Method for eliminating brazing blockage of tube-seat ring-shaped workpiece of stainless steel sandwich structure

A sandwich structure and ring-shaped workpiece technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing product quality reliability, reducing product production efficiency, and increasing production costs, so as to improve product quality reliability, Guarantee the production progress and eliminate the effect of brazing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

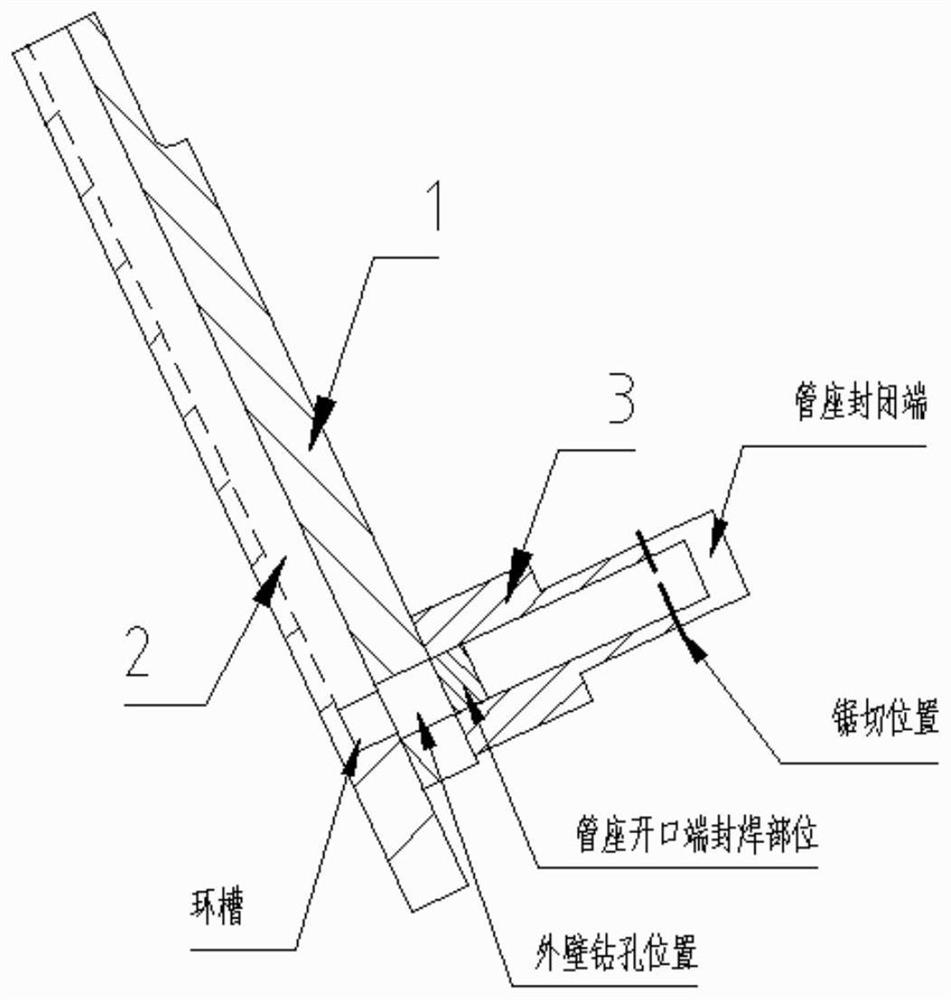

Image

Examples

Embodiment 1

[0035] (1) The inner wall is a quasi-conical workpiece with rib grooves processed on the outer surface, the groove depth is 2mm; the outer wall is a quasi-conical workpiece formed by three-section tailor welding, and the wall thickness is 1mm; the diameter of the small end of the inner wall and the outer wall is 800mm , the diameter of the large end of the inner wall and the outer wall is 1200mm, and the axial height is 600mm. The inner wall material is 1Cr18Ni9Ti stainless steel, and the outer wall material is 1Cr21Ni5Ti stainless steel. Measure the axial distance L1 between the center of the big end ring groove on the inner wall and the end face of the big end, and record it; after the surface grinding of the outer surface of the inner wall and the inner surface of the outer wall Press the outer wall, measure the height difference L2 between the big end of the inner wall and the outer wall, and record it. After disassembly, check the area where the chalk powder on the inner...

Embodiment 2

[0041] (1) The inner wall is a quasi-conical workpiece with rib grooves processed on the outer surface, the groove depth is 2.5mm; the outer wall is a quasi-conical workpiece formed by three-section tailor welding, and the wall thickness is 2mm; the diameter of the small end of the inner wall and the outer wall is 900mm, the diameter of the large end of the inner wall and outer wall is 1300mm, and the axial height is 700mm. The inner wall material is 1Cr18Ni9Ti stainless steel, and the outer wall material is 1Cr21Ni5Ti stainless steel. Measure the axial distance L1 between the center of the big end ring groove on the inner wall and the end face of the big end, and record it; after the surface grinding of the outer surface of the inner wall and the inner surface of the outer wall Press the outer wall, measure the height difference L2 between the big end of the inner wall and the outer wall, and record it. After disassembly, check the area where the chalk powder on the inner su...

Embodiment 3

[0047](1) The inner wall is a quasi-conical workpiece with rib grooves processed on the outer surface, the groove depth is 2.2mm; the outer wall is a quasi-conical workpiece formed by three-section tailor welding, and the wall thickness is 1.5mm; the diameter of the small end of the inner wall and outer wall The diameter of the large end of the inner wall and the outer wall is 1250mm, and the axial height is 650mm. The inner wall material is 1Cr18Ni9Ti stainless steel, and the outer wall material is 1Cr21Ni5Ti stainless steel. Measure the axial distance L1 between the center of the big end ring groove on the inner wall and the end face of the big end, and record it; after the surface grinding of the outer surface of the inner wall and the inner surface of the outer wall Press the outer wall, measure the height difference L2 between the big end of the inner wall and the outer wall, and record it. After disassembly, check the area where the chalk powder on the inner surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com