A kind of transparent, high strength polyimide airgel and preparation method thereof

A polyimide and aerogel technology, applied in high-strength polyimide aerogel and its preparation, in the transparent field, can solve the problem of loss of thermal insulation performance, specific surface area, high porosity, and inability to achieve silica aerogelation. The transparency of the glue, the inability to replace the silica aerogel, etc., to achieve the effect of low thermal conductivity, reduction of stress concentration points, and uniform unloading of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

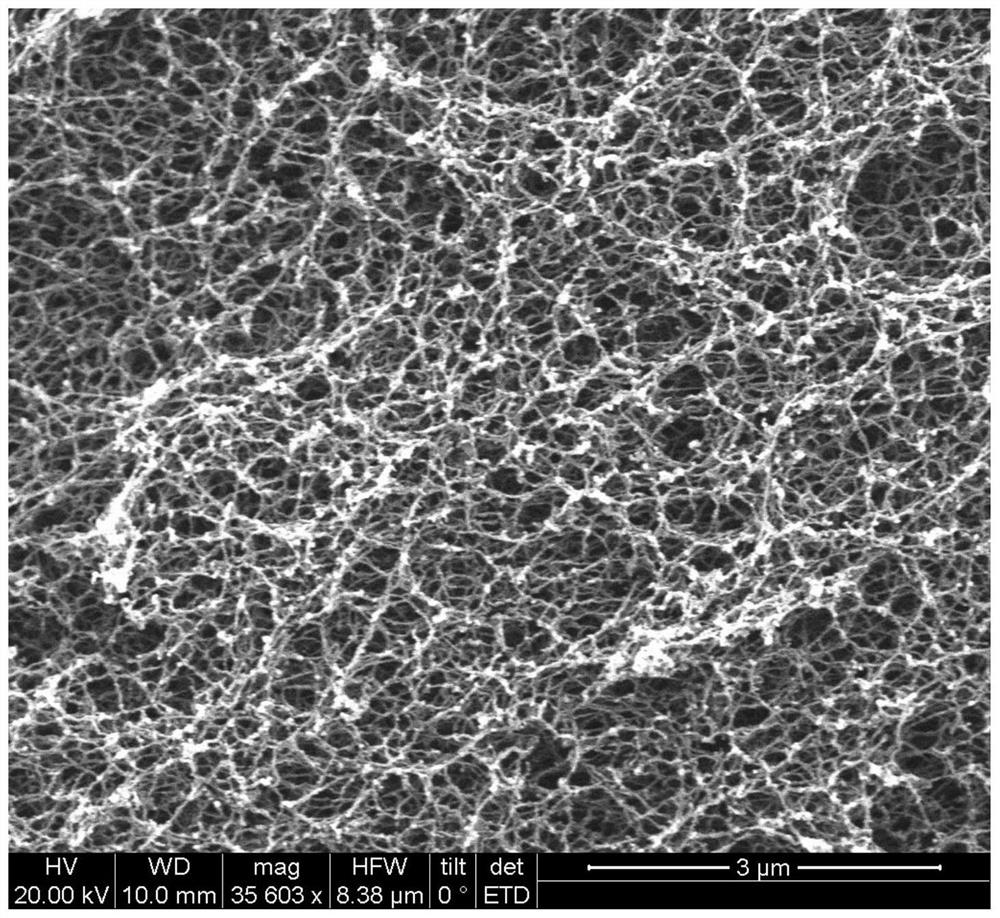

Image

Examples

preparation example Construction

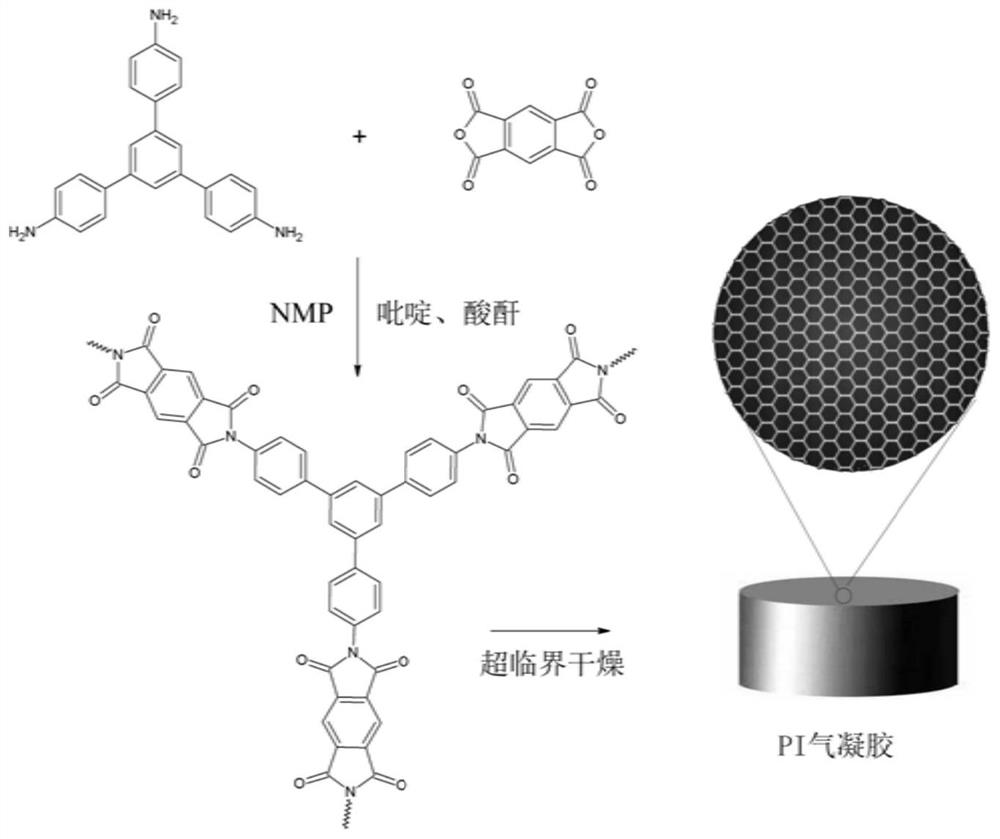

[0027] The embodiment of the present invention provides a method for preparing a transparent, high-strength polyimide airgel, comprising the following steps:

[0028] Step 1. Dissolving aromatic triamine monomers and dianhydride monomers in a solvent according to a certain amount of proportioning to carry out polycondensation reaction until the reaction system is completely transparent;

[0029] Specifically, in the embodiment of the present invention, it is preferable to carry out the reaction under stirring, and when the reaction is complete until the system is completely transparent, ensure that the system does not contain any solid impurities;

[0030] In the embodiment of the present invention, the solvent is N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAc), dimethylsulfoxide (DMSO) or N-methylpyrrolidone (NMP); the aromatic triamine monomer is preferably 4,4',4"-triaminotriphenylmethane (TAPM); the dianhydride monomer is preferably 3,3',4, At least one of 4'-be...

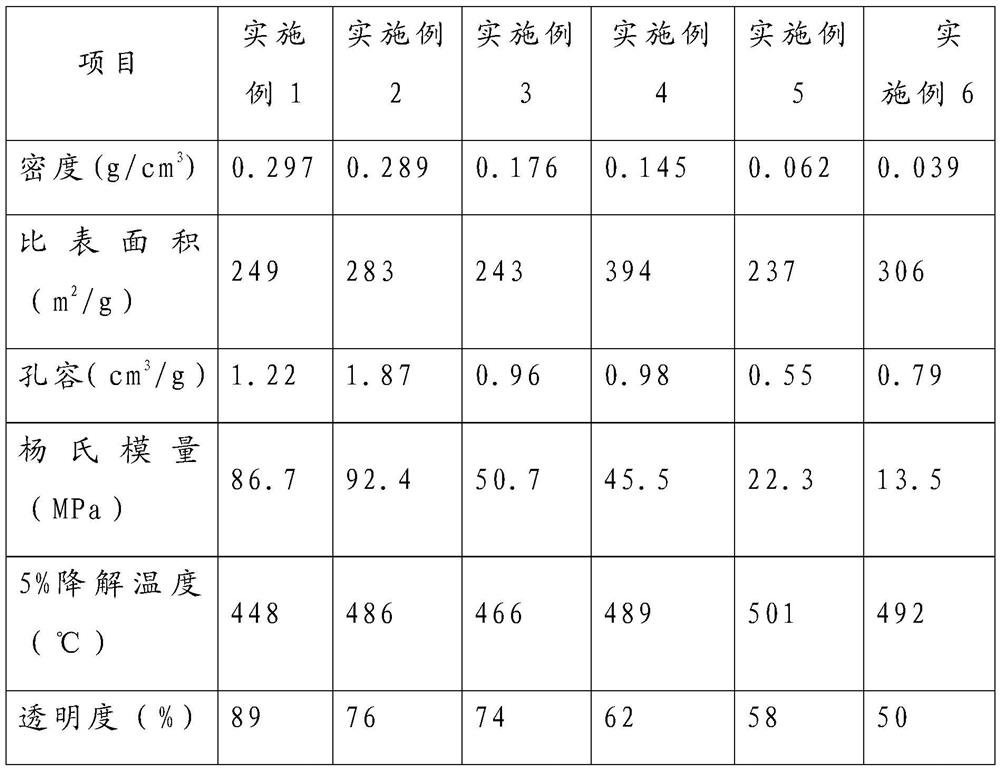

Embodiment 1

[0041] (1) Synthesis of polyimide wet gel:

[0042] Take 10mmol TAPM and fully dissolve it in 60ml of anhydrous DMF, then add 10.5mmol BTDA under stirring, and stir at 0°C until completely dissolved, the solution viscosity increases and polyamic acid is formed, and the reaction system is completely transparent at this time; then add 80mmol BTDA A mixture of acid anhydride and triethylamine (the mass ratio of acetic anhydride and triethylamine is 1:1), after rapid stirring for 10 minutes, ultrasonic defoaming for 30 minutes; finally, the resulting solution was left to stand at 0°C, and formed after about 5 hours gel.

[0043] (2) Solvent replacement of gel:

[0044] Place the formed gel in 5 times the volume of DMF, change the DMF every 12 hours, replace it twice, then use 5 times the volume of ethanol for solvent replacement, change the ethanol every 5 hours, and obtain polyimide after 2 days Amino Gel.

[0045] (3) Drying of wet gel:

[0046] The substituted alcohol gel w...

Embodiment 2

[0049] (1) Synthesis of polyimide wet gel:

[0050] Take 11mmol TAPM, fully dissolve in 100ml anhydrous DMSO, then add 11mmol PMDA under stirring, stir at 40°C until completely dissolved, the viscosity of the solution increases, and polyamic acid is formed, and the reaction system is completely transparent at this time; then add 80mmol acetic anhydride and triethylamine (the mass ratio of acetic anhydride and triethylamine is 1:1), after rapid stirring for 5 minutes, ultrasonic defoaming for 10 minutes; finally, the obtained solution was left standing at 40°C, and after about 5 hours, a gel was formed. glue.

[0051] (2) Solvent replacement of gel:

[0052] Place the formed gel in 2 times the volume of DMSO, change the DMSO every 12 hours, and replace it 3 times, then use 2 times the volume of methanol for solvent replacement, change the methanol every 5 hours, and obtain polyimide after 2 days Amino Gel.

[0053] (3) Drying of wet gel:

[0054] The substituted alcohol gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com