Paper advance mechanism of transverse cutting machine

A technology of paper feeding mechanism and cross-cutting machine, which is used in papermaking, cardboard articles, paper/cardboard containers, etc., can solve the problems of unreliable guarantee of product quality and low accuracy of conveyed products, and achieves high reliability of product quality and improved product quality. The effect of correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

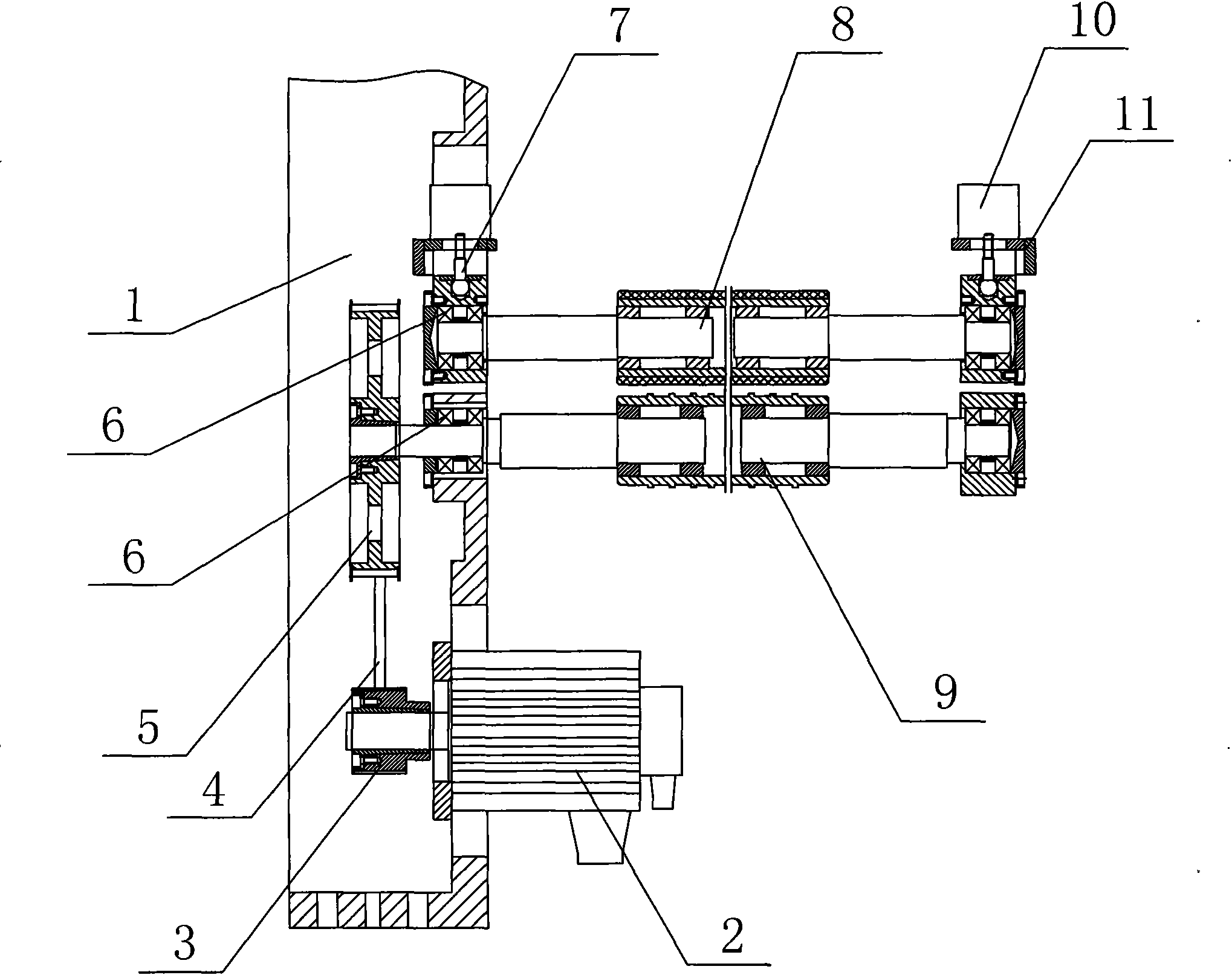

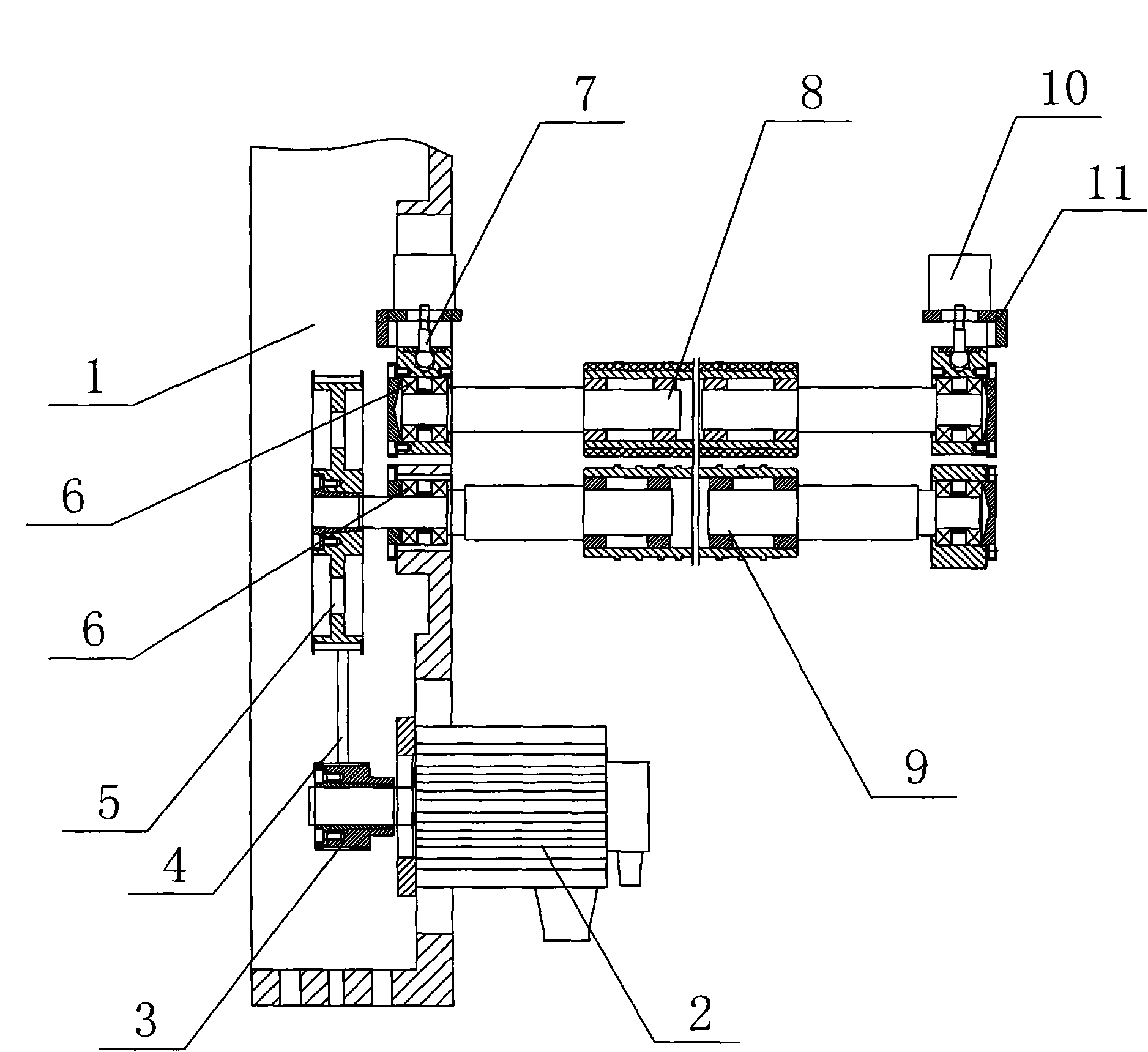

[0015] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the paper-feeding mechanism of a cross-cutting machine in the present invention. In this embodiment, a paper-feeding mechanism of a cross-cutting machine includes an active power servo motor 2 arranged on a frame 1, and the main power servo motor 2 The power output end of the motor is provided with a motor synchronous wheel 3, and the motor synchronous wheel 3 is connected to the lower pressure roller synchronous wheel 5 through a synchronous belt 4, and the lower pressure roller synchronous wheel 5 is fixed on the lower pressure roller 9, and the lower pressure roller synchronous wheel 5 is fixed on the lower pressure roller 9. The pressure roller 9 is a rubber pressure roller, which is used to arrange gummed paper, and the lower pressure roller 9 is arranged on the frame 1 through the bearing 6, and the feed roller 8 is arranged on the lower pressure roller 9, and the feed roller 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com