and relatively good mechanical properties; meanwhile, the moisture permeability and the light transmittance are relatively high; the inhibition rate of colletotrichum gloeosporioides for causing a mango anthracnose disease reaches about 96 percent and the bacterium-inhibition effect is remarkable. According to the fresh-keeping film, nano-silver is treated by utilizing acetic acid, and the dispersity of the nano-silver in tetraethyl orthosilicate is improved, so that a stress concentration point is reduced and the mechanical properties of the fresh-keeping film are improved; one layer of the aerogel is formed on the surface of the nano-silver by utilizing tetraethyl orthosilicate, so that the moisture permeability of the fresh-keeping film is improved; an aerogel layer and the nano-silver have a cooperative effect to realize the effects of adsorbing and inhibiting the colletotrichum gloeosporioides, and the bacterium-inhibition rate is improved; neopentyl glycol is used for further treating silicon dioxide aerogel modified nano-silver and a crosslinking point can be formed by compound particles; the crosslinking point and a polyvinyl alcohol substrate can be subjected to crosslinking reaction to form a uniform crosslinking network, so that the mechanical properties of the fresh-keeping film are greatly improved.

Owner:BENGBU WEIGUANG PLASTIC PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com