Patents

Literature

59results about How to "High product quality and reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

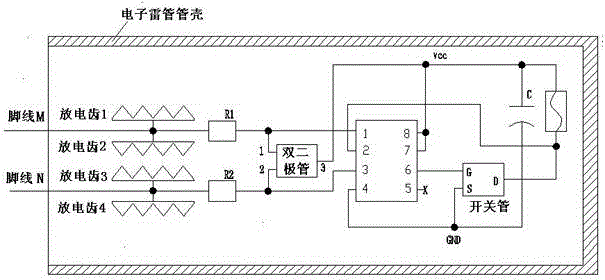

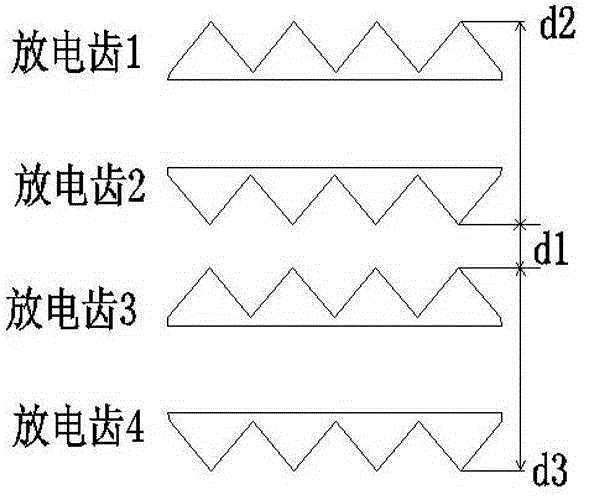

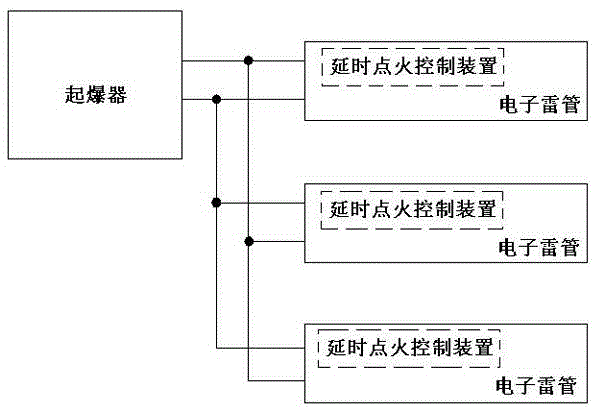

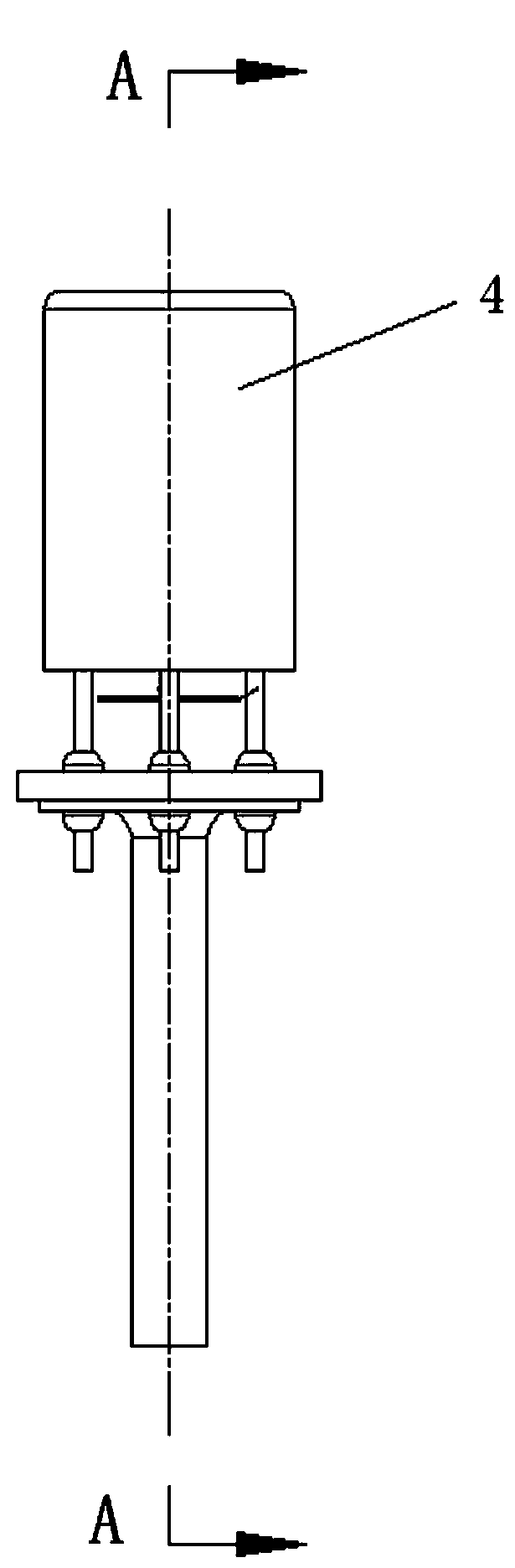

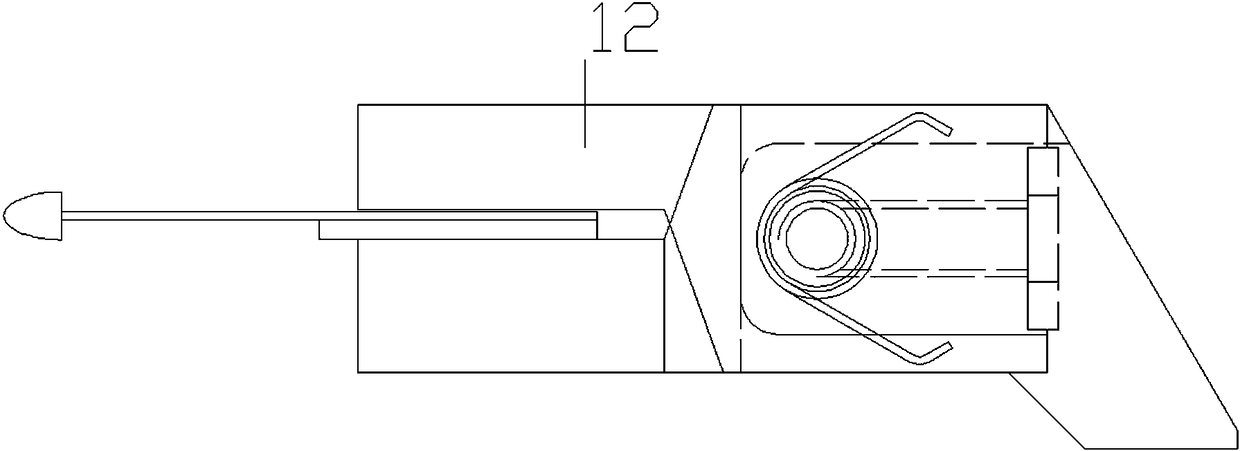

A delayed ignition control device and an electronic detonator

InactiveCN104154829AImprove structural strengthImprove reliabilityAmmunition fuzesCapacitanceDetonator

The invention relates to a delayed ignition device, especially a delayed ignition control device and an electronic detonator for timing initiation. For the problems of the prior art, a delayed ignition control device and an electronic detonator are provided; upon reaching the timing initiation time of the electronic detonator, an energy-storage capacitor can discharge electricity to a detonating fuse head by matching a processor and a switching tube; the component improves the use security of the electronic detonator; meanwhile, in order to prevent the electrostatic influence produced by putting the device into an electronic detonator, an electrostatic protection structure is formed on an electronic detonator cap wire bonding pad accessory in front of a current-limiting resistor. The device comprises a cap wire M and a cap wire N, and comprises an electrostatic protection device, an electronic delay module, an energy-storage device, and a detonating fuse head which are integrated on a printed board. The electrostatic protection device is configured to release static electricity input at any two of the cap wire M, the cap wire N and a detonator shell. The electrostatic protection structure is formed on the cap wire input end bonding pad. The electronic delay module is in both-way communication with an exploder via the cap wire M and the cap wire N.

Owner:WUXI SHENGJING ELECTRONICS TECH CO LTD

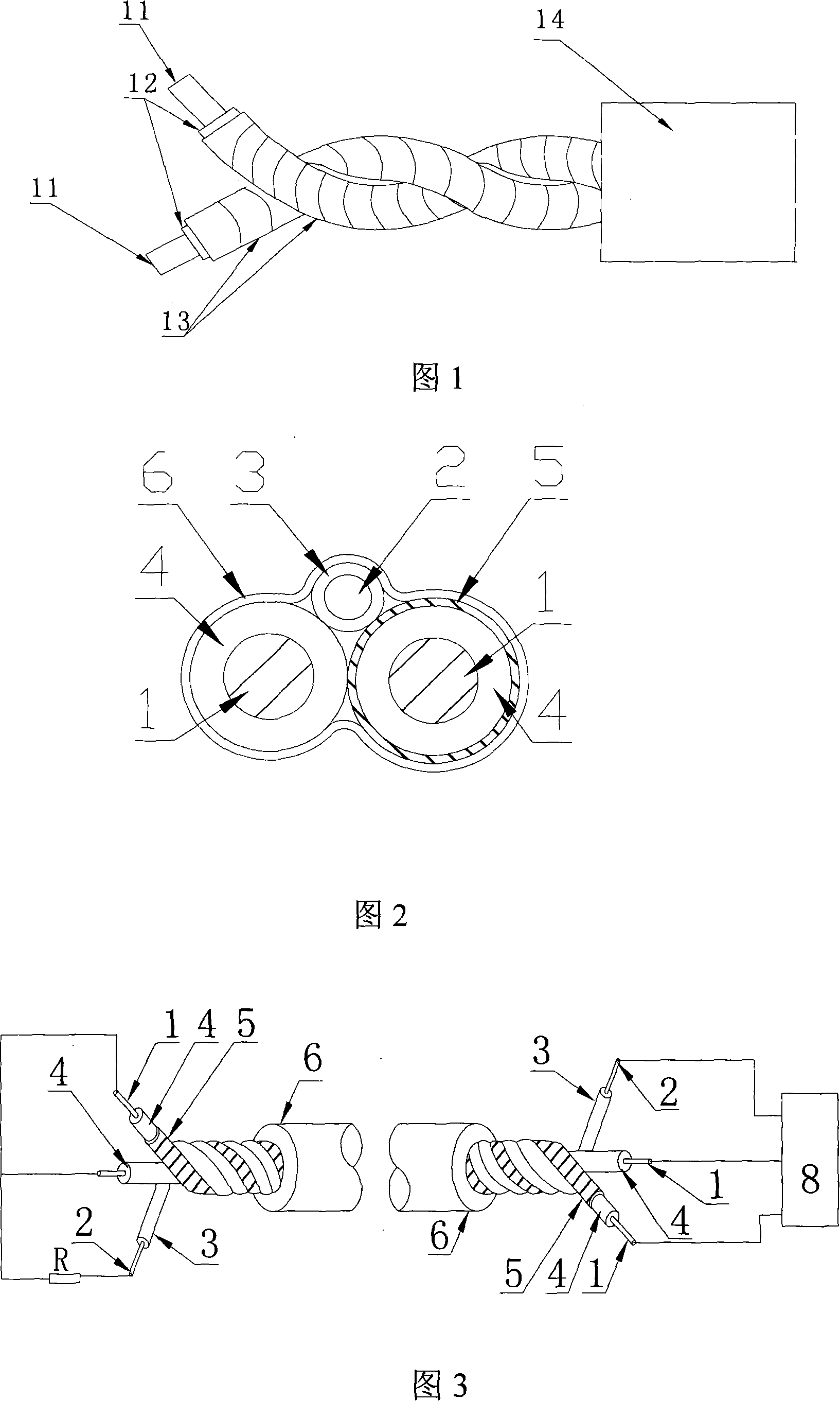

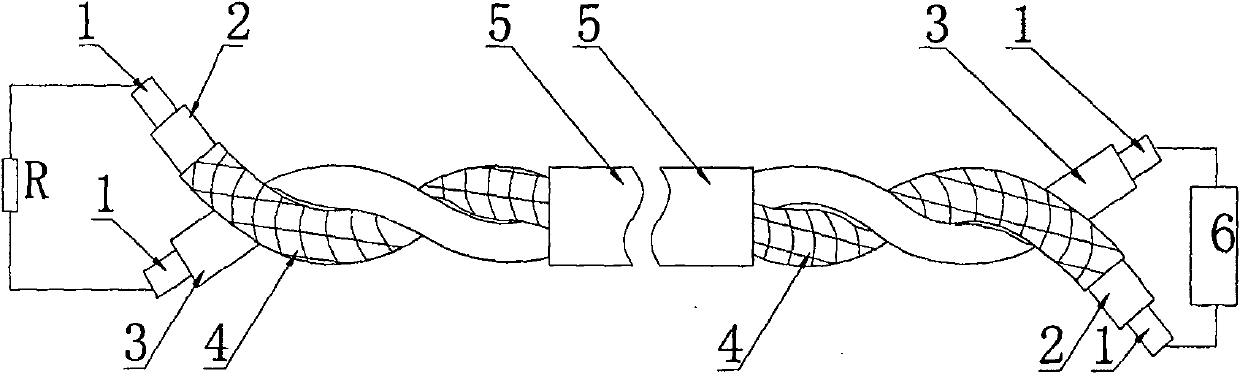

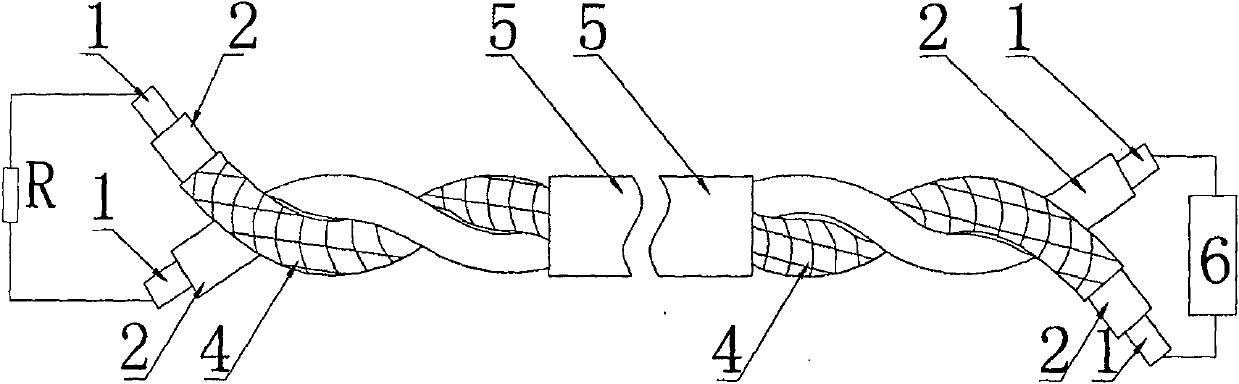

Composite linear temperature digital quantity and analog quantity sensing detector in two-chip structure

ActiveCN101046414AImprove safety and reliabilityImprove securityThermometers using electric/magnetic elementsUsing electrical meansMetal foilTemperature sense

The composite linear temperature sensing detector consists of one temperature sensing cable, one microcomputerized modulator and three terminal resistors connected together to form one closed circuit signal acquiring circuit. It features the structure of the temperature sensing cable comprising two stranded elastic metal conductor wires, including one covered with one insulating layer of 40-180 deg.c Vicat softening point and one outer metal foil or other conducting material layer serving as common pole, and the other covered with one semiconductor layer and one outer insulating layer of 40-180 deg.c Vicat softening point. These two wires are stranded in the pitch of 20-200 mm and covered with extruded plastic shield layer. The composite linear temperature sensing detector has high temperature sensing sensitivity, no dependence on the length, high reliability and low cost.

Owner:SHENYANG P T SECURITY TECH

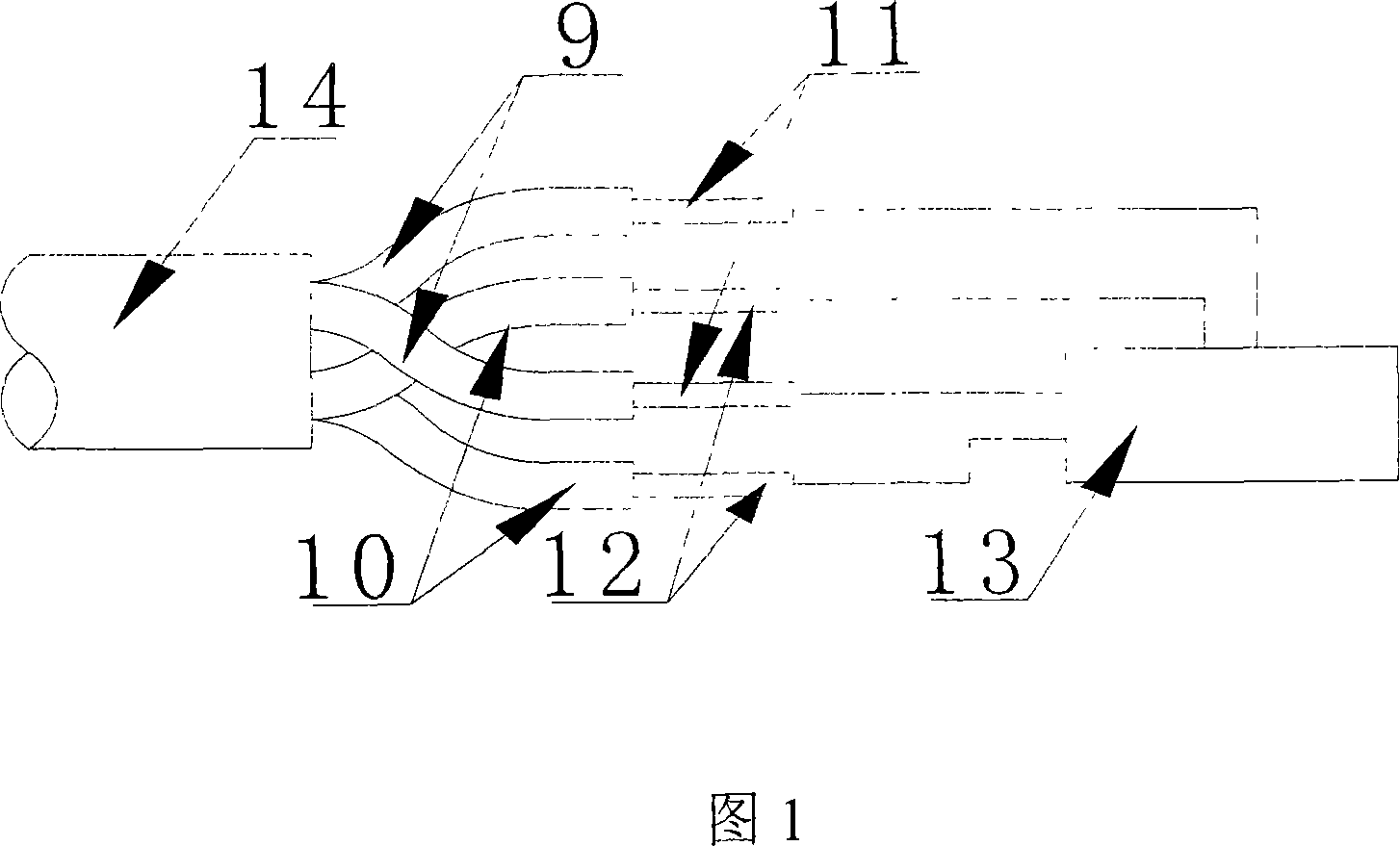

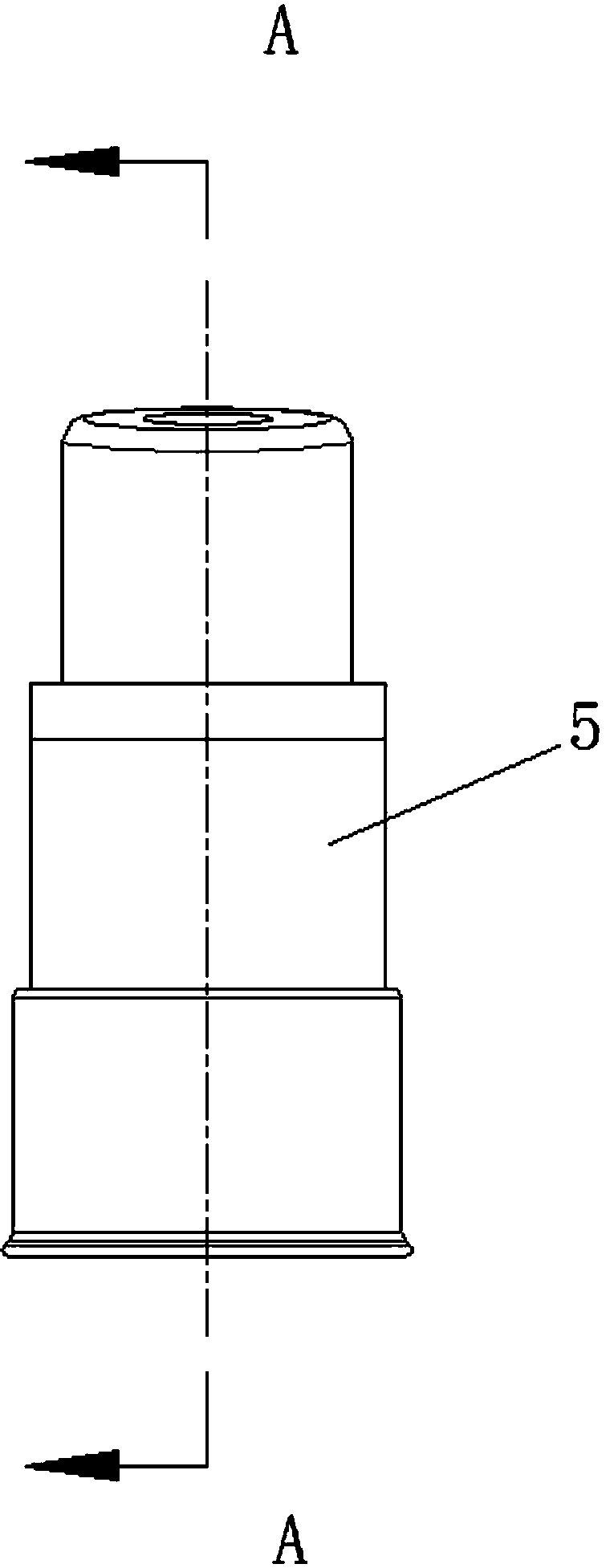

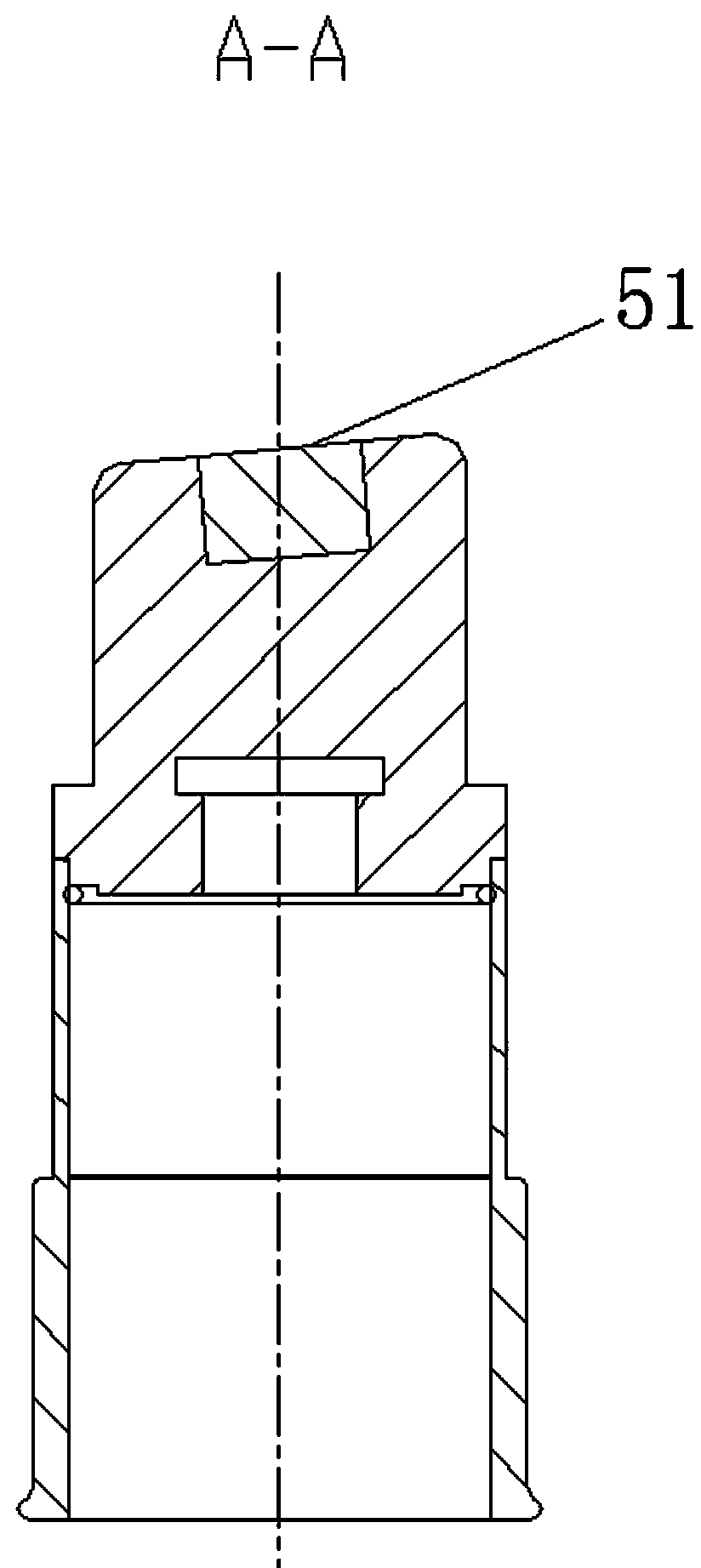

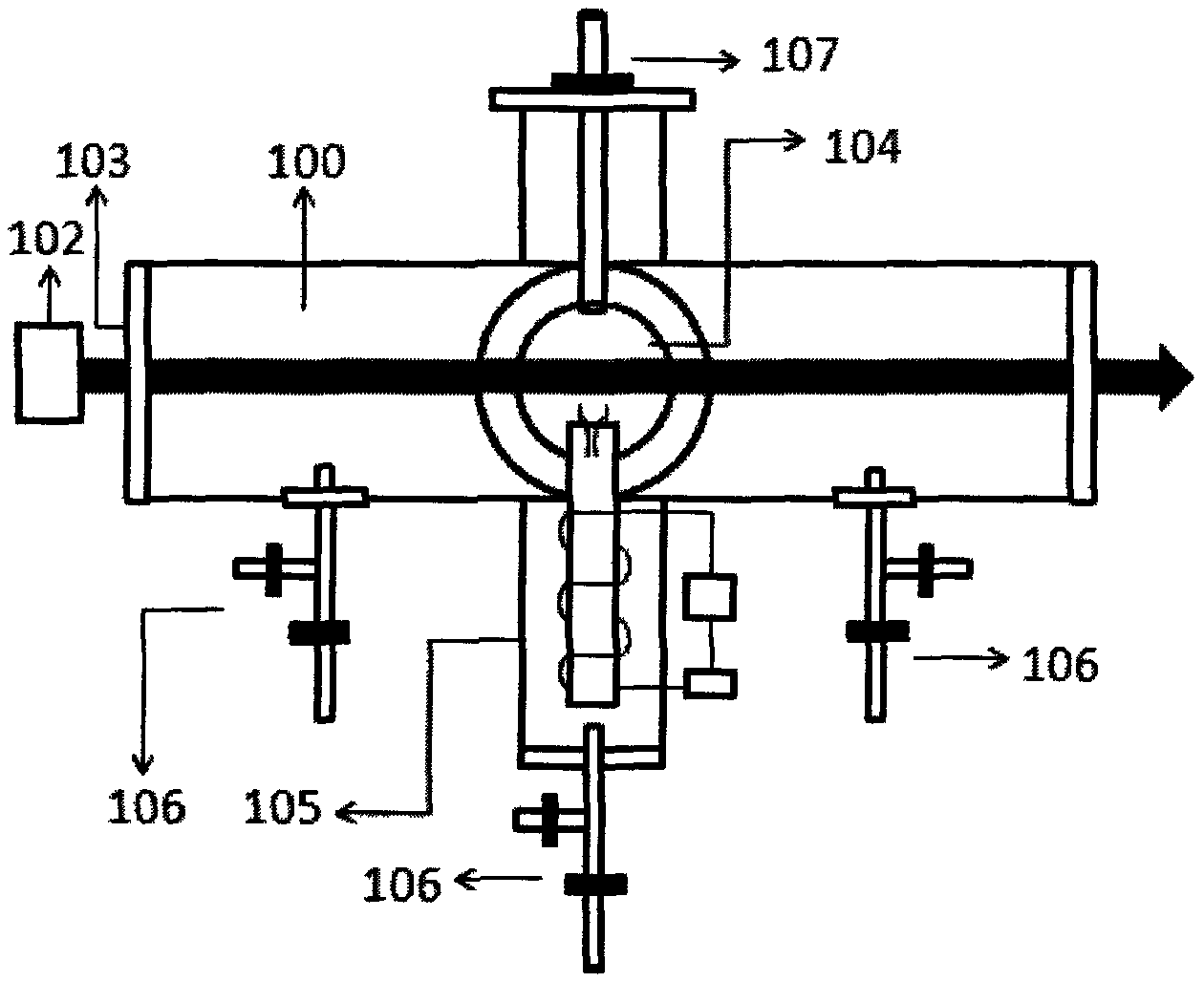

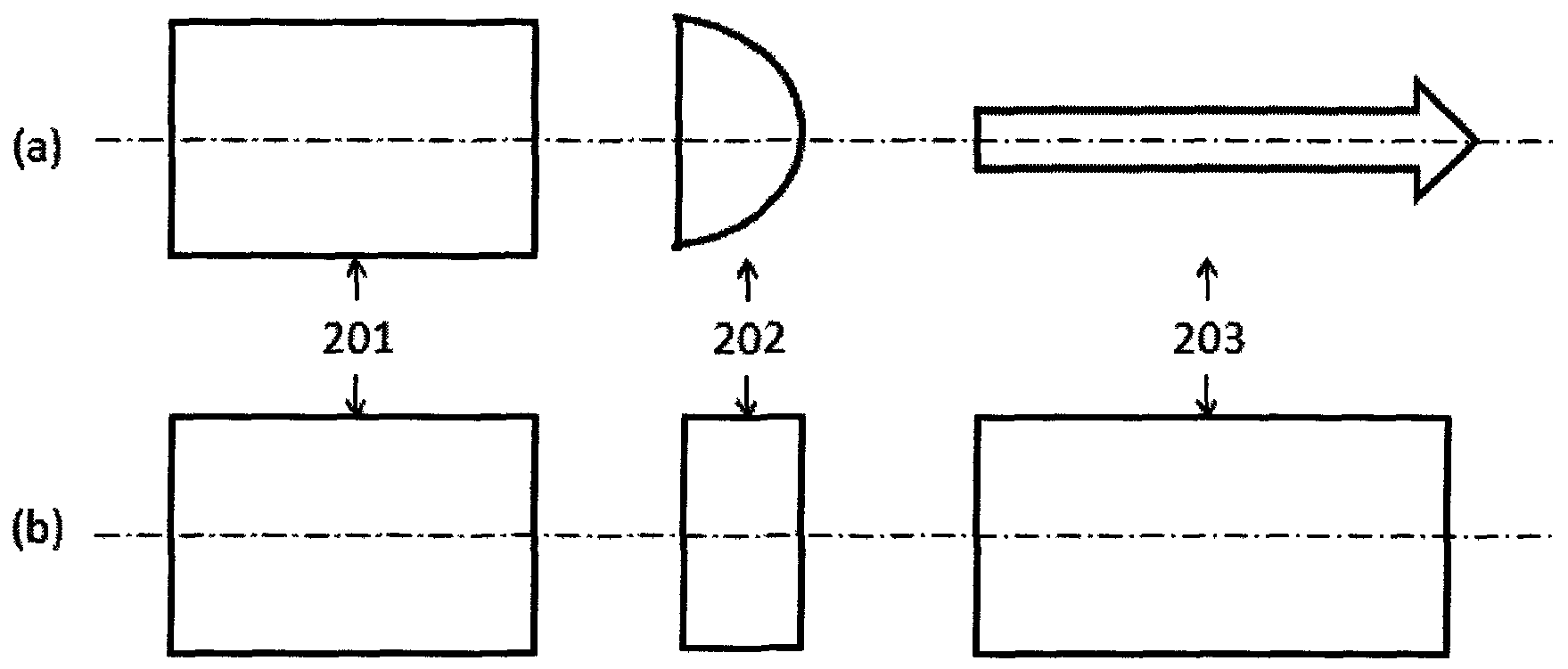

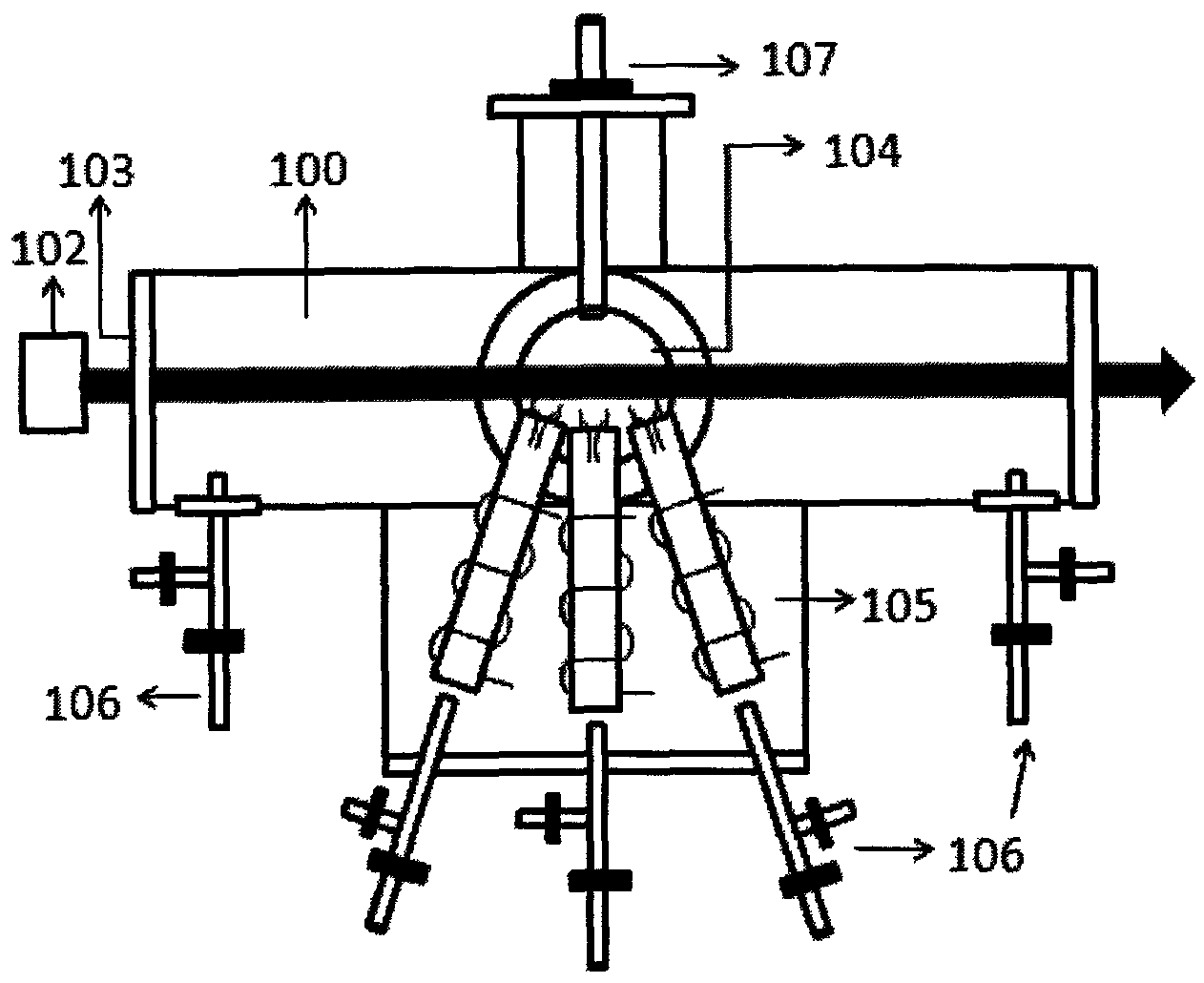

X-ray tube cathode and anode alignment device and alignment method with same

ActiveCN103560062AHigh precisionImprove production efficiencyElectrode assembly manufactureBarrel ShapedX-ray

The invention relates to an X-ray tube cathode and anode alignment device and an alignment method with the device. The device and the method are used for production of X-ray tubes. The X-ray tube cathode and anode alignment device is characterized in that a locating sleeve body and a locating module are included, the locating sleeve body is a hollow barrel-shaped body, the locating module is fixedly arranged in the locating sleeve body, a groove locating block is arranged at the end, protruding out of the locating sleeve body, of the locating module, a locating inclined block is arranged at the end, in the locating sleeve body, of the locating module, the groove locating block is matched with a cathode head locating groove of an X-ray tube cathode component, and the locating inclined block is matched with an anode target corner of an X-ray tube anode component. Alignment is carried out by the alignment device to improve cathode and anode alignment precision, and the work of engraving central lines in cathode and anode parts is eliminated. Production and work efficiency is improved, the high consistency of products is guaranteed, and the reliability of product quality is obviously improved.

Owner:HANGZHOU KAILONG MEDICAL INSTR

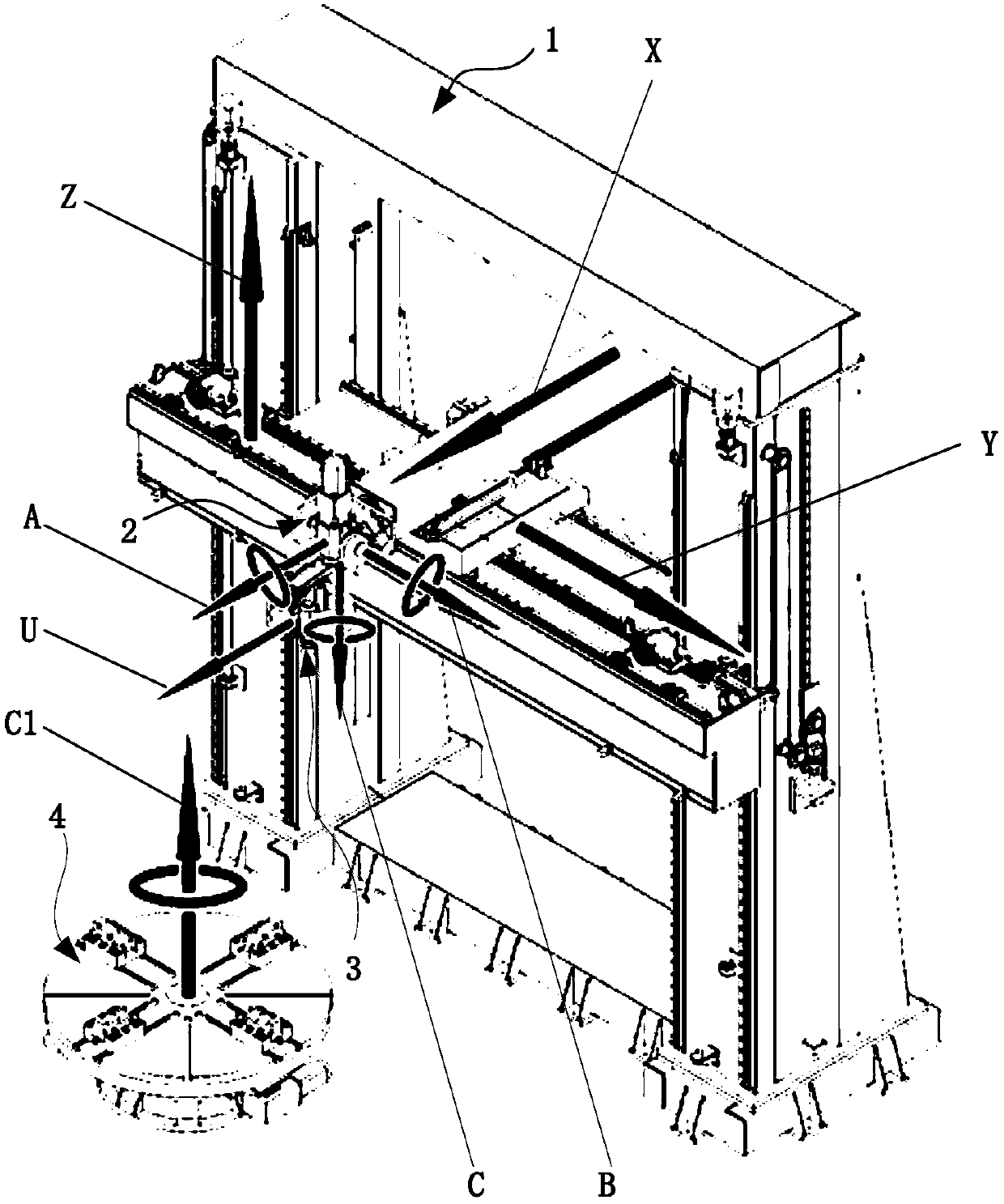

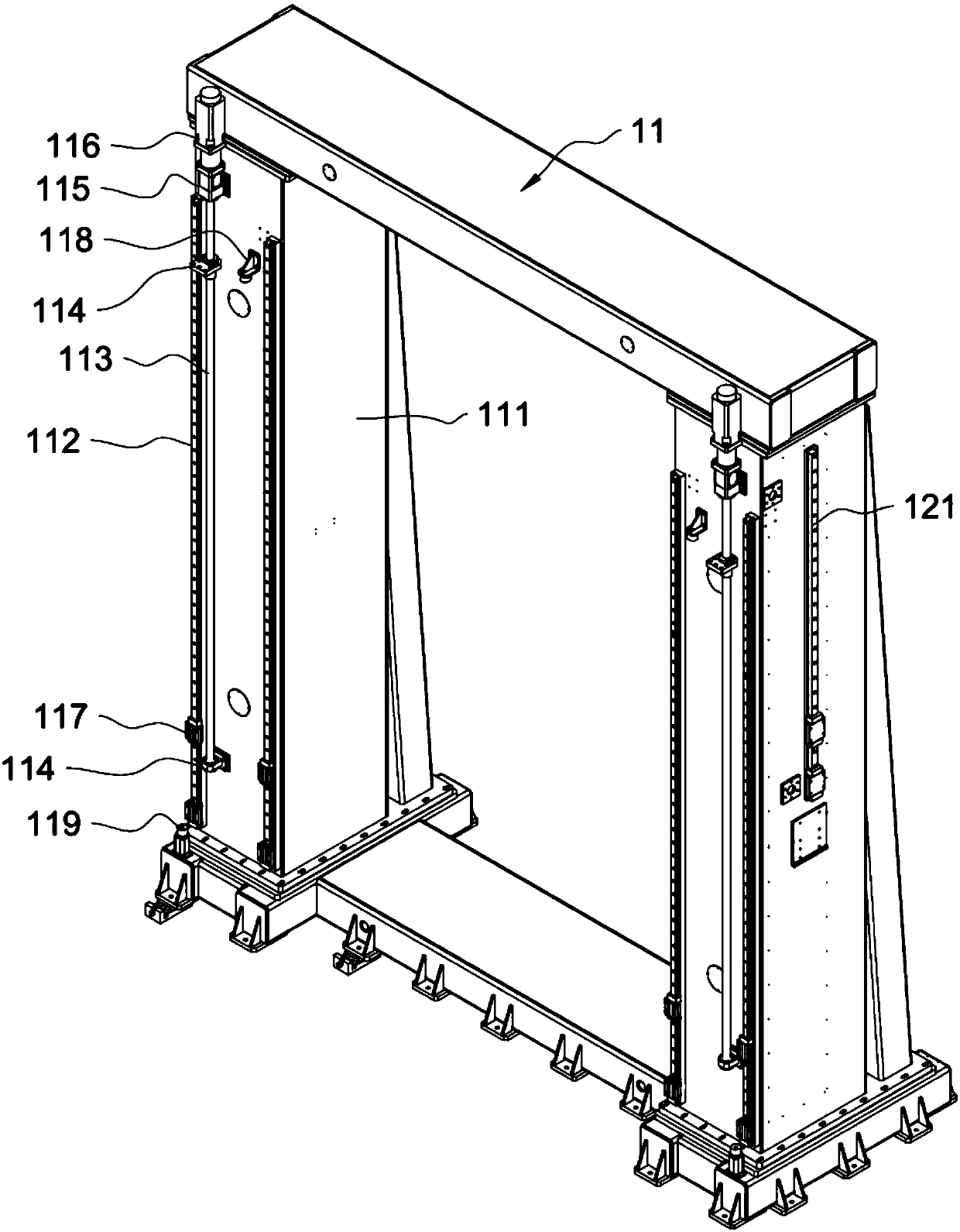

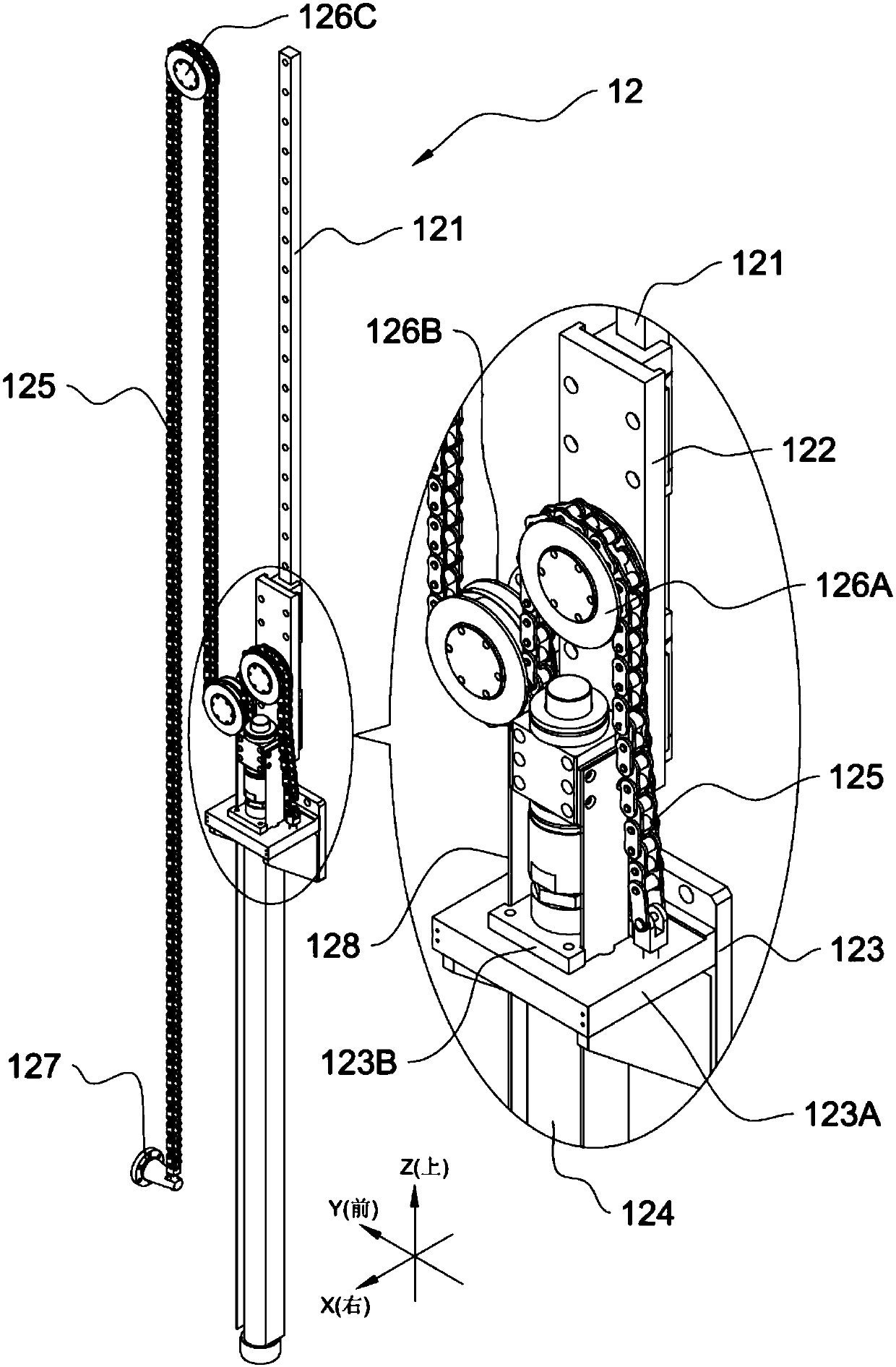

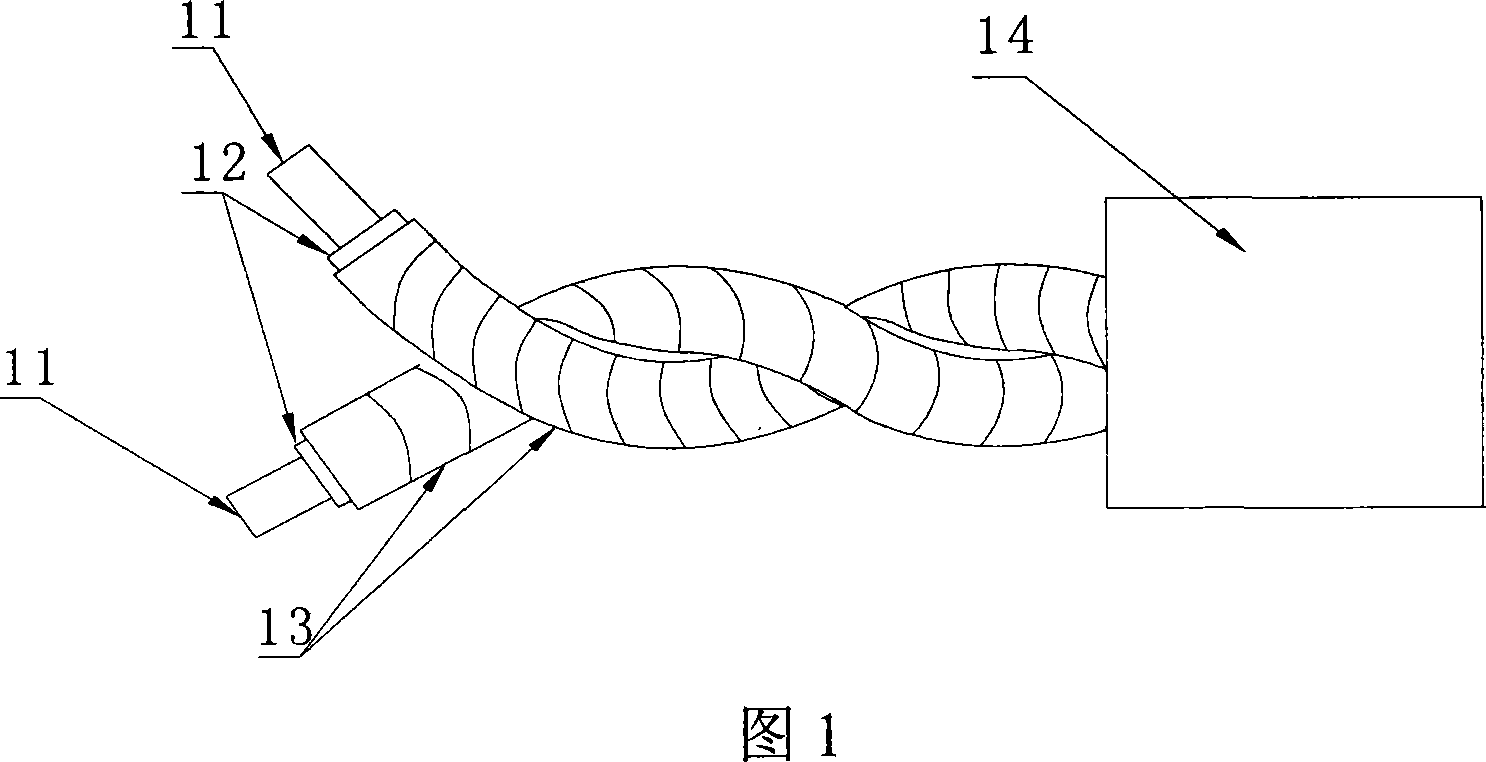

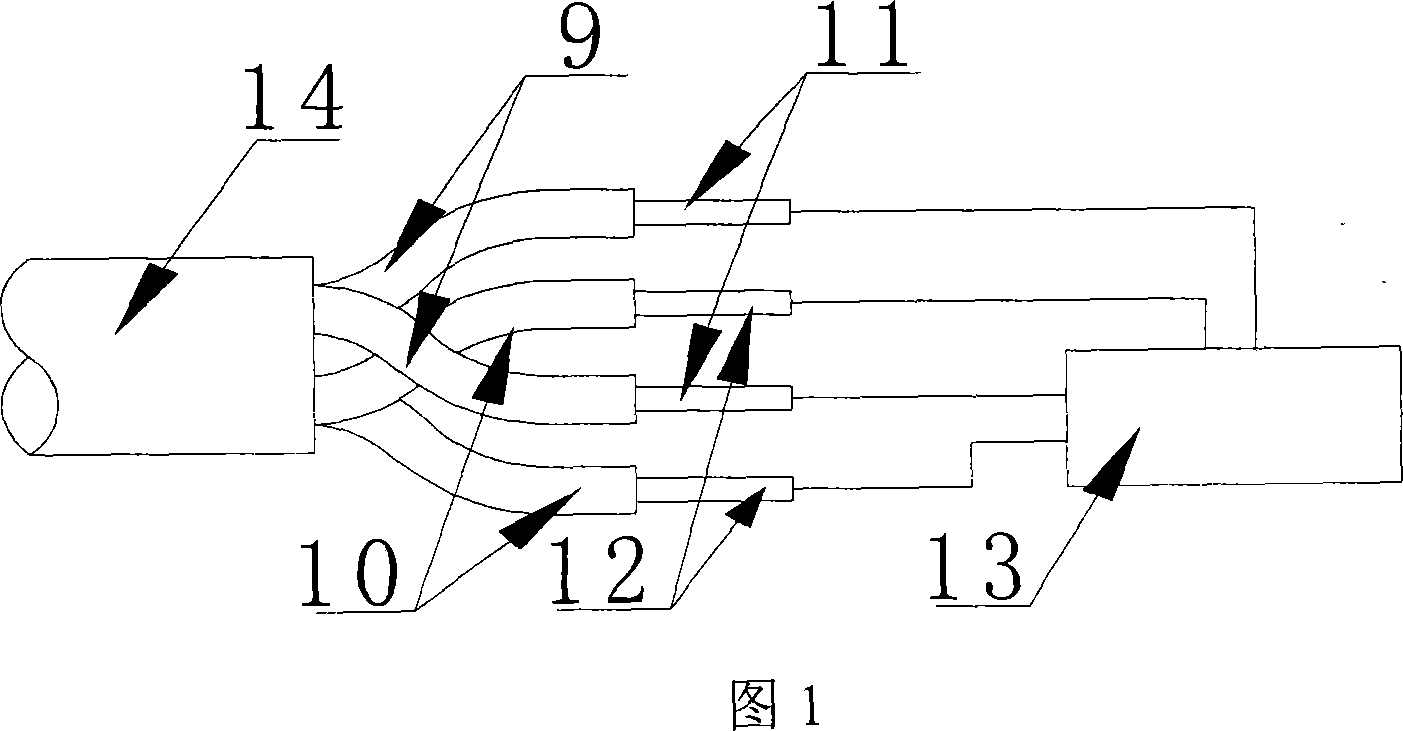

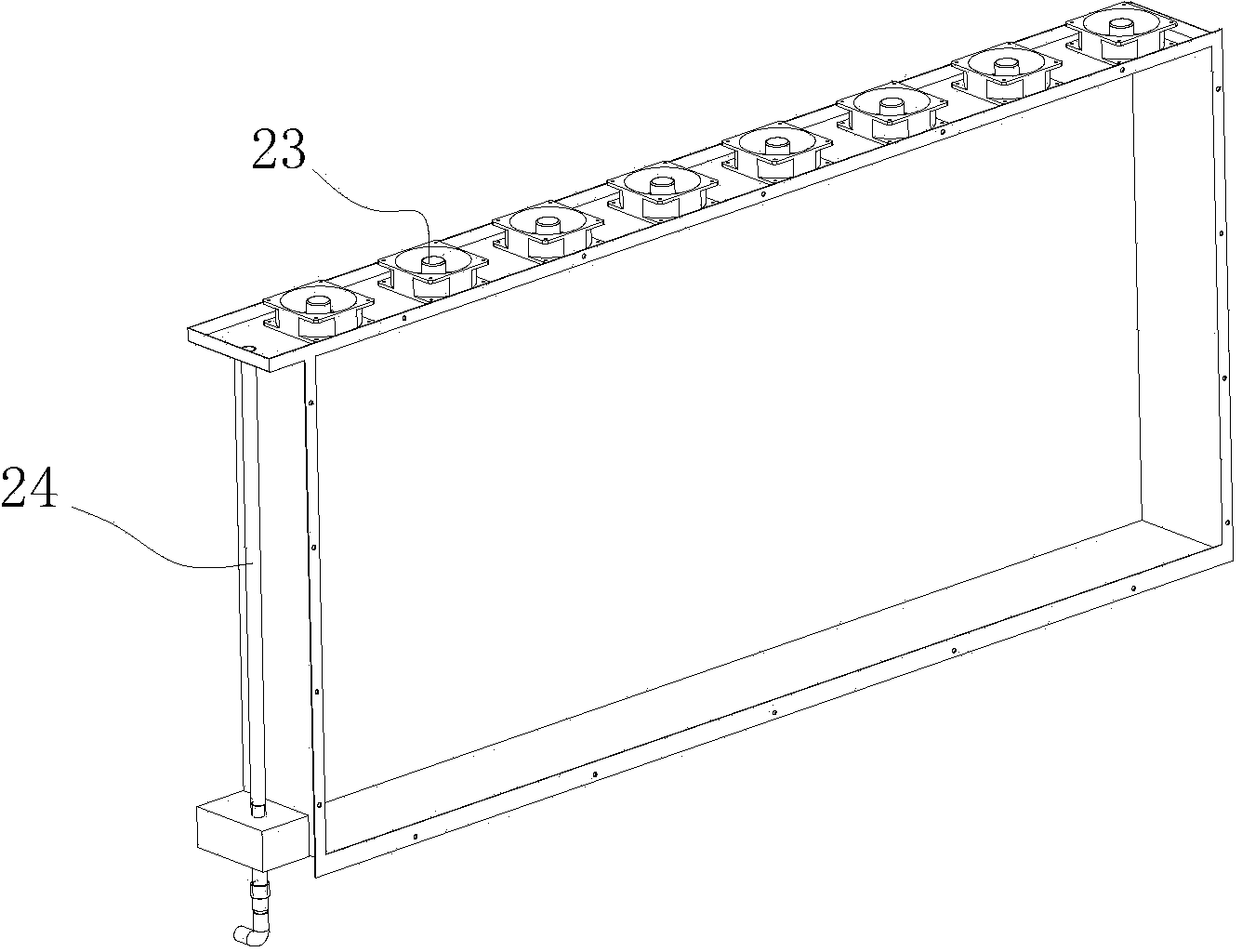

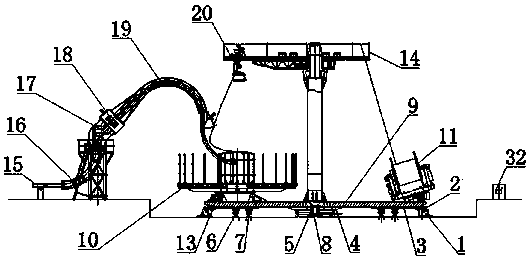

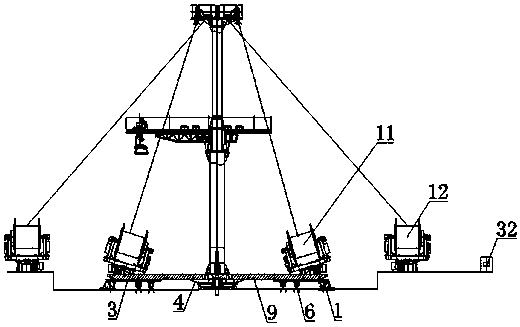

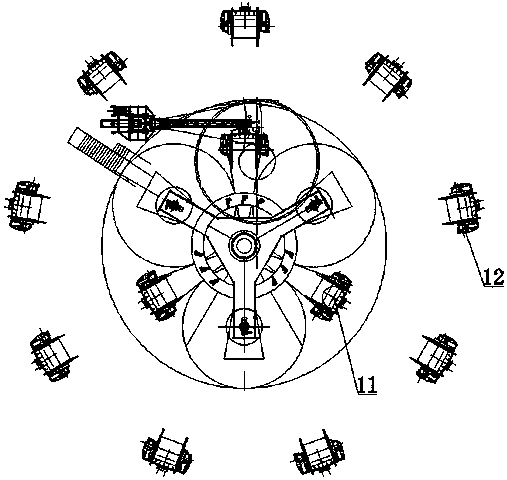

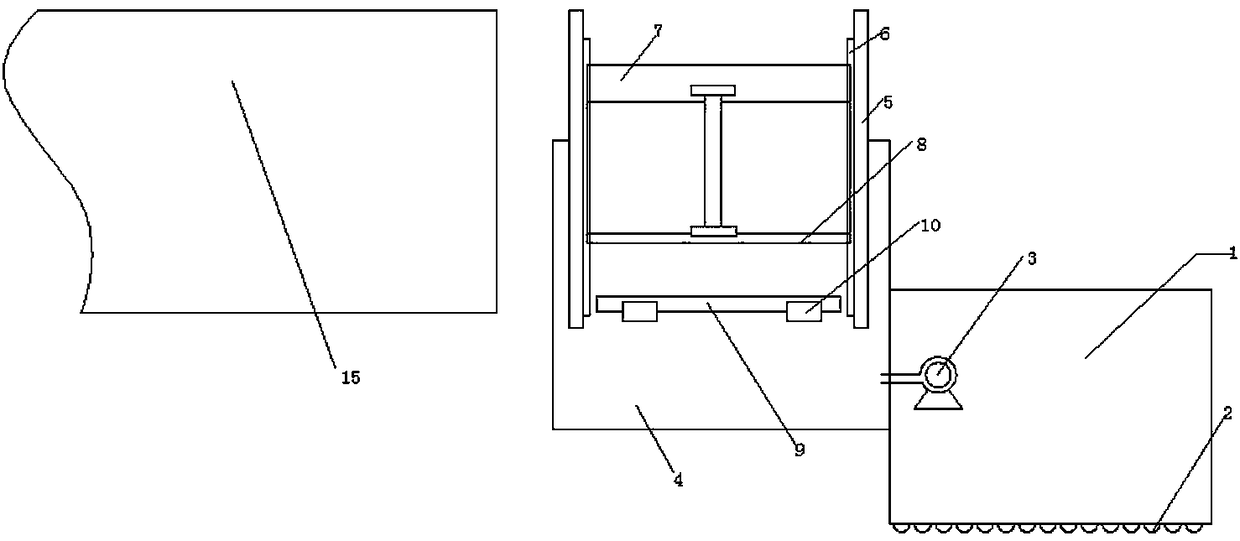

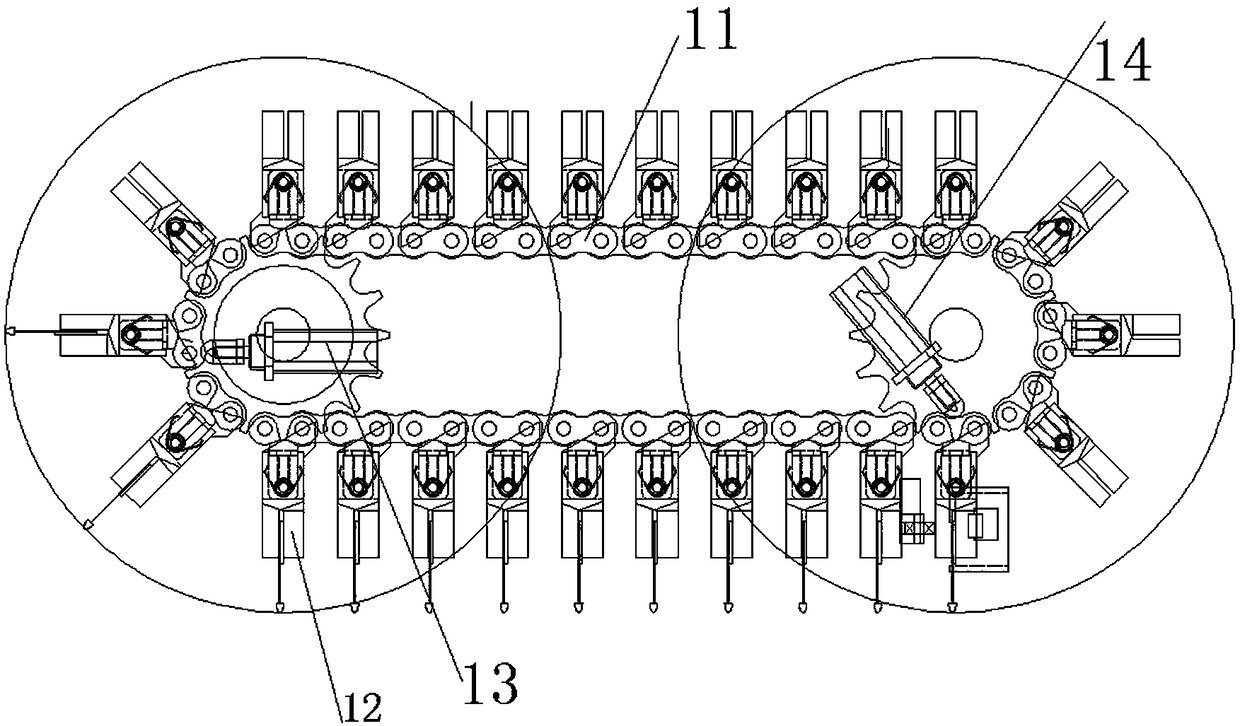

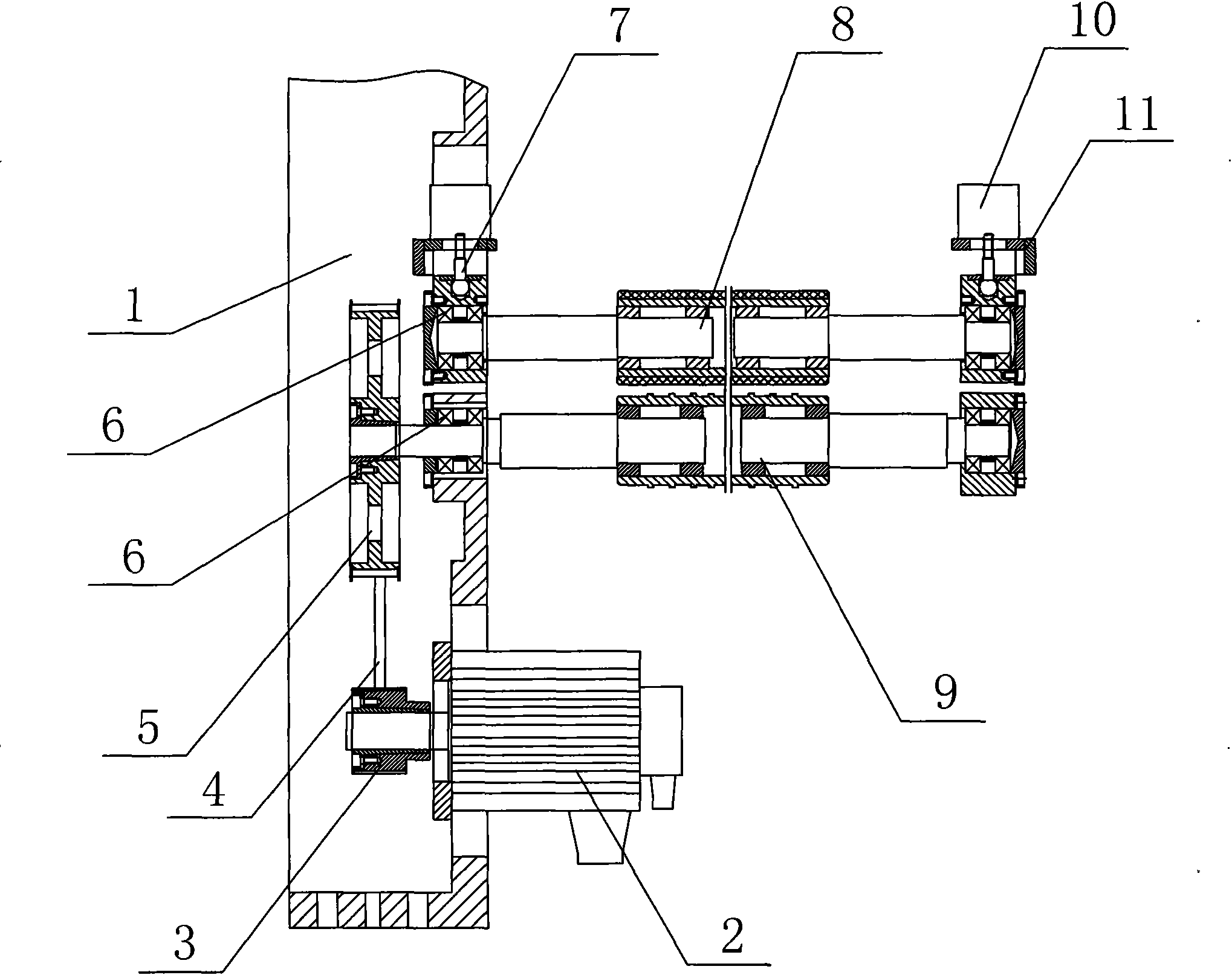

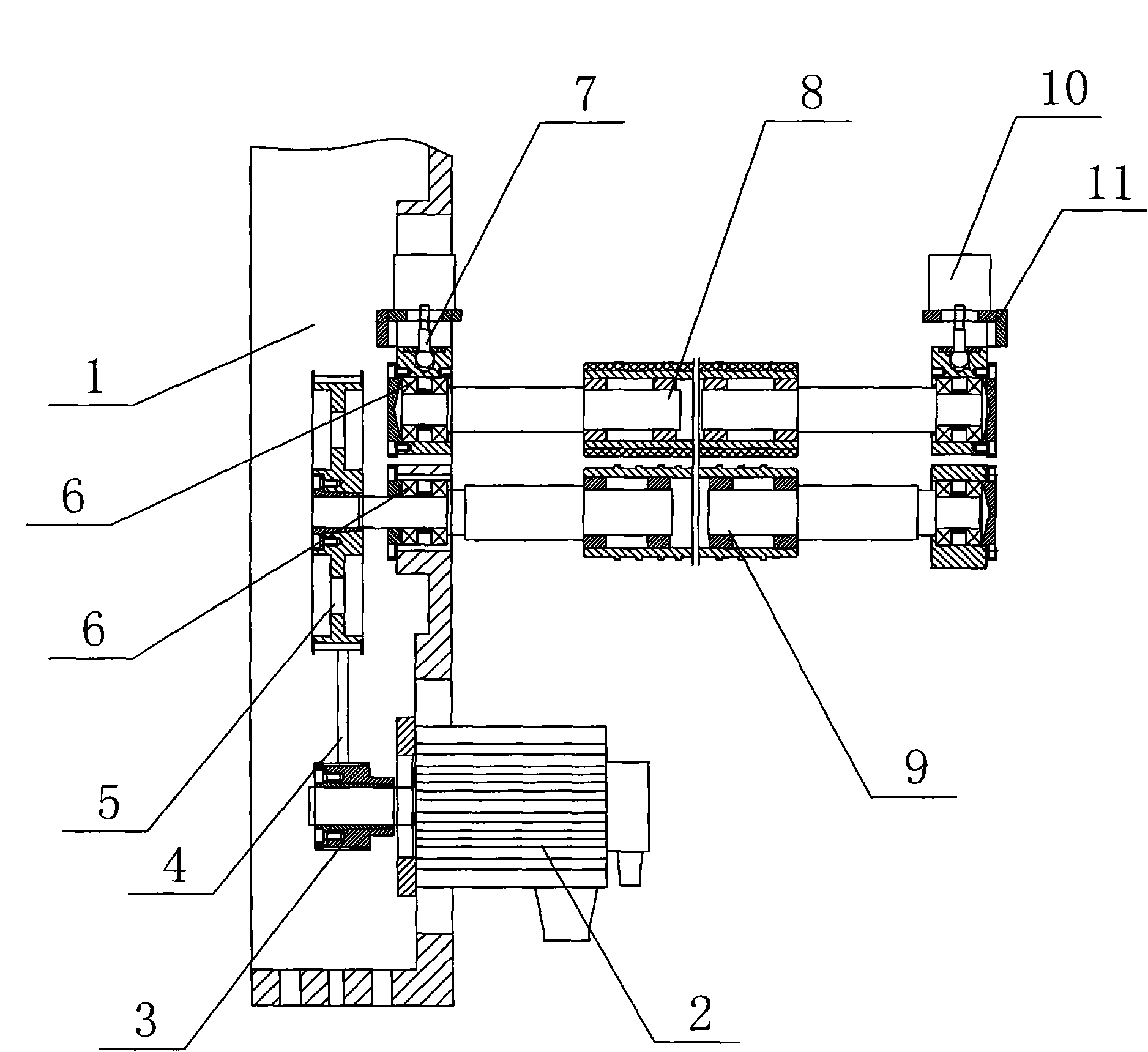

Large-scale seven-shaft linkage numerical control laying and winding integrated forming equipment

The invention belongs to the field of machine design and manufacturing-high grade numerical control machine tool and basic manufacturing equipment, and relates to large-scale seven-shaft linkage numerical control laying and winding integrated forming equipment. A main machine which is formed by three linear shafts and one rotating working table rotating shaft, and a laying and winding head which is driven by three rotating shafts are adopted to composite three translation movement and four rotation movement to achieve laying and winding head spatial motion track control and workpiece rotation.A conveying belt u shaft is adopted to drive winding and rewinding of a cloth belt and speed adjustment to achieve eight-shaft control seven-shaft linkage laying, and therefore automatic forming of acomposite material skin structure with all kinds of spacial special-shaped hook surfaces is achieved. The spatial motion track of the laying winding head can be directly controlled, even a workpiecewith the special-shaped hook surface can be accurately attached to the surface of the laying winding head for laying and winding, and therefore forming operation of material cutting after solidifyingand forming can be reduced and even avoided. Pollution is reduced, the cost is saved, and efficiency is improved. The automatic tow placing technology provides an equipment platform suitable for engineering application research and manufacture.

Owner:HUAZHONG UNIV OF SCI & TECH +4

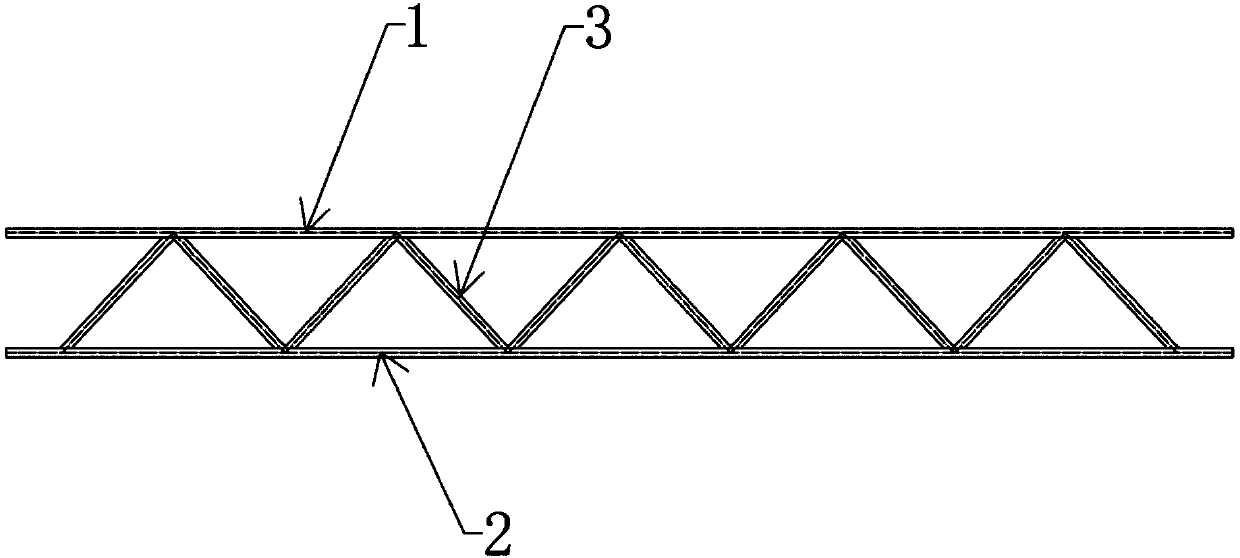

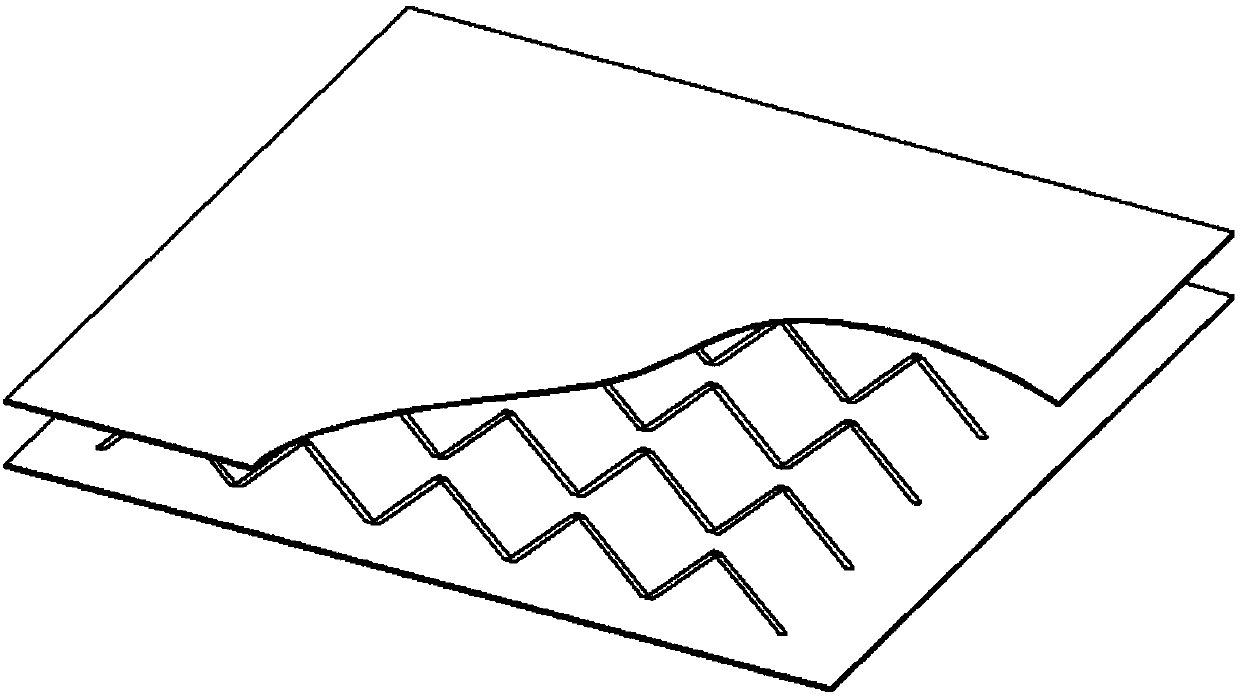

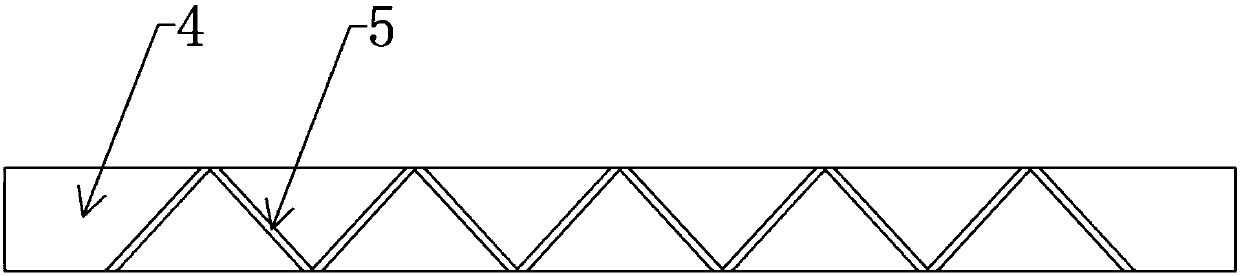

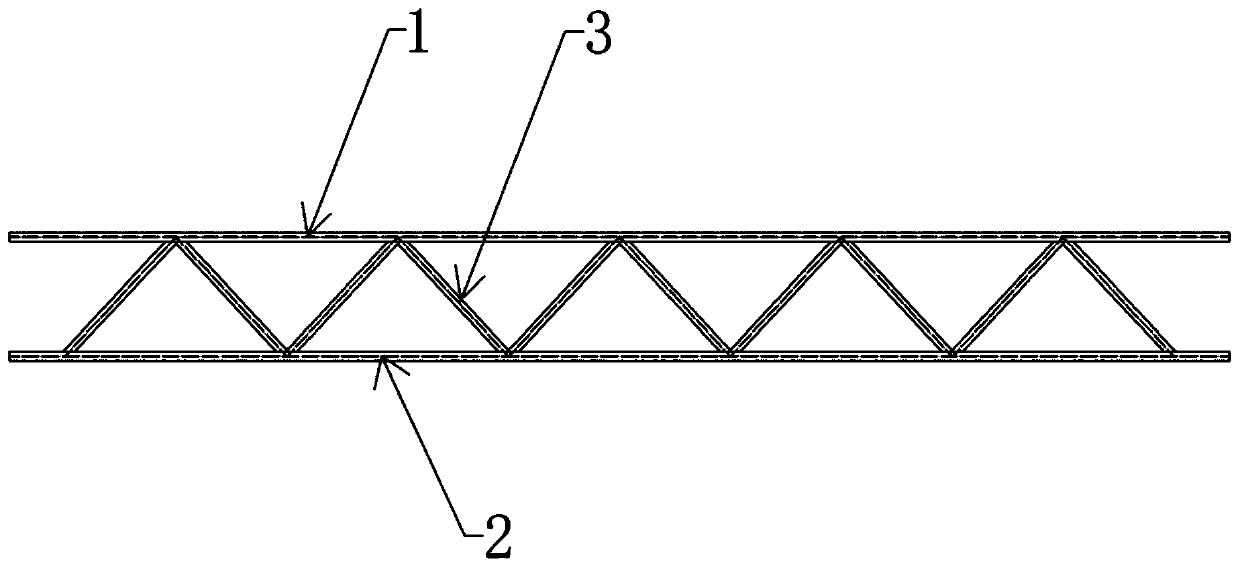

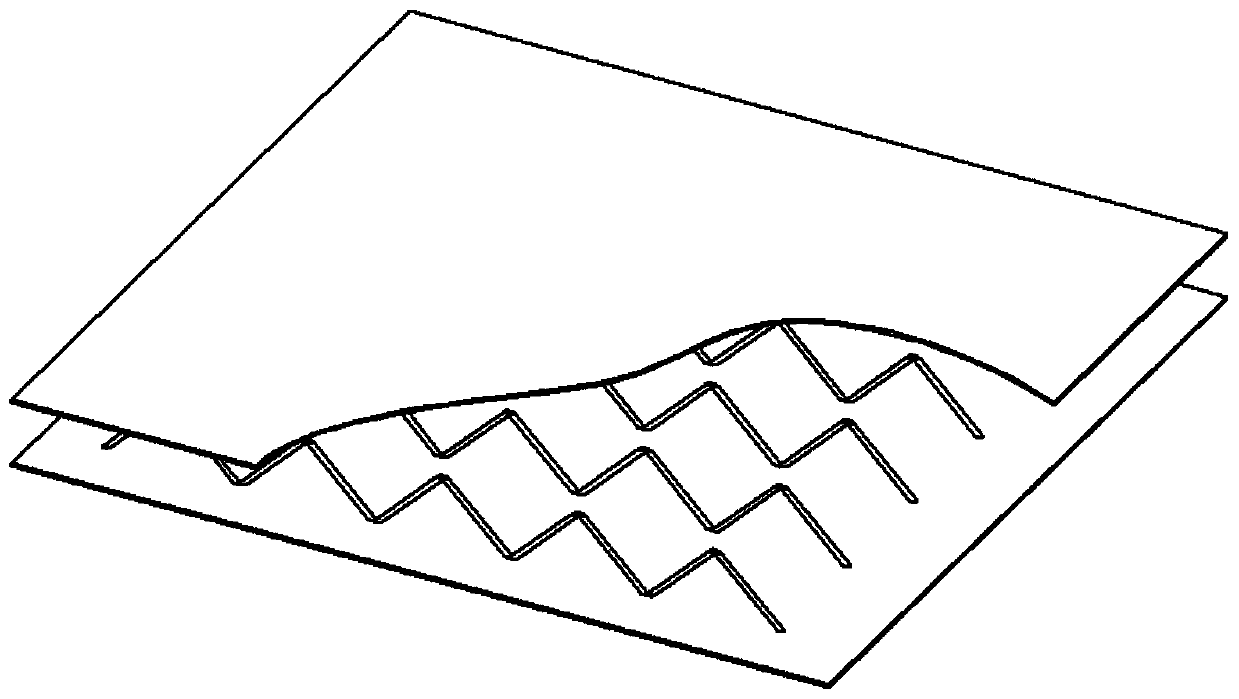

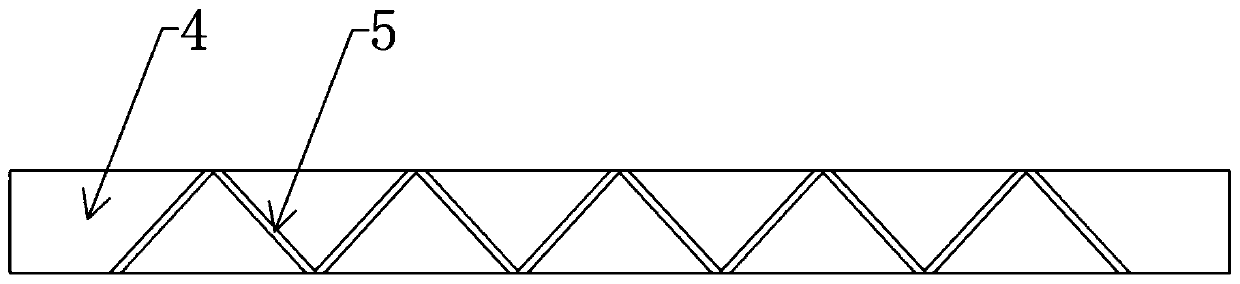

Composite lattice structure and preparation method

ActiveCN107599445AIncrease productivitySuitable for large-scale production of composite lattice structuresLayered productsFiberShell molding

The invention provides a composite lattice structure and a preparation method. The composite lattice structure is composed of an upper face plate, a lower face plate and a lattice core arranged between the upper face plate and the lower face plate. The lattice core is formed in the manner that lattice core triangular fibers and trapezoidal fibers are interlaced. Foam interlayers are arranged in the upper face plate and the lower face plate. A specific injection manner is applied to the composite lattice structure for VARTM formation. The preparation method of the composite lattice structure comprises the seven steps of (1) preparing a fusible alloy mold core; (2) inserting the triangular fibers; (3) laying fibers on the bottom layers of the upper face plate and the lower face plate; (4) inserting the trapezoidal fibers; (5) arranging the face plate interlayers and laying surface fibers of the face plates; (6) conducting VARTM (vacuum assisted resin transfer molding) formation; (7) heating and melting the fusible alloy mold core. The composite lattice structure and the preparation method effectively solve the connection problem between a composite lattice core and the face plates, integrated formation is achieved, the quality is reliable, the technology is simple, and the node strength is high.

Owner:HARBIN ENG UNIV

Double temperature warning linear temperature-sensing detector

InactiveCN101050983AUse unlimited lengthSmall sectionThermometers using electric/magnetic elementsUsing electrical meansSemiconductor materialsEngineering

A linear temperature sensing detector of double-temperature alarm is prepared for cladding insulation layer with Vicat softening point of 40-180deg.c on one elastic metal conductor, cladding insulation layer then conduction material layer on another elastic metal conductor, twisting two conductor with conductor cladded with semiconductor layer together, storing start-up resistance value of alarm signal in modulator of microcomputer and realizing alarm signal output of double-temperature and, fixed-temperature by utilizing two said elastic metal conductors to short-circuit with conduction material layer then with semiconductor layer at different temperature.

Owner:张陈

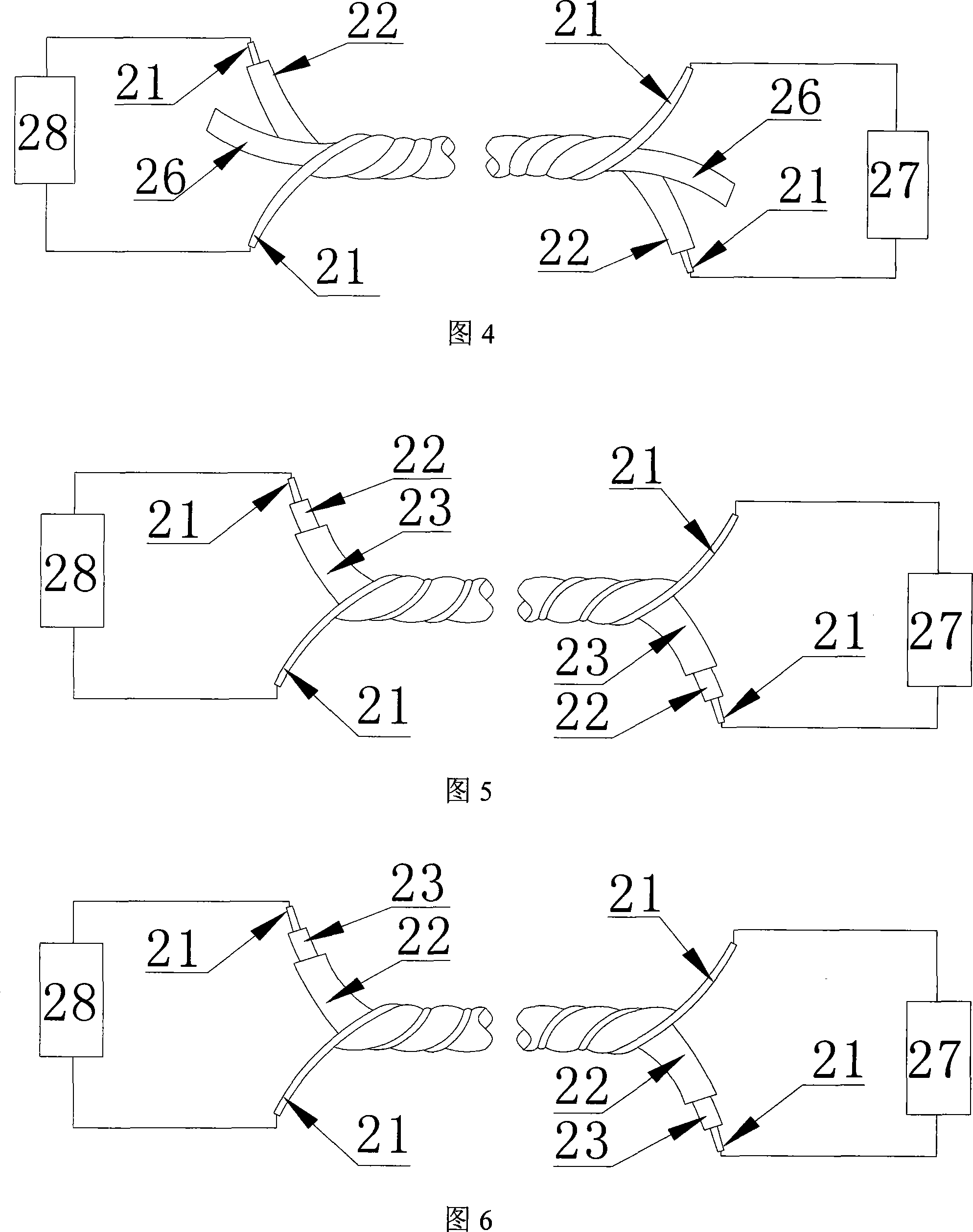

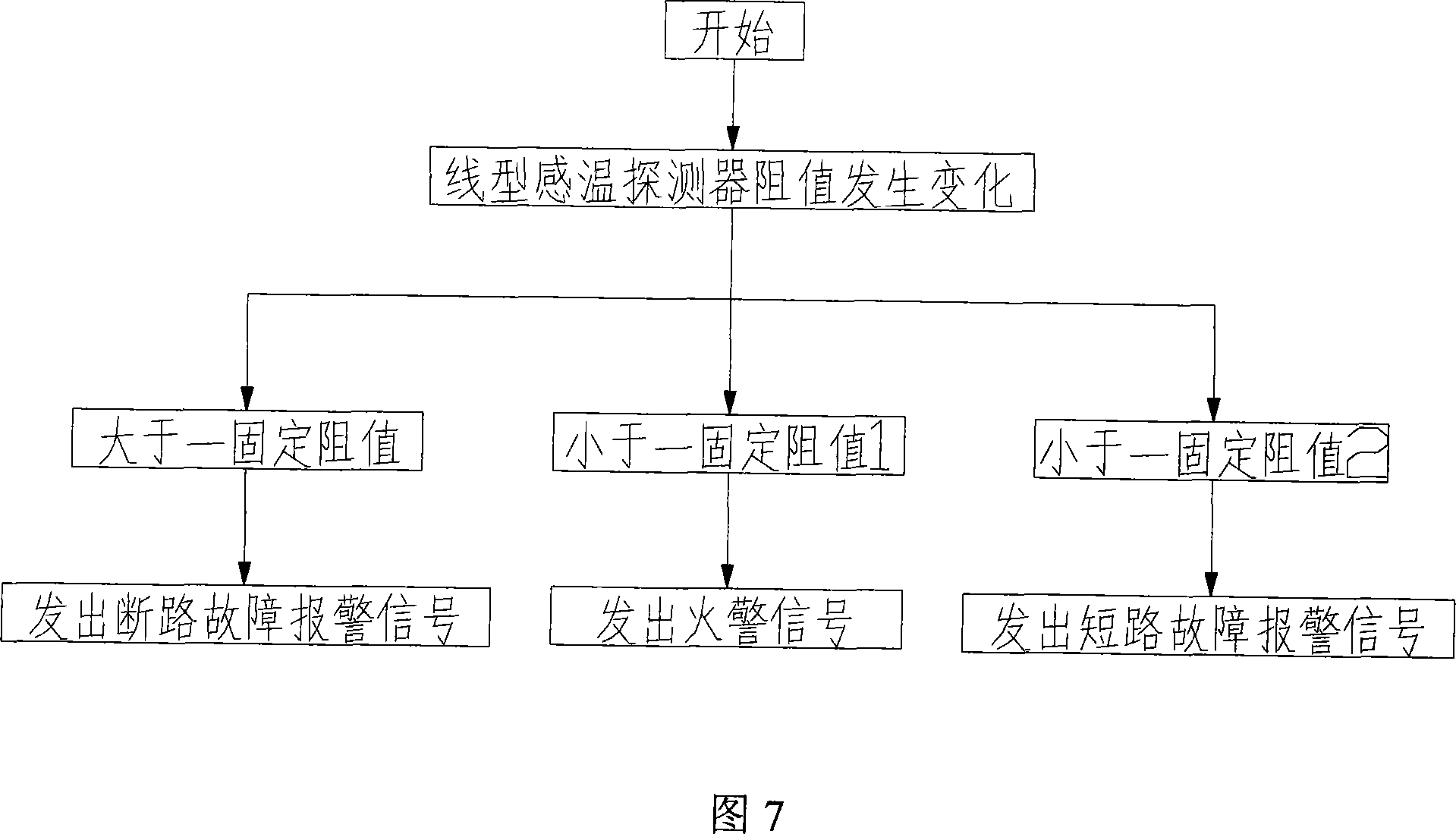

Past retrieve cable type linear temperature-sensing fire disaster detector

InactiveCN101256704AQuick responseHigh sensitivityThermometers using electric/magnetic elementsUsing electrical meansElectrical conductorElectric cables

The invention is to provide an unrecoverable cable linear temperature sensing fire probe which realizes recoverable temperature sensing multilevel alarm. Both ends of the temperature sensing cable are respectively connected to a microcomputer modulator and a terminal resistor to form a closed circuit signal collecting circuit, characterized in that the structure of the temperature sensing cable is: two elastic metal conductors adopted respectively coat CTR special material layer with different Vicat softening point, two cores with different coat layers intertwisted in back-twist intertwist way. The intertwisted node distance is preferably between 20mm to 200mm to prepare the temperature sensing cable. The microcomputer modulator monitors the resistance value or voltage alternation between two elastic metal conductors, arranging two resistance values or voltage alarming signal starting values in a memory of the microcomputer modulator to realize double level constant temperature alarming signal output and realizes a malfunction alarming signal output according to the short circuit, the open circuit between the two elastic metal conductors and power cut of the microcomputer modulator.

Owner:张陈

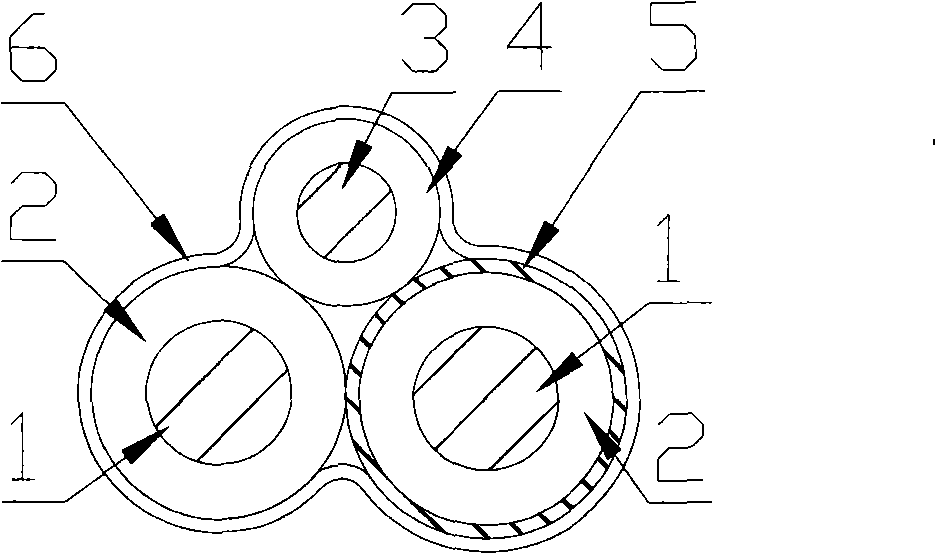

Recoverable cable type linear temperature-sensing detector

ActiveCN101078654AAchieve reuseThe alarm temperature is not limited by the length of useThermometers using electric/magnetic elementsUsing electrical meansElectrical conductorBand shape

The invention relates to a recovery cable linear temperature detector. As two ends of temperature cable are connected with microcomputer modulator and terminal resistance R respectively a closed signal collection circuit is formed. It is characterized in that the structure of temperature cable is that an elastic metal conductor is covered by melting NTC characteristic material layer with vicat softening point in 40deg.C-180deg.C; anther is an elastic metal conductor; after a hole belt or net insulation obstructing layer is set between two line cores they are twisted or winded; finally they are covered by outer sleeve layer in plastic protrusion together. Multiple starting resistance values for alarming temperature signals heated on one meter of temperature cable are set in memory of microcomputer modulator, which inspects resistance change of melting NTC characteristic material layer between conductors. When circumstance temperature makes melting NTC characteristic layer soften, elastic metal conduct and melting NTC characteristic material layer forms short circuit so that output of alarming signal of given temperature is realized. When short circuit and open circuit happen between two conductors by not fire factor, failure signals of short circuit and open circuit are outputted by microcomputer modulator. It is provided with simple process, high productivity and low producing cost.

Owner:SHENYANG P T SECURITY TECH

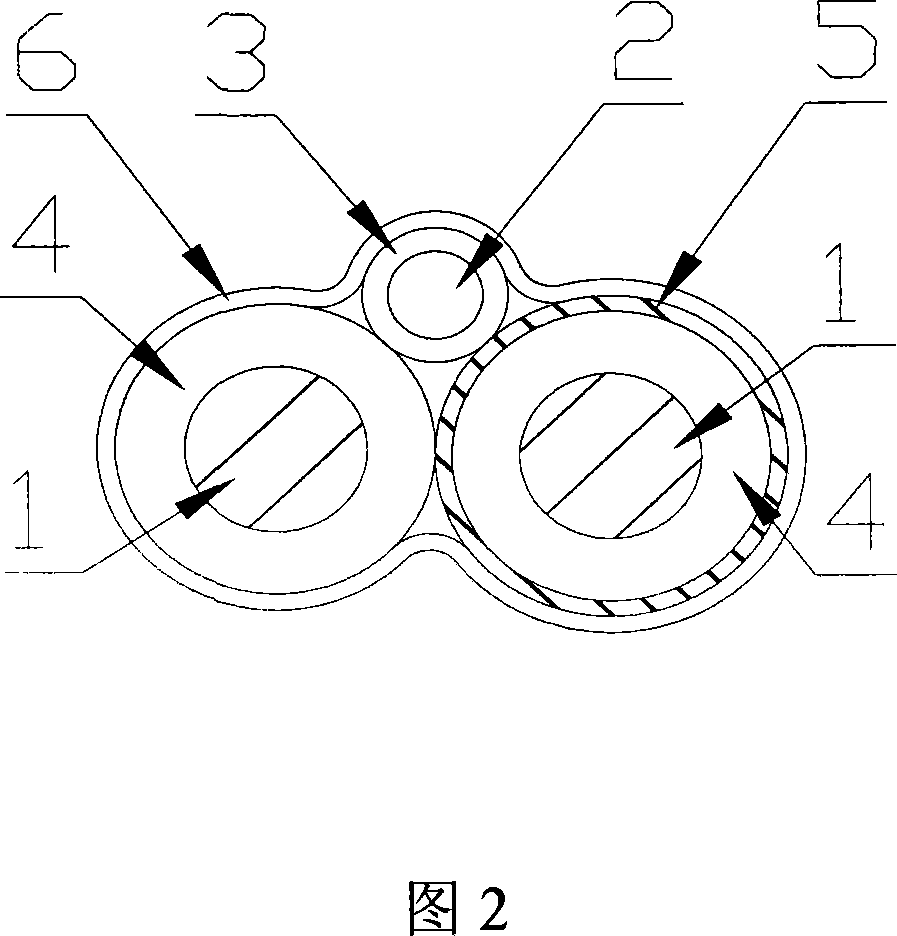

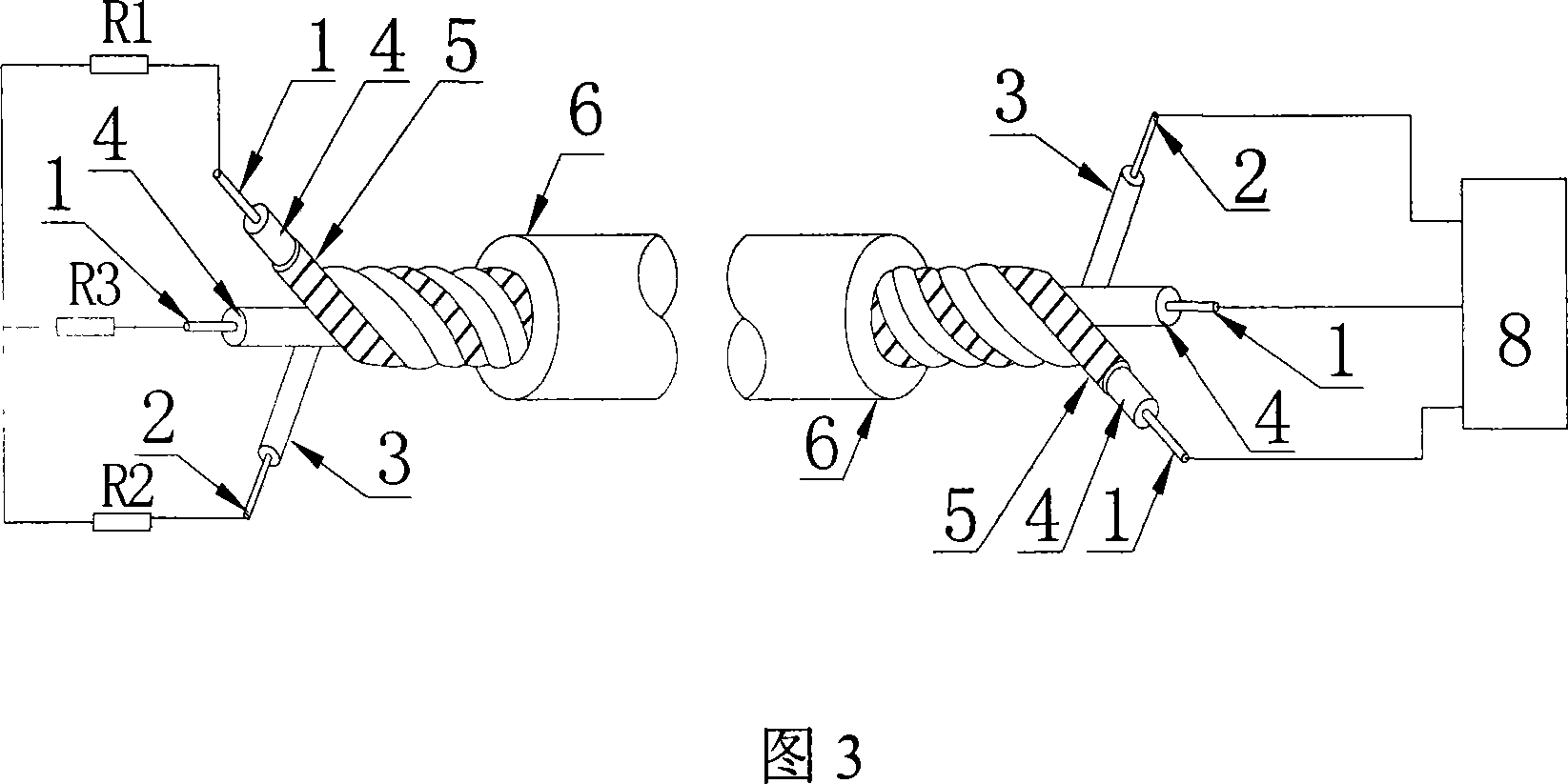

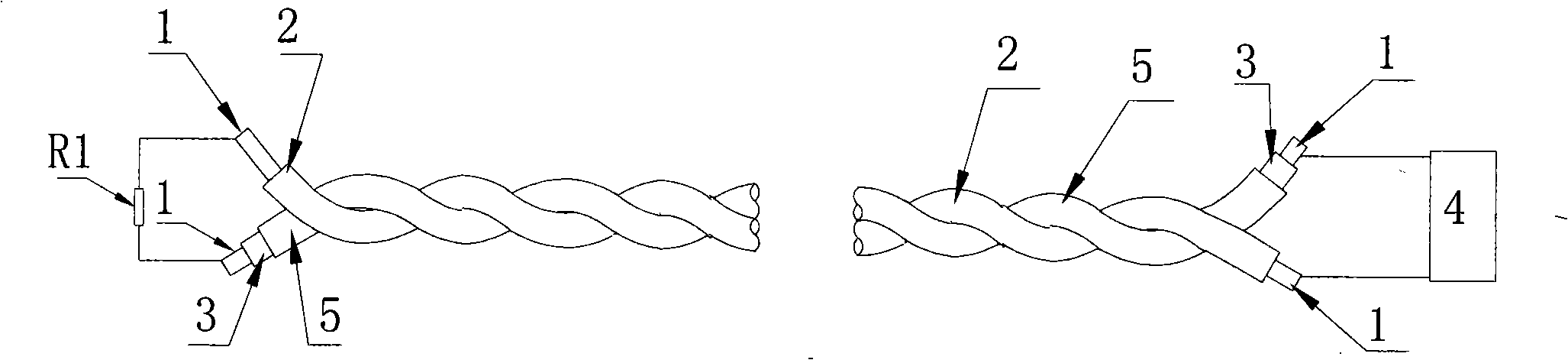

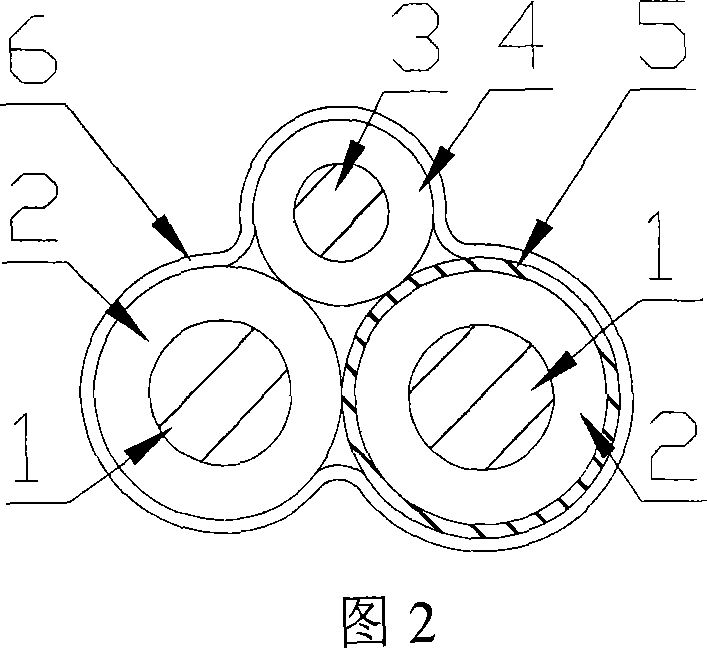

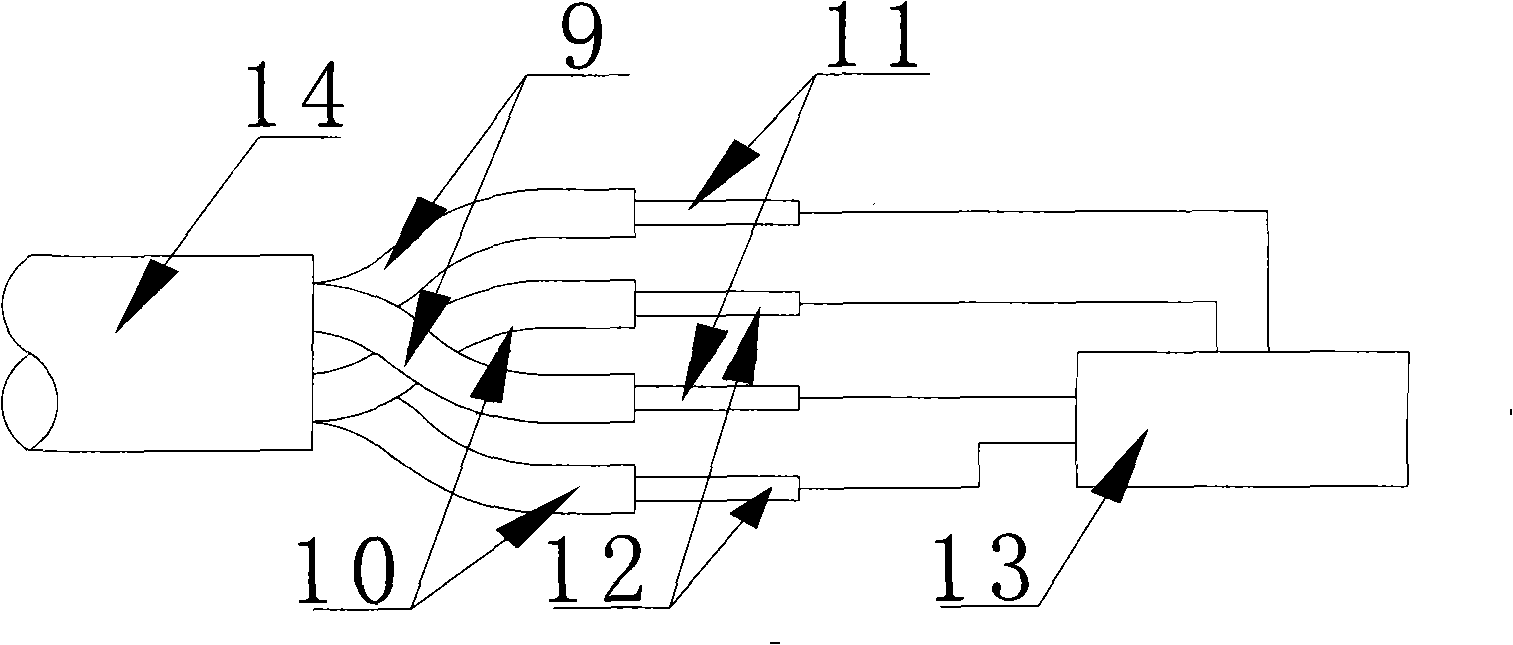

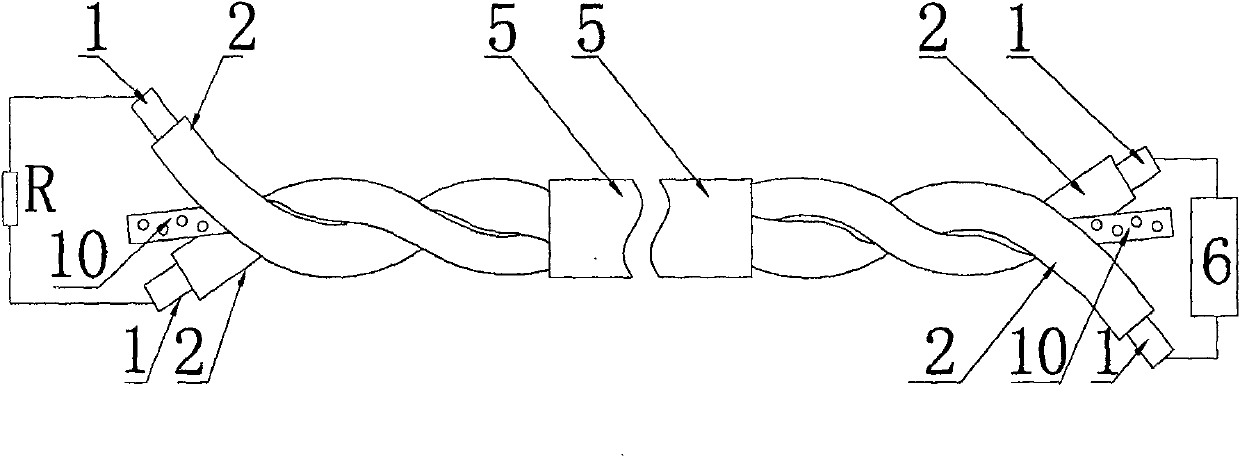

Three-core structure switch, analog composite type linetype temperature inductor

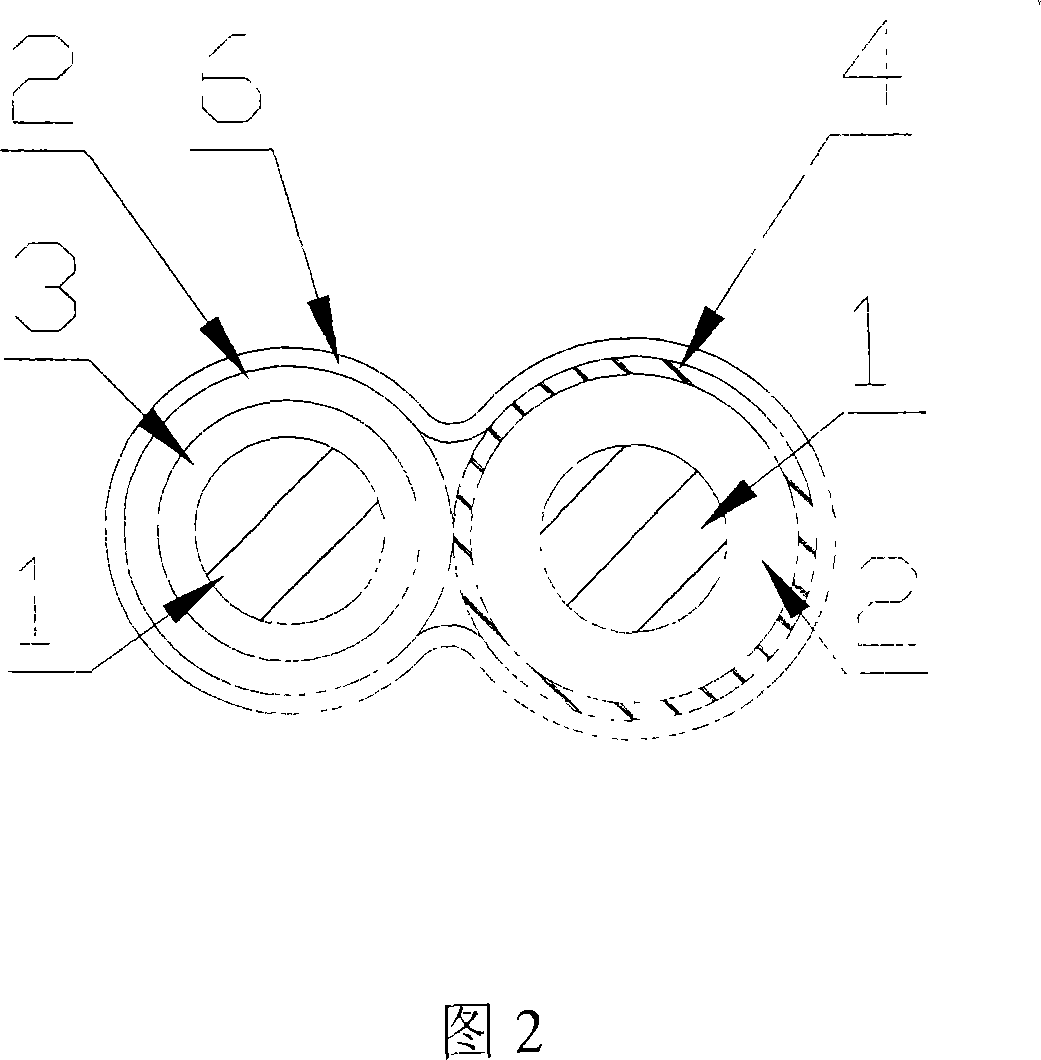

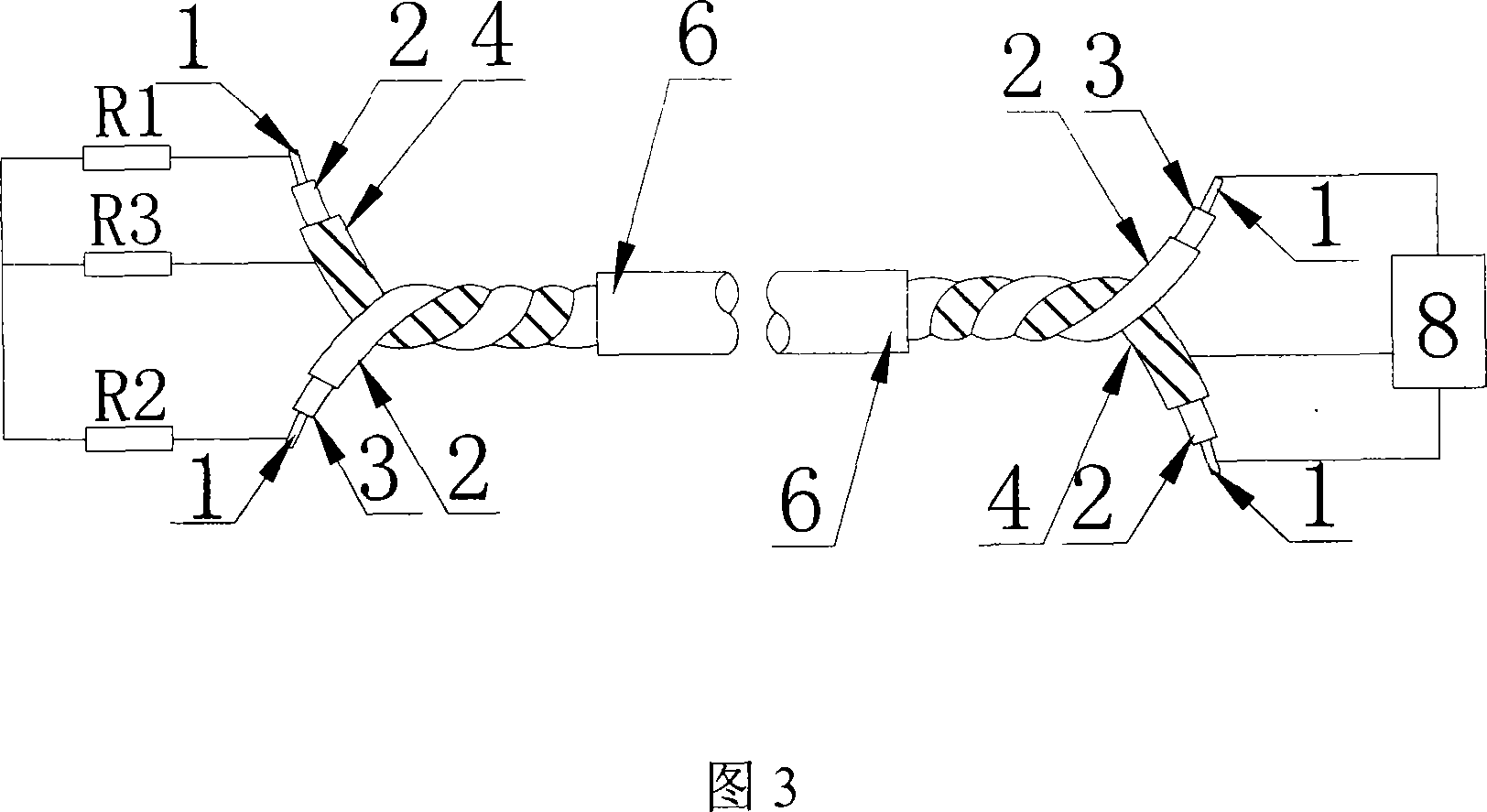

InactiveCN101059377AHigh sensitivityWide temperature rangeThermometers using electric/magnetic elementsUsing electrical meansElectrical conductorMetal foil

The invention relates to an on-off value and analog quantity composite linear temperature detector with three-core structure, wherein two ends of a temperature-sensitive cable are respectively connected with a microcomputer modulator (7) and three terminal resistances (R1, R2, R3) to form closed-circuit signal pick-up circuit. The invention is characterized in the structure of the temperature-sensitive cable that two elastic metal conductors (1) are respectively coated by an insulated layer (2) which soften point is 40-180Deg. C, wherein one conductor is also coated by a plastic-aluminum composite band, a plastic-copper composite band, or a metal foil layer (5), a conductor (3) is coated by a semi-conductive layer (4), three cores with coats are twisted together, while the twist distance is 20-200mm as best, to extrude an outer sleeve layer (6). The inventive product has high quality reliability, low cost, high temperature alarm sensitivity, to meet the demands of GB16280-2005 (linear temperature sensitive detector) and relative supplementary items.

Owner:张陈

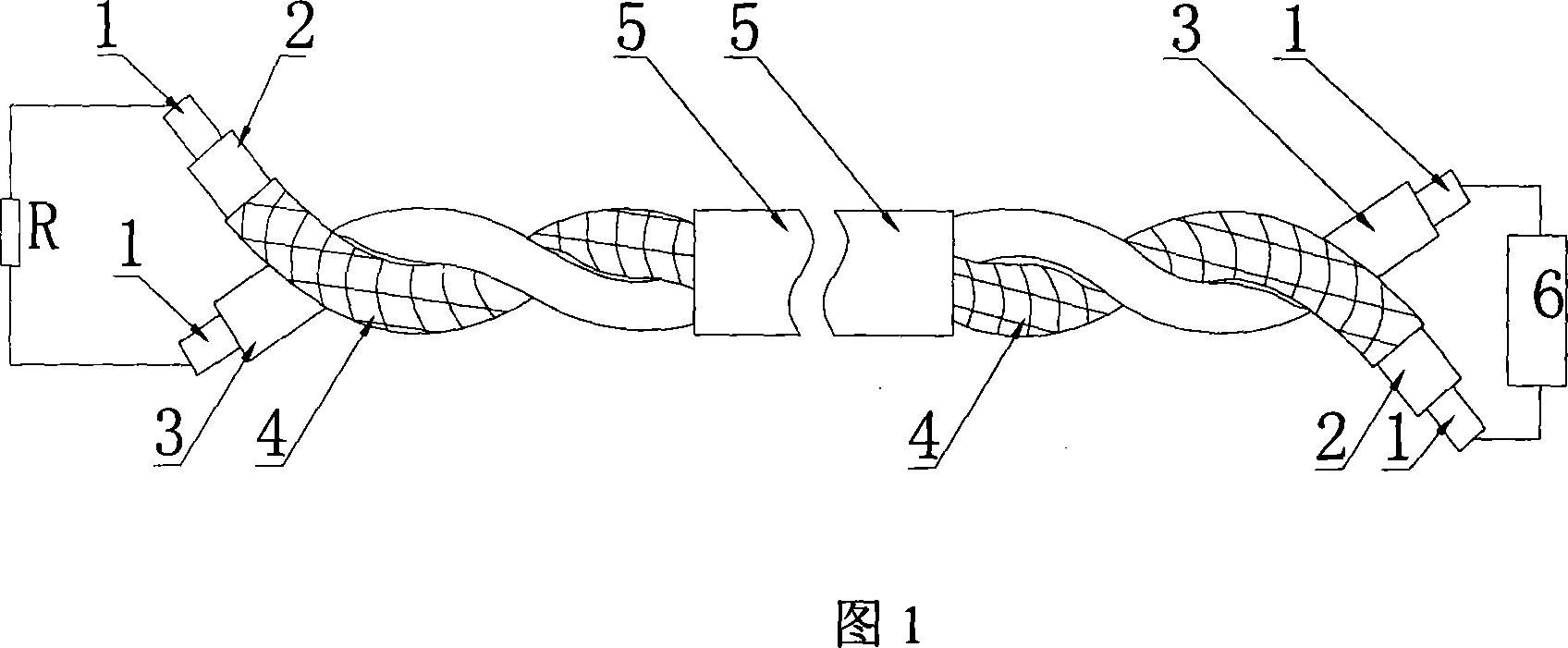

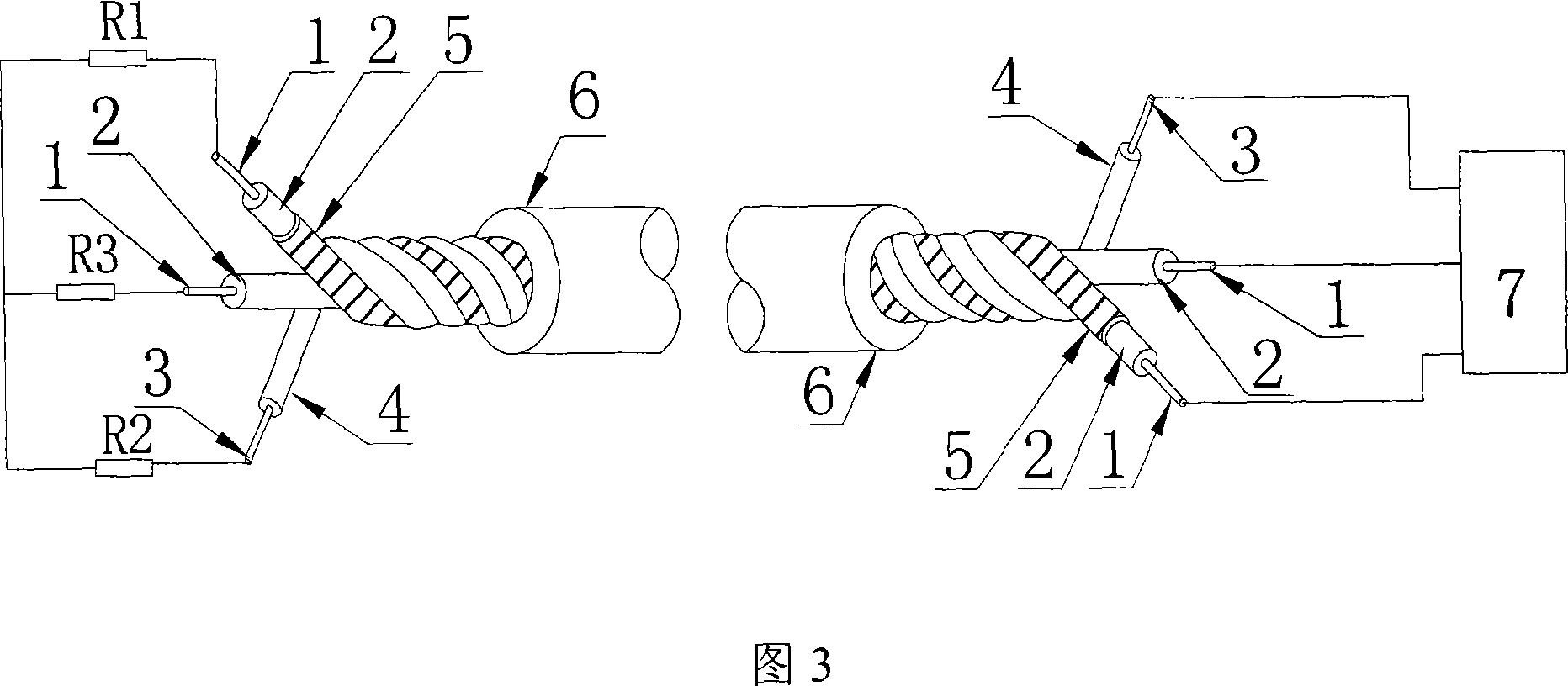

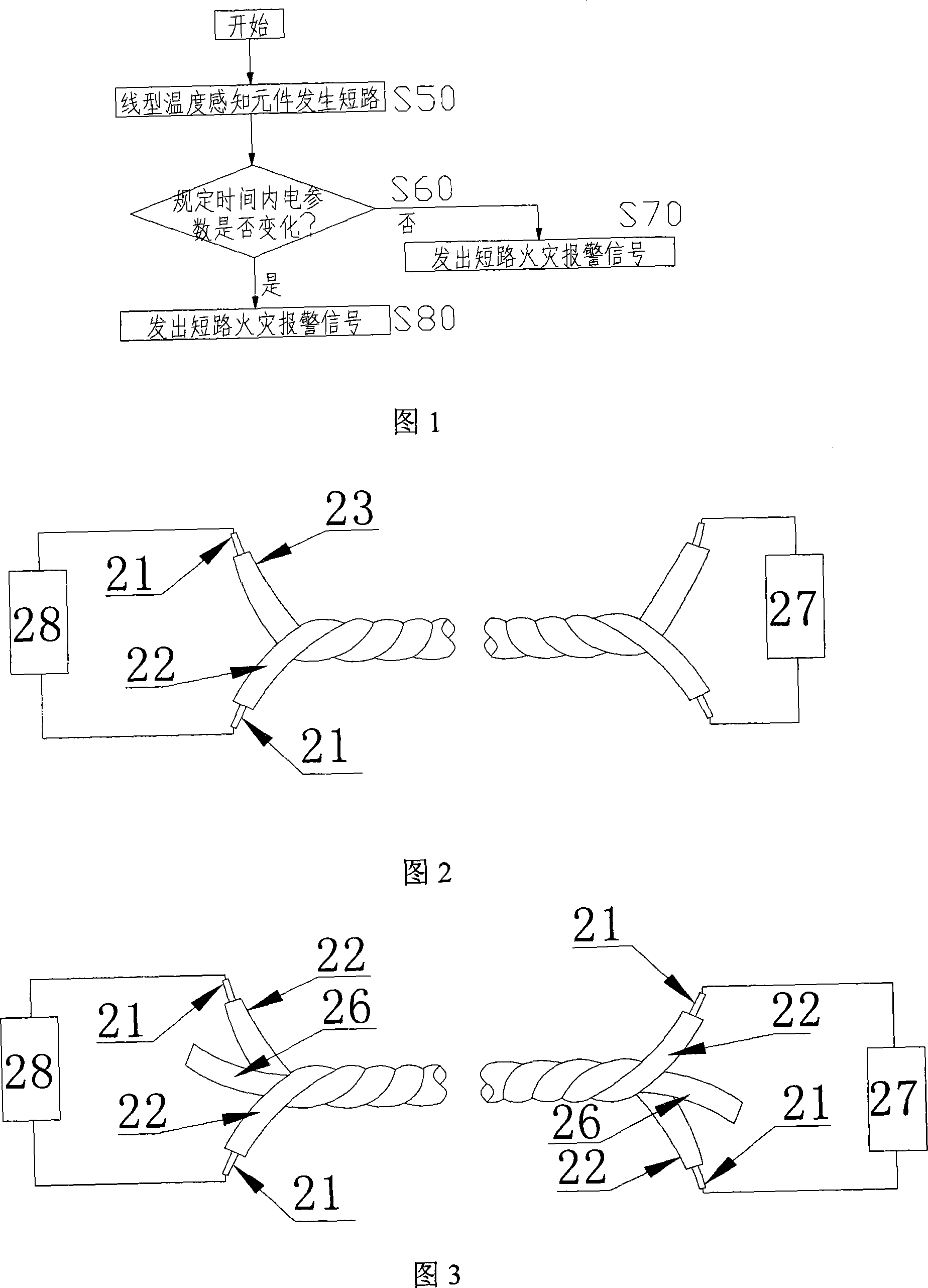

Rapid response on-off value linear temperature-sensitive detector and alarming method

InactiveCN101251944ASimple structureHigh alarm sensitivityCurrent/voltage measurementThermometers using electric/magnetic elementsElectrical conductorEngineering

The invention provides a quick response switching-value linear temperature-sensing detector and a warning method, implementing a warning of a switching-value fixed-temperature, an error output of short circuit, an error output of open circuit, and an error output of current failure of an electric signal processing device. The detector forms a closed circuit signal collection circuit by two ends of a temperature-sensing cable to be respectively connected with the electric signal processing device and a terminating resistance, and a resistance value of the terminating resistance R is optimized from 50 ohm to 50M ohm. The invention is characterized in that the temperature-sensing cable has a structure of three elastic metal conductors which are respectively covered by fusible or insulating material layers with Vicat softening points from 40 DEG C to 180 DEG C, three cores of conductors with coatings are intertwisted or wound together, a pitch of the intertwisting or winding is optimized from 20mm to 200mm, wherein one elastic metal conductor is used as a common port, while the other two metal conductors are used as a detecting end 1 and a detecting end 2 respectively.

Owner:张陈

Double temperature alarming irrecoverable type line type temperature-sensing detector

InactiveCN101149864AUse unlimited lengthSmall sectionThermometers using physical/chemical changesFire alarm electric actuationSemiconductor materialsInsulation layer

The wire-type non-restored two-temperature-alarming heat-sensing detector realizes two-grade fixed-temperature alarming and outputting of short-circuit break-circuit fault and the cut-off fault of a micro-computer modulator. Two ends of a heat-sensing cable are connected respectively with the micro-computer modulator and a terminal resistor to form a closed-circuit signal collection circuit. It is characterized in that the structure of the cable is three elastic metal conductors in which one is coated with an insulation material layer whose Vicat softening point is between 40-180 degree C, which can also be coated with or no aluminium-plastic or copper-plastic composite band or metal foil or conductive material layer, the other is coated with an insulation layer whose Vicat softening point is between 40-180 degree C and coated again with aluminium-plastic or copper-plastic composite band or metal foil or conductive material layer. The two conductor wires with same coatings or different coatings are twisted or wound together with a third conductor wire coated with a semi-conductor material layer and an external jacket is extruded on at same. The twisting or winding pitch of the three wires is optimized between 20mm-200mm.

Owner:张陈

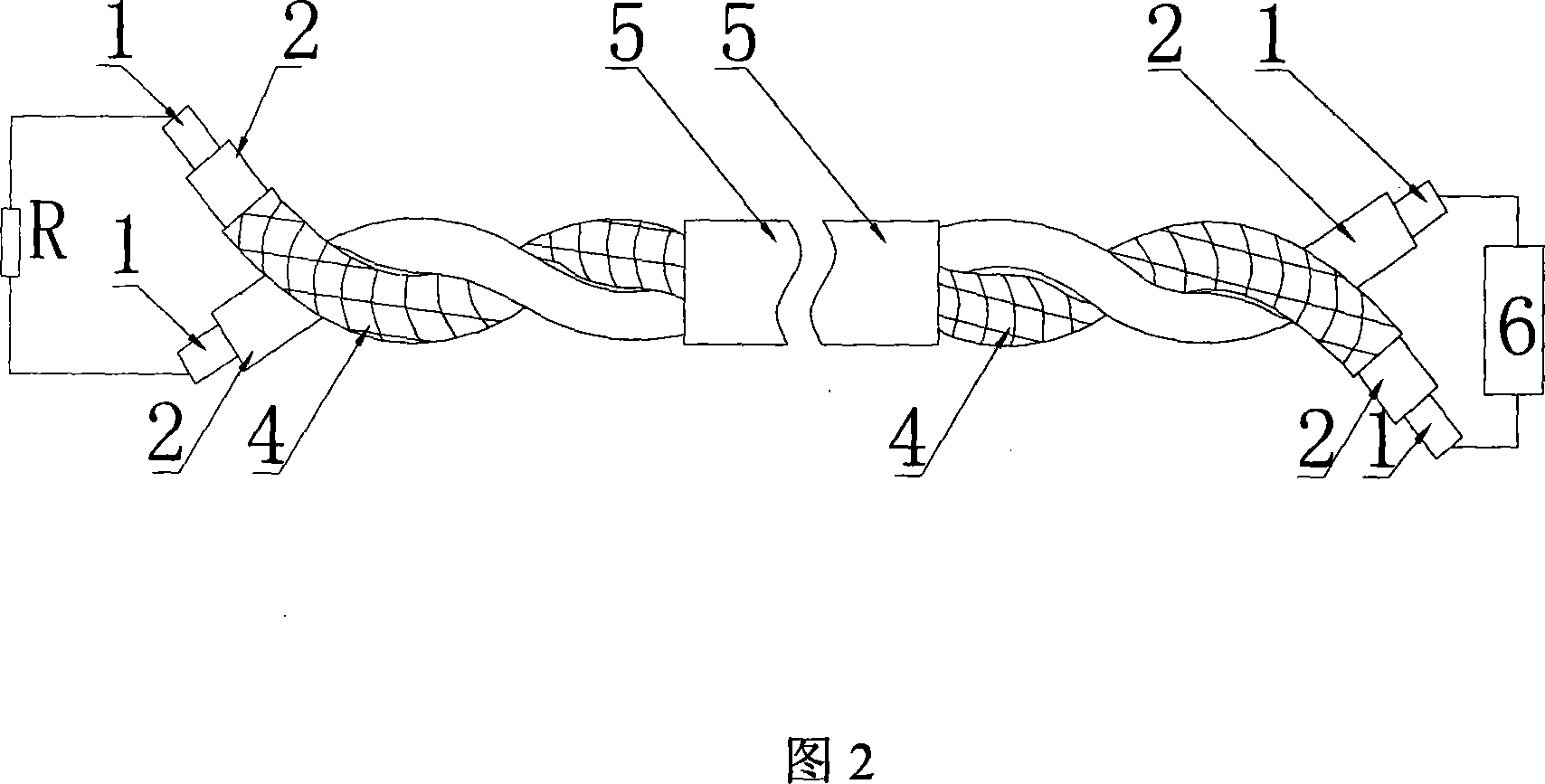

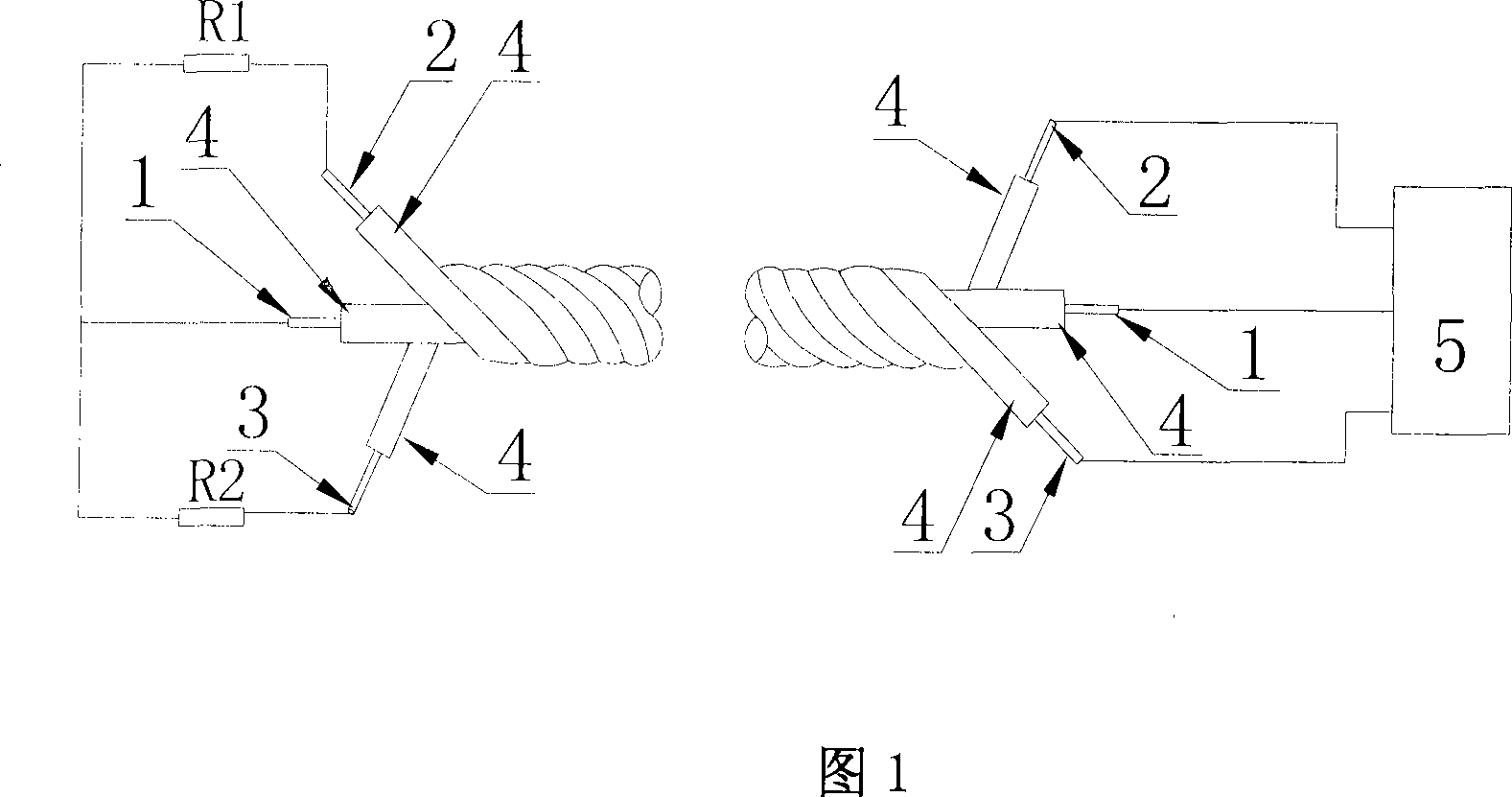

Switch quantity composite reparable cable-type line-type heat fire detector

InactiveCN101276505AImprove securityImprove reliabilityThermometers using electric/magnetic elementsElectrical testingElectrical conductorMetal foil

A switch amount resumable cable linetype temperature-sensing fire detector is provided, which can realize switch amount fixed temperature alarming, resumable temperature-sensing multi-stage alarming, short circuit fault alarming, circuit broken fault alarming, and electric signal processing device fault outputting. Two ends of a temperature-sensing cable are respectively connected with a microcomputer modulator and terminal resistors R1, R2 to form a closed-circuit signal collecting circuit, the fire detector is characterized in that, the structure of the temperature-sensing cable is configurated that, two elastic metal conductors are respectively coated with an insulative material layer, one of the elastic metal conductor coated with an insulative material layer is coated with an conductive layer which is an incontinuous conductive aluminium-plastic composite strip or copper plastic composite strip or metal foil; another metal wire is coated with a thermo-sensitive material layer with a critical temperature CTR; the three wire cores with coated layers are twisted together, wherein, the two elastic metal conductors with coated layers are twisted in a backtwist way, the metal wire with the coat layer is twisted with the two elastic metal conductors with coated layers in a filling way and then to extrusion-mold an oversheath layer.

Owner:张陈

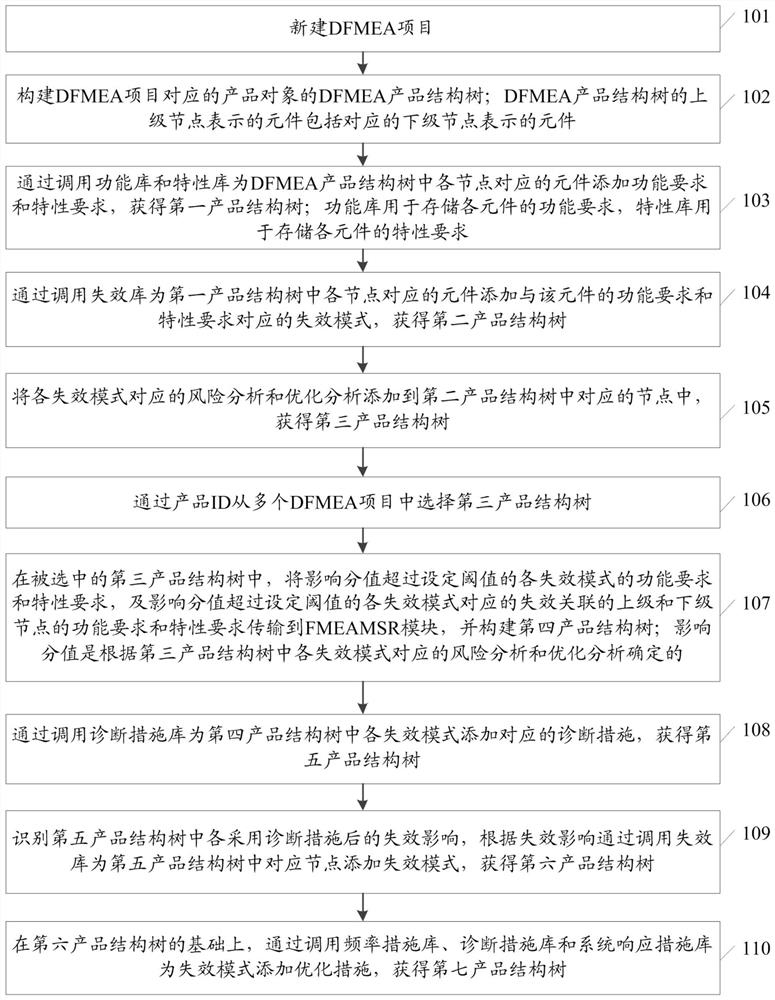

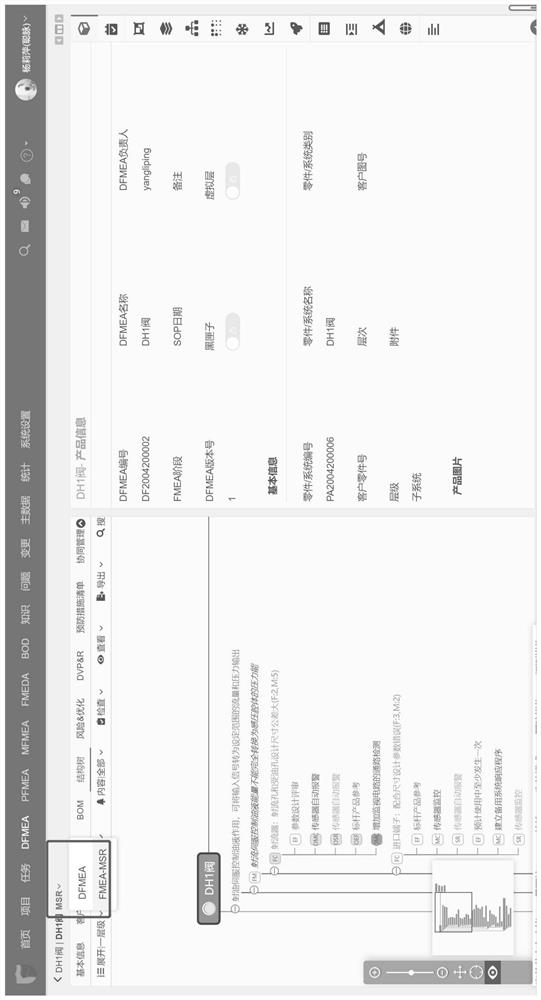

FMEA-MSR visualization method and system

PendingCN114201787AReduce riskHigh product quality and reliabilityComputer aided designSpecial data processing applicationsThresholdingComputer science

The invention relates to an FMEA-MSR visualization method and system, and the method comprises the steps: building a DFMEA product structure tree, and selecting the function requirements and characteristic requirements of all failure modes of which the influence scores exceed a set threshold value; the influence scores of the failure modes exceed a set threshold value, and function requirements and characteristic requirements of superior and subordinate nodes associated with failures corresponding to the failure modes are transmitted to an FMEA-MSR module, and a product structure tree is reconstructed according to the function requirements and the characteristic requirements transmitted to the FMEA-MSR module; and corresponding diagnosis measures and failure modes after the diagnosis measures are added are added to the reconstructed product structure tree, the failure influence is identified, and corresponding optimization measures are added, so that the product risk is reduced, and the product quality reliability is improved.

Owner:聪脉(上海)信息技术有限公司

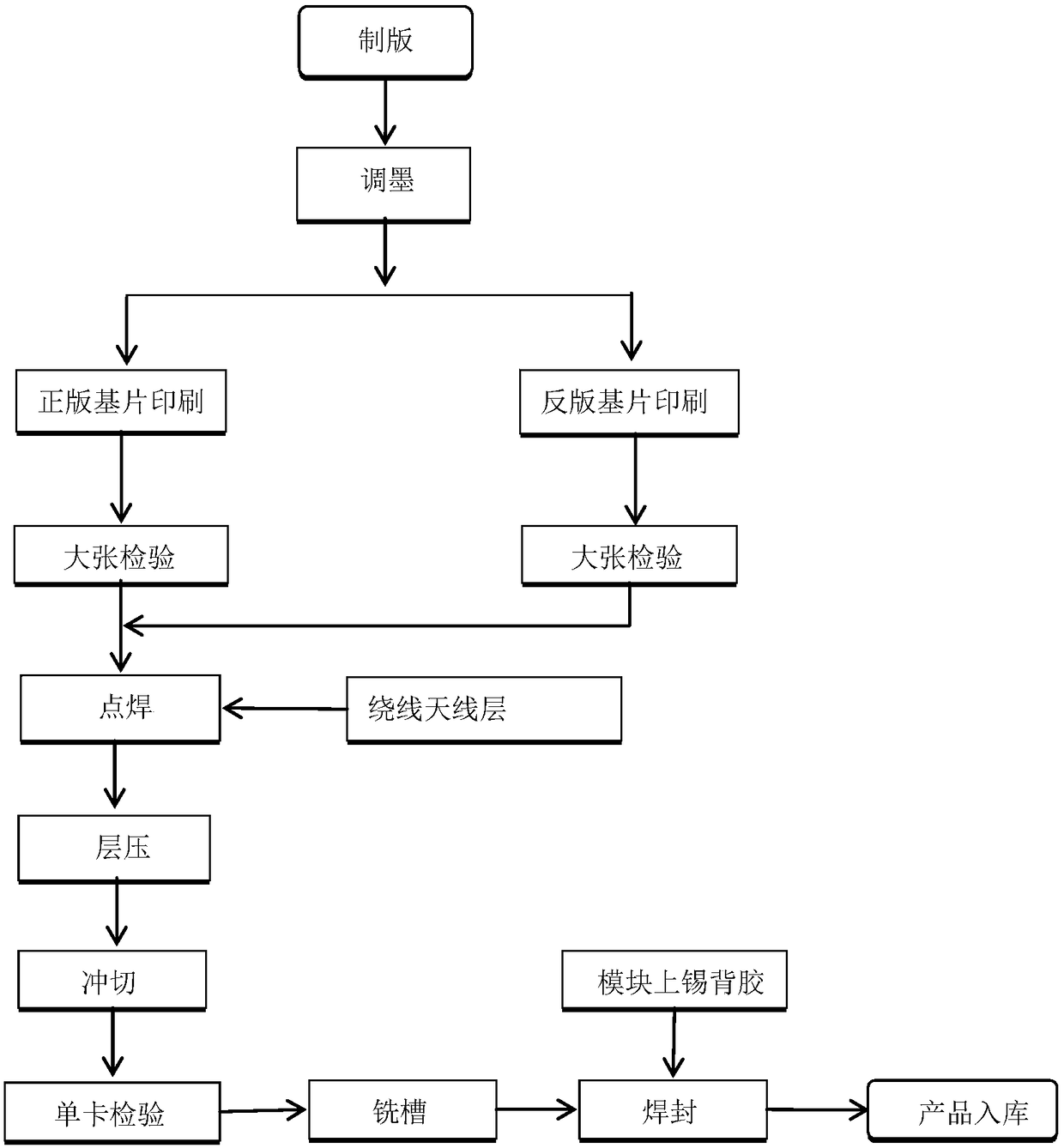

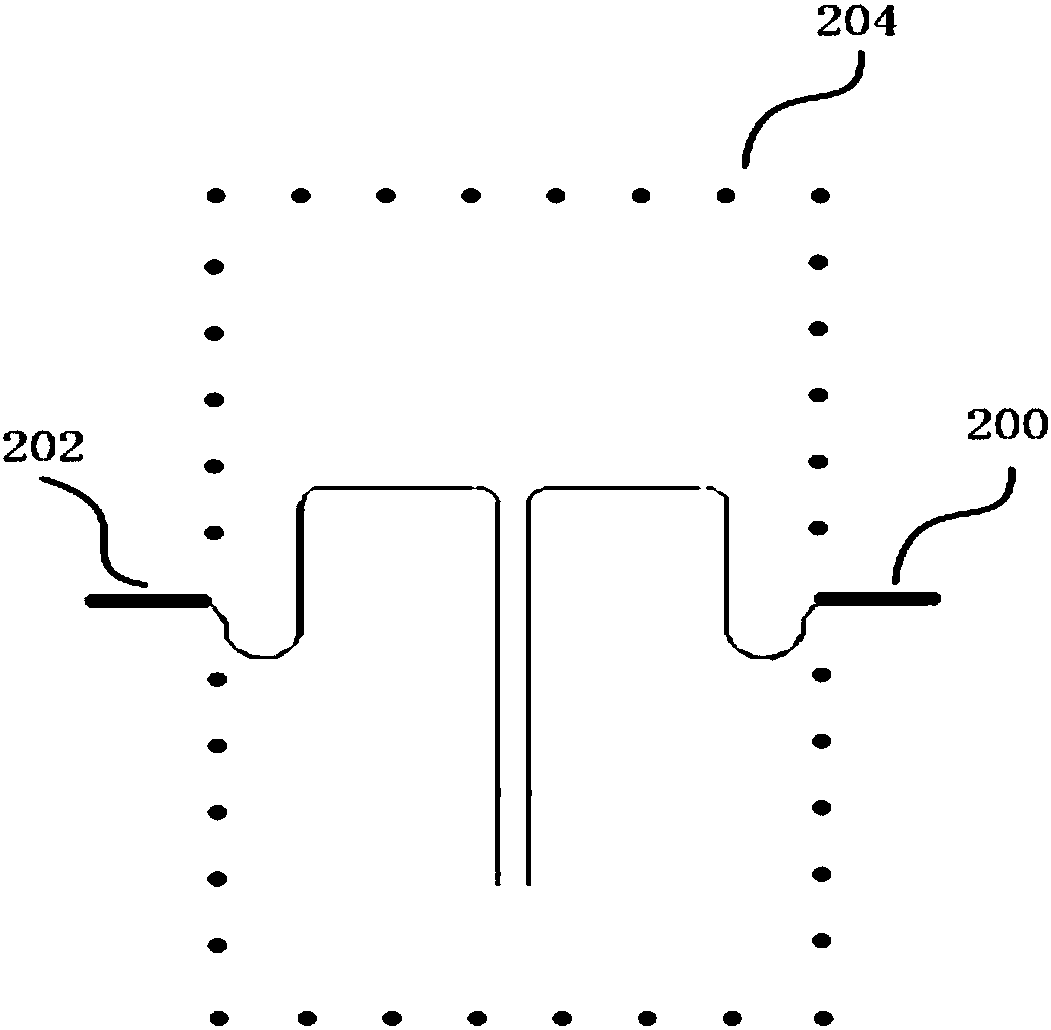

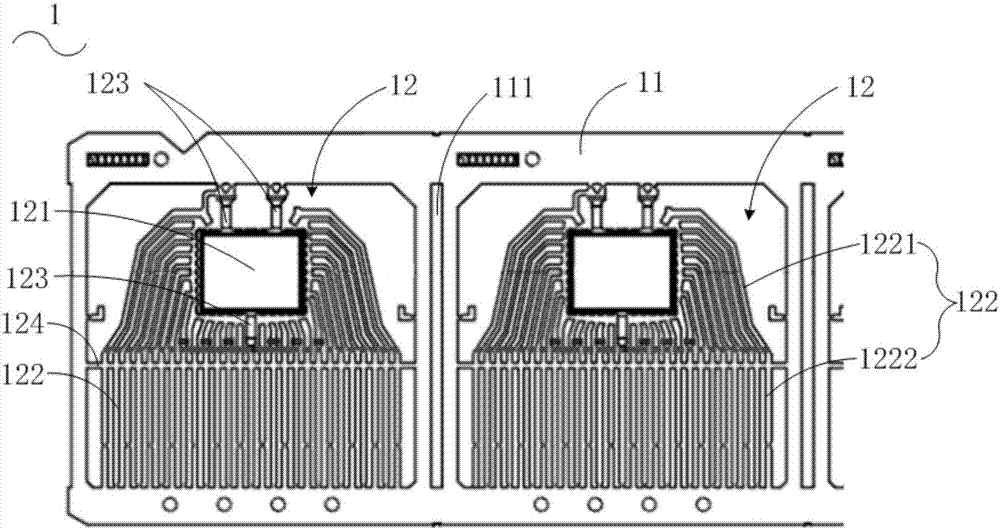

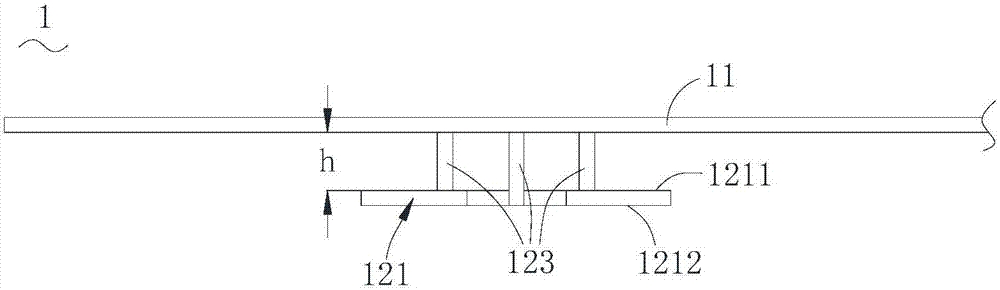

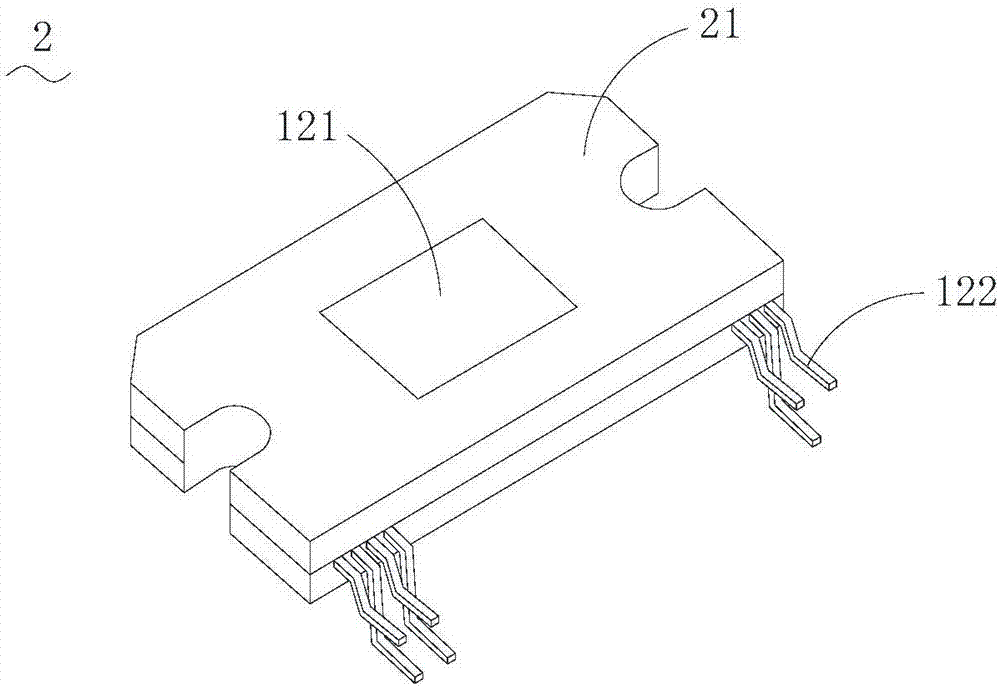

6PIN dual-interface chip smart card and preparation method thereof

The invention discloses a 6PIN dual-interface chip smart card and a preparation method thereof. The 6PIN dual-interface chip smart card comprises a 6PIN dual-interface chip module, a card body and a winding antenna, and the winding antenna is used for achieving welding sealing connection between the card body and the 6PIN dual-interface chip module. The 6PIN dual-interface chip smart card is characterized in that the winding antenna has an M-type winding head, and the length of the portion, between the 6PIN dual-interface chip module and the card body, of the head part of the winding antenna is 10-11 mm; the length of the portion, between the 6PIN dual-interface chip module and the card body, of the tail part of the winding antenna is 10-11 mm. According to the provided 6PIN dual-interfacechip smart card, the size of the chip module is 8.0*10.62mm, the area of the chip module is decreased, the cost is reduced, and more convenience is provided for a customer to conduct layout design ofthe card body. According to the provided preparation method for the chip smart card, the problem that the module reliability is reduced due to too high temperature during tinning is solved, and the quality of a prepared product is stable and reliable.

Owner:GIESECKE & DEVRIENT (CHINA) INFORMATION TECH CO LTD

New process for producing heating tube for washing machine

InactiveCN104057248AModerate densitySimple processOther washing machinesTextiles and paperVolumetric Mass DensityPulp and paper industry

The invention relates to the technical field of washing machine heating tube production, and discloses a new process for producing a heating tube for a washing machine. The new process comprises the following steps: (1) filling a tube, (2) filling powder, (3) contracting the tube, (4) sealing the tube, and (5) performing oil pressurizing. The new process for producing the heating tube for the washing machine is simple, few in production procedures, low in cost, and less in sizing reduction, the density of insulating medium magnesium oxide filled inside is moderate, obvious wrinkle and crack phenomena in direct formation can be avoided, the processing quality of the product is ensured, the consistency of the product appearance is better, and the reliability of the product quality is greatly improved.

Owner:ANHUI NINGGUO CITY TIANCHENG TECH DEV

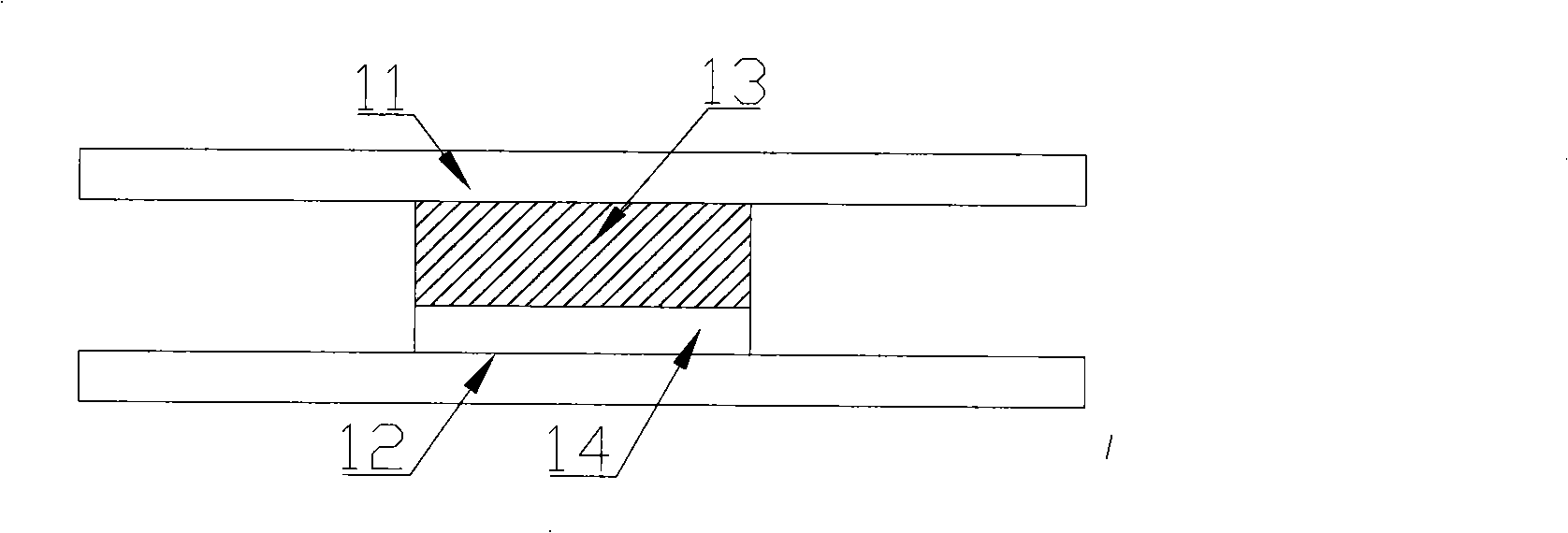

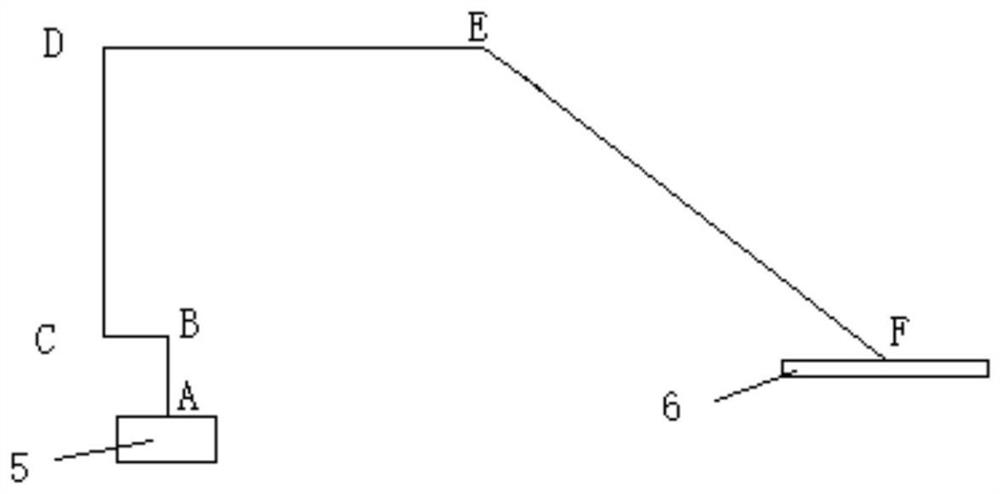

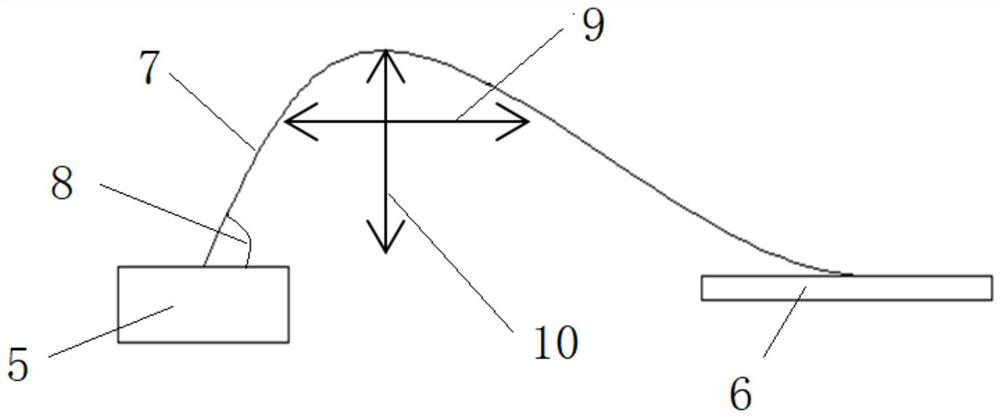

Bonding method for preventing injection molding deformation of long-span bonding lead of integrated circuit

PendingCN112687648ASolve the problem of line arc injection deformationSolve the problem of injection molding deformationSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingLead bonding

The invention discloses a bonding method for preventing injection molding deformation of a long-span bonding lead of an integrated circuit, and the method comprises the following steps: enabling a set gold wire to penetrate into a hole at the top of a chopper, and to penetrate out of a port at the bottom of the chopper; enabling the chopper port to drive the bonding wire to be bonded at the first bonding point A; enabling the port of the chopper to rise backwards to a set height point B according to a set inclination angle; translating the port of the chopper backwards to a set distance C point; vertically lifting the chopper port to a set height D point; moving the port of the chopper to a point E forwards and upwards according to a set height and a set distance; and moving the chopper port forwards and downwards to a second bonding point F to finish bonding and finish lead bonding between the first bonding point A and the second bonding point F. The problem that in an existing plastic packaging technology, under the conditions that the number of pins is large, the distance is small, gold wires are thin, and the span is long, a long-span bonding wire arc is deformed through injection molding is solved. And the method can be popularized to similar long-span lead wire key products according to the wire diameter of the gold wire.

Owner:GUIZHOU ZHENHUA FENGGUANG SEMICON

Recoverable cable type linear temperature-sensing detector

ActiveCN100588921CAchieve reuseThe alarm temperature is not limited by the length of useThermometers using electric/magnetic elementsUsing electrical meansElectrical conductorBand shape

The invention relates to a recovery cable linear temperature detector. As two ends of temperature cable are connected with microcomputer modulator and terminal resistance R respectively a closed signal collection circuit is formed. It is characterized in that the structure of temperature cable is that an elastic metal conductor is covered by melting NTC characteristic material layer with vicat softening point in 40deg.C-180deg.C; anther is an elastic metal conductor; after a hole belt or net insulation obstructing layer is set between two line cores they are twisted or winded; finally they arecovered by outer sleeve layer in plastic protrusion together. Multiple starting resistance values for alarming temperature signals heated on one meter of temperature cable are set in memory of microcomputer modulator, which inspects resistance change of melting NTC characteristic material layer between conductors. When circumstance temperature makes melting NTC characteristic layer soften, elastic metal conduct and melting NTC characteristic material layer forms short circuit so that output of alarming signal of given temperature is realized. When short circuit and open circuit happen betweentwo conductors by not fire factor, failure signals of short circuit and open circuit are outputted by microcomputer modulator. It is provided with simple process, high productivity and low producingcost.

Owner:SHENYANG P T SECURITY TECH

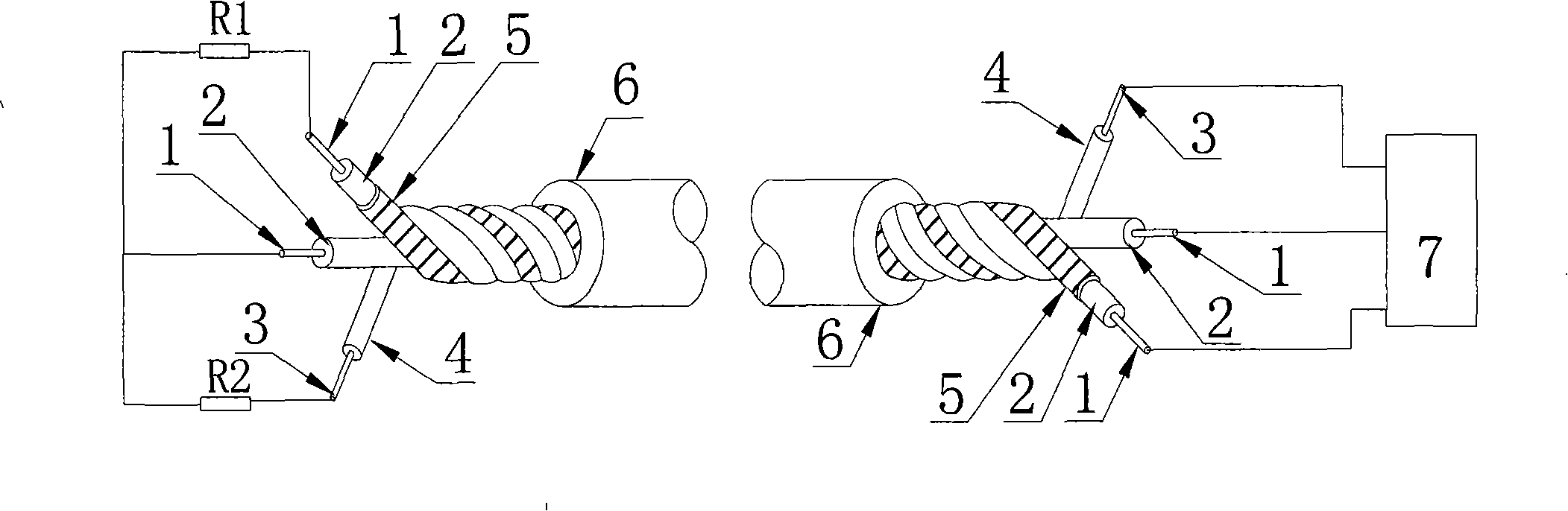

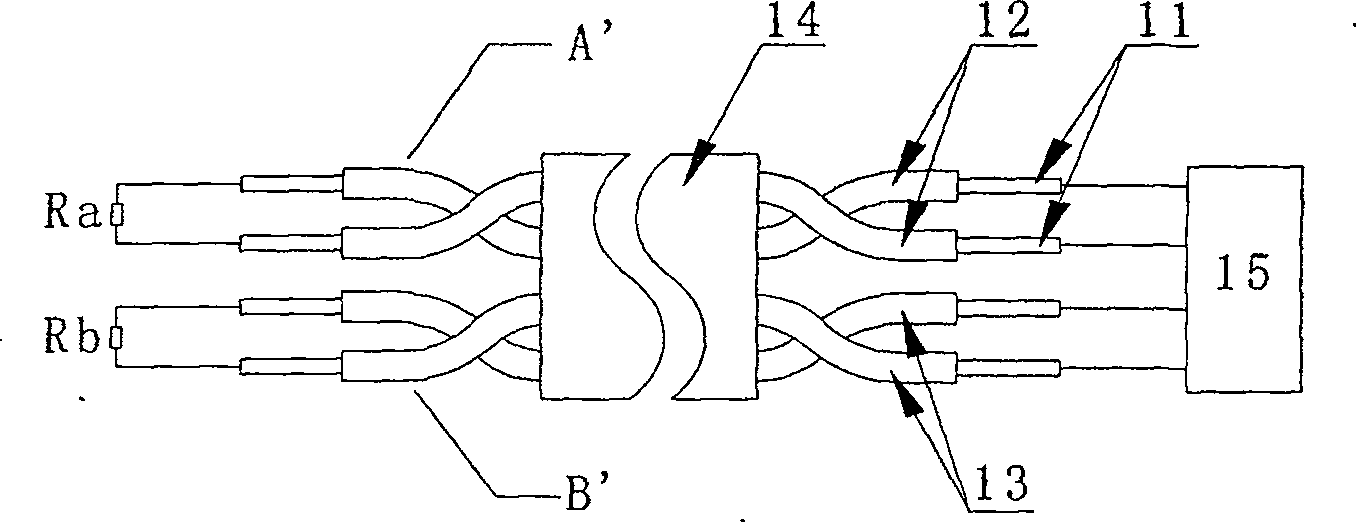

Recoverable cable type linear temperature difference-sensing detector

ActiveCN100495455CImprove reliabilityOmit judgment processingThermometers using electric/magnetic elementsInsulated cablesCapacitanceInsulation layer

A restorable cable-type temperature difference and sensing detector consists of a microcomputer modulator and a temperature sensing cable, and a terminal processor. The detector is characterized in that the temperature sensing cable in the detector is composed of a line-type temperature sensing component C and a line-type temperature sensing component D, which can generate two same equivalent electric parameter signals. The electric parameter signals can be voltage, resistance, capacitance, etc. When the temperature rising speed reaches or exceeds 10 Celsius system / min, the electric parameter values of the line-type temperature sensing component C and D have unequal changes, since the temperature sensing component C or D with external protection layer or heat insulation layer has the different heat transmission coefficient with the sensing component C or D without external protection layer or heat insulation layer. If the absolute difference between the two electric parameters collected by the microcomputer modulator is above or equal to the preset value, the detector will send alarm signals to realize alarm of temperature difference.

Owner:SHENYANG P T SECURITY TECH

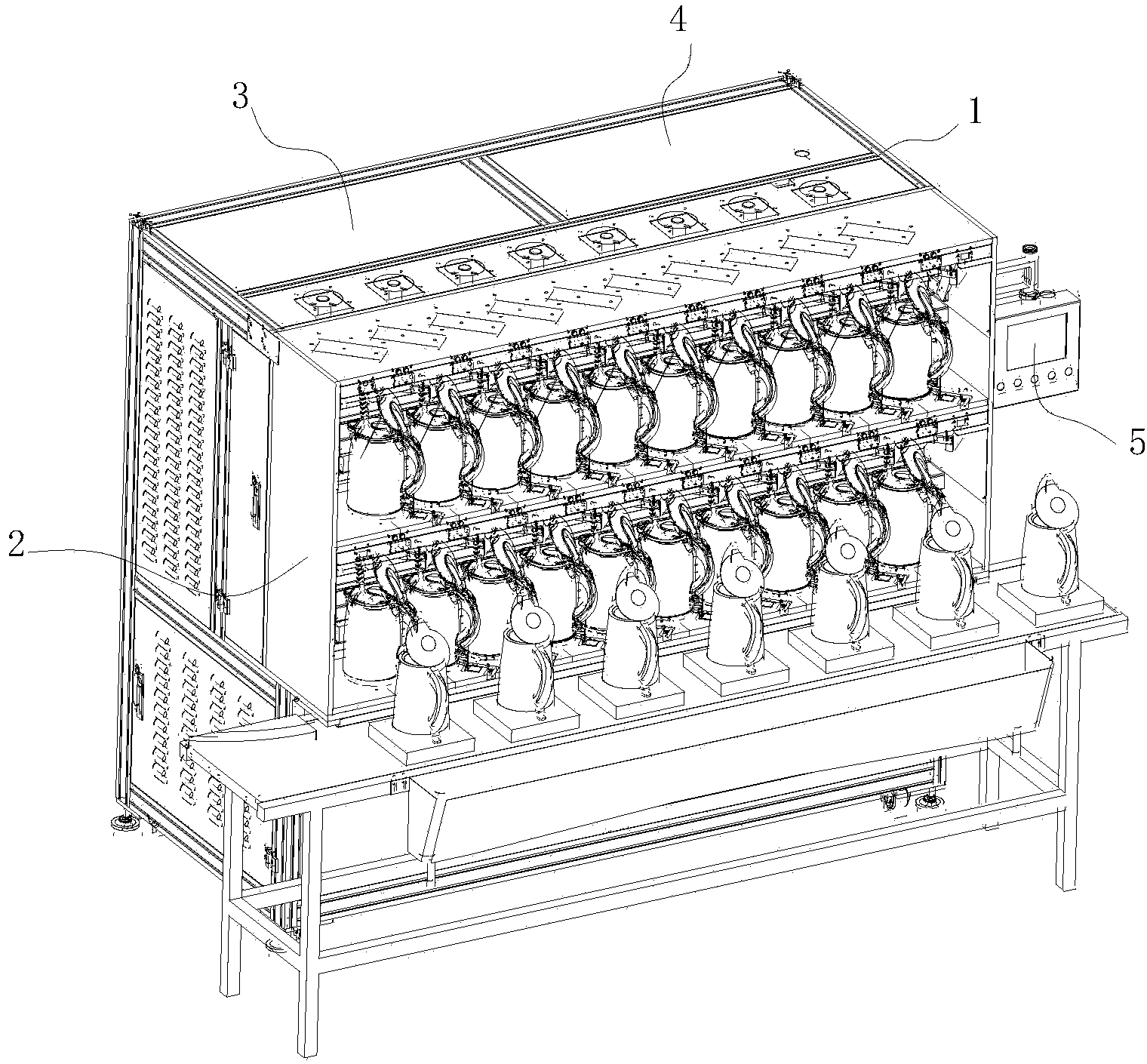

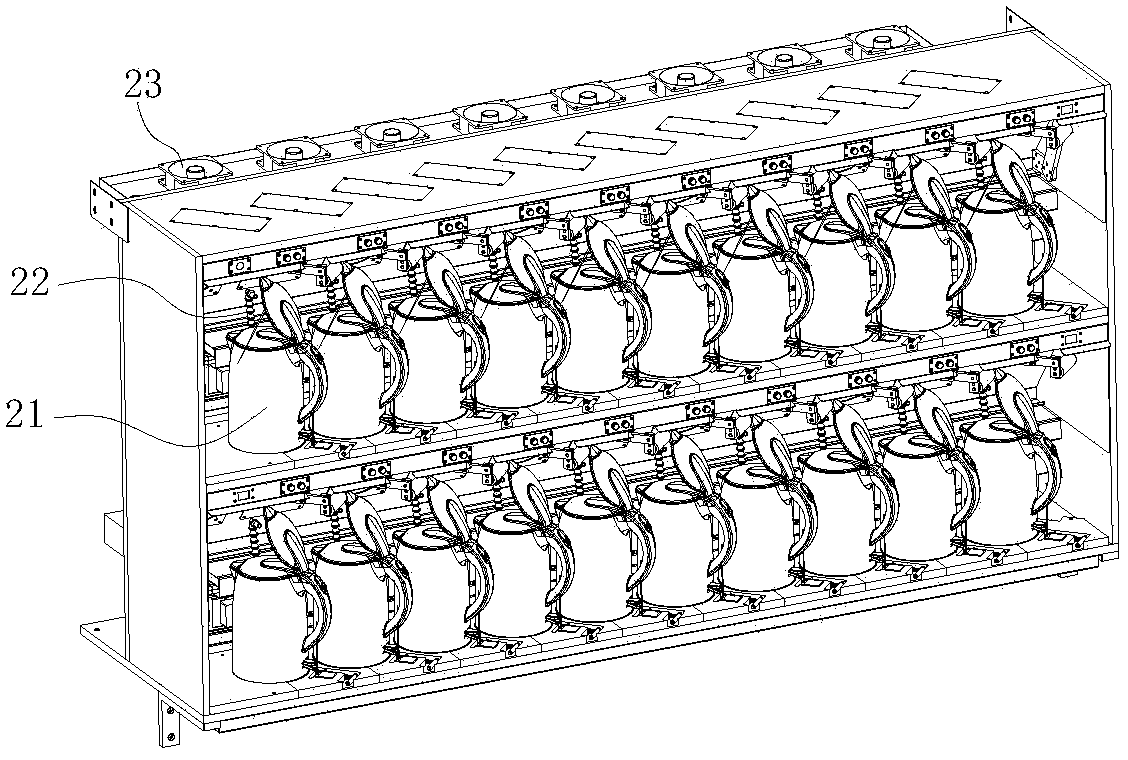

Electric kettle detecting device

ActiveCN104267279AReduce labor intensityImprove working environmentElectrical testingIndustrial AccidentEngineering

The invention belongs to the technical field of household appliance detection, and particularly relates to an electric kettle detecting device. The electric kettle detecting device comprises a rack, and the rack is provided with a testing cabinet, a water injection system, an electric control system and a turning touch screen. The water injection system and the electric control system are arranged on the back of the rack. The testing cabinet is arranged at the front portion of the rack. The testing cabinet is provided with a plurality of testing positions and a plurality of water injection nozzles, a plurality of steam exhausting fans are arranged on the top or the side of the testing cabinet, and a water drainage pipe is arranged at the side portion of the testing cabinet. According to the electric kettle detecting device, automatic testing and steam pumping and exhausting are achieved, the labor intensity of workers is relieved, the operating environment is improved, the problems that when water is boiled in a dry boiling mode, the manual detection omission ratio is very high, and scalding and other industrial accidents are prone to occurrence are solved, the dry-boiling water boiling testing omission ratio can be reduced, and the product quality reliability is enhanced, the production efficiency and the workshop manufacturing capacity are improved.

Owner:DONGGUAN GUANJIA ELECTRONICS EQUIP

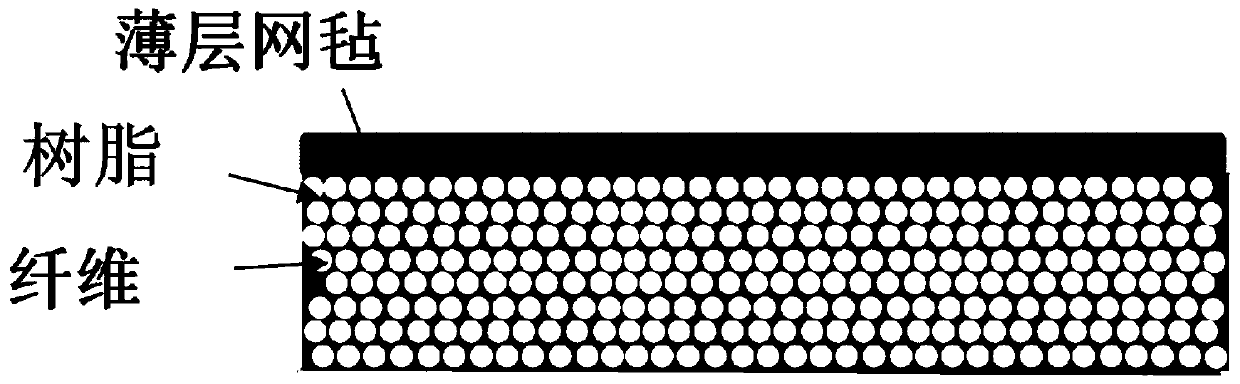

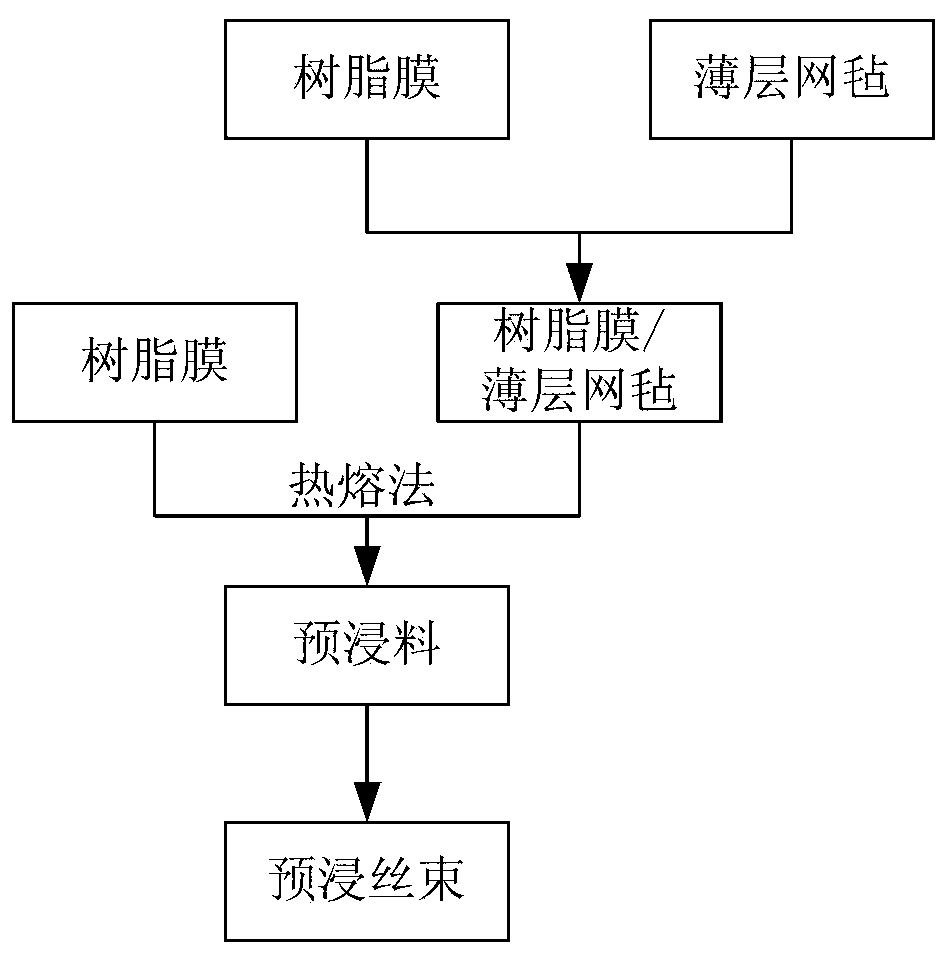

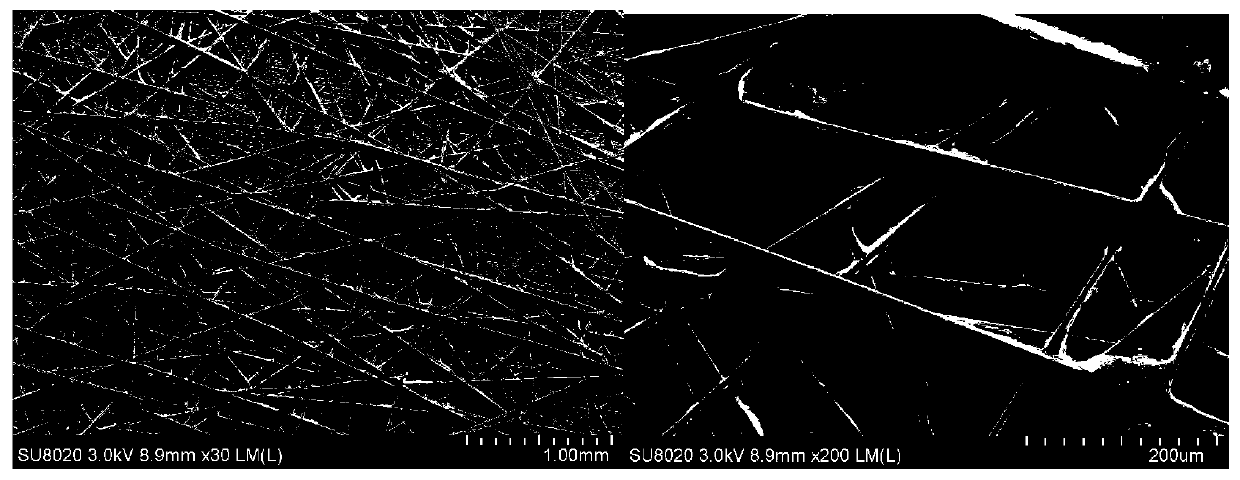

Prepreg and preparation method thereof

The invention provides a prepreg and a preparation method, the prepreg is composed of continuous reinforced fibers, a thin-layer mesh felt and resin, the prepreg is formed by compounding the continuous reinforced fibers and the thin-layer mesh felt by dipping in a double-sided resin film by a hot melting method, and the thin-layer mesh felt is located at one side of the continuous reinforced fibers, wherein the resin accounts for not more than 15% of the mass of the prepreg, the continuous reinforced fibers account for not less than 80% of the mass of the prepreg, and the balance is the thin-layer mesh felt. Through prepreg structure design and preparation process control, the prepreg meets the requirements of a subsequent slitting process and an RTM forming process, and is convenient to store and transport.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Laser-assisted nano-particle preparation method, and apparatus thereof

InactiveCN103585939AImprove stabilityHigh purityEnergy based chemical/physical/physico-chemical processesMicroballoon preparationMaterials preparationNanoparticle

The invention discloses a laser-assisted nano-particle preparation method, and an apparatus thereof, and belongs to the nano-material preparation field. The method comprises the following steps: a gaseous precursor is introduced into a plasma generating device and is activated by the plasma generating device, and the obtained activated gaseous precursor enters a reaction chamber; and laser beams emitted by a laser generating device pass are gathered through a lens on the wall of the reaction chamber, the gathered laser beams enter the reaction chamber and heat the activated gaseous precursor in the reaction chamber to crack the activated gaseous precursor in order to obtain active nano-particles, and the active nano-particles are collected by a collector. The nano-particle preparation method and the apparatus have the advantages of substantial reduction of the production cost, simple apparatus and good technological stability; and the prepared nano-particles have the advantages of high purity, good stability, uniform morphological particle size, high quality reliability and high yield.

Owner:李学耕 +1

Lead frame, semiconductor device and packaging technology thereof

PendingCN107481990ANo rebound desoldering phenomenonGood value for moneySemiconductor/solid-state device detailsSolid-state devicesDevice materialStructural engineering

The invention provides a lead frame, a semiconductor device and a packaging technology of the semiconductor device. The lead frame comprises a border and multiple chip packaging units arranged in the border in the length direction of the border; each chip packaging unit comprises a chip base island, multiple pins and multiple splice bars connecting the chip base island with the border; all the pins and the border are located on the same plane, a height variation exists between the chip base island and the plane where the border is located, and then after packaging is conducted, the back surface of the chip base island can be exposed for cooling. According to the lead frame, a cooling fin in the prior art is omitted, the cost performance is high, correspondingly, the process of riveting the cooling pin in the prior art is omitted in the lead frame manufacturing process, and the defect that poor contact is caused by riveting is overcome; when the lead frame is packaged, the possibility that soldering tin is splashed to the pins can be lowered, and the frequency of occurrence of open circuit and short circuit is lowered; in addition, the fins can be clamped and fixed from the two sides of the pins for wire soldering, wire soldering is more stable, and the reliability of the product quality is improved.

Owner:SHENZHEN STS MICROELECTRONICS

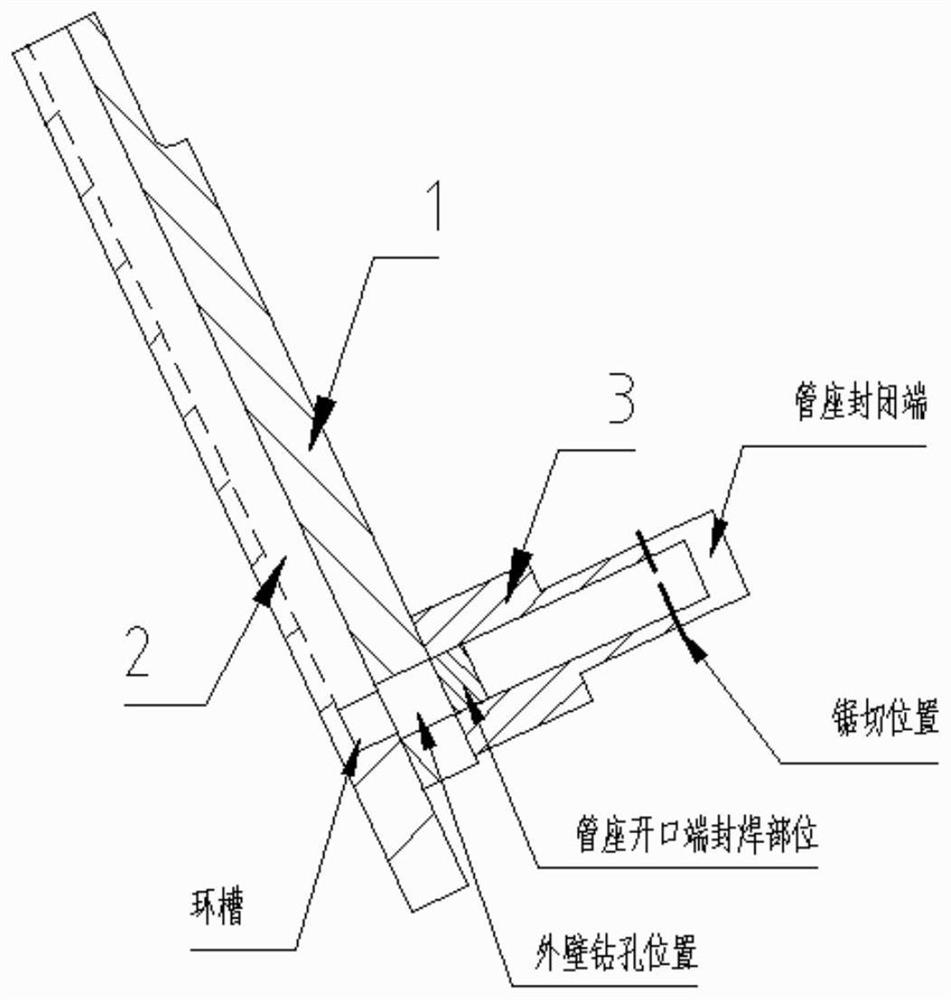

Method for eliminating brazing blockage of tube-seat ring-shaped workpiece of stainless steel sandwich structure

The invention relates to a method for eliminating the brazing blockage of a tube-seat ring-shaped workpiece of a stainless steel sandwich structure. The method comprises the following steps: measuring and recording the axial distance L1 between the inner-wall large-end ring-shaped groove center and the large-end surface; marking out an outer-wall drilling position line on the outer-wall outer surface according to the axial size L1-L2 with the outer-wall large-end surface as a reference, and carrying out drilling with the position line as a reference; carrying out seal welding on the open end of a tube seat by the adoption of manual argon arc welding, and grinding the welded open end to be level; welding the tube seat to the outer-wall drilling part, and sawing the closed end of the tube seat so as to turn the tube seat into an open state; electroplating nickel on the outer-wall inner surface and the inner-wall outer surface, and and carrying out spot welding on the inner-wall rib surface by using a brazing material; pressing the inner and outer walls, and carrying out seal welding on the large and small ends through manual argon arc welding; and carrying out brazing on the inner and outer walls, and carrying out X-ray inspection. Through the method, the brazing blockage can be eliminated; the adoption of a mechanical method for blockage elimination as well as manual argon repair welding or repeated brazing can be avoided; the product production progress can be guaranteed; the production cost can be reduced; and the product quality reliability can be improved.

Owner:XIAN SPACE ENGINE CO LTD

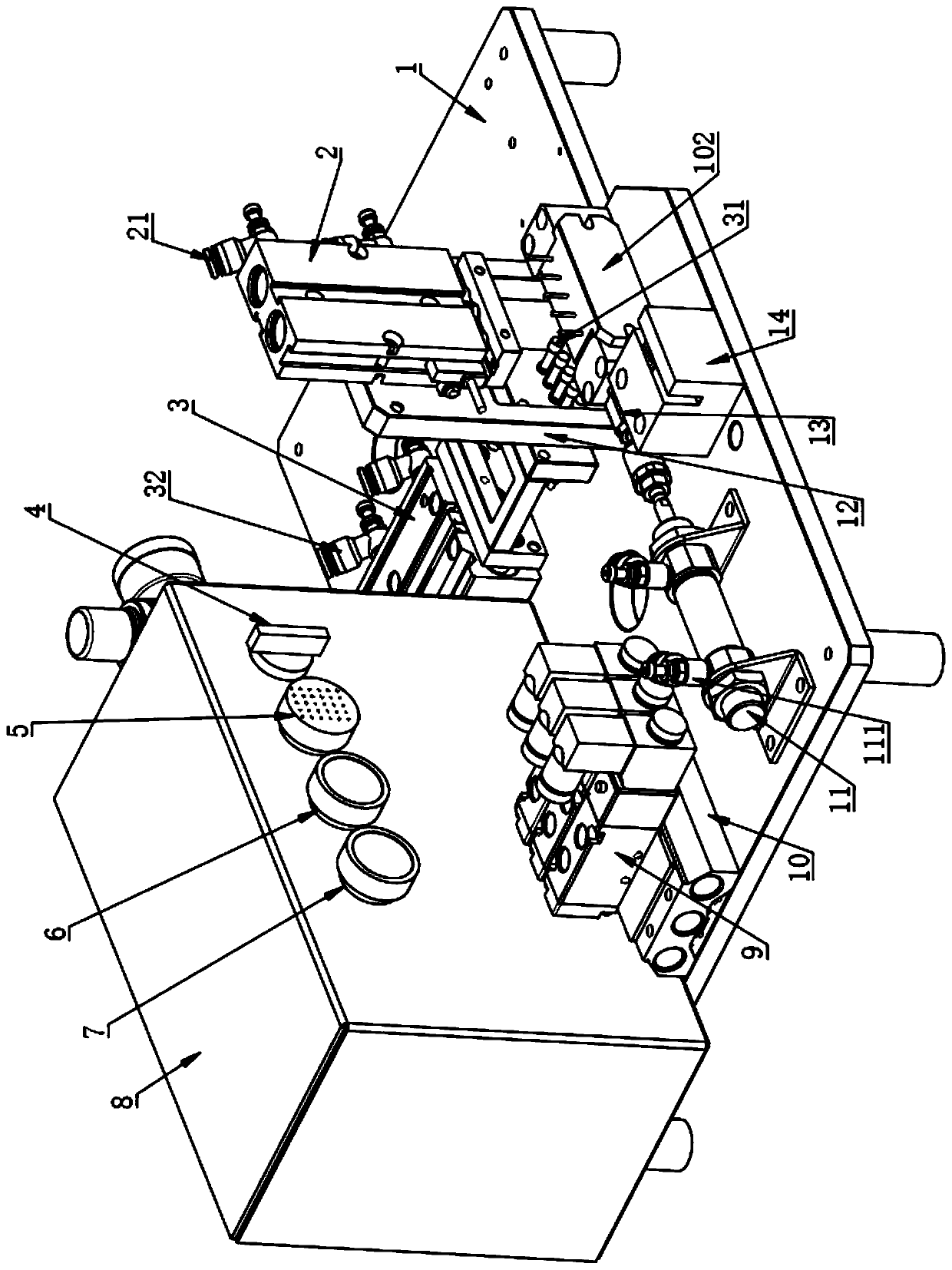

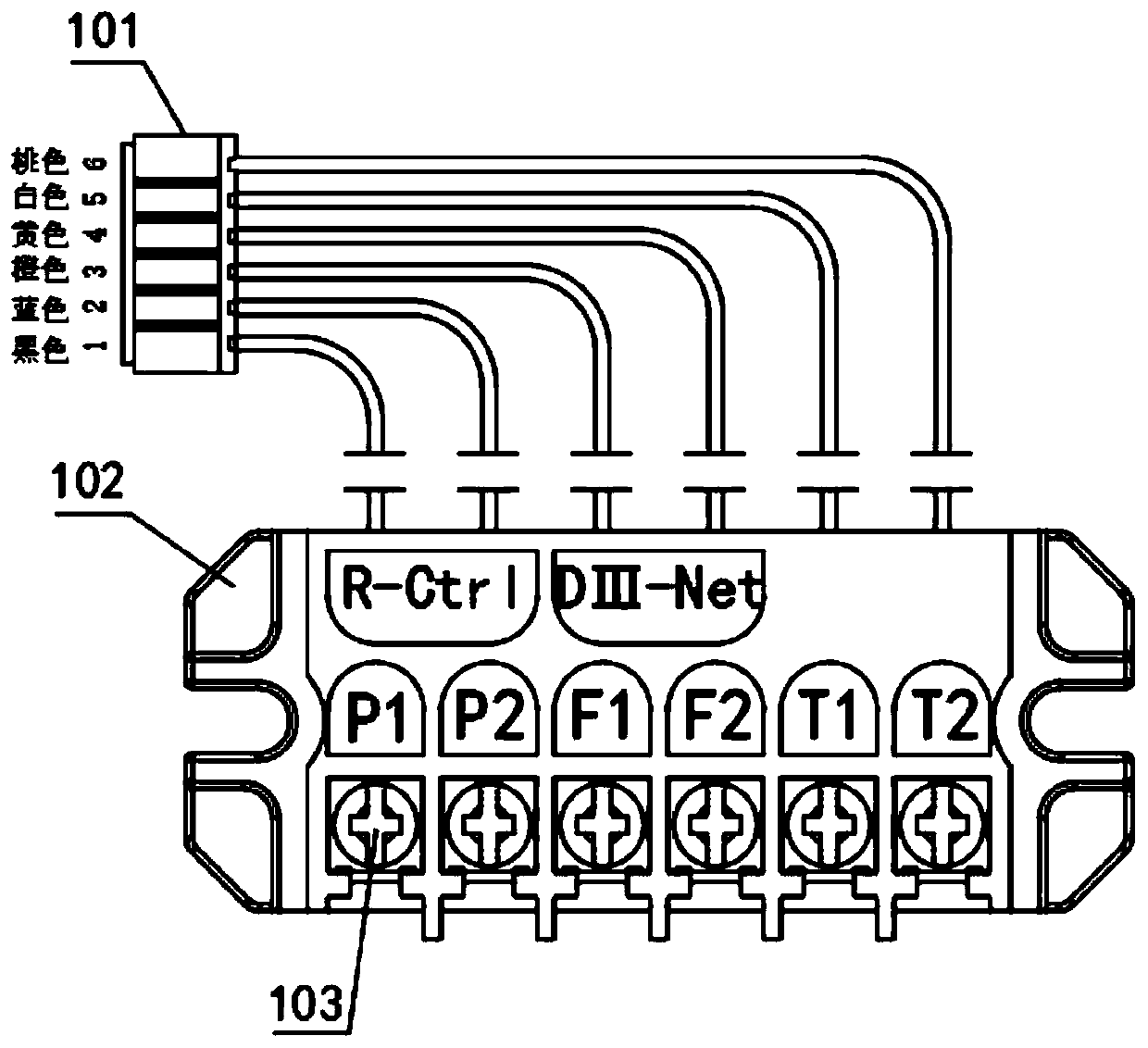

On-off tester for testing terminal blocks

According to an on-off tester for testing terminal blocks, a first cylinder on a platform support presses a connection terminal shell of a terminal block product to be tested; a lead end is in matching and inserting communication with a lead end connecting jig; and a second cylinder detection probe is in contact and is conducted with a press connecting bolt to form a detection loop, wherein whether a product is qualified or not is judged by an on-off condition of the detection loop. When a product is qualified, a magnetic switch sends a starting signal to a PLC controller; a third cylinder marks a side surface of a terminal end of the terminal block product to be tested with dots; a first cylinder and a second cylinder are released and retraced; and the qualified product which is marked with dots can enter a next process. Unqualified products are continuously pressed by the first cylinder and the second cylinder, the unqualified products can be taken out only by manually pressing a reset button, and the unqualified products are not marked with dots, so that the unqualified products are easy to distinguish and cannot enter the next process. The test result is accurate, and reliability of the product quality is improved. Professional wire testing instruments do not need to be purchase, and the on-off tester has a simple structure, is convenient to operate, and is low in production, manufacture, use and maintenance cost.

Owner:镇江宏联电工有限公司

A multifunctional vertical twisting and twisting machine

ActiveCN105139966BImprove boot utilizationLow input costCable/conductor manufactureCable machineEngineering

Owner:万达集团股份有限公司 +1

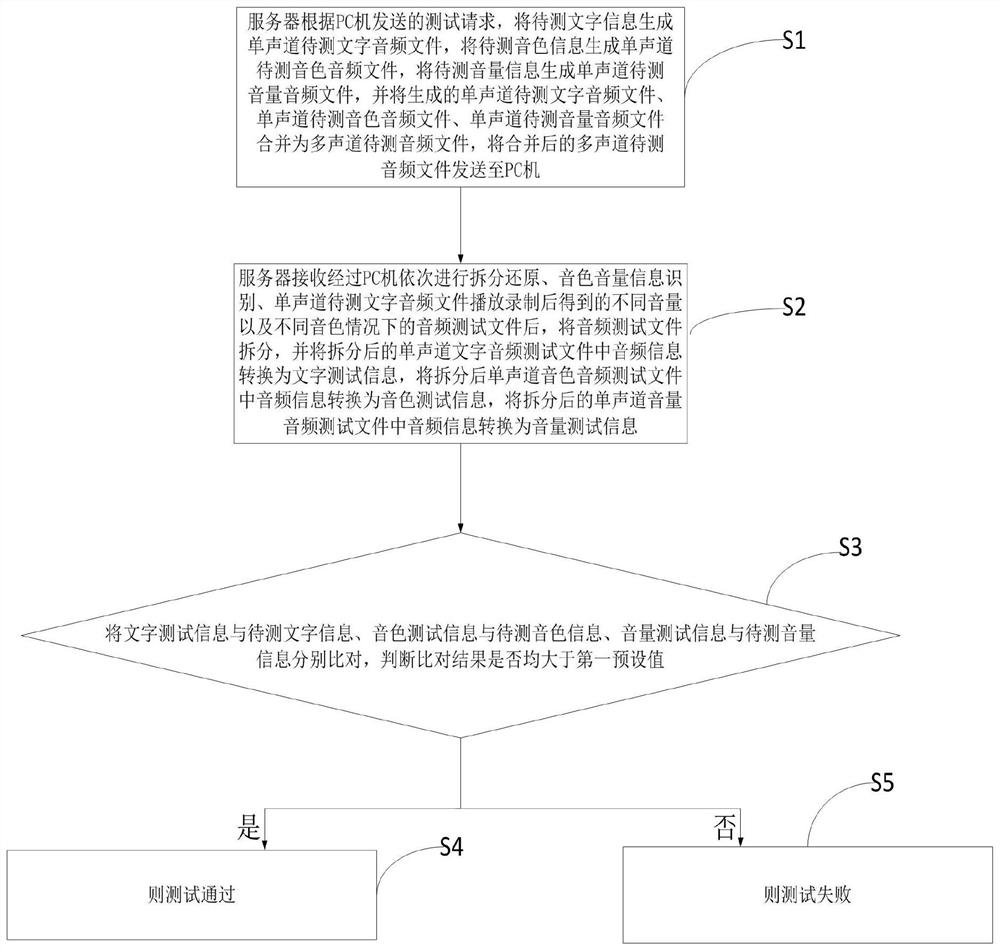

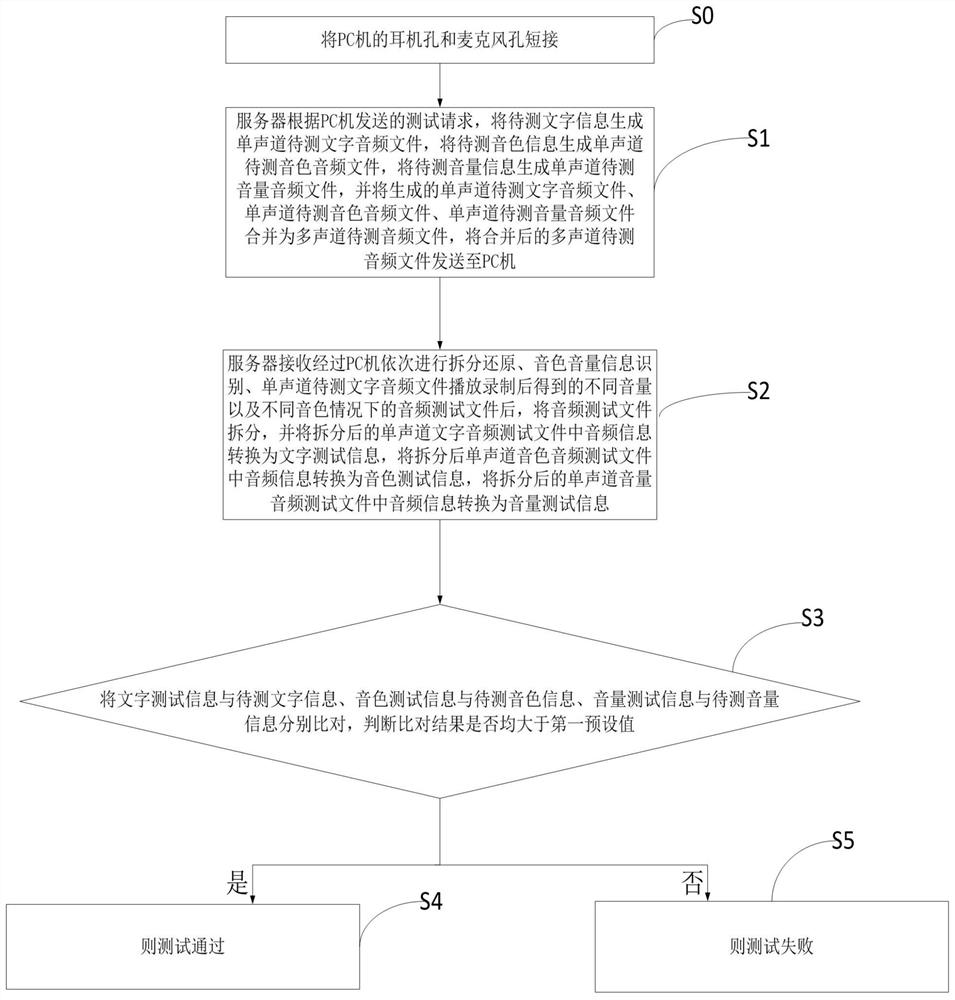

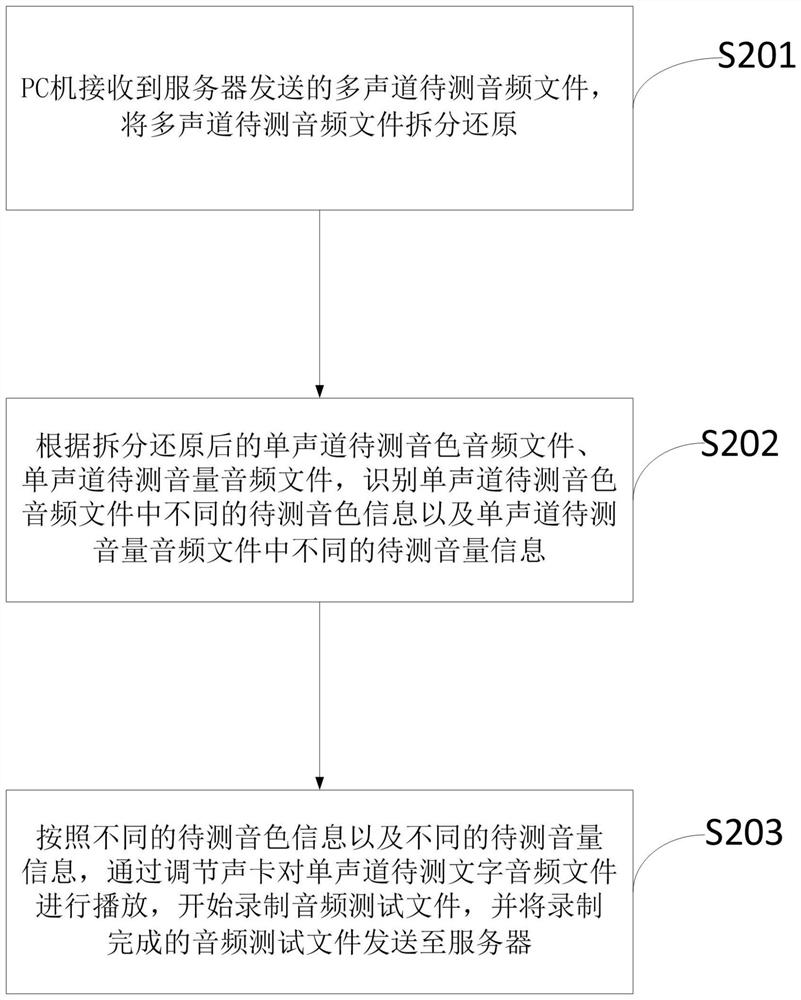

Method, device and system for testing sound card of PC (Personal Computer)

The invention provides a PC (Personal Computer) sound card testing method, which comprises the following steps: combining, by a server, a generated single-track to-be-tested character audio file, a single-track to-be-tested tone audio file and a single-track to-be-tested volume audio file into a multi-track to-be-tested audio file, and sending the multi-track to-be-tested audio file to a PC; receiving an audio test file under the conditions of different volumes and different timbres, which is obtained by sequentially carrying out splitting restoration, timbre volume information identification and single-track to-be-tested character audio file playing and recording through a PC (Personal Computer), and then splitting the audio test file; and comparing the character test information with the to-be-tested character information, the timbre test information with the to-be-tested timbre information and the volume test information with the to-be-tested volume information respectively. The invention further provides a PC sound card testing device and system; the accuracy and reliability of PC sound card testing can be improved, and the testing efficiency of the PC sound card under the conditions of different volumes and different timbres can be further improved.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

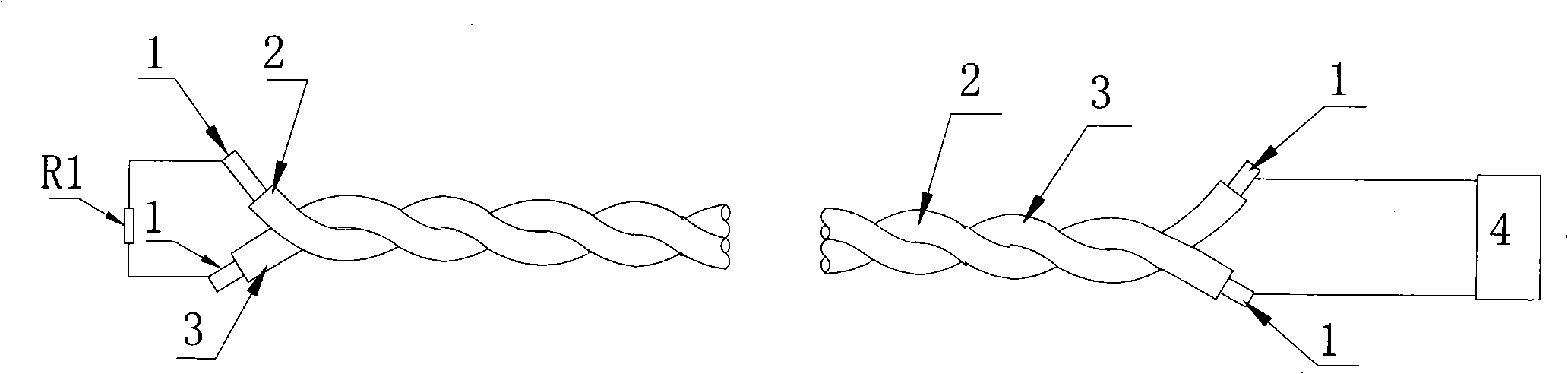

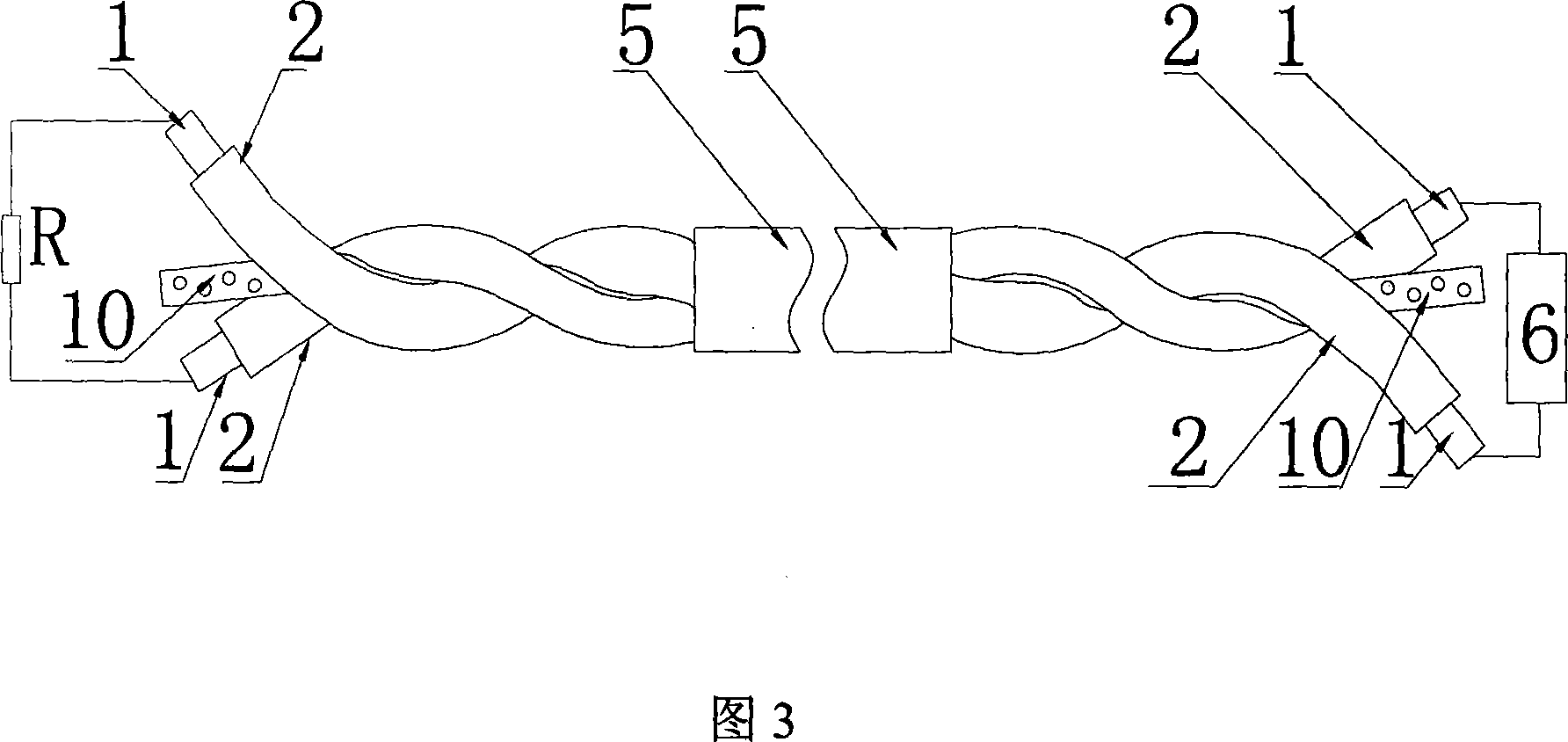

Beyond retrieve type single temperature alarming functional failure output linetype temperature-sensitive detector

InactiveCN101136128AUse unlimited lengthHigh product quality and reliabilityAlarmsElectrical resistance and conductanceElectrical conductor

The invention relates to a single-temperature fault-alarming outputting line-type heat-sensing detector which can not be restored. The detector comprises a heat-sensing cable two ends of which are respectively connected with a resistance signal processing device and a terminal resistance whose value is optimized between 50omega-50Momega to form a resistance signal connection circuit. It is characterized by the two elastic metal connectors of the heat-sensing cable, in which one connector is coated with insulation material layer and the other is coated with semi-conductor material layer. The two connectors are intertwisted or wound together in a pitch optimized between 20mm-200mm. In the resistance signal processing device are set with three signal starting resistance values of resistance change quantity. The resistance signal processing device judges and outputs set-temperature alarming signals, short circuit fault signals and broken circuit fault signals.

Owner:张陈

A kind of composite material lattice structure and preparation method

ActiveCN107599445BIncrease productivitySuitable for large-scale production of composite lattice structuresLayered productsFiberShell molding

The invention provides a composite lattice structure and a preparation method. The composite lattice structure is composed of an upper face plate, a lower face plate and a lattice core arranged between the upper face plate and the lower face plate. The lattice core is formed in the manner that lattice core triangular fibers and trapezoidal fibers are interlaced. Foam interlayers are arranged in the upper face plate and the lower face plate. A specific injection manner is applied to the composite lattice structure for VARTM formation. The preparation method of the composite lattice structure comprises the seven steps of (1) preparing a fusible alloy mold core; (2) inserting the triangular fibers; (3) laying fibers on the bottom layers of the upper face plate and the lower face plate; (4) inserting the trapezoidal fibers; (5) arranging the face plate interlayers and laying surface fibers of the face plates; (6) conducting VARTM (vacuum assisted resin transfer molding) formation; (7) heating and melting the fusible alloy mold core. The composite lattice structure and the preparation method effectively solve the connection problem between a composite lattice core and the face plates, integrated formation is achieved, the quality is reliable, the technology is simple, and the node strength is high.

Owner:HARBIN ENG UNIV

High-precision measuring device in air medium of finished thermistor

ActiveCN105944974BGuaranteed accuracyReduce labor intensityThermometer testing/calibrationSortingElectrical resistance and conductanceMaximum error

The invention provides a high-precision measurement device for thermistor finished products in an air medium. The measurement device comprises a feeding mechanism, a test mechanism and a sorting mechanism, wherein an air device is arranged on one side of the feeding mechanism, the feeding mechanism comprises a feeding box body, an automatic discharging mechanism is arranged on one side of the feeding box body, and a clamping conveying mechanism is arranged in the feeding box body. Paper tapes are conveyed into the test mechanism by the clamping conveying mechanism to be detected. Then, after being sorted by the sorting mechanism, the paper tapes are collected. Rails are arranged in the test mechanism and the sorting mechanism. The measurement device adopts PLC control. As the high-precision measurement device adopts an air medium sorting comparison process in measurement, the labor intensity of workers is low, and the production efficiency is high. Three to four equipment can be operated by one person, and measurement in the air medium does not require washing or drying, so that the environment is protected, energy is saved, the production cycle of products is short, labor force is greatly saved, and the quality reliability of the products is greatly improved. The maximum error of the test system is smaller than or equal to 0.02%.

Owner:JIANGSU SHIRUI ELECTRONICS CO LTD

Paper advance mechanism of transverse cutting machine

InactiveCN101954755AImprove accuracyAvoid stickingMechanical working/deformationPaper/cardboard articlesElectric machineryPulp and paper industry

The invention discloses a paper advance mechanism of a transverse cutting machine, comprising a power plant and a conveying plant, wherein the power plant and the conveying plant are arranged on a rack; the power plant comprises a main power plant and an assistant power plant; the conveying plant comprises a feed roller and a rubber compression roller, wherein the feed roller is arranged above the rubber compression roller; the main power plant is characterized in that a servo motor is connected with the rubber compression roller by a synchronous wheel; the assistant power plant is a cylinder which is connected with the feed roller; and the rubber compression roller is provided with gumming paper. The paper advance mechanism of a transverse cutting machine adopts a drum convey structure and a servo motor for main transmission; meanwhile, a circular arc synchronous belt is used for transmission to improve the accuracy for transmitting products; the gumming paper is arranged above a lower compression roller to prevent dust in a manufacturing shop from adhering on glue; and the product quality has high reliability.

Owner:无锡市亚联蜂窝机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com