Bonding method for preventing injection molding deformation of long-span bonding lead of integrated circuit

A technology of bonding wires and integrated circuits, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of many pins, small spacing, long-span bonding wire arc injection deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

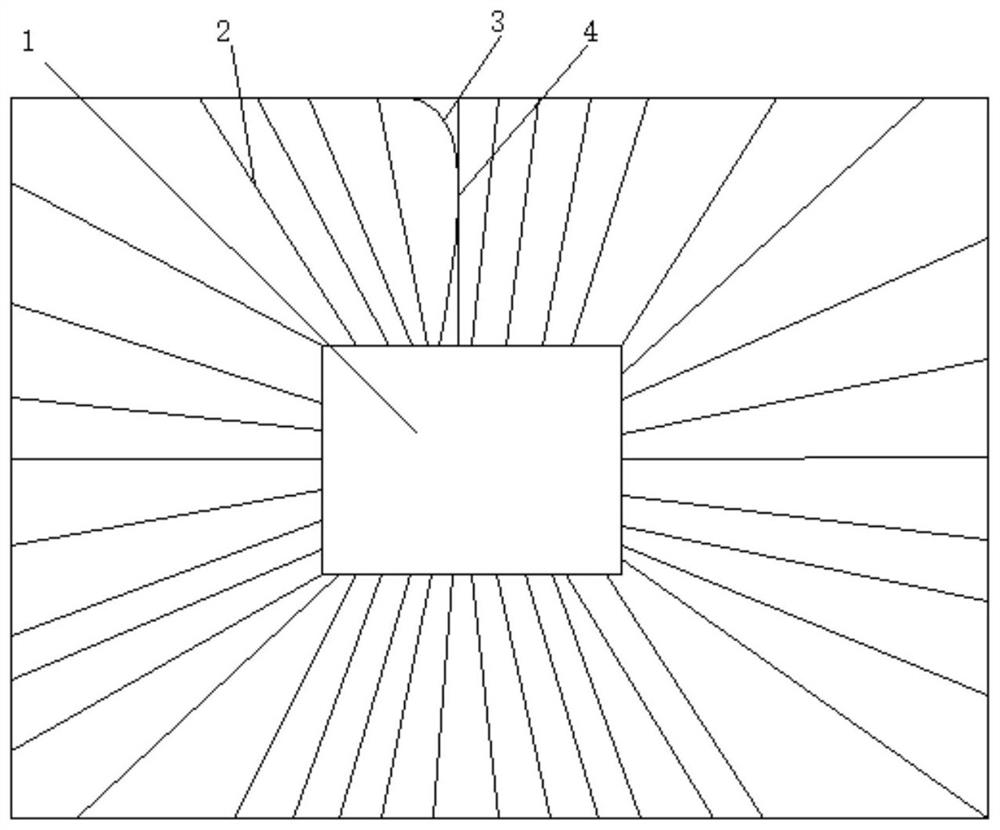

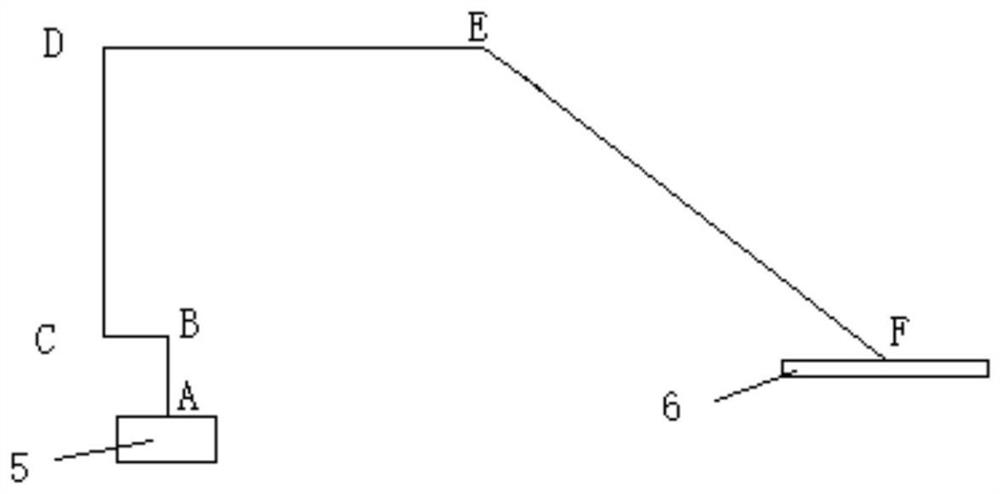

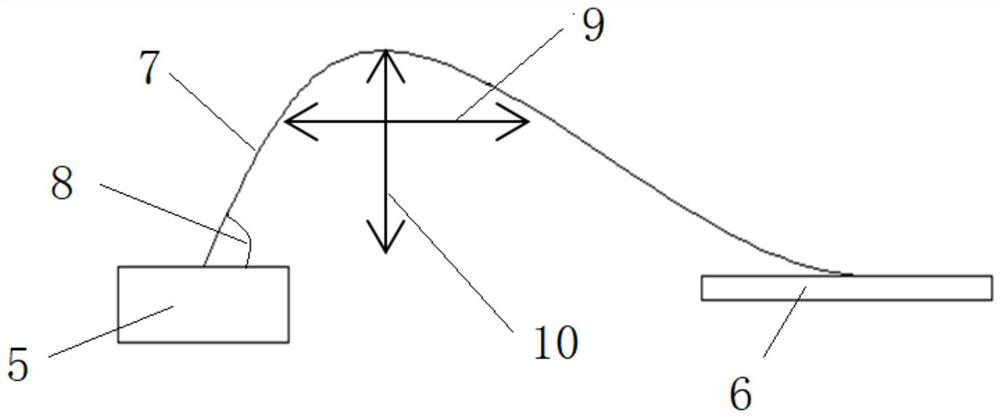

[0036] Taking the LQFP100 type plastic package product as an example, a φ20μm gold wire is used, and the bonding distance is between 3mm and 5mm. The bonding equipment used is ASM’s iHawk Xtreme GoCu. The conventional bonding wire arc height is generally set at 150 μm to 200 μm, and the inclination angle is generally set at 90°. When the bonding distance (AF) is greater than 3mm, use the original The shape of the arc parameters cannot avoid the problem of the offset of the bonding wire in the middle part. The schematic diagram of the conventional arc path is as follows figure 2 , image 3 shown.

[0037] According to the bonding method of the present invention, in order to avoid the offset of the bonding wire during the injection molding process, a new bonding wire arc structure is designed. As shown in Table 1:

[0038] Table 1 Long-distance bonding wire arc parameter test factor level table

[0039]

[0040] in:

[0041] 1. Height of broken line (AB): the distance f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com