A delayed ignition control device and an electronic detonator

A delay ignition and control device technology, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve the problems of large internal resistance, low strength, and low production efficiency of electronic switches, so as to improve product reliability, increase structural strength, The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

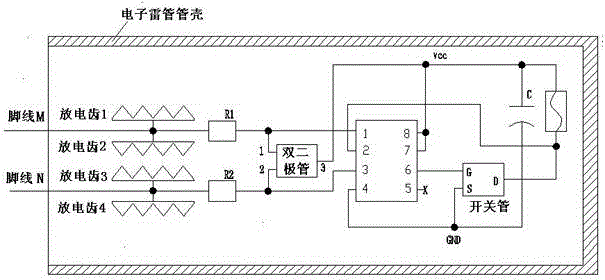

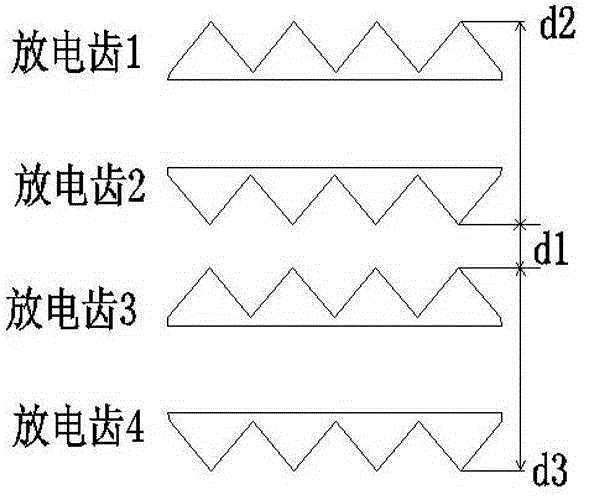

[0064] Embodiment 1: A delay ignition control device, including foot line M, foot line N, integrated with an electrostatic protection device, an electronic delay module, an energy storage device, an ignition head, and a first current limiting resistor R1 on a printed circuit board , The second current limiting resistor R2, anti-reverse connection device.

[0065] The electrostatic protection device is installed at the pad of the input terminal of the foot line M and the foot line N and on both sides of the foot line M and the foot line N, before the current limiting resistor, and is used to discharge the static electricity and the foot line of the foot line M and the foot line N input The static electricity input between the shell and the shell; the pad at the input end of the leg line is designed with an electrostatic protection structure; the electronic delay module is used for two-way communication connection with the detonator through the leg line M and the leg line N; when...

Embodiment 2

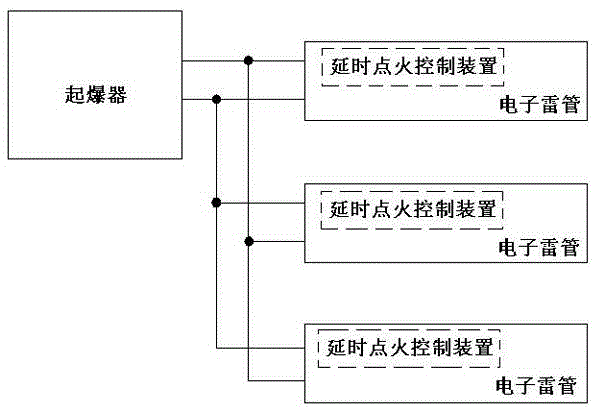

[0066] Embodiment 2, an electronic detonator with delayed ignition control, including foot wire M and foot wire N, is characterized in that it also includes an electrostatic protection device integrated on the printed board, an electronic time delay module, an energy storage device, an ignition head, The basic detonator, the current limiting device and the basic detonator shell; the electrostatic protection device, the electronic delay module, the energy storage device, the ignition head, and the basic detonator are all arranged inside the basic detonator shell; the electrostatic protection device is arranged on the current limiting device and Between the pads of the input terminal of the foot line M and the foot line N, it is used to discharge the static electricity input by the foot line M and the foot line N, and to discharge the static electricity input by the foot line M, the foot line N and the base detonator shell; the foot The welding pad at the line input end is design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com