Ptfe composite material and its preparation method

A technology of composite materials and raw materials, applied in the field of composite materials, can solve the problems of poor mechanical properties of polytetrafluoroethylene, achieve excellent mechanical properties, improve mechanical properties, and improve radial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A kind of preparation method of above-mentioned PTFE composite material, comprises the steps:

[0040] S10, mixing the PTFE powder and the filler powder to obtain a composite material powder, making the composite material powder wrap the continuous fiber to obtain a fiber powder tape.

[0041] S20, winding the fiber powder tape to form a fiber powder tape cylinder.

[0042] S30, sintering the fiber powder with the cylinder to obtain the above-mentioned PTFE composite material.

[0043] Preferably, before the sintering process, the metal cladding plate with the release material on the inner wall is wrapped on the surface of the fiber powder belt cylinder, so as to provide support and protection for the PTFE composite material during the sintering process and avoid deformation or damage.

[0044] Preferably, the release material is graphite powder or PTFE glass fiber cloth, which has the characteristics of high temperature resistance, wear resistance, chemical resistance...

Embodiment 1-19

[0052] Prepare PTFE composite according to the component ratio in Table 1 according to the following steps:

[0053] Put PTFE powder and Al metal powder into a mixer and mix them well to obtain composite material powder. In Examples 1-11 and Example 14, the continuous fibers are dispersed by tools or by hand to make them fluffy. In Example 14, the specific use The untwisting machine disperses the continuous fibers. The composite material powder is mixed with the continuous fiber, so that the composite material powder wraps the continuous fiber and then is gathered to obtain a powder belt.

[0054] Cover the release material on the surface of the winding roller, adjust the pressing roller to closely contact the winding roller, then feed the fiber powder tape from one end surface between the two rollers, turn the winding roller, and the pressing roller will press the fiber powder tape on the winding roller, The fiber powder belt is hoop-wound without gaps until it reaches the o...

Embodiment 20

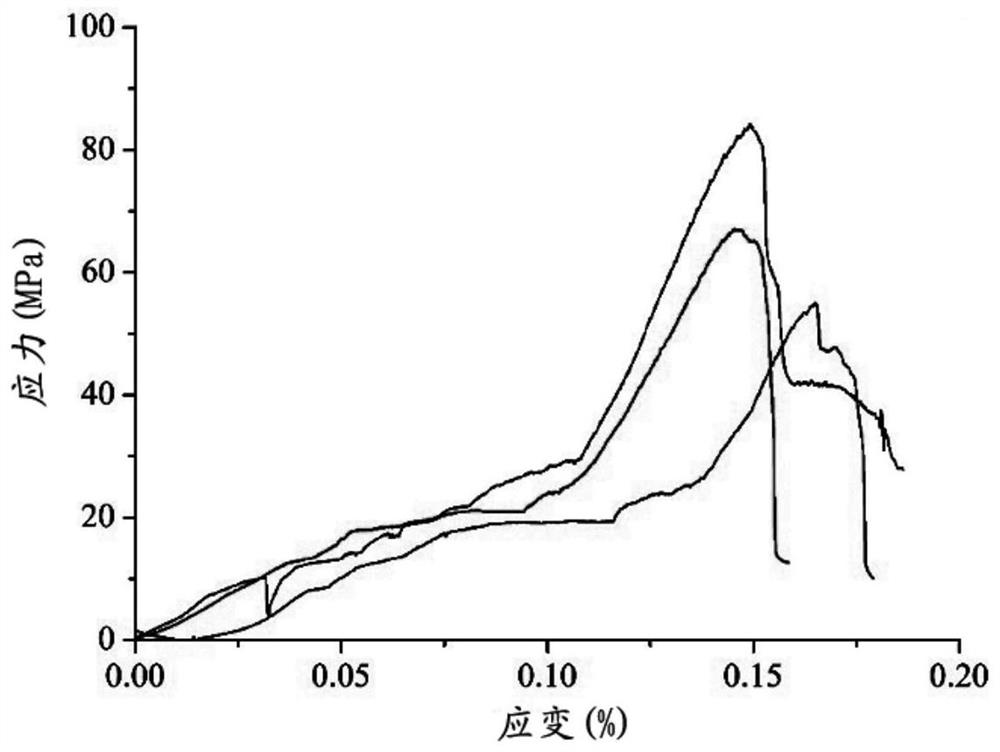

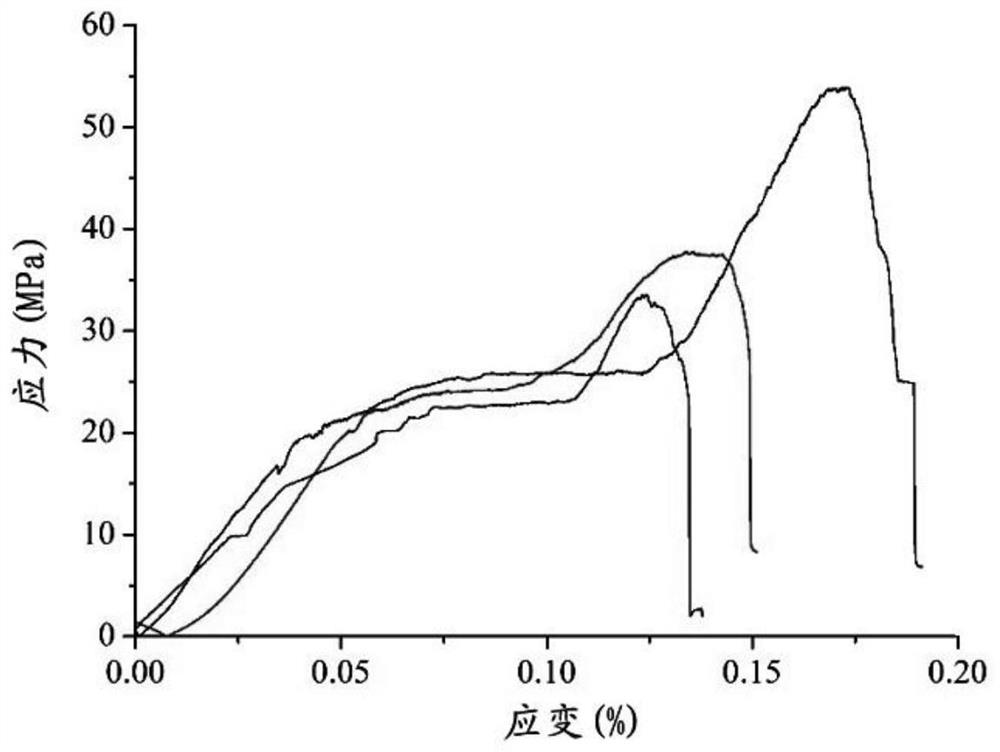

[0060] The mass percentages of PTFE powder, Al powder, and PBO fiber were 68.9%, 24.8%, and 6.3%, respectively. The PTFE composite material was prepared according to the steps of Example 1, except that only hoop winding was performed. The prepared PTFE composite material has a height of 155 mm, an inner diameter of 155 mm, and a barrel mass of 316 g. The thickness of the barrel at different measurement positions is shown in Table 2. The thickness of the barrel at about 10 mm from the edge is measured every 60°. Both sides of the cylinder are measured, the average thickness of one end is 2.05mm, and the average thickness of the other end is 2.08mm. Slice samples were taken for tensile strength test, the tensile strength in the fiber direction (hoop direction) was 53.6 MPa, and the tensile strength in the fiber vertical direction (axial direction) was 6.56 MPa.

[0061] Table 2

[0062] Measurement orientation (°) One end thickness(mm) Thickness of the other end (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com