X-ray tube cathode and anode alignment device and alignment method with same

An X-ray tube, cathode and anode technology, which is applied in the field of X-ray tube cathode and anode alignment devices, can solve the problems of poor product consistency, low production efficiency, unstable quality, etc., to improve product quality reliability and improve production efficiency. , the effect of improving the accuracy of alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

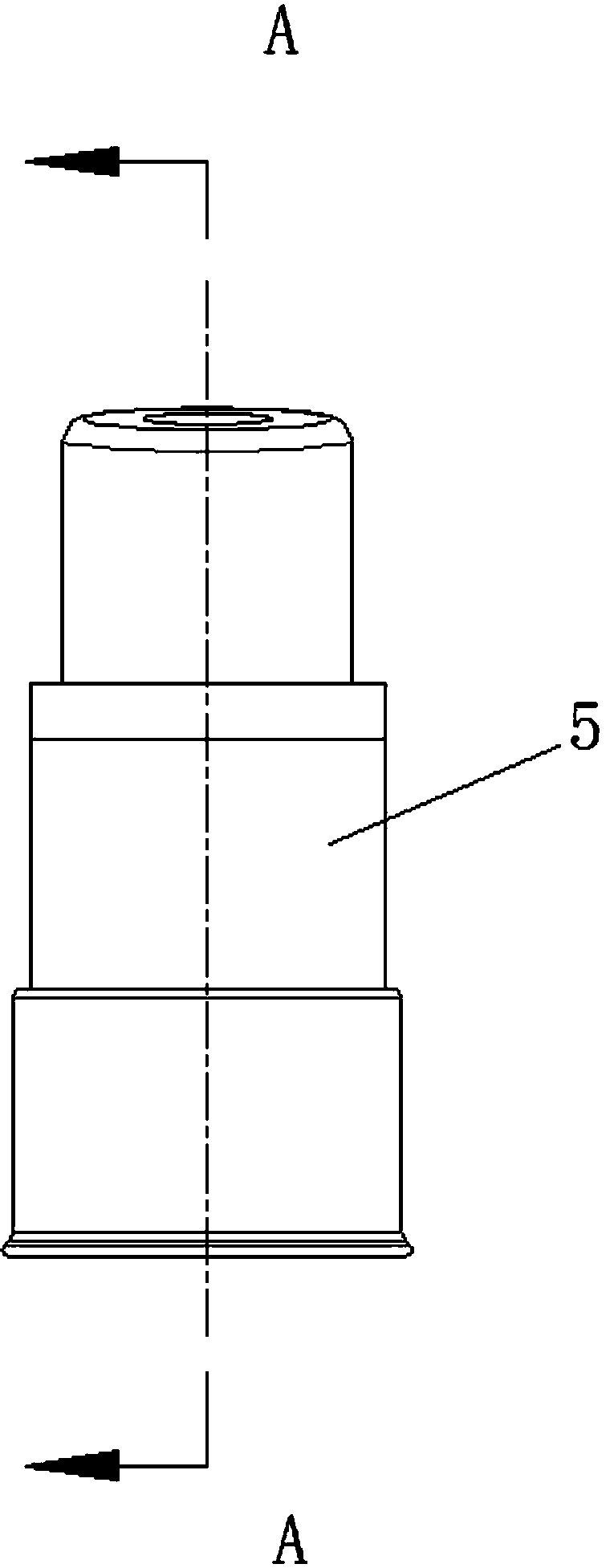

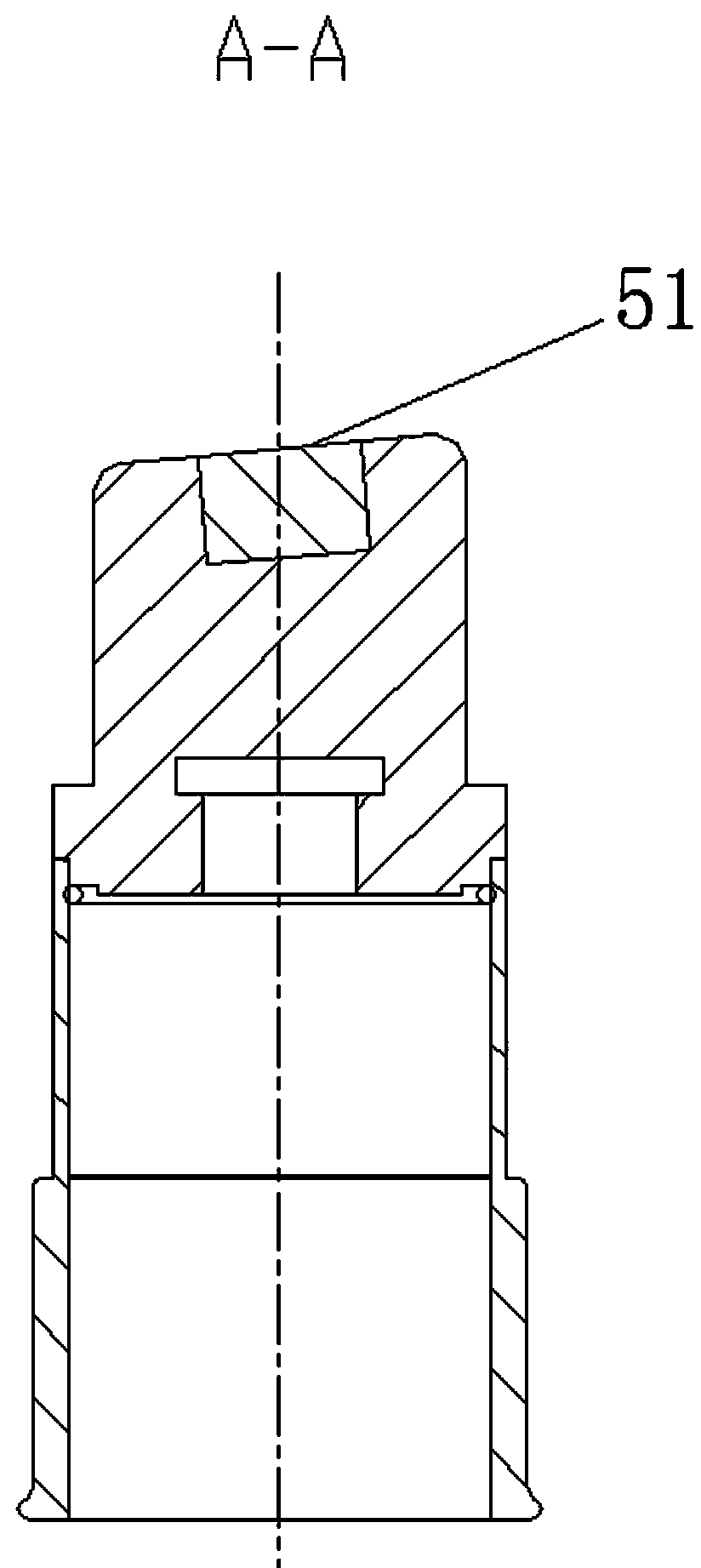

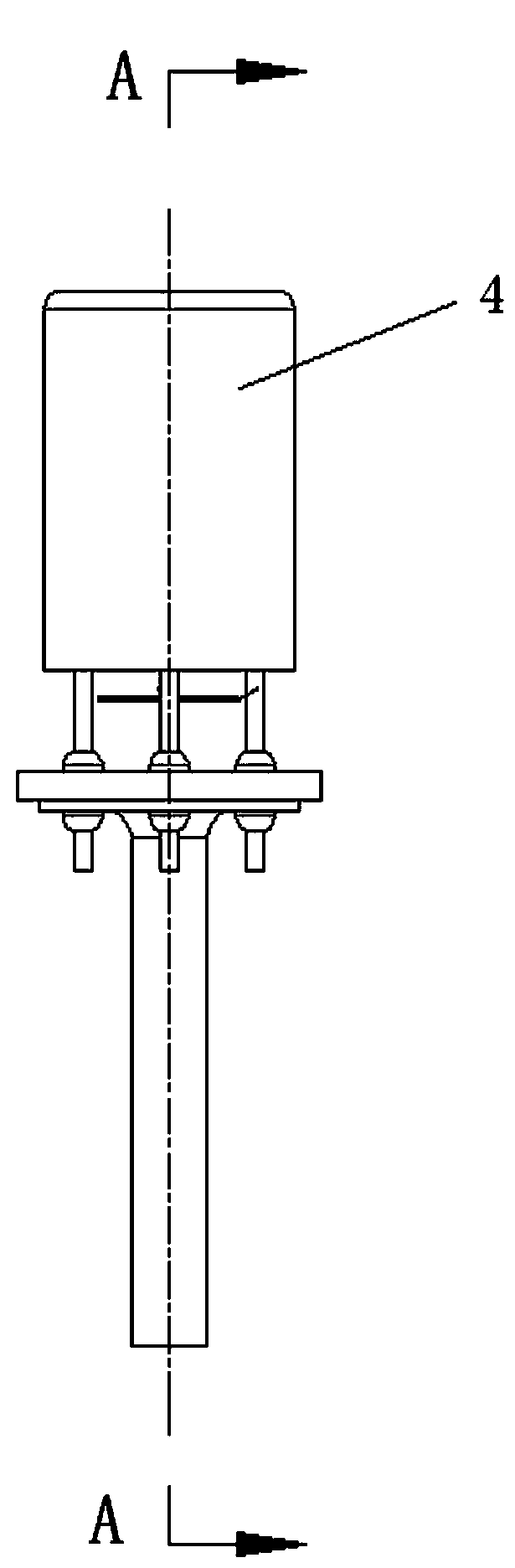

[0028] Embodiment one: see Figure 1-7 , the X-ray tube cathode and anode alignment device 1 in this embodiment includes a positioning sleeve body 2 and a positioning module 3, the positioning sleeve body 2 is a hollow cylindrical body, the positioning module 3 is fixed in the positioning sleeve body 2, and the positioning module 3 One end protruding out of the positioning sleeve body 2 is provided with a slot positioning block 31, and one end of the positioning module 3 located in the positioning sleeve body 2 is provided with a positioning inclined block 32, and the slot positioning block 31 and the cathode head positioning groove 41 of the X-ray tube cathode assembly 4 match, and the positioning slant block 32 matches the anode target angle 51 of the X-ray tube anode assembly 5 . The size and size of the positioning sleeve 2 and the positioning module 3 can be produced (manufactured) in a targeted manner according to the size of the cathode assembly 4 and the anode assembly...

Embodiment 2

[0031] Embodiment two: see Figure 8-11 , an X-ray tube cathode and anode alignment method, including a glass bulb 9, an anode assembly 5, a cathode assembly 4 and an anode and cathode alignment device 1, the cathode assembly 4 is installed in the glass bulb 9, it is characterized in that, using the above-mentioned preferred The X-ray tube cathode and anode alignment device 1 in the scheme performs cathode and anode alignment, and the steps are as follows:

[0032] 1) Preliminary calibration and fixing of the sealed cathode assembly 4 and anode assembly 5 of the X-ray tube on a lathe;

[0033] 2) Set the cathode and anode alignment device 1 on the anode assembly 5 and rotate the angle so that the anode target angle 51 in the anode assembly 5 is in contact with the positioning inclined block 32, and then check the internal adhering situation through the observation port 6 or the positioning viewing hole 8 After confirming that they are closely attached, tighten the set screw 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com