On-off tester for testing terminal blocks

A terminal block, on-off test technology, applied in sorting and other directions, can solve the problems of inconvenient operation, high cost investment, affecting the accuracy of test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

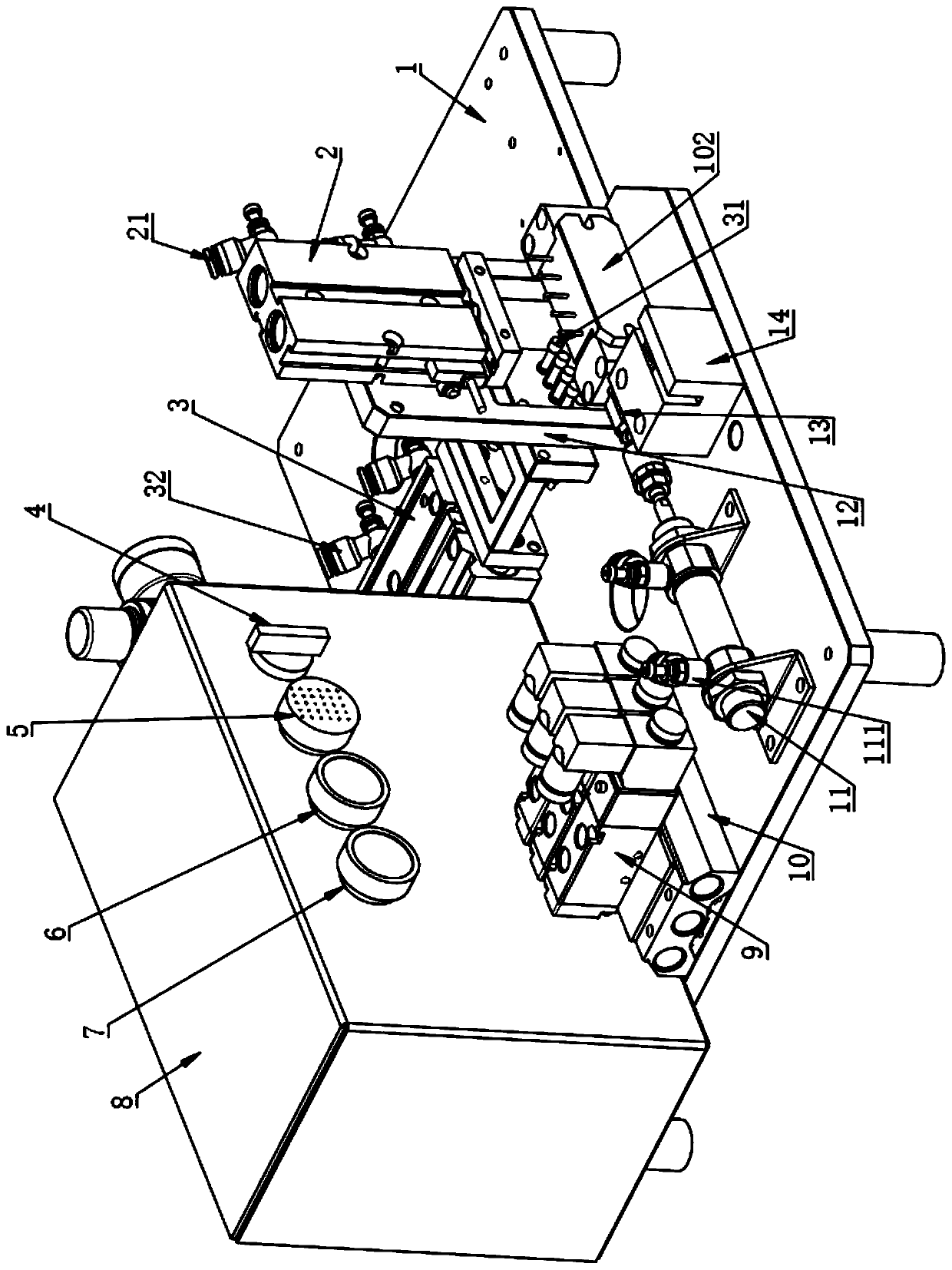

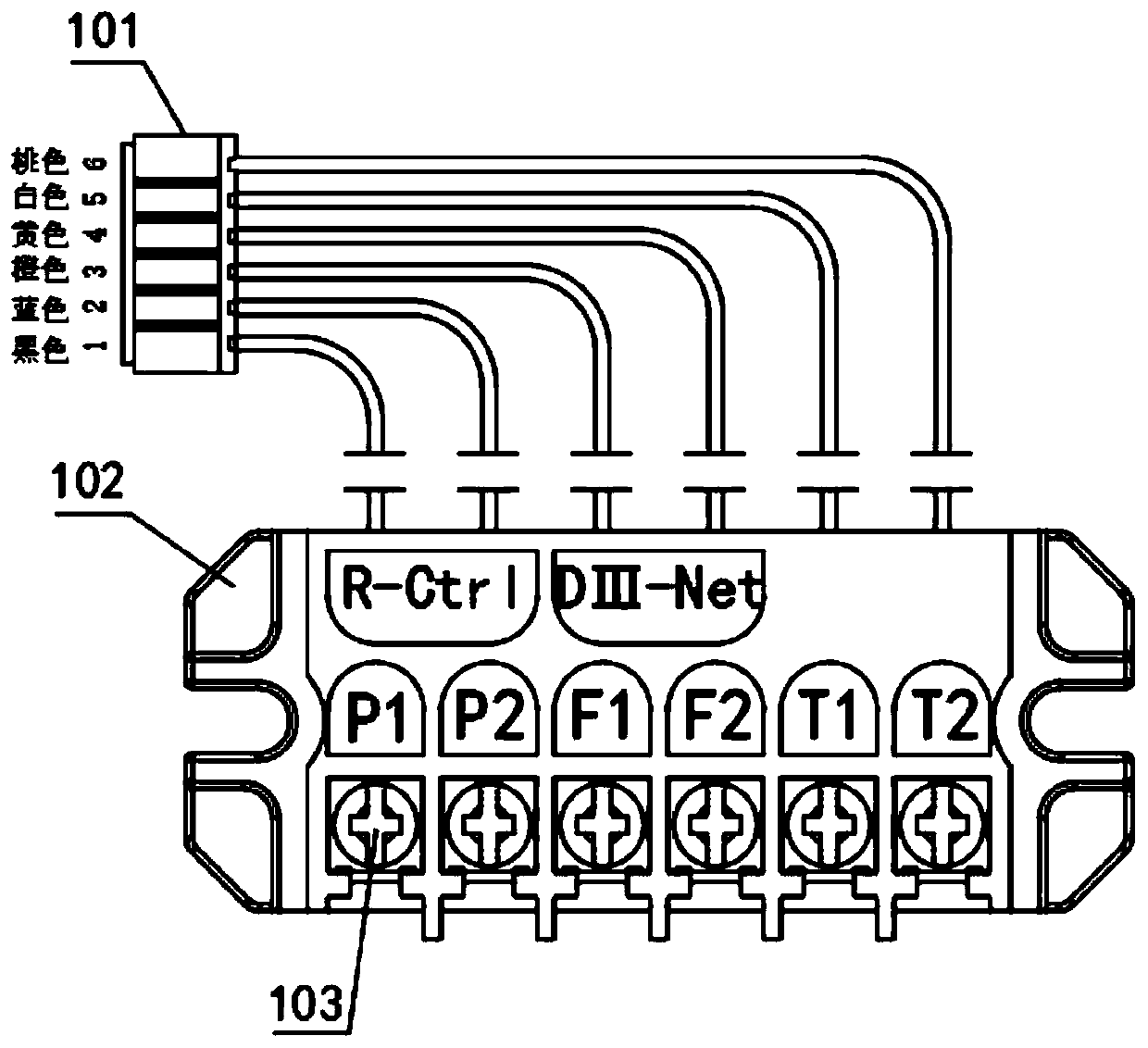

[0018] As shown in the figure, a terminal block test on-off testing machine, first set a thick plate to form a test platform 1, set a vertically upwardly extending door-shaped bracket 12 on the front side of the upper end of the platform 1, on the upper part of the bracket 12 A first cylinder 2 arranged from top to bottom is fixedly installed, and a hollow window is set at the bottom of the support 12. The terminal block product to be tested is placed on the platform through the terminal 102, and its two ends are separated by the front of the hollow window on both sides of the support. The position of the limit block is limited, the telescopic rod of the first cylinder 2 can extend downwards, and be pressed against the housing of the terminal 102; the platform 1 is fixedly installed at the rear side of the bracket 12, and is arranged longitudinally from back to front The second cylinder 3, the front end of the telescopic rod of the second cylinder 3 is connected with the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com