High impact-resistance anti-smoldering polystyrene resin composite and preparation method thereof

A technology of polystyrene resin and polystyrene, which is applied in the field of high-impact anti-smoldering polystyrene composition and its preparation, and can solve the problems of inability to take into account toughness and easy smoldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

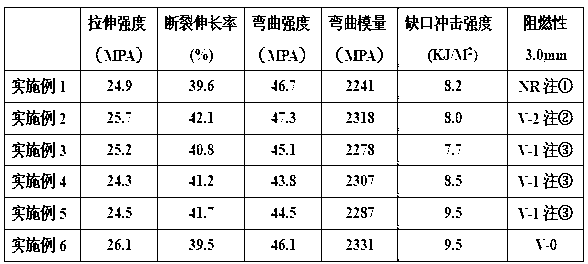

Examples

Embodiment 1

[0027] High-impact polystyrene 84.0 parts, brominated flame retardant decabromodiphenylethane 8.0 parts, brominated flame retardant tetrabromobisphenol A 3.0 parts, auxiliary flame retardant antimony trioxide 4.0 parts, stabilizer sub 0.2 parts of tris(2,4-di-tert-butylphenyl) phosphate, and 0.6 parts of lubricant magnesium stearate.

[0028] The preparation method is as follows:

[0029] (1) Measure each component according to the formula;

[0030] (2) Pour high-impact polystyrene and diffusion oil into the high-speed mixer first, and mix for 3 minutes;

[0031] (3) Then pour the brominated flame retardant, auxiliary flame retardant, stabilizer, lubricant, and diffusion oil into the high-speed mixer in sequence, and mix for 3 minutes;

[0032] (4) The fully mixed materials are melted, mixed, extruded, cooled, pelletized and packaged through a twin-screw extruder.

Embodiment 2

[0034]High-impact polystyrene 83.0 parts, brominated flame retardant decabromodiphenylethane 9.0 parts, brominated flame retardant brominated polystyrene 3.0 parts, auxiliary flame retardant antimony trioxide 4.0 parts, stabilizer bis (2,4-di-tert-butylphenyl) pentaerythritol diphosphite 0.2 part, lubricant paraffin 0.6 part.

[0035] The preparation method is the same as in Example 1.

Embodiment 3

[0037] High-impact polystyrene 82.0 parts, brominated flame retardant tetrabromobisphenol A 10.0 parts, brominated flame retardant tris(tribromophenoxy) triazine 3.0 parts, auxiliary flame retardant antimony trioxide 4.0 parts , Stabilizer β-(3,5-di-tert-butyl, 4-hydroxyphenyl) octadecyl propionate 0.2 parts, lubricant white mineral oil 0.6 parts.

[0038] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com