A method for forming a rectangular reinforced pipe fitting made of carbon fiber composite material

A composite material and molding method technology, which is applied in the field of forming carbon fiber composite material rectangular reinforced pipe fittings, can solve the problems of difficult control of forming pressure, poor inner cavity precision of products, and many internal defects of products, etc., and achieves easy operation of mold assembly and demoulding , The molding pressure is stable and controllable, and the product quality is highly reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

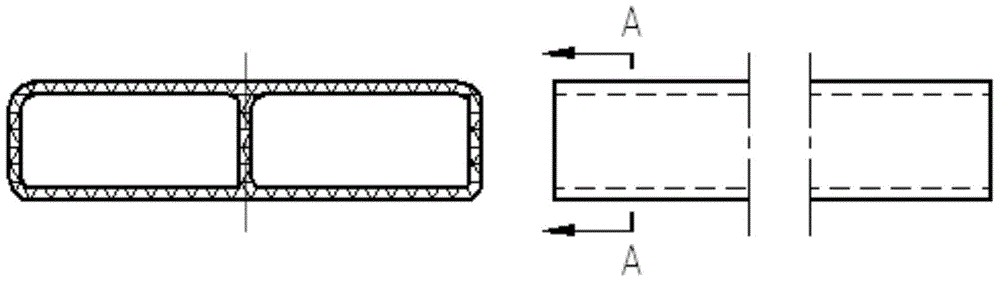

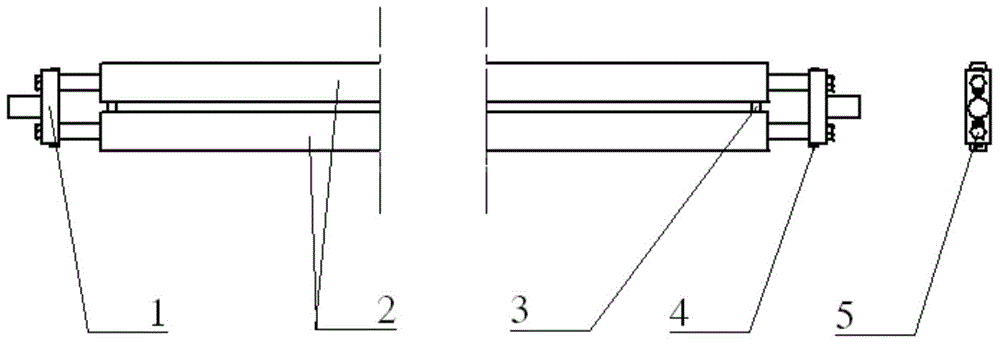

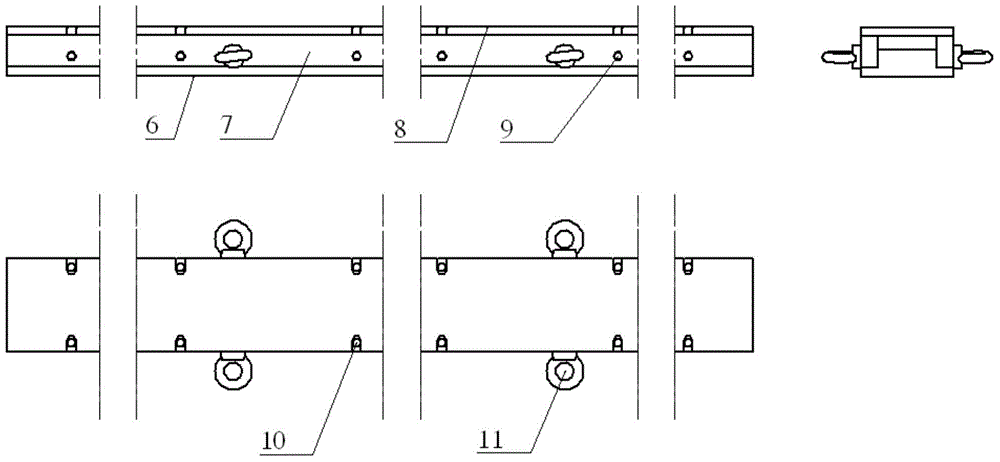

[0032] Such as figure 1 As shown, a method for forming a rectangular reinforced pipe of carbon fiber composite material. The cross section of the rectangular reinforced pipe to be formed is a "day"-shaped structure; a rib in the middle divides the inner cavity of the rectangular pipe into two rectangular hollows. Cavity, that is, the left cavity and the right cavity; the left cavity and the right cavity have the same shape; the left cavity and the right cavity both run through the length direction of the pipe fitting; the product wall thickness is 2mm, and carbon fiber reinforced ring is used Oxygen resin prepreg tow is wound symmetrically to be quasi-isotropic. The inner cavity of the product is rounded R3, and the shape is rounded R5; the product can be divided into two parts when winding, one part is called the inner tube, the wall thickness is 1mm, and the inner tube cavity is rectangular. The inner cavity of the reinforced pipe fittings, the quantity is 2 pieces. The oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com