Composite lattice structure and preparation method

A lattice structure and composite material technology, applied in the field of composite lattice structure and preparation, composite lattice structure preparation technology field, can solve the problem of inability to prepare curved surface composite lattice structure, lattice core fiber rod with low strength, Complex metal mold processing and other problems, to achieve the effect of high product quality reliability, low finished product porosity, and reduced impact on mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] A kind of preparation method of composite material lattice structure of the present invention, concrete preparation steps:

[0059] Step 1: Preparation of low melting point alloy core mold;

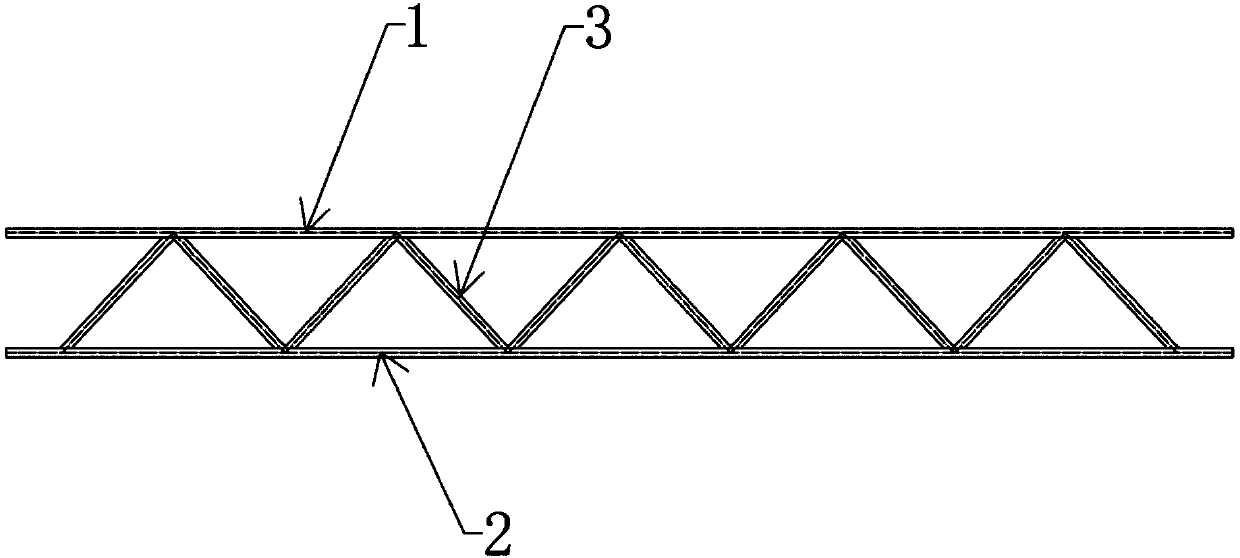

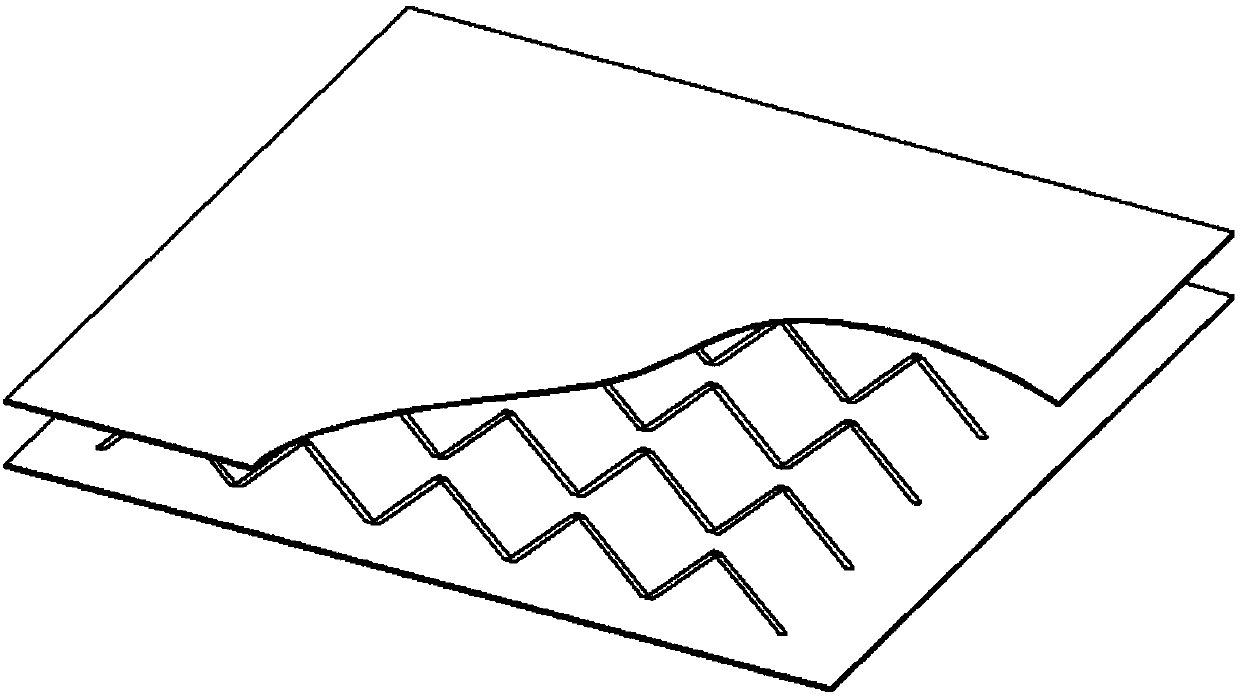

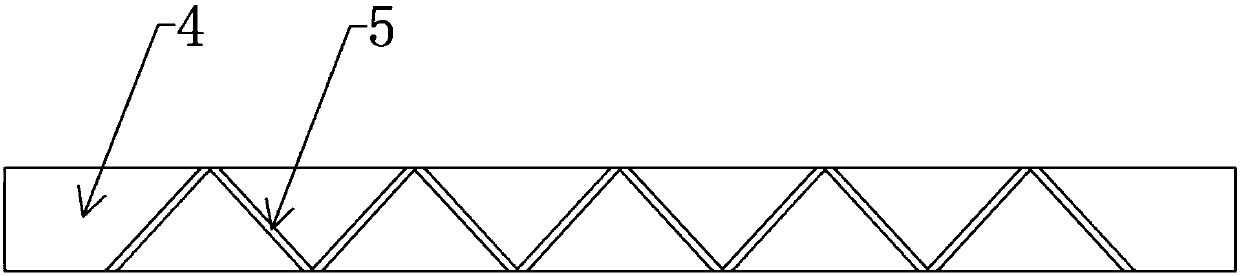

[0060] combine image 3 and Figure 4 As shown, the present invention adopts a fusible alloy core molding technology, and the used fusible alloy core 4 is cast from a low-melting point alloy, which contains through holes 5 .

[0061] The low-melting-point alloy is Wood's alloy, whose melting point is higher than the forming temperature and lower than the Martin heat-resistant temperature of the material. The present invention adopts Wood's alloy with a melting point of 60-70 degrees Celsius, and the alloy composition: 38-50% bismuth, 25-31% of lead, 12.5-15% of tin, and 12.5-16% of cadmium.

[0062] The hole 5 is a through hole or a square hole, the diameter of which is the same as that of the rod of the lattice core 3, and the axis coincides with the axis of the lattice core. ...

Embodiment

[0096] In order to prove the mechanical performance advantage of the composite material lattice structure prepared in the present invention, adopt ABAQUS finite element software to carry out numerical simulation, Figure 17 The finite element model shown shows a 100mm x 100mm plate domain with two lattice core members at an angle of 45 degrees, hinged around the plate.

[0097] Composite lattice structures generally fail at nodes. In order to accurately simulate the failure behavior at nodes, Surface-based Cohesive Behavior is used to simulate the delamination behavior between fibers. The finite element model of each bundle of fiber rods is established, and the C3D8R three-dimensional solid reduced integration element is used for simulation. The material is carbon fiber, the thickness of the panel is 4mm, and the section of the trapezoidal fiber rod is 2mm×2mm. In order to discuss the influence of triangular fibers on the structural force, the failure modes of no triangular f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com