Lead frame, semiconductor device and packaging technology thereof

A technology of lead frame and packaging technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as defects, complicated lead frame manufacturing process, and easy-to-appear products, so as to reduce the possibility and avoid The effect of poor contact defects and stable bonding wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

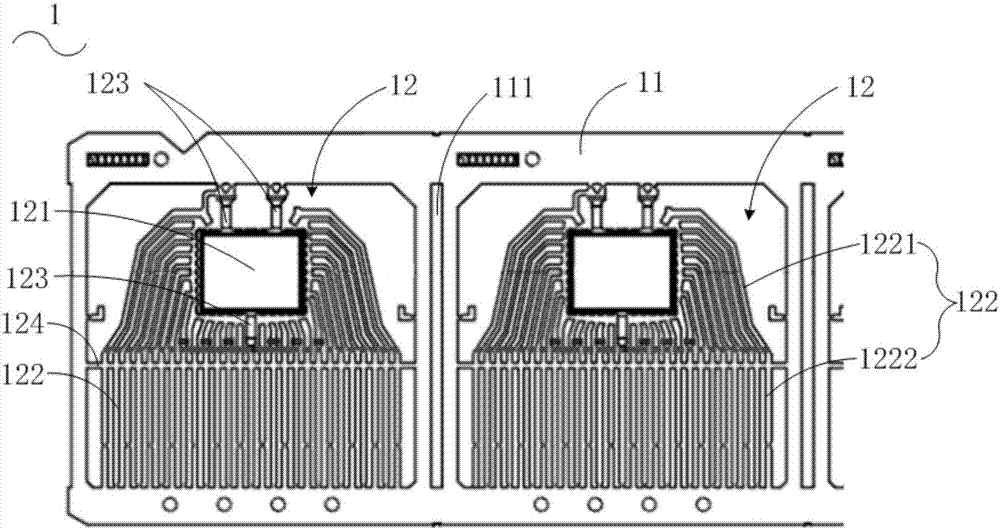

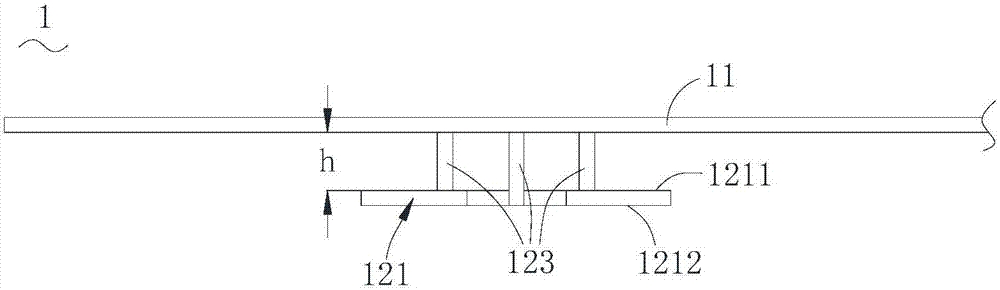

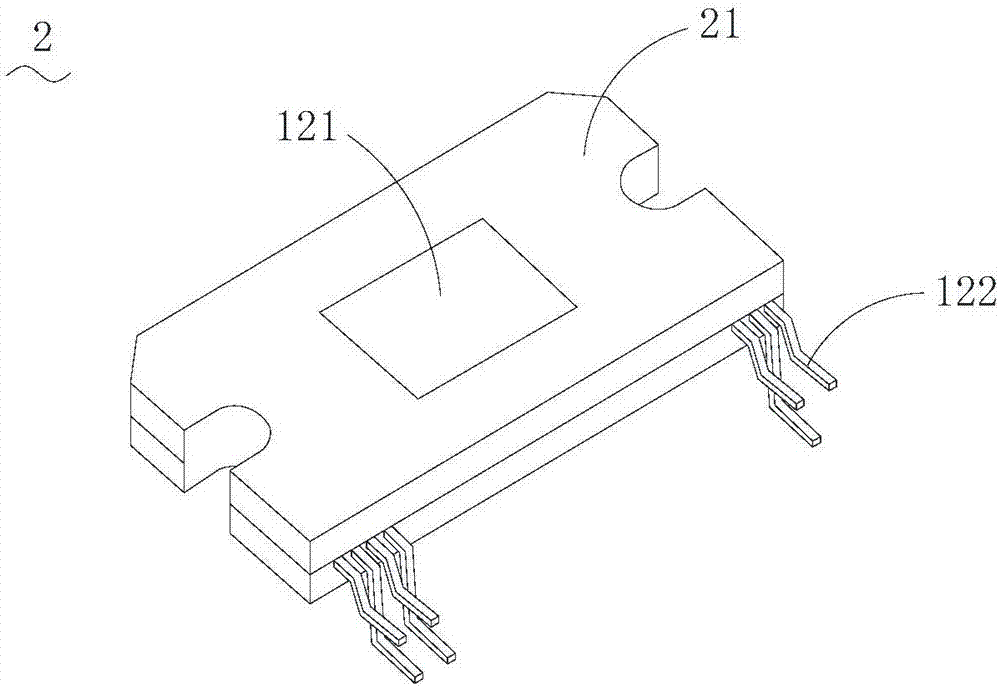

[0026] refer to figure 1 , the lead frame 1 of the preferred embodiment of the present invention includes a frame 11 and a plurality of chip packaging units 12 sequentially arranged along the length direction of the frame 11, and each chip packaging unit 12 is isolated from each other. The lead frame 1 is an integral structure, which is formed by punching and removing excess parts from a sheet base material, and the peripheral structure of the chip packaging unit 12 is the frame 11 .

[0027] Preferably, in this embodiment, the frame 11 has a separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com